Properties Changes of Chicken Breast during Sous-Vide Cooking and Acceptance for Elderly. Soraya Kerdpiboon*, Nuttapon Suraphantapisit, Possathorn Pongpaew, and Pramual Srikalong

Published Date : 2019-04-1

DOI : https://doi.org/10.12982/CMUJNS.2019.0012

Journal Issues :

Number 2 , April-June 2019

ABSTRACT

The sous-vide process has been used in cooking to maintain nutrients and improve texture of meat. This improvement in nutrients and softening of the texture could be advantageous for the elderly. The objective of this research was to study effects of sous-vide cooking on the properties and changes of chicken breast fillet and their sensory acceptance by the elderly. Chicken breast fillets were vacuum packed and cooked at 60 oC for different times from 1 to 8 h comparing the effects with a common way of cooking as a control (100 oC for 30 min). Sous-vide cooked chicken had significantly (P<0.05) higher yield percentage, water holding capacity (WHC) and redness and lower hardness, chewiness and lightness than the control. With increased sous-vide cooking time the yield percentage, WHC, redness and hardness significantly (P<0.05) decreased, while lightness and chewiness significantly increased (P<0.05). Sous-vide cooking for 3, 4 and 5 h resulted in the lowest hardness, which was in the range of 40.05-60.01 N and lowest chewiness in the range of 11.24-16.88, but the highest springiness in the range of 0.03-0.04. A sensory evaluation panel of 50 people of 60-70 years old tested samples of the sous-vide breast chicken after cooking for 3, 4 or 5 h. Their evaluation showed that cooking for 4 h had the highest acceptance score compared with other times.

Keywords: Chicken, Chicken breast, Elderly, Sous-vide, Tenderness

INTRODUCTION

Sous-vide cooking is used in the processing food, as well as in catering and food services, to improve the properties and maintain nutrients in sheep meat (Roldàn et al., 2013) chicken sausage (Naveena et al., 2017) carrots and brussels sprouts (Chiavaro et al., 2012) and fish curry (Shakila et al., 2012). Sous-vide cooking involves vacuum packing in pouches and then cooking for protracted periods (Baldwin, 2012), which can result in foods having less change in color and improved texture (Creed, 1995). Kenji López-Alt (2015) reported that chicken breast cooked at 60 oC for longer than 30 min was safe from Salmonella that might contaminate meat and meat product.

The population of Thailand in 2016 had of over 14% (about 10 million people) considered elderly (National Statistical Office, 2017) who might have problems chewing and swallowing, because of digestive tract, hormone, sensory perception and body composition (Whitney et al., 2011). The production of foods designed particularly for the elderly is important and sous-vide cooking could be used to make meat more palatable and of a more suitable texture The objective of this research was to evaluate the changes in physical properties of chicken breast during sous-vide cooking and determine its acceptance by a sensory evaluation panel composed of elderly people.

MATERIALS AND METHODS

Materials

Uncooked chicken breast fillets were purchased from a local supermarket. Each fillet weighed 200-250 g. The fillets were skinless and the exudate from the fillets was blotted dry with tissue, rather than washing that could affect moisture content. The samples were vacuumed pack in laminate low density polyethylene (LLDPE) bags of 15×23 cm size before going to sous-vide process.

Sous-vide process

The vacuum packed samples were sous-vide cooked using a water bath at 60oC for 1, 2, 3, 4, 5, 6, 7 or 8 h. After cooking, the samples were cooled at 4oC for 30 min and then stored at room temperature (28oC) prior to analysis.

Boiling process

As a control the same chicken breast fillets were boiled in a water bath at 100oC for 30 min then cooled at 4oC and maintained for 30 min and then stored at room temperature (28oC) prior to analysis. This is a way chicken is commonly prepared in Thailand.

Determination of properties

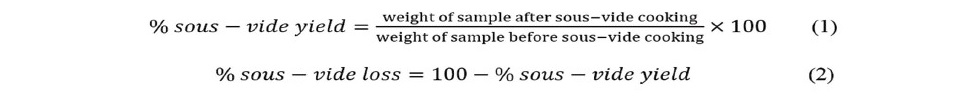

Sous-vide yield and sous-vide loss. The sous-vide yield and sous-vide loss were measured by weighing the sample before and after cooking (Kongpeam et al., 2015). Percentage of sous-vide yield and sous-vide loss were calculated using equations (1) and (2), respectively.

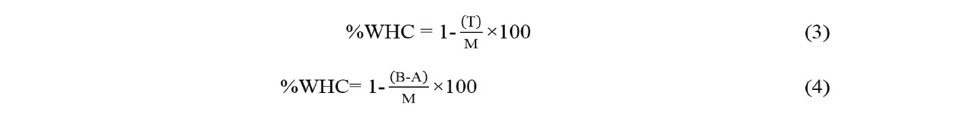

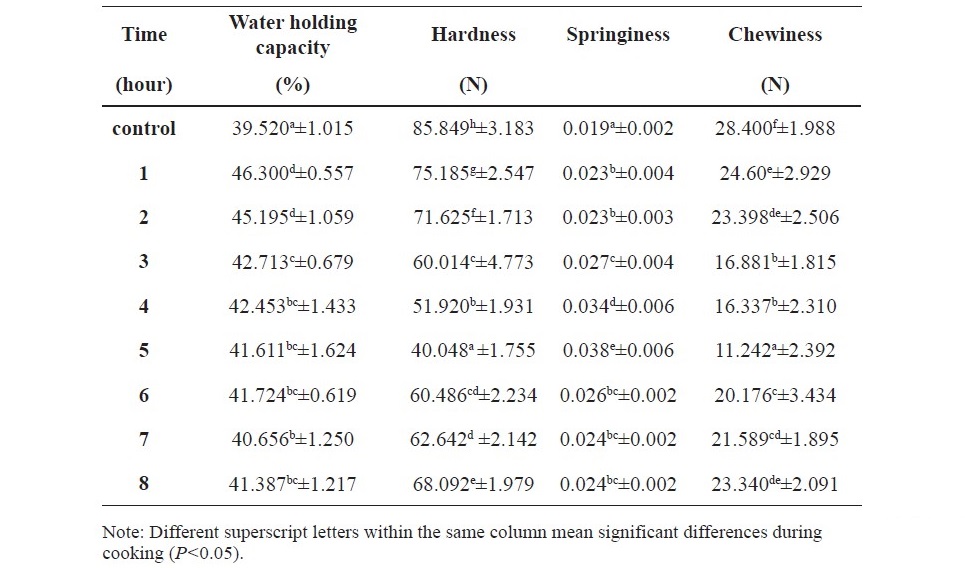

Water holding capacity. The water holding capacity of samples were measured according to the method of Hughes et al. (1996). Sample (10 g) were weighed at room temperature (28oC) and placed in a LLDPE bag (B) and heated in a water bath at 90oC for 10 min. After heating, samples were cooled to room temperature and maintained for 10 min then wrapped in filter paper and centrifuged (Eppendorf 5804r, Germany) at 9,000 g for 10 min at 4oC. The filter paper was removed and total fluid loss during heating and centrifugation (T) and sample after heating and centrifugation (A) were recorded. Moisture content of sample (M) was determined by following the method of AOAC (2000). Percentage of water holding capacity was calculated using equations (3) or (4).

where T is total water loss (g).

M is total water content in sample (g).

B is weight of sample before analyze (g).

A is weight of sample after centrifugation (g).

Color measurement. The color of fillets and drip solution were measured using a colorimeter (CR-400, Konica Minolta, Japan) and presented in terms of L* (lightness), a* (redness) and b* (yellowness) with 3 replications.

Texture profile analysis. Samples after cooking were cut to 1.5×1.5×2 cm perpendicular to fibers and the texture was measured using a texture analyzer (TA-XTplus, England) following the method described by Roldàn et al. (2013). The parameters were quantified in terms of hardness (N) maximum force required to after deforming force was removed. Also chewiness and elastic resistance were determined.

Sensory evaluation. Fifty people aged between the ages of 60- 70 years was selected at random for the panel to evaluate sensory attributes of samples. Cooked fillets were cut into 2×2×2 cm and flavored with soy sauce. Attributes of each sample was assessed by each member of the panel in terms of appearance, color, flavor, tenderness, juiciness and overall acceptance using a 9 point hedonic scale where 9 = like extremely, 8 = like very much, 7 = like moderately, 6 = like slightly, 5 = neither like nor dislike, 4 = dislike slightly, 3 = dislike moderately, 2 = dislike very much and 1 = dislike extremely, respectively.

Experimental design. The effects of sous-vide cooking time (1, 2, 3, 4, 5, 6, 7 or 8 h) in LLDPE bags at 60oC plus one treatment for 30 minutes at 100oC (not in a plastic bag as a control) with 3 replications were analyzed by one-way analysis of variance (ANOVA). This gave an experimental design of (8 + 1)3 = 27 treatments in total. Mean and standard deviations (SD) were calculated with statistical software. A significant difference test at 95% confidence level (P<0.05) was applied to determine differences of evaluated parameters.

RESULTS

Effect of sous-vide cooking time on yield percentage of chicken breast

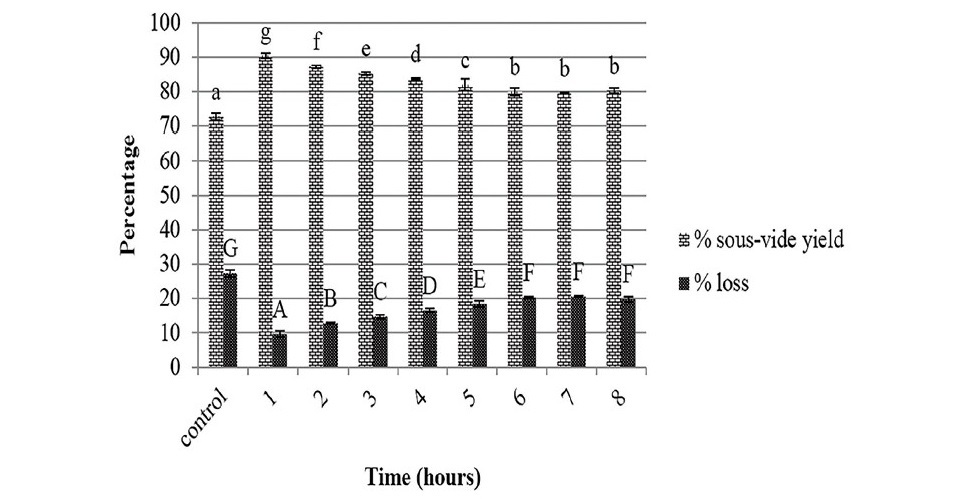

All the samples, after sous-vide cooking for 1 to 8 h, had significantly (P<0.05) higher yield percentage and lower cooking loss compared to the control (Figure 1). Control samples had a yield percentage of 72.68% and a cooking loss of 27.32%. There were also significant (P<0.05) effects of sous-vide cooking time so that as the cooking time increased the sous-vide yield decreased and the percentage of cooking loss tended to increase (Figure 1). Yield percentage of samples decreased from 90.45% to 79.57%, while their cooking loss increased from 9.55% to 20.43%, during cooking from 1 h to 8 h.

Figure 1. Percentage of sous-vide yield and loss of chicken breast fillet during cooking.

Note: Different superscript letters a,b,...,g mean significant differences of sous-vide yield percentage (P<0.05); Different superscript letters A,B,...,G mean significant differences of loss percentage (P<0.05).

Effect of sous-vide cooking time on water holding capacity and texture of chicken breast

Sample that had been sous-vide cooked for all the times tested (1-8 h) had significantly (P<0.05) higher WHC, higher springiness, lower hardness and lower chewiness compared to the control samples in all cases (Table 1). There was also a trend to the longer sous-vide cooking time resulting in significantly (P<0.05) lower WHC. Samples that had been sous-vide cooked for 5 h had the lowest springiness, hardness and chewiness, following by those cooked for 4, 3 and 6 h, respectively. Results were in accordance with springiness of sample.

Table 1. Water holding capacity and texture of chicken breast fillet after various sous-vide cooking times at 60oC compared to the control (not in a plastic bag at 100oC for 30 min).

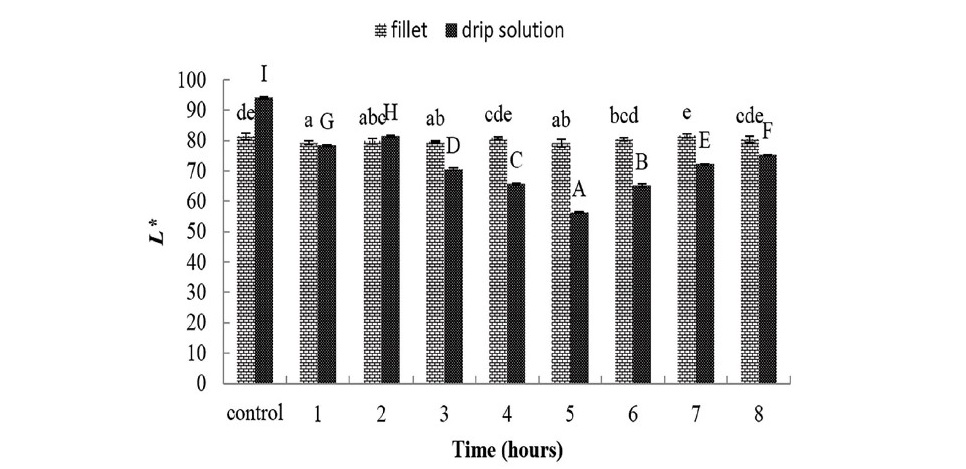

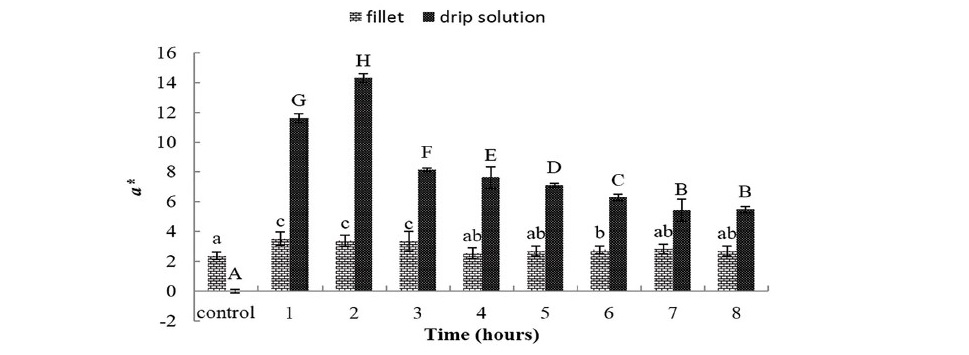

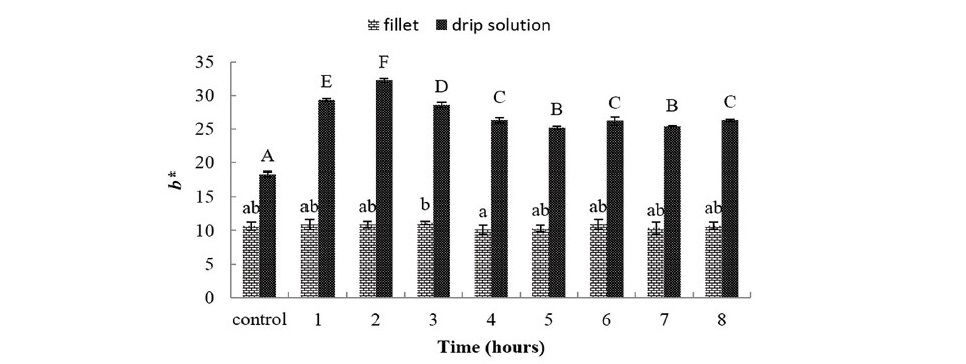

Effect of sous-vide cooking time on color of chicken breast

There was little difference in the color measurements of the chicken fillets with lightness (L*) in the range of 79.27-81.59 (Figure 2), yellowness (a*) in the range of 10.17-11.17 (Figure 3) and redness (b*) in the range of 3.53-3.36 (Figure 4). Also no clear trends were evident when comparing the sous-vide cooking with conventional cooking (control) or between the different times for the sous-vide cooking. There was significant (P<0.05) variation in the drip solutions with the control samples being the lightest and a trend for samples to darken between 1 and 5 h of sous-vide cooking and then to become lighter from 5 to 8 h (Figure 2). During sous-vide cooking, chicken breasts lose some of their water holding capacity and released drip solution.

Figure 2. L* of chicken breast fillet and solution during cooking.

Note: Different superscript letters a,b,...,e mean significant differences in lightness of chicken breast fillet (P<0.05); Different superscript letters A,B,...,G mean significant dif- ferences in lightness of drip solution (P<0.05).

Figure 3. a* of chicken breast fillet and solution during cooking.

Note: Different superscript letters a,b,c mean significant differences in redness of chicken breast fillet (P<0.05); Different superscript letters A,B,...,H mean significant differences in redness of drip solution (P<0.05).

Figure 4. b* of chicken breast fillet and solution during cooking.

Note: Different superscript letters a,b mean significant differences in yellowness of chick- en breast fillet (P<0.05); Different superscript letters A,B,...,F mean significant differences in yellowness of drip solution (P<0.05).

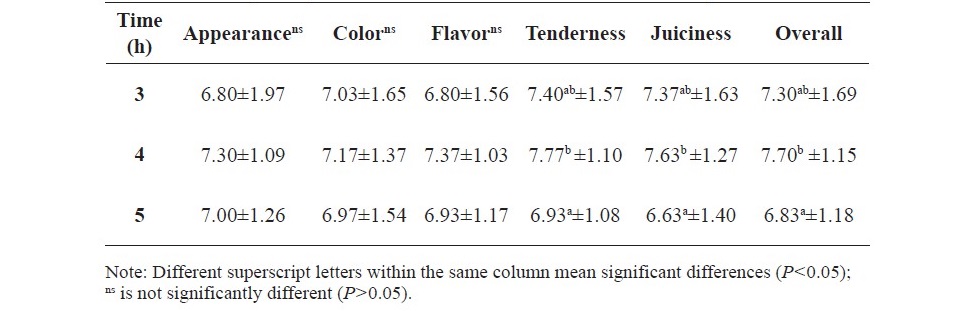

Sensory acceptance of sous-vide breast chicken to elderly

The lowest hardness and chewiness of the samples were found in sous-vide cooked samples for 5, 4 and 3 h (Table 1). Panelists could detect no significant difference (P<0.05) between samples for appearance, color and flavor but sous-vide cooking for 5 hours resulted in lower overall scores and scores for tenderness and juiciness were lower than sous-vide cooking for 4 hours with sous-vide cooking for 3 hours as an intermediate value (Table 2). Scores were so close that it is unlikely that these findings would be important in terms of selecting a cooking period for elderly palates.

Table 2. Sensory acceptance of sous-vide breast chicken of elderly.

DISCUSSION

Chicken breast lost drip solution during cooking, an effect previously re- ported by Mudalal et al. (2014) who found that chicken breast, with an initial moisture content of 73.8%, had a reduced moisture content, after cooking, of 27.4%. This effect could be explained from previous work where cooking vacuum packed chicken breast at 60oC for at least 1 h had a higher water holding capacity as a result of different heat transfer from the water to the chicken compared with traditional cooking methods (Baldwin, 2012).

The redness of the drip solutions after sous-vide cooking could be related to the aggregation of protein. During the first period of cooking (2 h), the drip solution would consist of myoglobin and pigments released from chicken breast. After longer cooking, the drip solution had reduced redness due to protein denaturation. This effect is in accordance with Palka and Daun (1999) and Baldwin (2012) who showed that during cooking, actin and myosin start to shrink at 35-40oC and then myosin is denatured at 50oC. The myosin becomes aggregated and induces light scatter that affected lightness until the protein shrinks. The sarcoplasmic protein, mostly enzymes and myoglobin, expanded after heating at 40oC with a release of drip solutions followed by aggregation and gelation at about 60oC. At this temperature, myoglobin will change to haemochrome and give a tan color to chicken breast.

The effect of sous-vide cooking on the textural property of meat is related to protein aggregation and gelling that can induce lowering of hardness. However, after heating for longer periods, the meat became harder and difficult to chew again because the elastic modulus increases and requires larger tensile stress to extend fractures (Baldwin, 2012). The sous-vide cooking time that gave the lowest hardness and chewiness and the highest springiness after was 5 h. This was explained by Astruc et al. (2012) who found that heat induced structural changes decreased hardness, but that after higher water loss (with longer cooking times) the texture of the fillets would have increased hardness.

CONCLUSION

Sous-vide cooking could maintain the water content of chicken breast fillets and induce a higher percentage of sous-vide yield, WHC and improve texture of sample, while lightness and yellowness of samples were slightly different compared to traditional cooking. Increasing the sous-vide cooking time resulted in decreases in percentage of sous-vide yield, WHC and redness, while percentage of sous-vide loss increased. However, the cooking conditions slightly affected lightness and redness of the chicken breast. The sous-vide cooking time at the temperature tested (60oC) for 3-5 h resulted in fillets with lower in hardness and chewiness, while springiness was higher than those of the other cooking times. The sensory evaluation panel of 60-70 year olds accepted sous-vide chicken breast especially after a cooking time of 4 h.

ACKNOWLEDGEMENTS

This work is supported by King Mongkut’s Institute of Technology Ladkrabang (grant number KREF056004). The authors thank the Faculty of Agro-Industry, King Mongkut’s Institute of Technology Ladkrabang for providing instruments.

REFERENCES

AOAC. 2000. Official methods of the association of official analytical chemists. Association of Official Analytical Chemists, Washington D.C. Astruc, T., Peyrin, F., Venien, A., Labas, R., Abrantes, M., Dumas, P., and Jamme, F. 2012. In situ thermal denaturation of myofibre sub-type proteins studied by immunohistofluorescence and synchrotron radiation FT-IR mirospec troscopy. Food Chemistry. 134: 1044-1051. https://doi.org/10.

1016/j.foodchem.2012.03.012

Baldwin, D.E. 2012. Sous-vide cooking: A review. Gastronomy and Food Science. 1(1): 15-30. https://doi.org/10.1016/j.ijgfs.2011.11.002

Chiavaro, E., Mazzeo, T., Visconti, A., Manzi, C., Fogliano, V., and Pellegrini, N. 2012. Nutritional quality of sous vide cooked carrots and brussels sprouts. Journal Agricultural Food Chemistry. 60(23): 6019-6025. https://doi.org/10.1021/jf300692a

Creed, P.G. 1995. The sensory and nutritional quality of ‘sous vide’ foods. Food Control. 6(1): 45-52. https://doi.org/10.1016/0956-7135(95)91453-R

Hughes, E., Cofrades, S., and Troy, D.J. 1996. Effect of fat level, oat fibre and carrageenan on frankfurters formulated with 5, 12 and 30% fat. Journal of Meat Science. 45: 273-281. https://doi.org/10.1016/S0309-1740(96) 00109-X

Kenji López-Alt, J. 2015. The food lab’s complete guide to sous vide chicken breast [Internet]. [cited 2016 August 15]. Available from: www.seriouseats. com/2015/.../the-food-lab-complete-guide-to-sous-vide-chicken-breast

Kongpeam, I., Kerdpiboon, S., and Peuchkamut, Y. 2015. Flank steak of local

Thai beef preparation using sous-vide process. 14th Asean Food Conference, the Bigger Picture on Asean through Food Technology; 2015 Jun 24-26; Philippines. Asean Food Conference. 7 p. https://doi.org/10.14457/KMITL. res.2015.75

Mudalal, S., Babini, E., Cavani, C., and Petracci, M. 2014. Quantity and functionality of protein fractions in chicken breast fillets affected by white striping. Poultry Science. 93(8): 2108-2116. https://doi.org/10.3382/ps.2014-03911 National Statistical Office. 2017. Report of the survey of elderly in Thailand [Internet]. [cited 2017 October 10]. Available from: https://www.m-society.go.th/article_attach/14494/18145.pdf

Naveena, B.M., Khansole, P.S., Kumar, M.S., Krishnaiah. N., Kulkarni,V.V., and Deepak, S.J. 2017. Effect of sous vide processing on physicochemical, ultrastructural, microbial and sensory changes in vacuum packaged chicken sausages. Food Science and Technology International. 23(1): 75-85. https://doi.org/10.1177/1082013216658580

Palka, K., and Daun, H. 1999. Changes in texture, cooking losses, and myofibrillar structure of bovine M. Semitendinosus during heating. Meat Science. 51: 237-343. https://doi.org/10.1016/S0309-1740(98)00119-3

Roldàn, M., Antequera, T., Martín, A., Mayoral, A.I., and Ruiz, J. 2013. Effect of different temperature-time combinations on physicochemical, micro- biological, textural and structural features of sous-vide cooked lamb loins. Meat Science. 93: 572-578. https://doi.org/10.1016/j.meatsci.2012.11.014

Shakila, R.J., Raj, B.E., and Felix, N. 2012. Quality and safety of fish curry processed by sous vide cook chilled and hot filled technology process during refrigerated storage. Food Science and Technology International. 18(3): 261-269. https://doi.org/10.1177/1082013211415177 Whitney, E., DeBruyne, L.K., Pinna, K., and Rolfes, S.R. 2011. Nutrition for health and health care. 4th Eds. Wadsworth

Soraya Kerdpiboon*, Nuttapon Suraphantapisit, Possathorn Pongpaew, and Pramual Srikalong

Faculty of Agro-Industry, King Mongkut’s Institute of Technology Ladkrabang, Bangkok 10520, Thailand

*Corresponding author. E-mail: soraya.ke@kmitl.ac.th

Total Article Views

Article history:

Received: July 16, 2018;

Revised: October 24, 2018;

Accepted: November 1, 2018