Application of Vacuum Cooling Technology and Active Packaging to Improve the Quality of Chinese Kale

Pichaya B. Poonlarp* and Danai BoonyakiatPublished Date : 2019-08-24

DOI : 10.12982/CMUJNS.2015.0077

Journal Issues : Number 2, May - August 2015

ABSTRACT

This research studied the effect of vacuum cooling combined with active packaging on the quality of Chinese kale from an initial core temperature of 22-25°C to a final core temperature of 4±1°C. The study results illustrate that the optimum condition for Chinese kale under the vacuum cooling process is obtained with the best parameters at a holding time of 5 minutes. The total cycle time was 17 minutes and the electrical energy consumption was 0.017 kWh, with a resulting electricity cost of THB 0.06 per kilogram of Chinese kale. Precooled Chinese kale was then packaged in six different types of packaging material, namely perforated polyethylene, polypropylene and active packaging with different oxygen transmission rates (OTR): 10,000-12,000, 12,000-14,000, 8,000-16,000cc m-2 day-1 and stored at 4±1°C. Subsequently, the effect of vacuum cooling with active packaging on the quality of Chinese kale was investigated. The results showed that the Chinese kale precooled under vacuum cooling process with the best active packaging (M1) had a longer storage life of 14 days compared to the normal storage life of non-precooled Chinese kale packaged in perforated polyethylene (Doi Kham bag) of 3 days.

Keywords: Precooling, Vacuum cooling, Quality, Storage life, Active packaging

INTRODUCTION

Vacuum cooling technology is a proven technology widely applied in post-harvest processing of agricultural products (Chen, 2006). Vacuum cooling is achieved through boiling part of the moisture of the product under vacuum conditions. The major characteristic of vacuum cooling is that the product can be quickly cooled, at speeds unsurpassed by conventional cooling methods. Traditionally, it has been used to remove field heat of leafy vegetables after harvest in order to prolong product shelf life (Zheng and Da Weng, 2005) (Anon, 1981, cited in Food Processing Industry). The benefits of vacuum cooling have been widely reported (e.g., Chen and Hsueh, 2007). It can cool lettuce from 25°C to 1°C and, if combined with cold storage at 1°C, it can increase the shelf life of lettuce from 3-5 days at ambient temperature to 14 days (Artes and Martines, 1995). Vacuum cooling is a new technology; therefore, the research is limited, especially on Chinese kale.

The aim of this study was to study the effect of vacuum cooling combined with active packaging on the quality of Chinese kale. In a previous study on the effects of active packaging and passive modified atmosphere packaging (MAP): PP type on Chinese kale quality (Boonyakiat and Poonlarp, 2012), research results showed that the selection of proper material is key to achieving head space conditions that can control the respiration rate, water loss and color retention. Among the treatments, OPP3 is the best packaging, prolonging the storage life of Chinese kale for about 14 days compared to about 3 days if packed in a perforated PE bag (control). Therefore, the present work explored the advantage of applying combined vacuum cooling technology with active packaging on the quality of Chinese kale.

MATERIALS AND METHODS

Plant Materials

Chinese kale. (Brassica oleracea L. var. alboglabra) was harvested at commercial maturity in May 2011 from an experimental field of the Mae Sapok Royal Project Development Center, Royal Project Foundation, Chiang Mai Province, Thailand. The samples were immediately transported by truck to the collection center, the Royal Project Foundation. Subsequently, the samples were immediately transported to the laboratory at Chiang Mai University, Chiang Mai Province.

Experimental Method 1: Study on optimum process parameters for vacuum cooling of Chinese kale.

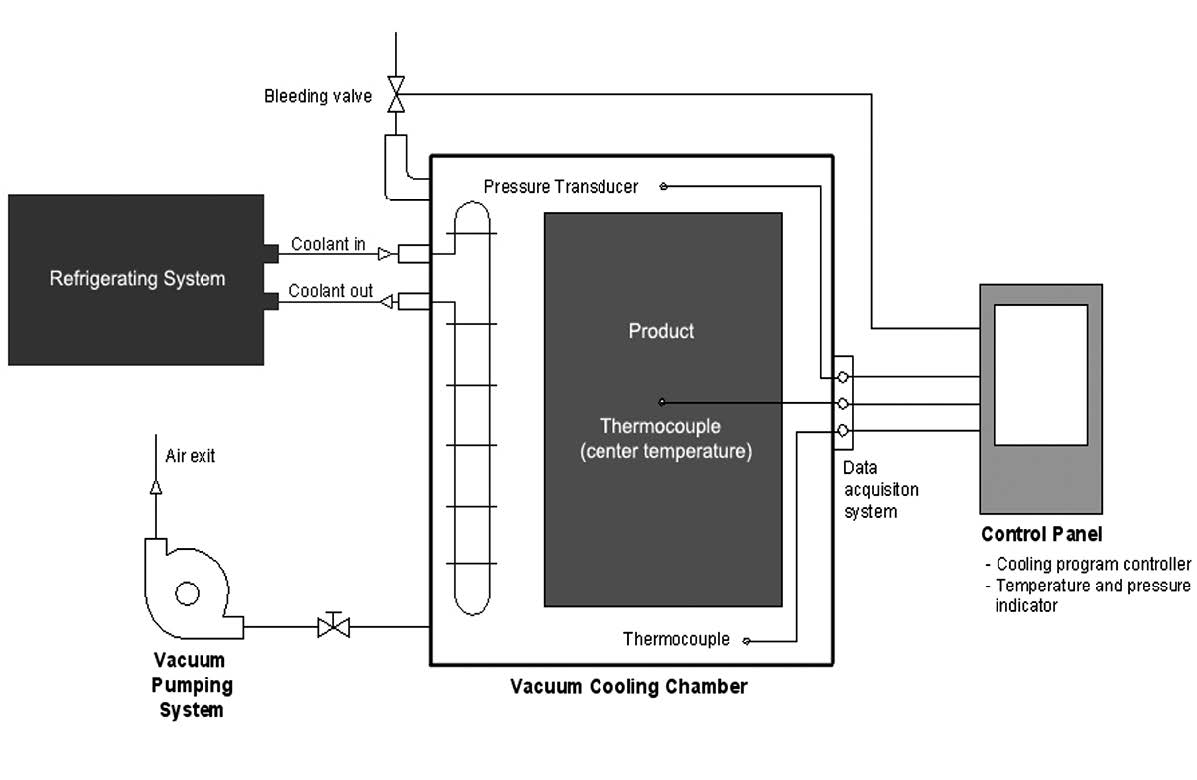

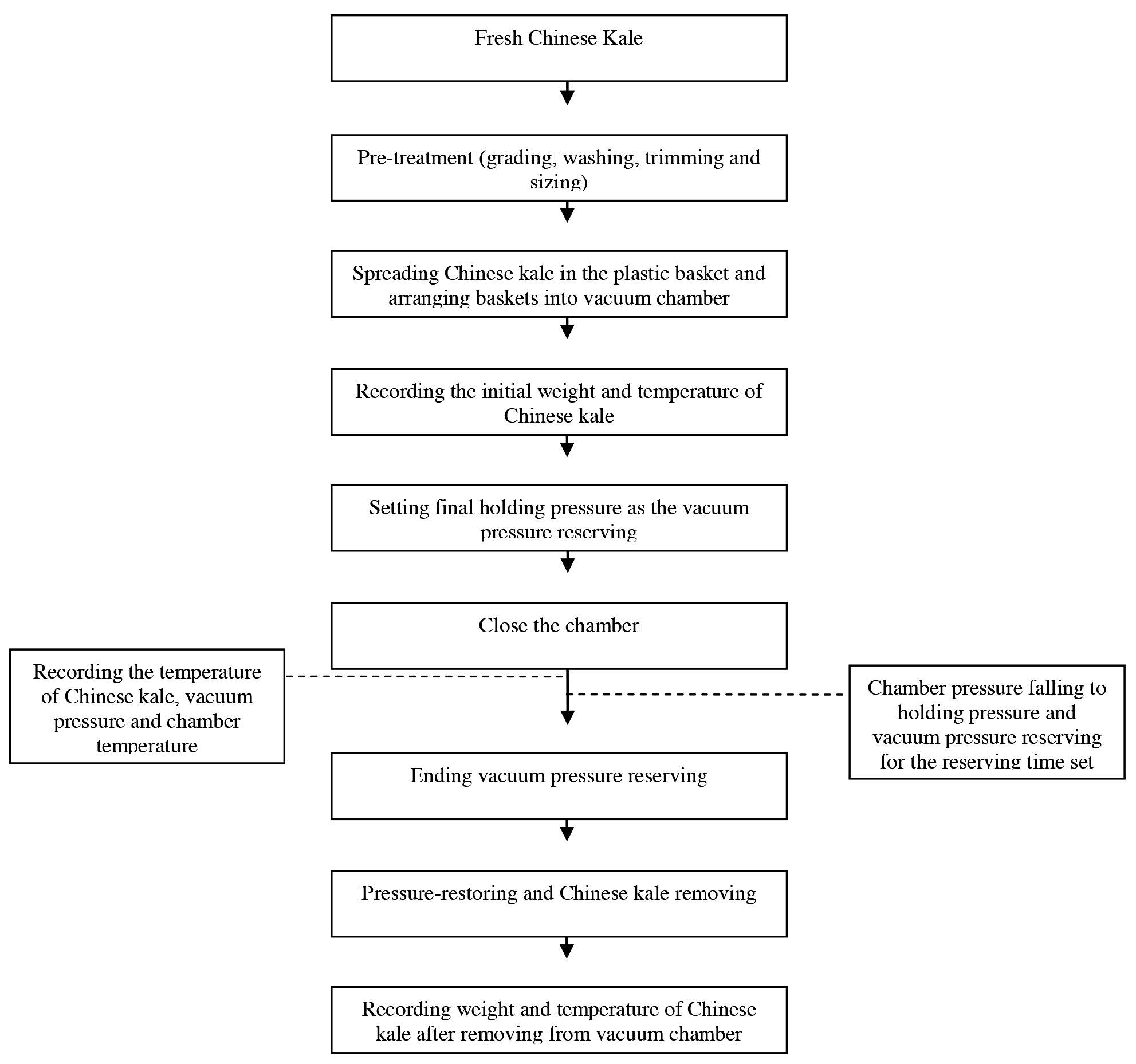

Chinese kale was graded and trimmed of defects and undesirable parts. The graded Chinese kale was then weighed and spread in 60 baskets (1,500 grams/basket) and the baskets arranged in the vacuum chamber. The initial weight and temperature of Chinese kale were recorded; subsequently all baskets were placed inside the cooling chamber (Figure 1). The final pressures for vacuum-cooled Chinese kale were set at two different levels: 6 and 7 mbar and at three levels of vacuum pressure reserving: 5, 10 and 15 minutes, for each level of pressure. Chamber pressure, air temperature, relative humidity of the air and produce center temperature were recorded every minute. Immediately after removing the samples from the cooling chamber, the weight was recorded. The flow chart of the vacuum cooling process of Chinese kale is shown in Figure 2. The energy consumption of the vacuum cooling process was measured and the electricity expense in Thai Baht was calculated.

Figure 1. The schematic diagram of the research vacuum cooler.

Figure 2. Flow chart of the vacuum cooling process.

Experimental Method 2: Studying the effect of vacuum cooling combined with active packaging on the quality of Chinese kale.

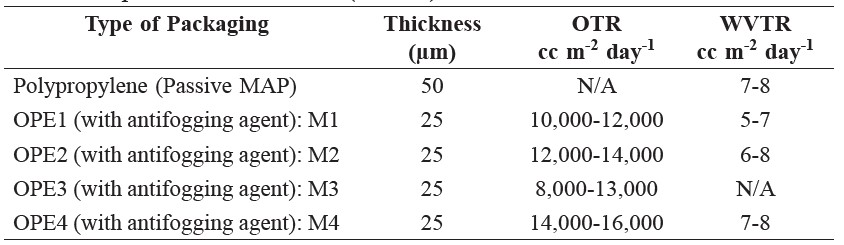

Chinese kale from experiment 1 was cleaned and put into ready-to-sell packages. The following package types were used: perforated (12 holes of 0.5 mm diameter) polyethylene bag (Doi Kham brand) 40 μm thick, polypropylene 50 μm thick and four-oriented polyethylene 25 μm thick with oxygen transmission rates (OTR) ranging from 8,000 to 16,000 cc m-2 day-1 (Table 1). Each bag contained approximately 100 g of Chinese kale sized 8cm x 15cm with a surface area of 130 cm2. The bags were sealed and stored at 4°C until the end of its storage life. Physicochemical properties were analyzed every day as follows: weight loss (%); color as L value (L*); chroma (C*) and hue angle (ho) using a colorimeter (Chromameter, Minolta CR-310); ascorbic acid, extracted and analyzed according to the method described by AOAC (2000); total soluble solids (TSS), measured by making a slurry of the whole leaves and drops placed on a digital refractometer; and chlorophyll, extracted and analyzed according to Whitham (1971). Five trained panels determined the storage life. The intensity of the attributes physical appearance, odor, color, firmness on a 5-point hedonic scale (1 = “very poor” to 5 = “excellent”) was averaged to determine “overall quality”. A score of three was the threshold for produce acceptability. Oxygen and carbon dioxide headspace concentration of packaged Chinese kale were measured using a Headspace Gas Analyser (PBI Dansensor, Checkmate, Denmark). Three replicates were made at each sampling. The experimental design was factorial in CRD. All analyses were carried out in triplicate. The data calculated from the fitting procedure were compared by one-way variance analysis (ANOVA). A Duncan’s multiple range test with the option of homogeneous groups (p<0.5) was used to determined significance between samples.

Table 1. Value of oxygen transmission rate (OTR) at 23°C with 0% RH and water vapor transmission rate (WVTR) at 23°C with 85% RH.

RESULTS

Experimental Result 1: Study on optimum process parameters for vacuum cooling of Chinese kale.

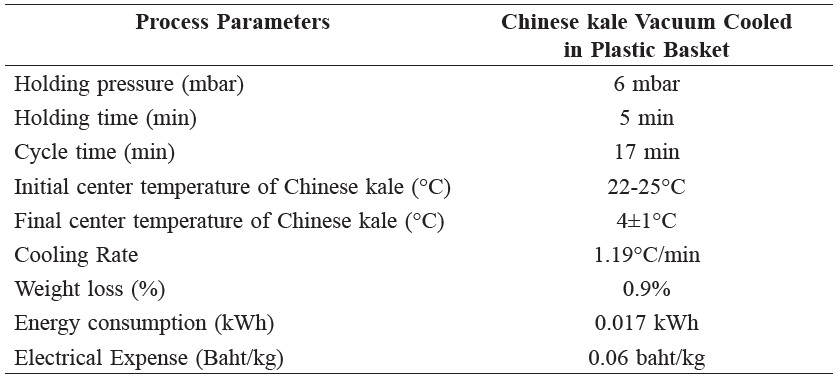

The optimum vacuum-cooling parameters for Chinese kale are displayed in Table 2. In cooling Chinese kale to 4±1°C, several sets of process parameters were investigated. The experimental results showed that the optimum parameter for vacuum cooling Chinese kale with an initial temperature of 22-25°C was obtained using a final holding pressure of 6 mbar and a reserving time of 5 minutes. The total time to cool the Chinese kale was 17 min. The weight loss percentage was 0.9%. Vacuum cooling 241 kilograms of Chinese kale consumed energy of approximately 0.21 kWh per 1°C reduction in temperature. Vacuum cooling at a final holding pressure of 6 mbar and a reserving time of 5 minutes cost 0.002 USD/kg (32.00 THB = 1 USD). The energy results of the current study were comparable to those of Chen (1986) for the lowest energy cost per unit of cooled produce using vacuum cooling.

Table 2. Optimum process parameters for Chinese kale vacuum cooled in a polypropylene basket.

Experimental Results 2: Studying the effect of vacuum cooling combined with active packaging on the quality of Chinese kale.

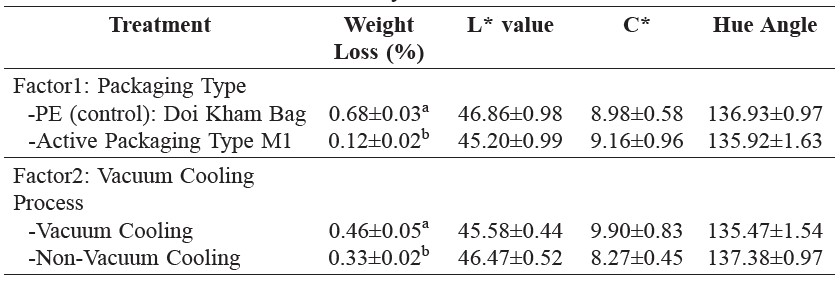

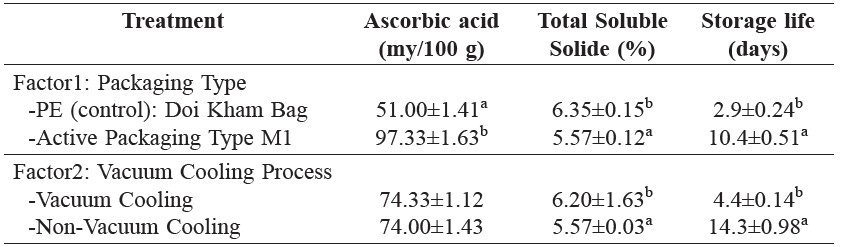

This study investigated the effect of vacuum cooling on the storage life and physicochemical properties of Chinese kale stored at 4°C. Vacuum cooling had no effect on the change of color (Table 3). However, precooled Chinese kale had a better appearance than non-precooled Chinese kale. The final pressure for vacuum cooling at 6 mbar with reserving time of 5 minutes was the best combination of parameters. All Chinese kale treatments remained green (did not change to yellow) when stored at 4°C for 5 days (the end of storage life). The color, L* value and hue angle tended to decrease by the end of storage, but chroma tended to stay stable throughout storage. Chlorophyll a, b and total chlorophyll tended to decrease with storage time, which correlated with the diminishing green color. The amounts of vitamin C tended to decrease with storage time. The effects of type of packaging and the interaction effect between vacuum cooling and type of packaging on vitamin C content, total phenolic content and antioxidant activity were significant. Vitamin C in Chinese kale was highest on the first day of storage. Chinese kale from the control treatment (perforated PE bag) and packaging type M1 stored at 4°C for 3 days had a vitamin C content of 51.00 and 97.33 mg/100 g fresh weight basis, respectively.

Type of packaging, vacuum cooling method and their interaction affected TSS, weight loss percentage, oxygen and carbon dioxide concentration in the packaging and storage life of Chinese kale significantly. TSS content generally increased with increasing storage time and was significantly lower in Chinese kale in packaging type M1. The results also indicated that TSS of Chinese kale correlated with fresh weight loss percentage and was affected by vacuum cooling (Table 3 and 4).

Table 3. Effect of vacuum cooling on weight loss and color (mean, ± S.E.) of Chinese kale stored for 3 days.

Note: Overall means with different letters in the same column are significantly different at P≤0.05.

The vacuum-cooled Chinese kale suffered a smaller loss of fresh weight, but had a lower TSS concentration than non-vacuum-cooled Chinese kale. Deterioration in the quality of Chinese kale, primarily due to wilting, indicated the effective storage life. Non-precooled Chinese kale packaged in perforated polypropylene stored at 4°C had the shortest storage life of 3 days. Vacuum-cooled Chinese kale packaged in M1 had the longest storage life of 14 days.

Table 4. Effect of vacuum cooling on chemical properties (mean of ± S.E.) of Chinese kale stored for 3 days.

Note: Overall means with different letters in the same column are significantly different at P≤0.05.

DISCUSSION

Experiment 1: Study on optimum process parameters for vacuum cooling of Chinese kale.

In vacuum cooling, the total pressure in the vacuum chamber is the sum of the partial pressure of air and water vapor. During vacuum cooling, the air is evacuated by vacuum pump and the water vapor condensed into water in the vapor condenser. The total pressure is reduced from atmospheric pressure to 6 mbar. As the pressure is reduced in the vacuum chamber, the point at which boiling starts is called the “flash point”. The weight loss that occurs during vacuum cooling is a direct result of water evaporation from the Chinese kale. The weight loss percentage is closely related to the final holding pressure as well as holding time; the lower the pressure, the higher the weight loss at any given holding time; the longer the holding time, the higher the weight loss at any given pressure.

Experiment 2: Studying the effect of vacuum cooling combined with active packaging on the quality of Chinese kale.

As illustrated from the results, the O2 concentration decreased rapidly to about 16-17% during the first 40 hours using packaging type M1 due to the high respiration rate of the produce. The headspace gas composition is strictly related to both the gas transmission rate through the film and the respiration rate of the packaged produce; the higher the barrier properties of the packaging, the faster the decrease in the headspace O2 concentration and the increase in the headspace CO2 concentration. Cheng (2006) found that bamboo shoots treated with vacuum cooling and hydro cooling prolonged the storage time and improved freshness, preserving quality efficiently. The excess mass loss reduced firmness and caused wilting of Chinese kale. Chinese kale packed in PP bag suffered a loss in quality, primarily due to its odor. Too low an O2 concentration and too high a CO2 concentration could induce off-flavor, therefore reducing storage life of the Chinese kale packed in PP bag. This sample was substantially compromised by wilting, due to produce mass loss. Firmness and wilting were two main factors influencing the acceptability of Chinese kale. The increase in TSS of Chinese kale throughout storage was likely attributed to continuous loss of moisture from the produce. Weight loss of Chinese kale continued to increase in all treatments throughout the storage period. The vacuum-cooled Chinese kale maintained higher firmness during storage, which was consistent with the study of Toa et al. (2007), which indicated that vacuum cooling of mushroom maintained remarkably higher firmness during storage. The results of the current study agree with the study of He et al. (2006) on the effects of pressure reduction rate on the quality of iceberg lettuce after vacuum cooling. They found that vacuum cooling and cold storage for two weeks maintained higher ascorbic acid content of lettuce. Additionally, Chen (2006) also reported the change of chlorophyll content in lettuce after two weeks of cold storage. His study found that the chlorophyll content under all treatments declined very quickly, and the mean loss of chlorophyll was approximately 66% of the initial value (Chen, 2006). The headspace oxygen concentration in all packaging types, except the control, decreased then reached equilibrium. For precooled and non-precooled Chinese kale packed in active packaging type M1, the O2 concentrations reached an equilibrium concentration of about 18.8% and 18.2%, respectively, after two days of storage, owing to the high OTR of the film. The CO2 concentrations of precooled and non-precooled Chinese kale packed in all active packaging type M1 reached equilibrium concentrations of about 1.2% and 1.5%, respectively, after six days of storage. Previous research showed that Chinese kale packaged in OPE3 (M3) and stored at 4°C without precooling also extended the storage life of Chinese kale to 14 days (Boonyakiat and Boonprasom, 2012).

CONCLUSION

The optimum vacuum-cooling parameters for Chinese kale were a final holding pressure of 6.0 mbar and a holding time of 5 minutes. Under these parameters, the weight loss of the Chinese kale was 0.9%. The weight loss percentage increased at lower pressures or longer holding times, holding the other constant. Precooling, type of packaging and interaction between precooling and type of packaging significantly affected the weight loss percentage, TSS, oxygen and carbon dioxide in the packaging, and storage life (P≤0.05), but had no effect on change of color (P>0.05). Precooled kale in packaging type M1 had the longest shelf life of 14 days. Non-precooled Chinese kale packaged in perforated polyethylene bag (Doi Kham bag) had the shortest shelf life of 3 days. With or without precooling, the right active packaging under refrigerated storage extended the storage life of Chinese kale. In addition, precooling delayed wilting.

ACKNOWLEDGEMENTS

The authors are grateful to the Postharvest Technology Innovation Center, Chiang Mai University, Thailand for financial support. Thanks also to the Royal Project Foundation for providing facilities.

REFERENCES

Anon. 1981. Rapid vacuum cooling. Food Processing Industry, 9, 49.

AOAC. 2000. Official Methods of Analysis of the Association of Official Analytical Chemist, Inc. Washington, DC.

Artes, F., and J.A. Martinez. 1995. Effects of vacuum cooling and packaging films on the shelf life of ‘salinas’ lettuce. In Proceedings of International Conference on Refrigeration and Quality of Fresh Vegetables. Paris: International Institute of Refrigeration, pp. 311-315.

Boonyakiat, D. and P.B. Poonlarp. 2012. Effect of active packaging on quality of Chinese Kale. CMU Journal of Natural Sciences, 11(1): 215-221.

Brand-Williams, W., M.E. Cuvelier, and C. Berset. 1995. Use of a free radical method to evaluate antioxidant activity. Lebensmittel Wissenschaft Technology 28: 25-30.

Cheng, H.P. 2006. Vacuum cooling combined with hydrocooling and vacuum drying on bamboo shoots, Applied Thermal Engineering 26: 2168-2175.

Cheng, H.P. and C.F. Hsueh. 2007. Multi-stage vacuum cooling process of cabbage. Journal of Food Engineering, 79: 37-46.

Chen, Y.L. 1986. Vacuum cooling and its energy use analysis. Journal of Chinese Agricultural Engineering, 32: 43-50.

He S.Y., G.P. Feng, H.S. Yang, Y. Wu, and Y.F. Li. 2004. Effects of pressure reduction rate on quality and ultrastructure of iceberg lettuce after vacuum cooling and storage, Postharvest Biology and Technology, 33: 263-273.

Liyun Zheng and Da-Wen Sun. 2005. 22 - Vacuum Cooling of Foods, In Emerging Technologies for Food Processing, edited by Da-Wen Sun, Academic Press, London, Pages 579-602, ISBN 9780126767575, http://dx.doi.org/10.1016/B978-012676757-5/50024-4.(http://www.sciencedirect.com/science/article/pii/B9780126767575500244)

Tao F., M. Zhang, and H. Yu. 2007. Effect of vacuum cooling on physiological changes in the antioxidant system of mushroom under different storage conditions, Journal of Food Engineering, 79: 1302-1309.

Whitham, F.H., D.H. Blaydes, R.M. Devin, and D. Van. 1971. Experiment in plant physiology. Nostrand Co. New York. 245 p.

Pichaya B. Poonlarp1,3* and Danai Boonyakiat2,3

1 Division of Food Engineering, Faculty of Agro-Industry, Chiang Mai University, Chiang Mai 50100, Thailand

2 Department of Plant and Natural Resources, Faculty of Agriculture, Chiang Mai University, Chiang Mai 50200, Thailand

3 Postharvest Technology Innovation Center, Chiang Mai University, Chiang Mai 50200, Thailand

*Corresponding author. Email: pichaya.aey@hotmail.com

Total Article Views