Impact of Microwave Cooling on Resistant Starch and Digestibility in High-Carbohydrate Foods: A Meta-Analysis

Muhammad Isra*, Widya Rahmawaty Saman, and Arif Murtaqi Akhmad MutsyahidanPublished Date : June 13, 2025

DOI : https://doi.org/10.12982/NLSC.2025.050

Journal Issues : Number 3, July-September 2025

Abstract Starch is extensively utilized in food processing for various functional purposes. However, the use of native starch is limited due to its incompatibility with specific processing conditions and final product characteristics. Microwave treatment has emerged as an efficient physical modification technique to enhance the content of resistant starch in food ingredients, offering lower energy consumption compared to conventional heating methods. Nevertheless, the impact of this method varies depending on the type of high-carbohydrate food, particularly in terms of resistant starch content, in vitro digestibility, include starch composition, amylose and amylopectin content, solubility, water absorption capacity, gelatinization, retrogradation, and starch digestibility. This meta-analysis aimed to evaluate the effect of microwave treatment combined with cooling on the resistant starch content of high-carbohydrate foods. A total of 23 studies were selected and analyzed following the PRISMA guidelines, from an initial pool of 3,663 articles. Data were analyzed using Hedges’d standardized mean difference (SMD) and confidence intervals (CI) via the OpenMEE software. The findings indicated that the microwave-cooling method had a statistically significant positive effect on resistant starch content in high-carbohydrate foods (SMD = 2.461; 95% CI: 1.652–3.270; P < 0.001). In conclusion, the microwave-cooling treatment significantly influences resistant starch content, in vitro digestibility, and physicochemical properties of high-carbohydrate foods, with strong statistical support at a 95% confidence level.

Keywords: Carbohydrate, Microwave-cooling, Meta-analysis, Starch

Funding: This research was funded by LPPM UNG via PNBP-Universitas Negeri Gorontalo according to DIPA-UNG No. 653/UN47/HK.02/2024, under contract No. 788/UN47.D1/PT.01.03/2024.

Citation: Isra, M., Saman, W.R., and Mutsyahidan, A.M.A. 2025. Impact of microwave-cooling on resistant starch and digestibility in high-carbohydrate foods: A meta-analysis. Natural and Life Sciences Communications. 24(3): e2025050.

INTRODUCTION

Starch, a carbohydrate abundantly found in various plant-based foods, can be categorized based on its digestibility into three types: rapidly digestible starch (RDS), slowly digestible starch (SDS), and resistant starch (RS) (Cheng et al., 2024). Resistant starch is not digested in the human small intestine and functions similarly to dietary fiber. It contributes to improved glycemic control by reducing glucose absorption and has been associated with a reduced risk of chronic diseases such as type 2 diabetes mellitus (Chavez-Esquivel et al., 2022). To achieve these physiological benefits, a daily intake of 10–20% RS from total carbohydrate consumption is recommended. However, most commercial food products contain less than 5% RS per serving (Jiang et al., 2024), highlighting the need to develop food ingredients with enhanced RS content.

Among the five types of RS, type 3 (RS3) is particularly attractive due to its thermal stability and ability to retain its functional properties during food processing. RS3 is formed through retrogradation a process that occurs when gelatinized starch is cooled, allowing linear chains of amylose to realign into crystalline structures (Sánchez-Rivera et al., 2013). RS3 is the most common form used in the development of functional foods and can be obtained from a variety of starch sources, including rice, corn, cassava, banana, and barley starch (Zhang et al., 2016; Li et al., 2019). This type of RS can be increased through physical modification techniques, such as microwave treatment.

Microwave heating, when combined with a cooling step, has emerged as an efficient method to enhance RS3 formation. The microwave-cooling process involves gelatinizing starch using microwave energy known for its rapid and uniform heating followed by a cooling phase that promotes retrogradation. Compared to conventional heating methods, this approach has demonstrated higher RS yields in some studies. For example, Huang et al., (2024) and Jiang et al., (2024) reported that microwave-cooling treatment increased RS3 content in white millet starch to 18.7%, surpassing the 12.3% achieved via the heat-moisture treatment (HMT) method.

Several studies have demonstrated the effectiveness of microwave treatment in increasing RS content in various carbohydrate sources, including rice (Armah et al., 2024), green beans (Kanagaraj et al., 2019), wheat (Goel et al., 2020), corn, potatoes, and chestnuts (Liu et al., 2015). However, results vary across starch types. In some cases, such as pea starch (Huang et al., 2024), taro (Fashi et al., 2023), hybrid rice (Wang et al., 2016), and sweet potato flour (Abedi et al., 2022), the RS content obtained through microwave-cooling was lower than that in their native form. Its formation is influenced by factors such as the amylose-to-amylopectin ratio and the processing method applied.

Given the variability of outcomes reported in individual studies, meta-analysis serves as a valuable statistical tool to synthesize findings and provide a more accurate estimate of the effect of microwave-cooling on RS3 formation. This method allows for the evaluation of the effectiveness of the treatment across different studies and helps identify patterns that may not be evident in single experiments (Isra et al., 2023). For instance, Barua et al., (2021) applied meta-analysis to assess the impact of microwave-cooling on RS content in various starches.

Despite the growing number of studies investigating microwave-cooling treatment on resistant starch formation, the results remain inconsistent and sometimes contradictory across different starch sources and processing conditions. Some studies report significant increases in RS content, while others show limited or even negative effects. These inconsistencies have made it difficult to draw generalized conclusions about the true effectiveness of the microwave-cooling method. Therefore, a meta-analysis is timely and necessary to synthesize the available evidence, resolve conflicting findings, and identify key factors such as starch type or processing parameters that influence the formation of resistant starch. This approach can help bridge existing knowledge gaps and guide future research and application in functional food development.

MATERIALS AND METHODS

Materials

The materials used in this meta-analysis study are research articles from reputable and accredited international publications, as well as articles from various online database web servers, such as Science Direct, Wiley Online Library, Taylor & Francis Online, Springer Link, and Google Scholars.

The tools used are Publish or Perish (version 8), Mendeley software (version 1.19.8 (2020), Zotero (version 5.0.97(2021)), OpenMEE software (version 10.10 (2020)), and Microsoft Excel (version 16.53 (2019)). Publish or Perish, Mendeley, and Zotero were used to select literature studies, while Microsoft Excel and OpenMEE were used to analyze the data.

Search and collection of study source articles

Articles were searched and selected based on the preferred reporting items for systematic reviews and meta-analysis statements (PRISMA) (Isra et al., 2023). The PRISMA analysis method can simplify the process of selecting research articles, including the stages; Identification, Adjustment, Selection, Selected Library, Analysis (Figure 1). The article selection process is carried out in several stages using parameters: completeness of text, title and duplication, abstract, and method. Journal articles are searched for through search sites that provide scientific publication databases such as Science Direct, Springer, Wiley Online Library, Scopus, Google Scholar, and PubMed. The keywords used in the search were "microwave cooling", "resistant starch", "physicochemical", and "In vitro digestibility". Keywords using is accompanied by Boolean operators (and, not) and advanced search features to make it easier to find suitable articles.

Article selection

The study selection process was conducted systematically in accordance with the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) guidelines. A PRISMA flow diagram has been included to illustrate the identification, screening, eligibility, and inclusion phases of the literature selection. Literature searches were performed using electronic databases such as Scopus, ScienceDirect, and Google Scholar. Retrieved references were managed using Mendeley software to identify and remove duplicates. The initial screening involved reviewing the titles and abstracts to assess relevance, followed by full-text reviews based on predefined inclusion and exclusion criteria.

The inclusion criteria were as follows: (1) articles published in reputable international journals between 2014 and 2024, (2) original research articles presenting primary data, (3) studies that used microwave-cooling methods for starch modification, and (4) articles reporting resistant starch content before and after modification (as control and treatment data, respectively), in addition to in vitro digestibility and physicochemical properties. Furthermore, selected articles were required to report complete statistical data, including the number of replicates for both control and treatment groups, mean values, and standard deviations.

The exclusion criteria included studies that lacked complete statistical data (e.g., missing standard deviation or standard error), literature reviews, book chapters, patents, and non-peer-reviewed sources. For studies with missing data, a thorough eligibility assessment was performed. If key numerical data were unavailable in the text, tables, or figures, the article was excluded from the analysis. In cases where data were presented only in graphical form, extraction was attempted using tools such as WebPlotDigitizer. However, if accurate data extraction was not feasible, the study was excluded to maintain the integrity and consistency of the analysis.

Data collection

Articles that meet the requirements from the journal web server using Zotero are used to carry out meta-analysis (OpenMEE). Research data from the selected journals is then extracted into a Microsoft Excel worksheet. Data was collected based on information regarding the author's name, year of publication, sample type, number of replications, and the mean value and standard deviation or standard error of resistant starch content, in vitro digestibility, and physicochemical properties in the control group and experimental group. The information must be sufficient to calculate the SMD (Standardized Mean Difference) and 95% CI (Confidence Interval) and identify publication bias.

Statistical analysis

The meta-analysis combined individual study results by converting their statistics into a common metric, Standardized Mean Difference (SMD), using Hedges’ g method. This effect size metric accounts for sample size and variance, thus studies were weighted according to the inverse of their variance, meaning that studies with larger sample sizes and smaller standard errors contributed more to the overall estimate than smaller, less precise studies. This weighting ensures that more reliable studies have a greater influence on the pooled results.

The analysis was performed using the OpenMEE software, which generates forest plots to visually assess effect sizes and confidence intervals. Additionally, heterogeneity among studies was evaluated statistically to determine variability in effect sizes across different studies.

Publication bias was assessed using funnel diagram analysis and Egger's regression test to detect asymmetry, which may indicate bias due to selective publication of significant results. This test provides insight into whether smaller studies with nonsignificant findings may be underrepresented in the literature. If publication bias is detected, appropriate sensitivity analyses or trim-and-fill adjustments are considered to ensure the robustness of the conclusions.

The analysis was carried out using a random effects model that combines data from several studies (Navickis et al., 2012). The moderator variables used for subgroup analysis are country, type of carbohydrate food, in vitro digestibility, physicochemical properties, Starch Composition, and Amylose Interaction. The data used is data on RS levels from various carbohydrate sources. The effect size of each method is calculated to determine how much influence the method has on a food group. A positive effect size with a P-value <0.05 indicates that microwave-cooling method can significantly increase RS levels. The significance of the impact of In vitro digestibility, physicochemical properties, Starch Composition, and Amylose Interaction can be assessed if the CI value does not reach zero. Heterogeneity between study variability is represented using the I^2 statistical value (I^2 > 50% indicates sufficient heterogeneity) (Haghighatdoost et al., 2021).

RESULTS

The reference selection process using the PRISMA method is summarized in Figure 1. From an initial 3,663 articles, a total of 23 studies were finally included in the meta-analysis after applying strict inclusion and exclusion criteria. These studies encompass 23 food materials modified using the microwave-cooling method.

Figure 1. The process of selecting literature/study articles for further meta-analysis.

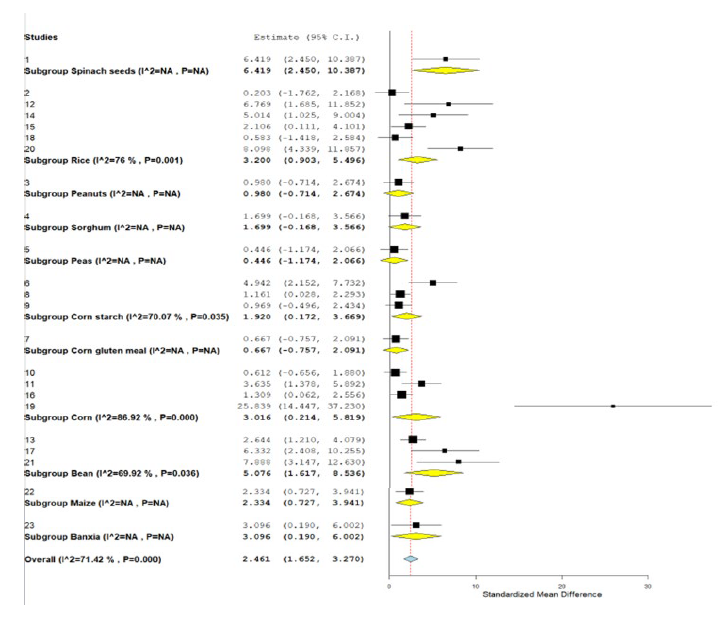

To improve visual clarity and reduce redundancy in the presentation of results, a forest plot was used (Figure 2) to summarize the individual and overall effect sizes, while subgroup analysis tables and figures were employed to compare effect sizes among different food types (e.g., cereals, tubers, legumes). The detailed numerical findings were moved to a supplementary table to streamline the main text and emphasize key trends visually.

Interestingly, although the majority of studies reported increased RS levels after microwave-cooling, a few food types such as certain rice and corn varieties showed reduced RS content post-treatment. This contradiction may be explained by the inherent differences in starch structure, amylose/amylopectin ratio, grain maturity, and moisture content, all of which significantly affect starch retrogradation during the cooling phase. For example, high amylopectin content in some rice and corn varieties may reduce the formation of RS3 due to limited linear chain formation needed for recrystallization. Moreover, processing parameters such as microwave power, exposure duration, and cooling time/temperature also differ between studies, contributing to varied outcomes. In some studies, inadequate cooling duration or excessive gelatinization may have disrupted the retrogradation process, resulting in lower RS formation. These findings highlight the importance of standardizing processing parameters and considering raw material characteristics in future studies.

Data analysis

Data from the analysis of resistant starch (RS) content from each selected article (n = 23) were summarized in Table 1, presenting the percentage change in RS levels from native starch to modified starch. The average RS content in native starch was 20.70%, which increased to 50.48% after microwave-cooling modification, with an average increase of 29.78%.

All eligible data were entered into the OpenMEE software, which required the input of means, standard deviations, and sample sizes for both control and treatment groups. This information was used to compute Hedges’d (Standardized Mean Difference/SMD), which corrects for small sample bias and is suitable for meta-analyses with heterogeneous sample sizes.

Analysis of variability in study design, starch type, and experimental conditions, a random effects model was applied instead of a fixed effects model. The random effects model assumes that the true effect size may vary between studies and thus takes into account both within-study sampling error and between-study variance. This choice is appropriate when heterogeneity is expected, which is confirmed in our analysis by the high heterogeneity statistic (I² = 71.42%), indicating substantial inconsistency between studies.

Table 1. Data on changes in levels of resistant starch in foodstuffs.

|

No. |

Foodstuffs |

Countries |

Resistant starch control (%) |

Resistant starch after modification (%) |

Change in resistant starch (%) |

Effect size (OpenMEE) |

Literature study |

||

|

Variant |

Mean |

||||||||

|

1 |

Spinach seeds |

India |

41.13 |

58.90 |

17.77 |

6.419 |

4.100 |

Kanagaraj, Ponnambalam, and Antony, 2019 |

|

|

2 |

Rice |

India |

11.80 |

18.70 |

6.90 |

0.203 |

1.005 |

Wang & Bai, 2017 |

|

|

3 |

Peanuts |

India |

33.00 |

44.64 |

11.64 |

0.980 |

0.747 |

Goel et al., 2020 |

|

|

4 |

Sorghum |

Poland |

10.10 |

12.30 |

2.20 |

1.699 |

0.907 |

Massarolo et al., 2019 |

|

|

5 |

Peas |

Mexico |

30.00 |

40.69 |

10.69 |

0.446 |

0.683 |

Liu et al., 2015 |

|

|

6 |

Corn starch |

Vietnam |

60.11 |

85.90 |

25.79 |

4.942 |

2.026 |

Nongmaithem and Meda, 2017 |

|

|

7 |

Corn gluten meal |

Nigeria |

16.58 |

19.93 |

3.35 |

0.667 |

0.528 |

Afolabi et al., 2018 |

|

|

8 |

Corn starch |

Italia |

5.07 |

6.99 |

1.92 |

1.161 |

0.334 |

Cervini et al., 2021 |

|

|

9 |

Corn starch |

USA |

46.7 |

48.50 |

1.80 |

0.969 |

0.559 |

Wang et al., 2016 |

|

|

10 |

Corn |

China |

87.45 |

94.08 |

6.63 |

0.612 |

0.419 |

Wang et al., 2019 |

|

|

11 |

Corn |

Australia |

2.55 |

71.04 |

68.49 |

3.635 |

1.326 |

Wang et al., 2021 |

|

|

12 |

Rice |

Brazil |

0.48 |

26.70 |

26.22 |

6.769 |

6.727 |

Jiang et al., 2024 |

|

|

13 |

Bean |

China |

18.61 |

46.74 |

28.13 |

2.644 |

0.535 |

Narwojsz et al., 2020 |

|

|

14 |

Rice |

China |

5.00 |

82.75 |

77.75 |

5.014 |

4.143 |

Li et al., 2019 |

|

|

15 |

Rice |

India |

14.12 |

35.70 |

21.58 |

2.106 |

1.036 |

Sandhu et al., 2020 |

|

|

16 |

Corn |

Taiwan |

11.76 |

41.74 |

29.98 |

1.309 |

0.405 |

Zhao et al., 2018a |

|

|

17 |

Bean |

Canada |

6.44 |

81.68 |

75.24 |

6.332 |

4.007 |

Piecyk and Domian, 2021 |

|

|

18 |

Rice |

China |

11.88 |

16.02 |

4.14 |

0.583 |

1.042 |

Deka and Sit, 2016 |

|

|

19 |

Corn |

Poland |

4.37 |

80.42 |

76.05 |

25.839 |

33.782 |

Zhao et al., 2018b |

|

|

20 |

Rice |

USA |

8.36 |

40.80 |

32.44 |

8.098 |

3.679 |

Barua, Rakshit, and Srivastav, 2021 |

|

|

21 |

Bean |

India |

5.01 |

79.21 |

74.20 |

7.888 |

5.852 |

Krongworakul et al., 2020 |

|

|

22 |

Maize |

China |

14.28 |

50.52 |

36.24 |

2.334 |

0.672 |

Vatansever et al., 2021 |

|

|

23 |

Banxia |

China |

31.29 |

77.00 |

45.71 |

3.096 |

2.198 |

Garcia-Valle et al., 2021 |

|

|

The average levels of control resistant starch (n= 23); 20.70% |

|||||||||

|

The average content of resistant starch after modification (n= 23); 50.48% |

|||||||||

|

The average increase in resistant starch (n=23); 29.78% |

|||||||||

The OpenMEE output included forest plots (Figure 2), which visually present the effect size (SMD) and 95% confidence intervals (CI) for each individual study and the overall pooled estimate. The forest plot showed a significant overall effect of microwave-cooling treatment on increasing resistant starch levels, with a pooled SMD of 2.461 (95% CI: 1.652 to 3.270, P < 0.001). The horizontal lines in the forest plot reflect the confidence intervals of each study, and the diamond at the bottom represents the summary effect and its precision.

Figure 2. Forest plot of the results of the meta-analysis study of all data.

Effect of differences in carbohydrate foods on increasing levels of resistant starch

Forest plot results show that high carbohydrate foods have a significant effect on increasing resistant starch levels with an SMD effect value of 2.461 with a 95% CI (1.652 to 3.270) P<0.001, and the heterogeneity value (I^2) is included in the high category, namely 71.42 I^2. The forest plot results for the carbohydrate food sub-group data show that the microwave-cooling modification method for natural starch significantly increases the levels of modified resistant starch. The results of the forest plot data analysis of the influence of carbohydrate food types are presented in Figure 3.

The heterogeneity level measured by I^2 at 71.42% indicates that the variation among the analyzed studies is quite high, thus falling into the high heterogeneity category. Furthermore, the forest plot results for the carbohydrate-based food sub-group data show that the modification method using microwave heating followed by cooling on natural starch significantly increases the levels of modified resistant starch. These findings suggest that certain processing methods can optimize the formation of resistant starch in high-carbohydrate foods, potentially providing health benefits, particularly in controlling glycemic response and improving digestive health.

Figure 3. Forest plot of the results of the meta-analysis of the study of the effect of different types of carbohydrate foods.

Effect of high carbohydrate foods on in vitro digestibility and physicochemical properties

Further analysis was carried out to determine the effect of high-carbohydrate foods on in vitro digestibility and physicochemical properties. Each test of in vitro digestibility (IVD), physicochemical properties (Phys-Chem), with additional parameters Starch Composition (SC), and Amylose Interaction (AI) in the literature is analyzed, and forest plot data can be retrieved (Figure 4). Based on the forest plot results, high carbohydrate foods with an SMD effect value of 2.461 with a 95% CI (1.652 to 3.270) P<0.001 significantly influence in vitro digestibility and physicochemical properties.

In the context of high-carbohydrate foods, physicochemical properties include starch composition, amylose and amylopectin content, solubility, water absorption capacity, gelatinization, retrogradation, and starch digestibility. These factors play an important role in determining the texture, stability, and bioavailability of starch in the digestive system. Higher amylose content can increase the formation of resistant starch through retrogradation, which contributes to health benefits such as blood glucose control and improved gastrointestinal health. In addition, physical modifications such as heating and cooling can change the physicochemical properties of starch, thereby affecting in vitro digestibility and potential nutritional benefits. Understanding these physicochemical properties is essential in the development of healthier and more value-added functional food products.

Figure 4. Forest plot of the results of the meta-analysis of the study of the effect of carbohydrate foods on in vitro digestibility (IVD), physicochemical properties (Phys-Chem), Starch Composition (SC), Amylose Interaction (AI).

Effect of meta-analysis of studies on the development of carbohydrate foods in various countries

Effect Size value data shows that the meta-analysis results based on subgroup countries recorded nine countries that conducted research on the topics of microwave-cooling, food ingredients, in vitro digestibility and physicochemical properties with an SMD effect value of 2.461 with a CI of 95% (1.652 to 3.270) P<0.001. Most studies were conducted in China, with six studies, and in second place were conducted in India, with five studies and several studies in Poland, Mexico, Vietnam, Nigeria, Italy, and the USA.

The results of the meta-analysis indicate that research on microwave-cooling methods, food ingredients, in vitro digestibility, and physicochemical properties has been conducted in nine different countries, demonstrating a global interest in the development of carbohydrate-based foods. The studies, particularly those from China and India, suggest a significant contribution to the field, with China leading in the number of studies (six) and India following closely (five). Additionally, research from countries such as Poland, Mexico, Vietnam, Nigeria, Italy, and the USA further supports the notion that the development of carbohydrate foods through various modification methods is being explored across different regions. The presence of a significant Standardized Mean Difference (SMD) effect value of 2.461 (95% CI: 1.652–3.270, P<0.001) further confirms the impact of these studies in advancing carbohydrate food development globally.

Figure 5. Forest plot results of meta-analysis of studies on the development of carbohydrate foods in various countries.

DISCUSSION

Microwave-cooling modification is a physical process involving gelatinization and retrogradation mechanisms. Microwave treatment provides rapid and uniform heating through micron-level energy transfer, disrupting the starch granules' crystalline structure (Zhao et al., 2018a; Zhang et al., 2020). The cooling phase allows for the recrystallization of amylose chains, resulting in type 3 resistant starch (RS3) (Krongworakul et al., 2020). This process of retrogradation is the principal reason for increased RS levels following treatment (Zhao et al., 2018b).

Despite the general trend of increased RS, some foodstuffs such as rice (2 and 18), peanuts (3), sorghum (4), peas (5), corn starch (9), corn gluten (7), and corn (10) did not show significant improvement in RS content, and in some cases, even demonstrated a decrease. This could be attributed to excessive thermal exposure during microwave heating, leading to degradation of RS1 and RS2 fractions. Overheating disrupts polymer chain integrity, particularly within the degree of polymerization range of 25–30, and prevents proper retrogradation (Garcia-Valle et al., 2021). During gelatinization, starch loses its birefringence and swells irreversibly under high water and heat conditions, further reducing its capacity to re-crystallize.

The observed decrease in RS content can be hypothesized to originate from its unique biochemical composition, where a significant protein matrix encloses the starch granules, limiting water uptake and starch swelling during microwave heating. This limited gelatinization may inhibit the formation of recrystallized amylose structures required for RS3 formation. Furthermore, protein-starch interactions in corn gluten may lead to increased starch degradation under microwave conditions, exacerbated by the uneven heating pattern typical in heterogeneous matrices. Excessive heat may accelerate the breakdown of amylose and amylopectin chains before they have a chance to undergo retrogradation, resulting in a net loss of RS (Garcia-Valle et al., 2021; Piecyk and Domian, 2021).

On the other hand, microwave heating can be beneficial in promoting RS formation. The process enhances gelatinization followed by retrogradation, thereby reducing starch digestibility and increasing RS levels (Van et al., 2016; Wang et al., 2019). High-moisture microwave heating breaks amylose double helices and dissociates hydrogen bonds, separating amylopectin from the main starch chain. This results in increased viscosity of the starch paste. During subsequent cooling, molecular chains realign and form hydrogen bonds to create new crystalline regions hence producing more RS3 (Vatansever et al., 2021).

Effect size analysis further confirms the interdependence among RS content, in vitro digestibility, and physicochemical properties. Microwave-cooling not only alters the starch’s molecular structure but also affects how it behaves under digestive conditions. Retrograded starch becomes more resistant to enzymatic hydrolysis, slowing glucose release during digestion. This, in turn, influences physicochemical traits such as amylose content, water absorption, and texture. Therefore, the relationship between microwave treatment, cooling, digestibility, and structural changes is reciprocal modifying one parameter inevitably influences others. These findings underscore the importance of understanding starch thermal behavior to develop carbohydrate-based foods with optimized nutritional profiles.

This study also highlights the global attention microwave-cooling methods have received in food research. Studies from at least eight countries in the past decade suggest growing interest in this area, with a strong emphasis on functional food development. Trends in developed countries show increased demand for low-carbohydrate foods and natural whole grains, aligning with the purpose of RS-enhancing modifications.

Moreover, meta-analysis enables a broader view of regional trends in carbohydrate food research. Some regions focus on improving rice-based products, while others explore alternative sources like wheat and corn. These differences reflect not only agronomic availability but also cultural and economic influences on diet.

This meta-analysis confirms that the microwave-cooling method significantly influences resistant starch (RS) content, in vitro digestibility, and physicochemical properties of carbohydrate-based foods. The overall effect size (SMD = 2.461; 95% CI: 1.652–3.270; P < 0.001) indicates a strong treatment effect. The heterogeneity value (I² = 71.42%) falls into the high category, reflecting variability among the included studies. According to Isra et al., (2022), high heterogeneity is common and acceptable in meta-analyses involving food systems due to natural diversity in experimental conditions, raw materials, and analytical techniques.

The microwave-cooling method emerges as an effective strategy for enhancing RS content and modifying related digestibility and physicochemical properties. These results encourage more targeted applications in food processing and highlight the necessity of tailored treatment protocols based on food type to achieve desirable functional and nutritional outcomes.

CONCLUSION

This meta-analysis confirms that the microwave-cooling method significantly enhances resistant starch (RS) content, in vitro digestibility, and physicochemical properties of carbohydrate-based foods, with a robust effect size (SMD 2.461; 95% CI: 1.652 to 3.270; P < 0.001). However, the effectiveness of this method varies depending on the starch source, food matrix, and processing parameters, indicating the need for tailored application strategies.

To guide practical implementation, food manufacturers should prioritize starches with higher amylose content and systematically optimize microwave-cooling conditions such as moisture level, temperature, and cycle time to promote RS3 formation. Developing standardized microwave-cooling protocols will be critical to ensure reproducible results and facilitate industrial scalability.

Importantly, future meta-analyses in this domain would benefit substantially from incorporating a formal risk of bias assessment for each included study. This step is essential not only to evaluate the internal validity of individual studies but also to increase the overall credibility and reliability of the synthesized evidence. A structured risk of bias analysis enables the identification of methodological weaknesses that may distort results, supports more accurate interpretation of heterogeneity, and provides a stronger foundation for evidence-based recommendations. By including this assessment, future research will be better positioned to inform both scientific advancement and policy or industry-level decision-making in food science and technology.

ACKNOWLEDGEMENTS

The author expresses his deepest gratitude and appreciation to LPPM Universitas Negeri Gorontalo for funding research in the Accelerative Research Program Expert Assistant Accelerated Research Scheme (RA3) UNG PNBP Funds for Budget Year 2024.

AUTHOR CONTRIBUTIONS

Muhammad Isra carried out research design, data collection and data analysis, Widya Rahmawaty Saman carried out meta-analysis data selection and summarized the discussion, Arif Murtaqi Akhmad corrected the English language and journal writing procedures. All authors have read and approved of the final manuscript.

CONFLICT OF INTEREST

The authors declare that they hold no competing interests.

REFERENCES

Abedi, E., Sayadi, M., and Pourmohammadi, K. 2022. Effect of freezing-thawing pre-method on enzymatic modification of corn and potato starch treated with activated α-amylase: Investigation of functional properties. Food Hydrocolloids. 129: 107676.

Afolabi, T.A., Opara, A.O., Kareem, S.O., and Oladoyinbo, F.O. 2018. In vitro digestibility of hydrothermally modified Bambara groundnut (Vigna subterranean L.) starch and flour. Food Science and Nutrition. 6(1): 36–46.

Armah, J.O., Appiah, V., Egblewogbe, M.N.Y.H., and Ocloo, F.C.K. 2024. Characterization of flour produced from gamma irradiated dried cassava (Manihot esculenta) chips. Radiation Physics and Chemistry. 218(12): 111651.

Barua, S., Rakshit, M., and Srivastav, P.P. 2021. Optimization and digestogram modeling of hydrothermally modified elephant foot yam (Amorphophallus paeoniifolius) starch using hot air oven, autoclave, and microwave methods. LWT. 145: 111283.

Cervini, M., Frustace, A., Garrido, G.D., Rocchetti, G., and Giuberti, G. 2021. Nutritional, physical and sensory characteristics of gluten-free biscuits incorporated with a novel resistant starch ingredient. Heliyon. 7(3): e06562.

Chavez-Esquivel, G., Cervantes-Cuevas, H., and Vera-Ramírez, M.A. 2022. Effect of dual modification with citric acid combined with ultrasonication on hydrolysis kinetics, morphology and structure of corn starch dispersions. International Journal of Biological Macromolecules. 222: 1688–1699.

Cheng, Z., Zheng, Q., Duan, Y., Hu, K., Cai, M., and Zhang, H. 2024. Optimization of ultrasonic conditions for improving the characteristics of corn starch-glycyrrhiza polysaccharide composite to prepare enhanced quality lycopene inclusion complex. International Journal of Biological Macromolecules. 267(Pt 2): 131504.

Deka, D., and Sit, N. 2016. Dual modification of taro starch by microwave and other heat moisture methods. International Journal of Biological Macromolecules. 92: 416–422.

Fashi, A., Delavar, A.F., Zamani, A., Noshiranzadeh, N., and Mohammadi, M. 2023. Solid state cationization reaction of microporous starch with betaine hydrochloride under repeated heating/cooling cycles: Design of a green approach for corn starch modification. International Journal of Biological Macromolecules. 248: 125968.

Garcia-Valle, D.E., Agama-Acevedo, E., Nuñez-Santiago, M.C., Alvarez-Ramirez, J., and Bello-Pérez, L.A. 2021. Extrusion pregelatinization improves texture, viscoelasticity and in vitro starch digestibility of mango and amaranth flours. Journal of Functional Foods. 80: 104441.

Goel, C., Semwal, A.D., Khan, A., Kumar, S., and Sharma, G.K. 2020. Physical modification of starch: Changes in glycemic index, starch fractions, physicochemical and functional properties of heat-moisture treated buckwheat starch. Journal of Food Science and Technology. 57(8): 2941–2948.

Haghighatdoost, F., Gholami, A., and Hariri, M. 2021. Effect of resistant starch type 2 on inflammatory mediators: A systematic review and meta-analysis of randomized controlled trials. Complementary Therapies in Medicine. 56: 102597.

Huang, X., Chen, L., and Liu, Y. 2024. Effects of ultrasonic and ozone modification on the morphology, mechanical, thermal and barrier properties of corn starch films. Food Hydrocolloids. 147: 109376.

Isra, M., Andrianto, D., and Setiarto, R.H.B. 2022. Effect of microwave heat method for resistant starch levels and prebiotic properties of high carbohydrate foods: Meta-analysis study. Chiang Mai University Journal of Natural Sciences. 21(2):e2020032.

Isra, M., Andrianto, D., and Setiarto, R.H.B. 2023. Effect heat moisture method for resistant starch levels and prebiotic properties of high carbohydrate food: Meta-analysis study. Food Research. 7(1): 144–150.

Jiang, C., Zeng, X., Wei, X., Liu, X., Wang, J., and Zheng, X. 2024. Improvement of the functional properties of insoluble dietary fiber from corn bran by ultrasonic-microwave synergistic modification. Ultrasonics Sonochemistry. 104: 106817.

Kanagaraj, S.P., Ponnambalam, D., and Antony, U. 2019. Effect of dry heat method on the development of resistant starch in rice (Oryza sativa) and barnyard millet (Echinochloa furmantacea). Journal of Food Processing and Preservation. 43: 13965.

Krongworakul, N., Naivikul, O., Boonsupthip, W., and Wang, Y.J. 2020. Effect of conventional and microwave heating on physical and chemical properties of Jasmine brown rice in various forms. Journal of Food Process Engineering. 43: e13506.

Li, N., Cai, Z., Guo, Y., Xu, T., Qiao, D., Zhang, B., Zhao, S., Huang, Q., Niu, M., Jia, C., Lin, L., and Lin, Q. 2019. Hierarchical structure and slowly digestible features of rice starch following microwave cooking with storage. Food Chemistry. 295: 475–483.

Liu, X., Zheng, X., Song, Z., Liu, X., Kopparapu, N.K., Wang, X., and Zheng, Y. 2015. Preparation of enzymatic pretreated corn gluten meal hydrolysate and in vivo evaluation of its antioxidant activity. Journal of Functional Foods. 18: 1147–1157.

Massarolo, K.C., Ferreira, C.F.J., De Borba, V.S., Kupski, L., and Furlong, E.B. 2019. Particle size and physical-chemical characteristics of hydrothermally treated cornmeal on resistant starch content. Food Chemistry. 283: 39–45.

Narwojsz, A., Borowska, E.J., Polak-Śliwińska, M., and Danowska-Oziewicz, M. 2020. Effect of different methods of thermal method on starch and bioactive compounds of potato. Plant Foods for Human Nutrition. 75(2): 298–304.

Navickis, R.J., Haynes, G.R., and Wilkes, M.M. 2012. Effect of hydroxyethyl starch on bleeding after cardiopulmonary bypass: A meta-analysis of randomized trials. Journal of Thoracic and Cardiovascular Surgery. 144(1): 223-230.

Nongmaithem, R., and Meda, V. 2017. Optimization of microwave vacuum drying parameters for germinated lentils based on starch digestibility, antioxidant activity and total phenolic content. International Journal of Food Studies. 6(1): 44–55.

Piecyk, M., and Domian, K. 2021. Effects of heat–moisture method conditions on the physicochemical properties and digestibility of field bean starch (Vicia faba var. minor). International Journal of Biological Macromolecules. 182: 425–433.

Sánchez-Rivera, M.M., Almanza-Benitez, S., Bello-Perez, L.A., Mendez-Montealvo, G., Núñez-Santiago, M.C., Rodriguez-Ambriz, S.L., and Gutierrez-Meráz, F. 2013. Acetylation of banana (Musa paradisiaca L.) and corn (Zea mays L.) starches using a microwave heating procedure and iodine as catalyst: II. Rheological and structural studies. Carbohydrate Polymers, 92(2): 1256–1261.

Sandhu, K.S., Siroha, A.K., Punia, S., and Nehra, M. 2020. Effect of heat moisture method on rheological and in vitro digestibility properties of pearl millet starches. Carbohydrate Polymer Technologies and Applications. 1: 100002.

Van H, P., Chau, H.T., and Phi, N.T.L. 2016. In vitro digestibility and in vivo glucose response of native and physically modified rice starches varying amylose contents. Food Chemistry. 191: 74–80.

Vatansever, S., Whitney, K., Ohm, J.B., Simsek, S., and Hall, C. 2021. Physicochemical and multi-scale structural alterations of pea starch induced by supercritical carbon dioxide + ethanol extraction. Food Chemistry. 344: 128699.

Wang, H., Zhang, B., Chen, L., and Li, X. 2016. Understanding the structure and digestibility of heat-moisture treated starch. International Journal of Biological Macromolecules. 88: 1–8.

Wang, L., and Bai, X. 2017. The Producing Technology of Resistant Starch (RS) from Buckwheat Using Microwave Treatment. Sustainability in Environment. 2(3): 301.

Wang, M., Sun, M., Zhang, Y., Chen, Y., Wu, Y., and Ouyang, J. 2019. Effect of microwave irradiation-retrogradation treatment on the digestive and physicochemical properties of starches with different crystallinity. Food chemistry. 298: 125015.

Wang, J., Jiang, X., Gou, Z., Zheng, B., and Zhang, Y. 2021. Insights into the multi-scale structural properties and digestibility of lotus seed starch-chlorogenic acid complexes prepared by microwave irradiation. Food Chemistry. 361(11): 130171.

Zhang, T., Li, X., Chen, L., and Situ, W. 2016. Digestibility and structural changes of waxy rice starch during the fermentation process for waxy rice vinasse. Food Hydrocolloids. 57: 38–45.

Zhang, Y., Li, B., Xu, Z., He, S., Zhang, Y., Sun, L., Zhu, K., Li, S., Wu, G., and Tan, L. 2020. Jackfruit starch: Composition, structure, functional properties, modifications, and applications. Trends in Food Science & Technology 107(1): 268–283.

Zhao, K., Saleh, A.S.M., Li, B., Wu, H., liu, Y.U., Zhang, G., and Li, W. 2018a. Effects of conventional and microwave pretreatment acetylation on structural and physicochemical properties of wheat starch. International Journal of Food Science and Technology. 53(11): 2515– 2524.

Zhao, K., Li, B., Xu, M. J., Jing, L.Z., Gou, M., Yu, Z. and Li, W. H. 2018b. Microwave pretreated esterification improved the substitution degree, structural and physicochemical properties of potato starch esters. LWT-Food Science and Technology. 90: 116-123.

OPEN access freely available online

Natural and Life Sciences Communications

Chiang Mai University, Thailand. https://cmuj.cmu.ac.th

Muhammad Isra1,*, Widya Rahmawaty Saman1, and Arif Murtaqi Akhmad Mutsyahidan2

1 Food Technology Study Program, Faculty of Agriculture, Universitas Negeri Gorontalo, 96554, Gorontalo, Indonesia.

2 Laboratory of Food Technology Study Program Faculty of Agriculture, Universitas Negeri Gorontalo, 96554, Gorontalo, Indonesia.

Corresponding author: Muhammad Isra, E-mail: muhammadisra@ung.ac.id

ORCID: Muhammad Isra: https://orcid.org/0000-0002-6965-3873

Total Article Views

Editor: Sirasit Srinuanpan,

Chiang Mai University, Thailand

Article history:

Received: March 3, 2025;

Revised: May 21, 2025;

Accepted: May 26, 2025;

Online First: June 13, 2025