The Impact of Raw Milk Quality, particularly Thermoduric, and Storage Temperatures on the Keeping Quality of Pasteurized Milk

Tri Indrarini Wirjantoro*, Aphirak Phianmongkhol, Thipwimon Potivas and Yuwaporn Na ChiangmaiPublished Date : 2022-10-18

DOI : https://doi.org/10.12982/CMUJNS.2022.056

Journal Issues : Number 4, October-December 2022

Abstract This study was aimed to investigate the effect of raw milk qualities on their corresponding pasteurized milk stored at different chilled temperatures. Raw milk collected from two different sources, Banhong (BH) milk farm and Mae Tha (MT) collection center, were pasteurized at 78 ± 2ºC for 30 s and kept for 21 days at 4-8ºC. During the storage period, representatives of milk treatments were assessed for their chemical, microbiological and sensorial characteristics. Collected data revealed that there was only minor alteration for the chemical properties of pasteurized milk throughout the studied storage period. The microorganism numbers in the pasteurized milk were significantly increased during storage and higher at higher storage temperatures. Poorer microbial quality of raw milk, including thermoduric bacteria, strongly contributed to higher microbial load of the correspondence pasteurized milk during chilled storage. The coliform number of all the pasteurized milk samples was found to be below 1 cfu/ml during 21 days of storage, while no Escherichia coli, Listeria monocytogenes and Staphylococcus aureus was detected in the pasteurized milk samples. The appraisal of the sensory features of pasteurized milk, including color, flavor, odor, creamy taste, texture and overall acceptance, were gradually decreased with longer storage period.

Keywords: Pasteurized milk, Storage temperatures, Raw milk, Microbial quality, Chemical properties

Citation: Wirjantoro, T.I., Phianmongkhol, A., Potivas, T., and Chiangmai, Y.N. 2022. The impact of raw milk quality, particularly thermoduric, and storage temperatures on the keeping quality of pasteurized milk. CMUJ. Nat. Sci. 21(4): e2022056.

INTRODUCTION

Pasteurization is a minimum treatment required for some food commodities, in particular milk and milk products, to eliminate pathogenic microorganisms. The process can also extend the product shelf life by reducing the level of spoilage bacteria (McAuley et al., 2012; Ding et al., 2020). The minimum pasteurization condition applied for milk is at 72ºC for 15 s (Ding et al., 2020; Al-Farsi et al., 2021), even though in practical higher temperatures for up to 80-85ºC are sometimes applied. By doing pasteurization, pathogenic microorganisms, including Mycobacterium tuberculosis, Salmonella and Esherichia coli, are eliminated (Lewis, 2010). Other pathogens in raw milk, such as Mycobacterium avium subsp. paratuberculosis associated with Crohn’s disease (Mulan, 2019) and Coxiella burnetii, an aetiological agent of Q fever in humans (Ahmadi, 2020), should also be significantly decreased by the heat treatment. On the other hand, thermoduric, heat resistant and spore forming bacteria can survive the process (McAuley et al., 2012; Júnior et al., 2018). Due to these survival microorganisms, the application of refrigeration to extend the shelf life of pasteurized milk are necessary (Li et al., 2020). Depending on the storage temperatures, pasteurized milk can be preserved between 7 to 40 days (Lewis, 2010; Li et al., 2020; Zhu et al., 2020). Petrus et al. (2010) reported that the shelf life of pasteurized milk kept in high-density polyethylene bottle was estimated to be 43 and 36 days at 2 and 4ºC storage temperatures, respectively, while the milk filled in low-density polyethylene pouch had shelf life estimation of 37 and 35 days, respectively. Another work of Ziyaina et al. (2018) showed that pasteurized milk stored at 5 and 7ºC had shelf life periods of 30 and 24 days, respectively.

Beside storage temperatures, keeping quality of pasteurized milks are affected by raw milk quality, time and temperature pasteurization and post pasteurization contamination (Lewis, 2010; Zhu et al., 2020; Al-Farsi et al., 2021). It was suggested that the total bacterial count of raw milk at processing plant should be less than 300,000 cfu/ml (Barbano et al., 2006; Hasan et al., 2015). The work of Ding et al. (2020) about milk pasteurization at 72-85ºC for 15-30 s displayed that Streptococcus and Cyanobacteria were dominant genus in the milk processed at 85ºC for 15 s and at 80ºC for 15 s, respectively. This study also showed that residuals of Pseudomonas, Corynebacterium, Streptococcus, Cyanobacteria as well as Lactobacillus were found in different pasteurized milk treatments. A review by Sarkar (2015) delivered that milk pasteurized at lower temperatures (76.1 vs. 79.4ºC) significantly produced lower bacterial count (1.39 vs. 1.58 log cfu/ml, respectively) in pasteurized milk. Post pasteurization contamination is another important factor affecting the shelf life of pasteurized milk. Although the post pasteurization contamination could occur at various points after milk production, studies indicated that filling equipment as an area that particularly susceptible to the contamination (Alles et al., 2018). Martin et al. (2018) informed that there were four primary groups of psychrotolerant bacteria, which were important in post pasteurization contamination of fluid milk, including Pseudomonas; coliforms; non-Pseudomonas, non-coliform Gram negative bacteria and Gram positive spore forming bacteria.

Since pasteurized milk only receives a mild heat treatment, the growth of survival and contaminant bacteria in the final product is an important parameter determining the product shelf life. Factors, such as degradation resulting from microbial contamination, protein breakdown from microbial growth and fat hydrolysis leading to compounds associated with quality defects, determine the shelf life of pasteurized milk (Ziyaina et al., 2018). Although raw milk is the main ingredient in the production of pasteurized milk, there is a very limited up-to-date information that directly investigate the raw milk quality and the shelf life of its corresponding pasteurized product. Due to this scarce information, the current study was aimed to examine the effect of raw milk qualities on the keeping quality of the corresponding pasteurized milk kept at different storage temperatures.

MATERIALS AND METHODS

Procurement and quality assessment of raw milk

Raw milk in this study was collected from two dairy farms. The first farm was Banhong (BH) milk farm located in Banhong district, Lamphun province, Thailand and the second source was Mae Tha (MT) milk collection center in Mae Tha district, Lamphun province, Thailand. The BH milk farm was part of a project Lanna High Quality Milk, in which the quality of raw milk was controlled through improvement of farm management and milk collection center. The raw milk was transported at 4.0 ± 1.0ºC to a processing plant in Chiang Mai. In the processing plant, the raw milk was checked for antibiotic substances and its stability using 75% alcohol test. Both raw milk sources showed the absence of antibiotic substances and no coagulation in the 75% alcohol test (no shown data). Subsequently, the raw milk was stored at chilled temperature before pasteurization. Samples of the raw milk was also subjected to chemical and microbial analyses. The chemical assessment included pH value measured by a pH meter (OHAUS model ST3100, USA), total titratable acidity using 0.1 N NaOH (RCI Labscan, Thailand) with phenolphthalein indicator (RCI Labscan, Thailand) following the method of Ziyaina et al. (2018) and total soluble solid determined by a digital refractometer (ATAGO PR101, Japan). For fat, protein, total solids, solids-non-fat and specific gravity, they were evaluated using Lactoscope Fourier Transform Infrared Spectroscopy (FTIR) milk and dairy analyzer (Delta, Netherlands). The microbial qualities of raw milk were assessed for standard plate count (SPC) using 3M Petrifilm AC (3M, USA) with an incubation temperature of 32.0 ± 1.0ºC for 48 ± 3 h, laboratory pasteurized count (LPC) (Martin et al., 2011), coliform by 3M Petrifilm CC (3M, USA) incubated at 32.0 ± 1.0ºC for 24 ± 2 h, E. coli using 3M Petrifilm EC (3M, USA) incubated at 32 ± 1ºC for 24-48 h and somatic cell count measured by Delaval Cell Counter DCC (Delaval, New Zealand).

Production process and storage of pasteurized milk

Raw milk was pasteurized using a continuous method through plate heat exchanger. On the processing day, the raw milk was filtered for any foreign matters and thermized at 75 ± 3ºC for 30 s. It was then homogenized at 150 bar, pasteurized at 78.0 ± 2.0ºC for 30 s, cooled down to below 5ºC and filled in sanitized 200 ml glass bottle with aluminium twist-off lid under clean environment. The final pasteurized milk products were then stored for 3 weeks period at 4, 6 or 8 ± 1ºC. During the storage period, representative pasteurized milk samples were separated and analyzed for their chemical, microbiological and sensory properties.

Keeping quality of pasteurized milk at low storage temperature

Pasteurized milk samples separated from storage temperatures of 4, 6 or 8ºC were subjected to chemical analyses, such as pH values, total soluble solids, fat content, protein content, total solids and solids-non-fat content, using similar methods as in the raw milk. For microbiological properties, milk samples were analyzed for SPC (Maturin and Peeler, 2001), LPC, coliform (Feng et al., 2021) and enumeration of pathogens of E. coli (Feng et al., 2021), Bacillus cereus (Tallent et al., 2021b), Listeria monocytogenes (Hitchins et al., 2021) and Staphylococcus aureus (Tallent et al., 2021a). At the same time, the milk samples were also assessed for their sensory characteristics, including color, flavor, odor, creamy taste, texture and overall acceptance. The sensory assessment was carried out by 20 panelists using a 9-point hedonic scale (Gandy et al., 2008).

Statistical analysis

The analysis results of pasteurized milk during storage were statistically analyzed using analysis of variance (ANOVA) and Duncan test based on triplicate replication using IBM SPSS Statistics 22. Significance difference between treatments was set at P < 0.05. Data are presented as mean ± standard deviation (x̄ ± sd).

RESULTS

Raw milk qualities

Physicochemical characteristics of raw milk used in this study can be seen in Table 1. In general, the raw milk from MT collection center had higher pH values, total solids and acidity compared to those of the milk collected from BH milk farm. Higher milk constituents, particularly fat and protein, can be useful for some milk products, such as cheese, cream and butter. On the other hand, the milk of MT collections had lower specific gravity of the milk from BH milk farm.

Table 1. Physicochemical properties of raw milk.

|

Raw milk properties |

BH milk farm |

MT collection center |

|

pH values |

6.71 ± 0.01 |

6.76 ± 0.01 |

|

Total soluble solid (ºBrix) |

9.80 ± 0.10 |

10.10 ± 0.10 |

|

Total titratable acidity (% lactic acid) |

0.14 ± 0.00 |

0.16 ± 0.00 |

|

Fat (%) |

3.99 ± 0.01 |

4.17 ± 0.01 |

|

Protein (%) |

3.01 ± 0.01 |

3.09 ± 0.01 |

|

Total solid (%) |

12.42 ± 0.01 |

12.79 ± 0.01 |

|

Solids-non-fat (%) |

8.44 ± 0.01 |

8.61 ± 0.01 |

|

Specific gravity (g/ml) |

1.02 ± 0.00 |

1.02 ± 0.00 |

Note: * BH: Banhong milk farm, MT: Mae Tha collection center.

Table 2 displays the microbiological qualities of raw milk from BH milk farm and MT collection center. It was clearly shown that the raw milk quality of BH milk farm had lower microbial counts compared to that of the milk from MT collection center. Nevertheless, both of raw milk were suitable for further processing, since the total microorganisms, measured as Standard Plate Count, were lower than 3 x 105 cfu/ml (Barbano et al., 2006; Hasan et al., 2015) and somatic cell count was less than 750,000 cells/ml (Barbano et al., 2006).

Table 2. Microbiological qualities of raw milk.

|

Raw milk properties |

BH milk farm |

MT collection center |

|

Standard Plate Count (cfu/ml) |

14,700 ± 200 |

122,500 ± 23 |

|

Laboratory Pasteurized Count (cfu/ml) |

260 ± 5 |

4,500 ± 395 |

|

Coliform (cfu/ml) |

1,600 ± 50 |

2,300 ± 180 |

|

E. coli (cfu/ml) |

ND* |

80 ± 7 |

|

Somatic cell count (cells/ml) |

159,000 ± 1,000 |

490,000 ± 500 |

Note: * Not detect. BH: Banhong milk farm, MT: Mae Tha collection center.

Keeping quality of pasteurized milk at different storage temperatures

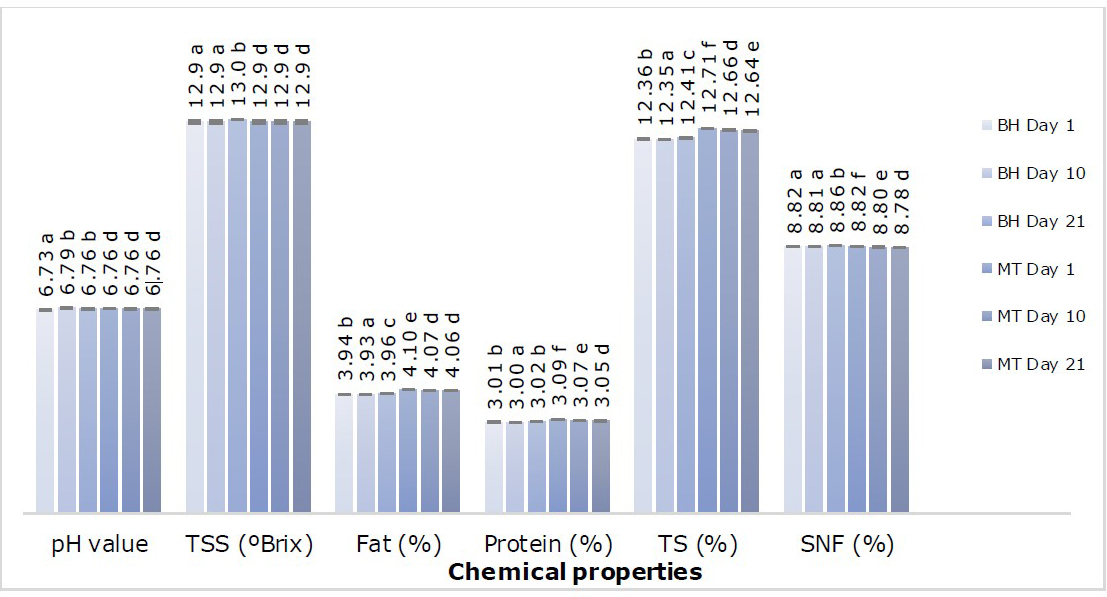

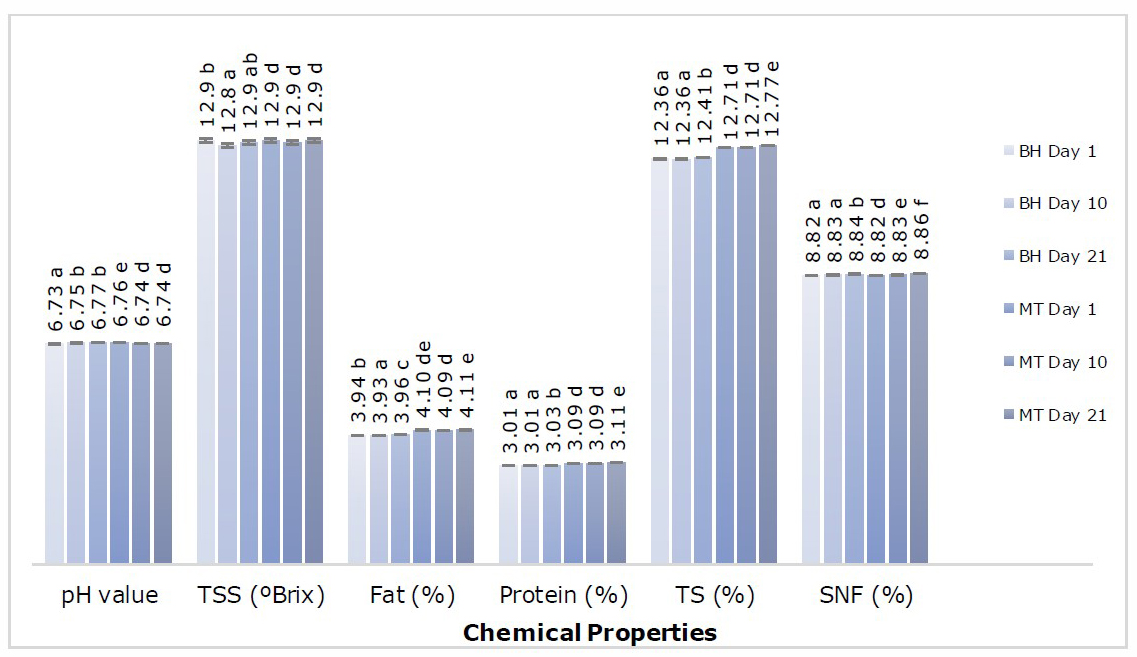

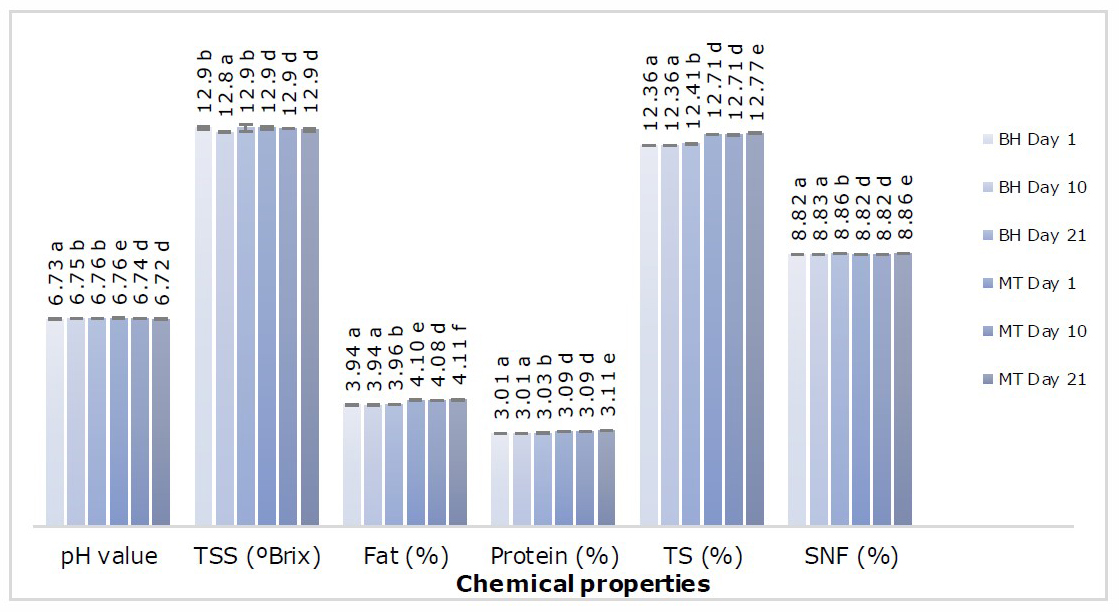

Raw milk from BH milk farm and MT collection center were undergone heating at 78 ± 2ºC for 30 s before stored at different refrigerated temperatures, including 4, 6 and 8ºC. Various storage temperatures used in this study were designed to anticipate fluctuation of temperatures during cold storage chain. Petrus et al. (2010) had cited that improper refrigeration of low-quality raw material and an inadequate packaging system caused problems in maintaining the quality of pasteurized milk. Changing in the chemical properties of pasteurized milk treatments during chilled storage are displayed in Figures 1–3. In general, collected data showed that the chemical qualities of pasteurized milk, including pH, total soluble solids, total solids, fat, protein and solids-non-fat, were slightly fluctuated during the storage period. However, the changing did not denote any spoilage patterns in all of the milk treatments.

Figure 1. Chemical properties of pasteurized milk kept at 4ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a chemical property and similar milk source indicate significantly different at P < 0.05.

Figure 2. Chemical properties of pasteurized milk kept at 6ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a chemical property and similar milk source indicate significantly different at P < 0.05.

Figure 3. Chemical properties of pasteurized milk kept at 8ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a chemical property and similar milk source indicate significantly different at P < 0.05.

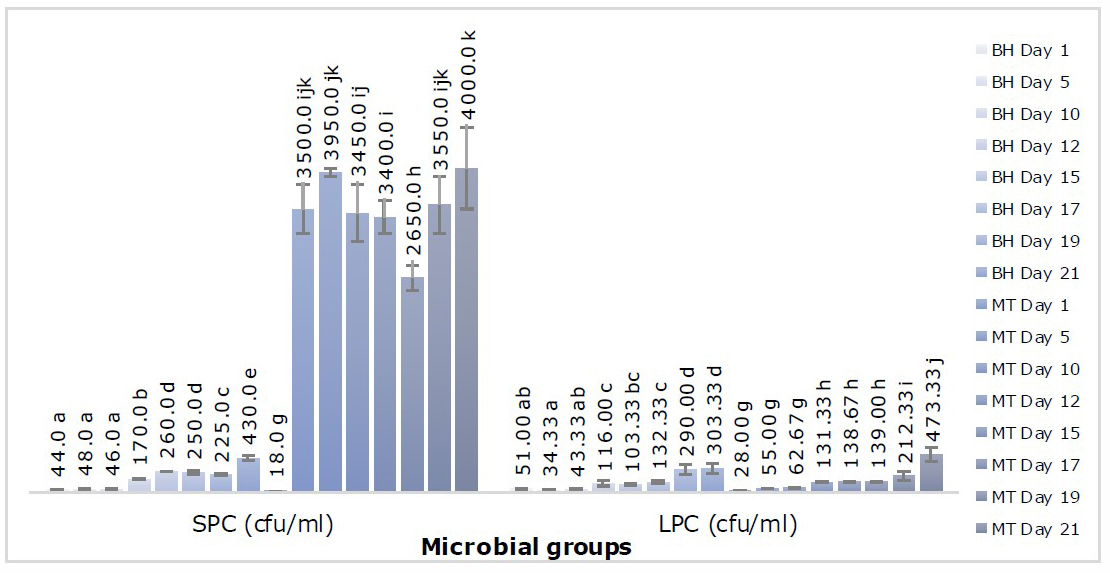

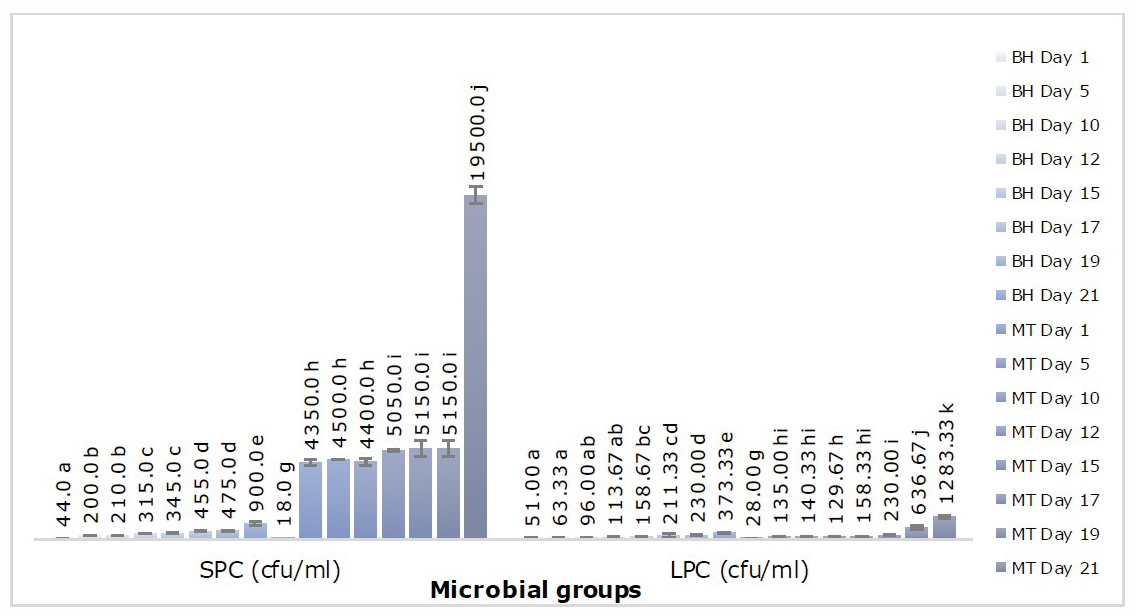

Compared to the chemical properties, the microbiological qualities of pasteurized milk stored at 4-8ºC for 21 days exhibited a significant increase during storage period as shown in Figures 4-6. Both of pasteurized milk had Standard Plate Count of less than 44 cfu/ml after the pasteurization process with MT pasteurized milk had lower microbial count than that of the BH pasteurized milk. This microbial number increased significantly with longer storage period and at higher storage temperatures, particularly for MT pasteurized milk (Figures 4-6 and Table 3). Therefore, the pasteurized milk had the highest microbial numbers at the end of 21 days storage and stored at 8ºC. The measurement of LPC for pasteurized milks in Figures 4-6 and Table 3 clearly exhibited that the thermoduric bacteria in pasteurized milk was also increased with longer storage period and higher at higher storage temperatures. This finding was consistent with the trend of Standard Plate Count, albeit at lower microbial numbers.

Figure 4. Microbiological properties of pasteurized milk kept at 4ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a microbial group and similar milk source indicate significantly different at P < 0.05.

Figure 5. Microbiological properties of pasteurized milk kept at 6ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a microbial group and similar milk source indicate significantly different at P < 0.05.

Figure 6. Microbiological properties of pasteurized milk kept at 8ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a microbial group and similar milk source indicate significantly different at P < 0.05.

Table 3. Standard plate count and laboratory pasteurized count (cfu/ml) of pasteurized milk kept at different storage temperatures of 4, 6 and 8ºC throughout the storage period of 3 weeks

|

Storage temperature (ºC) |

Standard Plate Count (cfu/ml) |

Laboratory Pasteurized Count (cfu/ml) |

||

|

BH* |

MT |

BH |

MT |

|

|

4 |

184.10 ± 130.50A |

3,064.70 ± 1263.10A |

134.20 ± 105.70A |

155.00 ± 138.10A |

|

6 |

267.50 ± 224.10A |

3,789.70 ± 1519.80A |

166.00 ± 97.60AB |

198.70 ± 167.20AB |

|

8 |

368.00 ± 247.90B |

6,014.70 ± 5458.00B |

162.10 ± 107.40B |

342.60 ± 405.50B |

Note: * BH: Banhong milk farm, MT: Mae Tha collection center.

A-C Different superscript letters within a column and storage temperature indicate significantly different at P < 0.05.

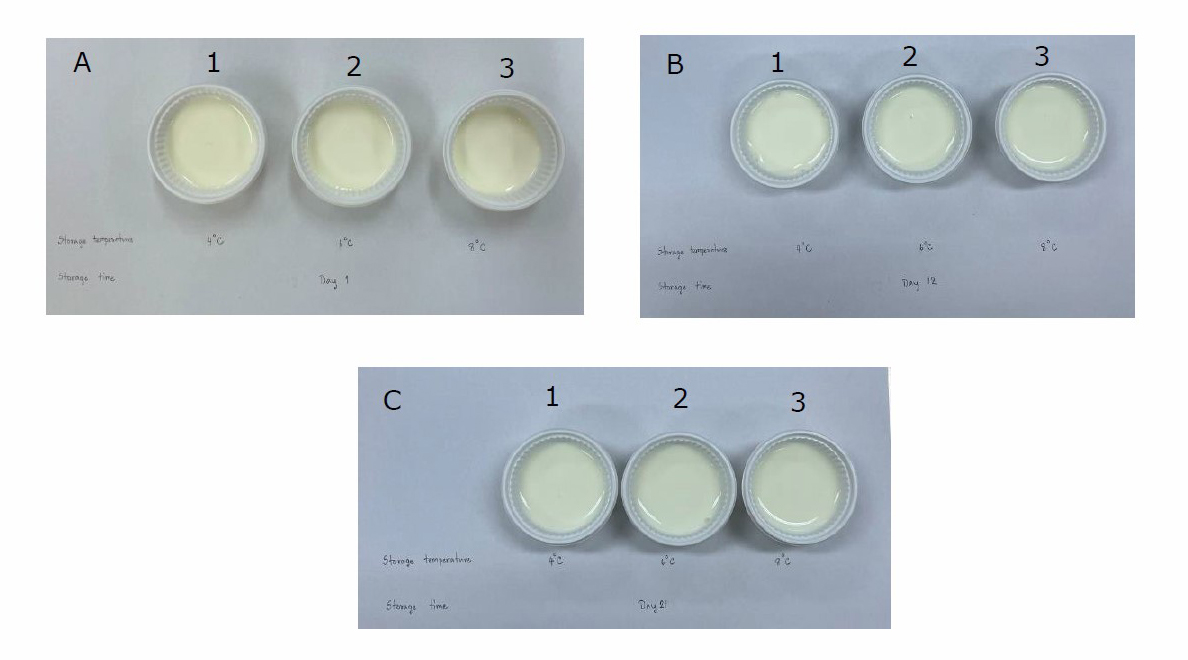

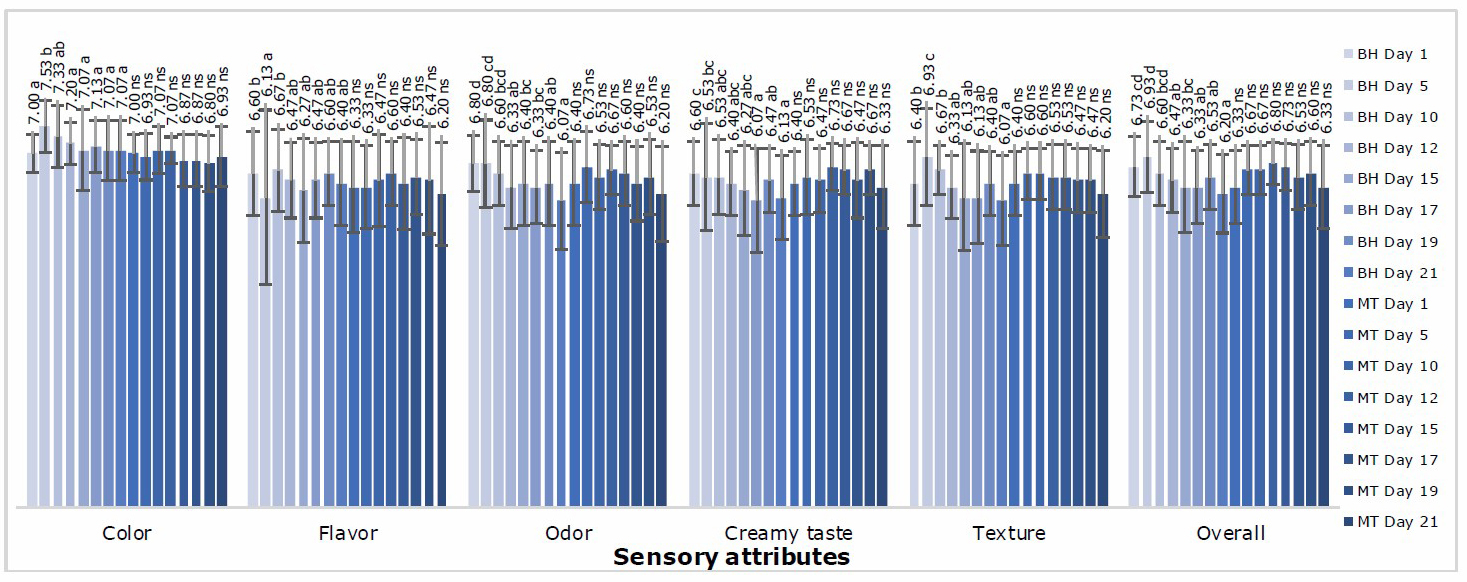

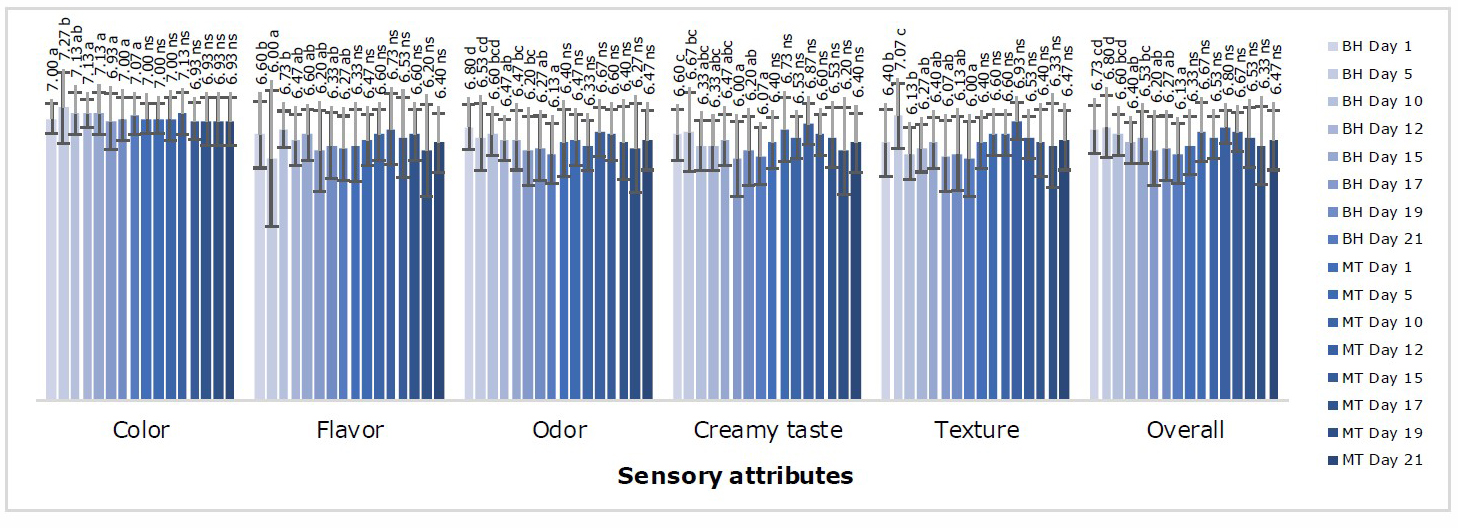

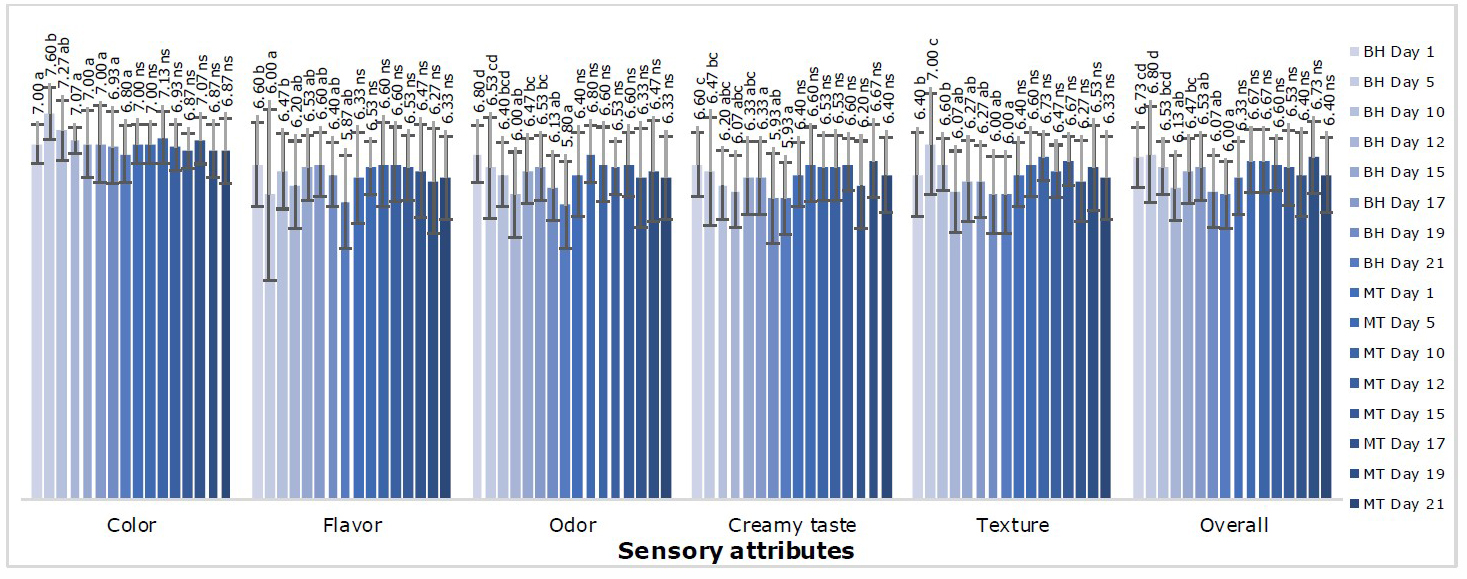

Beside chemical and microbiological qualities, the pasteurized milk treatments were also subjected to sensory characterization during 21 days of storage at 4-8ºC (Figure 7). This characterization is important affecting the product acceptance and shelf life (Jo et al., 2018). The sensory description of the milk samples is shown in Figures 8-10 for color, flavor, odor, creamy taste, texture and overall acceptance. In general, it could be seen that the sensory attributes of pasteurized milk were decreased with longer storage period, while different storage temperatures did not significantly affect the milk sensory properties (Table 4).

Figure 7. BH pasteurized milk samples stored at different storage temperatures of 4, 6 and 8ºC for 3 weeks period. A = Day 1, B = Day 12 and C = Day 21. 1 = pasteurized milk stored at 4ºC, 2 = pasteurized milk stored at 6ºC and 3 = pasteurized milk stored at 8ºC.

Figure 8. Sensory characteristics of pasteurized milk kept at 4ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a sensory attribute and similar milk source indicate significantly different at P < 0.05; ns: Not significant within a sensory attribute and similar milk source.

Figure 9. Sensory characteristics of pasteurized milk kept at 6ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a sensory attribute and similar milk source indicate significantly different at P < 0.05; ns: Not significant within a sensory attribute and similar milk source.

Figure 10. Sensory characteristics of pasteurized milk kept at 8ºC for 3 weeks. BH: Banhong milk farm, MT: Mae Tha collection center. The results are expressed as mean ± standard deviation (n = 3). Different letters within a sensory attribute and similar milk source indicate significantly different at P < 0.05; ns: Not significant within a sensory attribute and similar milk source.

Table 4. Sensory properties of pasteurized milk kept at different storage temperatures of 4, 6 and 8ºC throughout the storage period of 3 weeks.

|

Sensory properties |

at 4ºC |

at 6ºC |

at 8ºC |

|||

|

BH |

MT |

BH |

MT |

BH |

MT |

|

|

Colorns |

7.18 ± 0.57 |

6.94 ± 0.47 |

7.08 ± 0.55 |

6.98 ± 0.50 |

7.08 ± 0.60 |

6.97 ± 0.46 |

|

Flavorns |

6.45 ± 0.96 |

6.42 ± 0.86 |

6.40 ± 0.92 |

6.48 ± 0.83 |

6.33 ± 0.93 |

6.46 ± 0.79 |

|

Odorns |

6.47 ± 0.79 |

6.51 ± 0.72 |

6.43 ± 0.71 |

6.45 ± 0.76 |

6.33 ± 0.78 |

6.51 ± 0.76 |

|

Creamy tastens |

6.38 ± 0.82 |

6.53 ± 0.63 |

6.33 ± 0.77 |

6.53 ± 0.72 |

6.23 ± 0.78 |

6.49 ± 0.68 |

|

Texturens |

6.38 ± 0.84 |

6.47 ± 0.63 |

6.31 ± 0.82 |

6.53 ± 0.68 |

6.33 ± 0.82 |

6.50 ± 0.66 |

|

Overallns |

6.52 ± 0.72 |

6.58 ± 0.60 |

6.46 ± 0.70 |

6.54 ± 0.68 |

6.41 ± 0.71 |

6.54 ± 0.68 |

Note: * BH: Banhong milk farm, MT: Mae Tha collection center. ; ns : Not significant within a similar storage temperature.

DISCUSSION

Raw milk used in this study and was collected from two different dairy farms slightly had different physicochemical and microbiological properties. The fat and total solid of the raw milk (3.99-4.17% and 12.42-12.79%, respectively) were in an agreement with commercial pasteurized milk in Sudan, which were 3.82-4.37 and 12.4-13.1%, respectively, reported by Sulieman et al. (2014). On the other hand, the protein content in this study of 3.01-3.19% was slightly lower from the commercial milk in Sudan, which was 3.21-3.82% (Sulieman et al., 2014). Moreover, the amounts of fat, protein and total solid of raw milk in this study were lower than those of raw milk in Sudan (Elsheikh et al., 2015). Discrepancies in raw milk composition of different studies could be affected by synthetic and secretory tissues of the mammary gland, initiation and establishment of lactation, milk ejection reflex, breed and genetic factors, nutrition, environment and milking management practices (Elsheikh et al., 2015). For pH and total titratable acidity in the current study, they were closed with the values of pasteurized trim milk determined by Ansari et al. (2020) and a pH value of pasteurized milk of 6.72 found by Sadhu (2018). The pH value of raw milk was correlated with the milk stability during heat treatment (Nian et al., 2012).

For the microbiological properties, beside total microorganisms in raw milk somatic cell count is an important factor indicating udder health. The count was affected by several factors, including animal species, milk production level, lactation stage, individual and environmental factors and management practices (Li et al., 2014). LPC or Laboratory Pasteurized Count was carried out by heating milk samples at 62.8ºC for 30 min followed by standard microbial enumeration (Pantoja et al., 2009; Martin et al., 2011). The method measures the number of thermoduric bacteria in the milk samples after pasteurization (Pantoja et al., 2009). The results in Table 2 showed clearly that the raw milk from MT collection center had much higher number of LPC compared to that in the milk from BH milk farm. A LPC number for up to 11,140 cfu/ml had been earlier conveyed by Pantoja et al. (2009). The authors also mentioned that LPC could be used as an indicator of milking-equipment sanitation. In addition, Elmoslemany et al. (2009) wrote that high numbers of thermoduric count in bulk tank milk indicated the presence of heat tolerant bacteria on milking equipment.

Consistent with the results of Standard Plate Count and LPC, the numbers of coliform and E. coli were higher in the raw milk collected from MT collection center (Table 2). The presence of coliform in raw milk has been reported by several researchers, including a number of 1.0x104 to 2.0x105 cfu/ml for raw milk in Bangladesh by Banik et al. (2014), a number between 4.56 and 5.63 log cfu/ml for raw milk in Nairobi area by Wanjala et al. (2017), an amount of 2.3x102 to 9.4x102 cfu/ml for raw milk in Bangladesh by Hasan et al. (2015) and the presence between 0 and 1,520 cfu/ml for raw milk in USA by Pantoja et al. (2009). This showed that the coliform numbers in the current work were in the range of the coliform results from previous studies. Factors, such as poor hygiene, contaminated water, unsanitary milking practices and improperly washed and maintained equipment, could contribute to higher amounts of coliform in raw milk (Banik et al., 2014). In addition, Zucali et al. (2011) suggested that the presence of coliform was also correlated with cow cleanliness and cow environment. No E. coli was detected in the raw milk from BH milk farm, while some were found in the raw milk from MT collection center. The number of E. coli in this study was lower that the raw milk in Bangladesh, which was 2.3 to 9.4 x102 cfu/ml (Hasan et al., 2015). The presence of shiga-toxin producing E. coli in bulk tank milk worldwide was reported to be between 0 and 33.5% (Quigley et al., 2013). Since cow is one of the main reservoir of shiga-toxin producing E. coli, milk can be contaminated by the pathogen during milking or processing if the hygiene standard is not good (Quigley et al., 2013). Moreover, coliform, in particular E. coli, in raw milk could be used as an indicator of fecal contamination (Zucali et al., 2011; Hasan et al., 2015).

The chemical properties of pasteurized milks in the terms of pH, total solid, fat, protein and solids-non-fat had values that were closed to those of the corresponding raw milk (Table 1). Zhu et al. (2020) had reported that milk pasteurization at 63-64.5ºC for 30 min was a mild process, causing minor metabolite changes in the liquid and volatile fractions. The pH results in this study was in an agreement with the results of Al-Farsi et al. (2021), who stated that the pH and acidity of pasteurized milk stored at 5 and 8ºC for 12 days were 6.57-6.76 and 0.14-0.18% lactic acid, respectively. A slight alteration for fat, protein and total solid contents of pasteurized milk samples could be affected by proteolysis from the action of plasmin and protease from somatic cells or microbial proteases and lipolysis from lipases of somatic cells during storage (Li et al., 2020: Zhu et al., 2020). Results in Figures 1-3 also displayed that in general, different storage temperatures did not influence the chemical properties of pasteurized milks during 21 days of storage at low storage temperatures.

During storage at chilled temperature, the rate of microbial growth in the MT pasteurized milk was much higher than that of the BH pasteurized milk. This reflected that poorer microbial quality in raw milk (Table 2) could be a crucial factor in affecting the microbial property of the final product. A similar finding was also reported by Júnior et al. (2019). Azizkhani and Tooryan (2017) conveyed the numbers of Total Plate Count of Iranian commercial pasteurized milk samples at the end of their shelf lives were 2.16-6.72 log cfu/ml. Microbial numbers of 3.19 to 3.59 were found by Wanjala et al. (2017) for pasteurized milk in Nairobi region. On the other hand, Petrus et al. (2010) showed that pasteurized milk processed at 75ºC for 15 s in high-density polyethylene bottle and low-density polyethylene pouch had mesophilic counts of 4.00 ± 1.53 and 3.42 ± 0.72 log cfu/ml, respectively, after 21 days at 4ºC and mesophilic numbers of 7.01 ± 0.02 and 7.84 ± 0.25 log cfu/ml, respectively, after 9 days at 9ºC. The finding in this study and previous research works clearly demonstrated the important of storage temperatures of pasteurized milk as well as the microbial quality of raw milk. A summary from Sarkar (2015) disclosed that the shelf life of pasteurized milk was affected by raw milk quality, storage duration of raw milk prior to processing, the heat treatment that is employed, concentration of heat resistant microorganisms, the extent of post pasteurization contaminants, packaging system, post-pasteurization storage conditions and effect of light. Even though the number of Standard Plate Count of the MT pasteurized milk reached a number of 19,500 ± 500 cfu/ml on the 21st day of storage at 8ºC, this number was still lower than the Thai standard for milk products issued by the Ministry of Public Health (2013a), which specified that the number of bacteria in pasteurized milk should not be more than 50,000 cfu/ml at the end of the milk shelf life, and a limit of 20,000 cfu/ml for the legal limit in USA (Fromm and Boor, 2004).

Although the MT pasteurized milk had a lower number of LPC than that of the BH pasteurized milk after an overnight at refrigerated temperatures, the number of LPC in the first milk was significantly increased after 5 days storage at three different storage temperatures. On the other hand, the increase in LPC in the BH pasteurized milk was more gradual. This finding could be affected by the number of microorganisms in raw milk (Table 2). Results in this study were also consistent with some previous works that found thermoduric bacteria from raw milk could survive pasteurization process and grow during the storage period at chilled temperatures of 4-8ºC. A previous work of Júnior et al. (2018) had reported the identification of several thermoduric bacteria in raw milk included Bacillus licheniformis, Bacillus circulans and Paenibacillus. Some strains of B. licheniformis had proteolytic and lipolytic activities and the bacteria could grow at refrigerated temperatures (Júnior et al., 2018). Another work of Mugadza and Buys (2018) isolated Bacillus spp., including B. pumilus, B. subtilis, B. licheniformis, B. sonorensis and B. circulans, and Paenibacillus spp. from pasteurized milk processed at 73ºC for 15 s. When subjected the isolates to grow at temperature of 7ºC, the researchers found out that Paenibacillus spp. had the highest growth rate followed by B. pumilus (Mugadza and Buys, 2018). Major isolates Paenibacillus, Pseudomonas and Bacillus spp. from 43 pasteurized milk samples have also be conveyed by Martin et al. (2011). In order to maintain the keeping quality of pasteurized milk during refrigerated storage, it was advisable to avoid contamination of thermoduric microorganisms during milking, storage and transport of raw milk (Júnior et al., 2018).

It would be worthy to note that in the BH pasteurized milk with lower microorganism number in its raw milk, the survival microorganisms, such as thermoduric, would be the dominant microorganism in the final product (Figures 4-6). The growth of these survival microorganisms was found to be slower at refrigerated temperatures. It has been mentioned earlier that BH raw milk was part of the Lanna High Quality Milk that was aimed to produce high quality dairy products and this study proved that lower microbial numbers in the raw milk produced a better pasteurized milk quality. On the other hand, the MT pasteurized milk that had a higher initial microbial number of 122,500 ± 23 cfu/ml had a significant increase in the total microorganism number (Standard Plate Count) after 5 days storage at chilled temperatures and the LPC number was only a small proportion of the population. This finding clearly indicated that lower microbial count in the raw milk is one of the critical criteria to have a good quality pasteurized milk.

Although this study was concentrated with pasteurized milk, the finding of thermoduric bacteria in the final product could arise a concern for several milk products that used pasteurization as the main heat treatment to decrease the microbial load in raw milk. These products include cream, butter, fermented milk products (yogurt and cheese), milk powders and ice cream. It was reported earlier the presence of enterococci in milk post-pasteurization could cause spoilage problems because of the ability of the microorganisms to produce lipase (McAuley et al., 2012). The detection of spore and thermoduric bacteria for 3.24 ± 0.09 and 3.23 ± 0.10 log cfu/g, respectively, in non-fat dry milk powders was informed by Buehner et al. (2015). The authors concerned that these microbial load could have a serious implication if the product would be further process as a reconstituted milk products.

Pasteurized milk treatments were also subjected to pathogen analyses, such as E. coli, B. cereus, L. monocytogenes and S. aureus, as well as coliform testing. For the coliform analysis, all of the pasteurized milk samples had a number of less than 1 cfu/ml throughout the storage periods at different storage temperatures (no shown data). The coliform finding in this study was complied with the Thai regulation no. 352 about milk products (Minister of Public Health, 2013a) and consistent with the research of Al-Farsi et al. (2021), who worked with commercial pasteurized milks that were stored at 5 and 8ºC for 12 days. A previous work of Azizkhani and Tooryan (2017) had detected coliform at numbers between 0.25 ± 0.10 and 2.08 ± 0.11 log cfu/ml in ten Iranian commercial pasteurized milk samples. Regarding the results of E. coli, L. monocytogenes and S. aureus, the pathogens were not detected in all of the pasteurized milk samples examined during 21 days storage at 4-8ºC (no shown data). This result was consistent with the requirement of Thai standard no. 364 about pathogenic microorganisms in food (Minister of Public Health, 2013b) and were in an agreement with the outcome of Al-Farsi et al. (2021) study. On the other hand, the BH and MT pasteurized milk samples were found to have B. cereus at the end of their storage periods. The pathogen was detected in the BH pasteurized milk treatments for a number of less than 2.0 ± 0.0 cfu/ml on 19th and 21st storage days at 4ºC and for a number of less than 1.5 ± 0.7 cfu/ml on 19th and 21st storage days at 8ºC. The recovery of B. cereus in the MT pasteurized milk samples was revealed for a number of 1.0 ± 0.0 cfu/ml on the 19th storage day at 6ºC and for a number of 1.5 ± 0.7 cfu/ml on 19th and 21st storage days at 8ºC. The presence of B. cereus in the BH and MT pasteurized milk at low numbers was still conformed to the Thai standard no. 364 that allowed the pasteurized cow’s milk products to contain B. cereus for not more than 100 cfu/ml (Minister of Public Health, 2013b). The ability of B. cereus to produce endospore was one of the factor that causing the pathogen to be detected in the pasteurized milk (Deeth, 2017; Mugadza et al., 2019). Beside raw milk, the bacteria could also contaminate pasteurized milk from post processing contamination through processing equipment (Mugadza et al., 2019).

A declining of sensory acceptance of pasteurized milk samples in this study was unavoidable, since there was still chemical and microbiological changes in the milk treatments kept at refrigerated temperatures. It was previously stated that the flavor of high-quality milk would be bland, pleasantly sweet and free from defects (Fromm and Boor, 2004). During storage, the flavor profile of liquid milk products were affected by a combination of factors, including processing parameters, microbial growth levels, the extent of lipid and protein degradation and exposure to UV light (Fromm and Boor, 2004; Jo et al., 2018; Ziyaina et al., 2019). Moreover, the somatic cell count of raw milk and temperature of refrigerated storage could also influence the extent of enzyme activities (Barbano et al., 2006). Zhu et al. (2020) reported the increase of some metabolites during refrigerated storage of pasteurized milk, including some fatty acids, succinic acid, glycine, betaine, glycerol 3-phosphate, some tripeptides and volatile compounds of 2-nonanone and 2-heptanone.

The results of sensory evaluation in this study demonstrated that the panelists gave a preference of ‘slightly like’ to ‘moderately like’ (values of 6 to 7 based on 9-hedonic scale) for most of the sensory attributes of pasteurized milk, except for the flavor, odor and creamy taste of BH pasteurized milk stored at 8ºC and at the end of the milk shelf life. This finding was consistent with the report of Gandy et al. (2008). The researchers informed that panelists gave preferences of 6.2 for flavor acceptability and 6.1 for overall acceptability based on 9-point hedonic scale for pasteurized milk processed 77ºC for 15 s during 6 days storage at 7 ± 1ºC. The work of Petrus et al. (2009) conveyed the acceptability of panelists for pasteurized milk heated at 75ºC for 15 s. They found that the overall appreciation of the milk was 6.0 for milk in low-density polyethylene pouch and 5.8 for milk in high-density polyethylene bottle (based on 7-point hedonic scale) at the beginning of the storage period at 4ºC. These preferences were found to be reduced to 5.0 and 5.7, respectively, after 28 days of storage, confirming the results in this study.

CONCLUSION

It could be concluded that raw milk quality and storage temperature were important factors affecting the microbial quality of pasteurized milk. Higher microorganism numbers in raw milk and higher storage temperatures could significantly reduce the keeping quality of pasteurized milk. There was only minor changes for the chemical properties of pasteurized milk during 21 days of storage at chilled temperatures. Thermoduric bacteria could play a significant role in the keeping quality of pasteurized milk produced from raw milk with low microbial load. In addition, the sensory properties of pasteurized milk were gradually decreased at longer storage period.

ACKNOWLEDGMENTS

The authors are acknowledged the contribution of Ms. Wasana Borirak to perform English proofread of the manuscript.

AUTHOR CONTRIBUTIONS

Tri Indrarini Wirjantoro involved in designing the experiment procedures and wrote the manuscript. Aphirak Phianmongkhol contributed to the experiment design and participated in manuscript preparation. Thipwimon Potivas was in charge in conducting the experiments and doing statistical analysis. Yuwaporn Na Chiangmai assisted in the experiment design and experiment works. All of the authors have read and approved of the final manuscript.

CONFLICT OF INTEREST

The authors declare that they hold no competing interests.

REFERENCES

Ahmadi, E. 2020. Potential public health risk due to consumption of contaminated bovine milk with aflatoxin M1 and Coxiella burnetii in the west of Iran. International Journal of Dairy Technology. 70: 1-7.

Al-Farsi, M. Al-Gharibi, I., Al-Abri, A., Al-Humaimi, A., Al-Nabhani, F., Al-Hashmi, H., Al-Sarmi, K., and Al-Shibli, S. 2021. Evaluating the shelf-life of pasteurized milk in Oman. Heliyon. 7: e-06555.

Alles, A.A., Wiedman, M., and Martin, N.H. 2018. Rapid detection and characterization of postpasteurization contamination in pasteurized fluid milk. Journal of Dairy Science. 101: 7746-7756.

Ansari, J.A., Ismail, M. and Farid, M. 2020. Extension of shelf life of pasteurized trim milk using ultraviolet treatment. Journal of Food Safety. 40: e12768.

Azizkhani, M. and Tooryan, F. 2017. Chemical and microbial quality of Iranian commercial pasteurized milk samples at their expiration date. Journal of Food Quality and Hazards Control. 4: 53-57.

Banik, S.K., Das, K.K., and Uddin, Md.A. 2014. Microbiological quality analysis of raw, pasteurized, UHT milk samples collected from different locations in Bangladesh. Stamford Journal of Microbiology. 4: 5-8.

Barbano, D.M., Ma, Y., and Santos, M.V. 2006. Influence of raw milk quality on fluid milk shelf life. Journal of Dairy Science. 89(E Suppl.): E15-E19.

Buehner, K.P., Anand, S., and Djira, G.D. 2015. Prevalance of thermoduric bacteria and spores in nonfat dry milk powders of Midwest origin. Journal of Dairy Science 98: 2861-2866.

Deeth, H. 2017. Optimum thermal processing for Extended Shelf-life (ESL) milk. Foods. 6: 102.

Ding, R., Liu, Y., Yang, S., Liu, Y., Shi, H., Yue, X., Wu, R., and Wu, J. 2020. High-throughput sequencing provides new insights into the roles and implications of core microbiota present in pasteurized milk. Food Research International. 137: 109586.

Elmoslemany, A.M., Keefe, G.P., Dohoo, I.R., and Dingwell, R.T. 2009. Microbiological quality of bulk tank raw milk in Prince Edward Island dairy herds. Journal of Dairy Science. 92: 4239-4248.

Elsheikh, N.A.H., Rahamtalla, S.A. and Abdalla, M.O.M. 2015. Chemical composition of raw milk produced and distributed in Khartoum state, Sudan. Asian Journal of Agricultural and Food Science. 3: 34-39.

Feng, P., Weagant, S.D., Grant, M.A., and Burkhardt, W. 2021. BAM chapter 4: Enumeration of Escherichia coli and the coliform bacteria. Available at: https://www.fda.gov/food/laboratory-methods-food/bam-chapter-4-enumeration-escherichia-coli-and-coliform-bacteria, accessed on September 2021.

Fromm, H.I. and Boor, K.J. 2004. Characterization of pasteurized fluid milk shelf-life attributes. Journal of Food Science. 69: M207-M214.

Gandy, A.L., Schilling, M.W., Coggins, P.C., White, C.H., Yoon, Y., and Kamadia, V.V. 2008. The effect of pasteurization temperature on consumer acceptability, sensory characteristics, volatile compound composition, and shelf life of fluid milk. Journal of Dairy Science. 91: 1769-1777.

Hasan, Md.A., Islam, Md.A., Mahmud, M.S., Uddin, A.S.M.A., and Ahmed, S. 2015. Microbial analysis of raw and pasteurized milk from selected areas of Dinajpur, Bangladesh. Asian Journal of Medical and Biological Research. 1: 292-296.

Hitchins, A.D., Jinneman, K., and Chen, Y. 2021. BAM chapter 10: Detection of Listeria monocytogenes in foods and environmental samples, and enumeration of Listeria monocytogenes in foods. Available at: https://www.fda.gov/food/laboratory-methods-food/bam-chapter-10-detection-listeria-monocytogenes-foods-and-environmental-samples-and-enumeration, accessed on September 2021.

Jo, Y., Benoist, D.M., Barbano, D.M., and Drake, M.A. 2018. Flavor and flavor chemistry differences among milks processed by high-temperature, short-time pasteurization or ultra-pasteurization. Journal of Dairy Science. 101: 3812-3828.

Júnior, J.C.R., de Oliveira, A.M., de Godoi Silva, F., Garcia, L.N.H., de Oliveira Lobo, C.M., Alexandrino, B., Tamanini, R., and Beloti, V. 2019. Influence of the microbiological quality of raw milk on the shelf life of pasteurized milk. Semina: Ciências Agrárias, Londrina. 40: 1469-1476.

Júnior, J.C.R., Tamanini, R., de Oliveira, A.L.M, Alfieri, A.A., and Beloti, V. 2018. Genetic diversity of thermoduric spoilage microorganisms of milk from Brazilian dairy farms. Journal of Dairy Science. 101: 6927-6936.

Lewis, M. 2010. Improving pasteurised and extended shelf-life milk. p. 277-301. In M.W. Griffiths (ed) Improving the safety and quality of milk. Woodhead Publishing Limited, Oxford.

Li, N., Richoux, R., Boutinaud, M, Martin, P., and Gagnaire, V. 2014. Role of somatic cells on dairy processes and products: A review. Dairy Science and Technology. 94: 517-538.

Li, X., Li, L., Ma, Y., Wang, R., Gu, Y., and Day, L. 2020. Changes in protein interactions in pasteurized milk during cold storage. Food Bioscience. 34: 100530.

Martin, N.H., Boor, K.J., and Wiedmann, M. 2018. Symposium review: Effect of post-pasteurization contamination on fluid milk quality. Journal of Dairy Science. 101: 861-870.

Martin, N.H., Ranieri, M.L., Murphy, S.C., Ralyea, R.D., Wiedmann, M., and Boor, K.J. 2011. Results from raw milk microbiological tests do not predict the shelf-life performance of commercially pasteurized fluid milk. Journal of Dairy Science. 94: 1211-1222.

Maturin, L. and Peeler, J.T. 2001. BAM chapter 3: Aerobic Plate Count. Available at: https://www.fda.gov/food/laboratory-methods-food/bam-chapter-3-aerobic-plate-count, accessed on September 2021.

McAuley, C.M., Gobius, K.S., Britz, M.L., and Craven, H.M. 2012. Heat resistance of thermoduric enterococci isolated from milk. International Journal of Food Microbiology. 154: 162-168.

Minister of Public Health. 2013a. Notification of the Ministry of Public Health no. 352. Other milk products. Available at: http://food.fda.moph.go.th/law/data/announ_moph/V.English/P352_E.pdf, accessed on October 2021.

Minister of Public Health. 2013b. Notification of the Ministry of Public Health no. 364. Standards for pathogenic microorganisms in food. Available at: http://food.fda.moph.go.th/law/data/announ_moph/V.English/No.%20364%20Standards%20for%20Pathogenic%20Microorganisms%20in%20Food.pdf, accessed on October 2021.

Mugadza, D.T. and Buys, E. 2018. Bacillus and Paenibacillus species associated with extended shelf life milk during processing and storage. International Journal of Dairy Technology. 71: 301-308.

Mugadza, D.T., Owusu-Darko, R., and Buys, E.M. 2019. Source tracking Bacillus cereus in an extended-shelf-life milk processing plant using partial sequencing of rpoB and multilocus sequence typing. Journal of Dairy Science. 102: 135-139.

Mulan, W.M.A. 2019. Are we closer to understanding why viable cells of Mycobacterium avium subsp. paratuberculosis are still being reported in pasteurised milk? International Journal of Dairy Technology. 72: 332-344.

Nian, Y., Chen, B.Y., Aikman, P., Grandison, A., and Lewis, M. 2012. Naturally occurring variations in milk pH and ionic calcium and their effects on some properties and processing characteristics of milk. International Journal of Dairy Technology. 65: 490-497.

Pantoja, J.C.F., Reinemann, D.J., and Ruegg, P.L. 2009. Associations among milk quality indicators in raw bulk milk. Journal of Dairy Science. 92: 4978-4987.

Petrus, R.R., Loiola, C.G., and Oliveira, C.A.F. 2010. Microbiological shelf life of pasteurized milk in bottle and pouch. Journal of Food Science .75(1): M36-M40.

Petrus, R., Loiola, C., Silva, C., and Oliveira, C. 2009. Microbiological and sensory stability of pasteurized milk in Brazil. Chemical Engineering Transactions. 17: 939-944.

Quigley, L., O’Sullivan, O., Stanton, C., Beresford, T.P., Ross, R.P., Fitzgerald, G.F., and Cotter, P.D. 2013. The complex microbiota of raw milk. FEMS Microbiology Reviews. 37: 664-698.

Sadhu, S.P. 2018. Effect of cold chain interruptions on the shelf-life of fluid pasteurised skim milk at the consumer stage. Brazilian Journal of Food Technology, Campinas. 21: e2017064.

Sarkar, S. 2015. Microbiological considerations: Pasteurized milk. International Journal of Dairy Science. 10:206-218.

Sulieman, A.M.E., Babiker, G.A., and Elkahalifa, E.A. 2014. Assessment of chemical and microbiological quality of pasteurized milk sold in Wad Medani market, Gezira state, Sudan. Journal of Food and Nutritional Disorder. 3: 1000132.

Tallent, S., Hait, J., Bennett, R.W., and Lancette, G.A. 2021a. BAM chapter 12: Staphylococcus aureus. Available at: https://www.fda.gov/food/laboratory-methods-food/bam-chapter-12-staphylococcus-aureus, accessed on September 2021.

Tallent, S.M., Knolhoff, A., Rhodehamel, E.J., Harmon, S.M., and Bennett, R.W. 2021b. BAM chapter 14: Bacillus cereus. Available at: https://www.fda.gov/food/laboratory-methods-food/bam-chapter-14-bacillus-cereus, accessed on September 2021.

Wanjala, G.W., Mathooko, F.M., Kutima, P.M., and Mathara, J.M. 2017. Microbiological quality and safety of raw and pasteurized milk marketed in and around Nairobi region. African Journal of Food, Agriculture, Nutrition and Development. 17: 11518-11532.

Zhu, D., Kebede, B., Chen, G., McComb, K., and Frew, R. 2020. Effects of the vat pasteurization process and refrigerated storage on the bovine milk metabolome. Journal of Dairy Science. 103: 2077-2088.

Ziyaina, M., Govindan, B.N., Rasco, B., Coffey, T., and Sablani, S.S. 2018. Monitoring shelf life of pasteurized whole milk under refrigerated storage conditions: Predictive models for quality loss. Journal of Food Science. 83: 409-418.

Ziyaina, M., Rasco, B., Coffey, T., Mattinson, D.S., and Sablani, S. 2019. Correlation of volatile compound concentrations with bacterial counts in whole pasteurised milk under various storage condition. International Journal of Dairy Technology 72: 36-46.

Zucali, M., Bava, L., Tamburini, A., Brasca, M., Vanoni, L., and Sandrucci, A. 2011. Effects of season, milking routine and cow cleanliness on bacterial and somatic cell counts of bulk tank milk. Journal of Dairy Research. 78: 436-441.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand.

https://cmuj.cmu.ac.th

Tri Indrarini Wirjantoro1,*, Aphirak Phianmongkhol1, Thipwimon Potivas2 and Yuwaporn Na Chiangmai2

1 Division of Food Science and Technology, Faculty of Agro-Industry, Chiang Mai University, Chiang Mai 50100, Thailand.

2 Chiangmai Fresh Milk, 57/1 Moo 6, Tha Wang Tan, Saraphi, Chiang Mai 50140, Thailand.

Corresponding author: Tri Indrarini Wirjantoro, E-mail: triindrarini.w@cmu.ac.th

Total Article Views

Editor: Wasu Prathum-Aree,

Chiang Mai University, Thailand

Article history:

Received: April 17, 2022;

Revised: August 7, 2022;

Accepted: August 18, 2022;

Published online: August 24, 2022