Effect of Microwave Heat Treatment for Resistant Starch Levels and Prebiotic Properties of High Carbohydrate Foods: Meta-Analysis Study

Muhammad Isra, Dimas Andrianto and R. Haryo Bimo Setiarto*Published Date : 2022-03-31

DOI : https://doi.org/10.12982/CMUJNS.2022.032

Journal Issues : Number 2, April-June 2022

Abstract Microwave heat treatment is one of the most widely used starch physical modification techniques in analyzing the increase in resistant starch levels in foodstuffs. However, this technique has varying effects on each type of high-carbohydrate food. This study aims to analyze the type of carbohydrate food that significantly increases the levels of resistant starch and prebiotic properties by the microwave heat treatment technique. This study used 31 articles that were analyzed and selected through the PRISMA guide method from 11.232 selected libraries. Secondary data will be analyzed based on the percentage of Effect Size Hedges'd (standardized mean difference/SMD) and confidence interval (CI) values using OpenMEE software. The meta-analysis results showed that the microwave heat treatment method on high-carbohydrate foods had a significant effect on increasing levels of resistant starch and prebiotic properties (SMD 2.755; 95% CI: 2.106 to 3.403; P <0.001). Based on the meta-analysis results, it can be concluded that the microwave heat treatment technology has a significant effect with a 95% confidence level in increasing levels of resistant starch and prebiotic properties in high-carbohydrate foods.

Keywords: High carbohydrate foods, Meta-analysis, Microwave heat treatment, Prebiotic properties, Resistant starch

Citation: Isra, M., Andrianto, D., and Setiarto, R.H.B. 2022. Effects of Microwave Heat Treatment for Resistant Starch Levels and Prebiotic Properties of High Carbohydrate Foods: Meta-Analysis Study. CMU J. Nat. Sci. 21(2): e2022032.

INTRODUCTION

Resistant starch is a starch fraction that cannot be digested by digestive enzymes and is resistant to gastric acid so that it can reach the colon and be fermented by probiotic bacteria. Resistant starch is claimed to have beneficial physiological effects such as colon cancer prevention, hypoglycemic and cholesterol-lowering effects (Sajilata et al., 2006). Resistant starch is part of the starch fraction that cannot be digested by pancreatic enzymes in the small intestine. Since starch consists only of amylose and amylopectin, after digestion, starch is converted into simpler components (monosaccharides) by the amylase enzyme (Lombu et al., 2018). The principle of physical change of starch is generally heating. Physical modification treatments include extrusion, parboil, steaming, microwave irradiation, roasting, and hot water treatment. The physical modification methods can increase the content of resistant starch (Sajilata et al., 2006).

Microwave techniques using microwaves are included in the physical modification. The principle of microwave heat treatment is the dielectric microwave heating effect and the electromagnetic polarization effect. The polar molecules of starch particles rub against each other in a microwave field, generating a lot of heat. Thus, the temperature of the starch granules increases, changing the structure physical and chemical properties of starch (Fan et al., 2013; Lewandowicz et al., 2000).

Microwave heat treatment (MHT) affects starch through dielectric heating and electromagnetic polarization effects (Bilbao-Sáinz et al., 2007). The modification changes the physicochemical properties of starch and can improve the function of the original starch (Bemiller and Huber, 2015). Previously reported studies on millet starch focused on plant breeding and genotype (Wang et al., 2017), or compare the physicochemical properties of different varieties (Wang et al., 2018). Microwave gelatinization can destroy the crystallinity of starch before particle expansion, microwave gelatinization destroys the crystal structure of starch, and the molecular chain is broken. It has been reported that microwave heating can alter the features of starch through gelatinization and enzymatic resistance as well as molecular structure and arrangement (Fan et al., 2014).

The effect of microwave radiation on starch digestibility has been studied extensively (Emmi et al., 2012; Zeng et al., 2016). Generally, retrogradation occurs after microwave exposure, and the time of retrogradation affects starch digestibility. However, several studies using microwave irradiation in food resulted in different properties and levels of resistant starch. Meta-analysis can contain the latest information on increasing the properties and levels of resistant starch in foodstuffs with modified microwave treatment. Hence, this study aimed to investigate the type of carbohydrate food that has a significant effect on increasing levels of resistant starch and prebiotic properties through microwave heat treatment techniques.

MATERIAL AND METHODS

Materials

The materials used in this meta-analysis are research articles from reputable and accredited international publications from various online database web servers such as Science Direct, Wiley Online Library, Taylor & Francis Online, Springer Link, and Google Scholars.

Library Search Strategy

Analysis and selection of literature were carried out by following the rules of Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) is a series of analytical processes to select the required literature (Borenstein et al., 2009). PRISMA rules are used to facilitate reporting in the research journal selection process. The library selection is divided into several stages, namely selection based on title and duplication, selection based on abstract, selection based on method, and full-text selection. The literature was searched through the web server database Science Direct, Wiley Online Library, Taylor & Francis Online, Springer Link, and Google Scholars, using the keywords “microwave, resistant starch, foodstuff”. The three keywords are combined using a Boolean operator with the expression "and" then a selection is added in the form of the year of publication of the article (2011-2021) to narrow the search.

Study Library Selection

The selection of research literature was based on screening titles and abstracts and then reviewed to determine their suitability with predetermined inclusion and exclusion criteria. The inclusion criteria were the selection of a library of international journal reputable. The selected research is also the result of primary data research published in the last 10 years (2011-2021). It has data on levels of resistant starch before microwave treatment (control data) and after microwave treatment (experimental data) and is limited to research using microwave heat treatment techniques. Exclusion criteria were the study of research results using starch processing methods, analysis of prebiotic properties, and additional treatment methods other than microwave heat treatment (autoclaving cooling, lintnerization acid hydrolysis, and annealing).

Data collection

The research data in the selected study from the journal webserver using Zotero's assistance was then extracted into a Microsoft Excel worksheet. Data were collected based on the author's name, year of publication, food ingredients, a mean and standard deviation of control and experimental resistant starch levels, and the number of replicates.

Statistical Analysis

The data were analyzed using the Hedges'd effect (Standardized Mean Difference / SMD) with a 95% confidence interval (confidence interval value) by analyzing the Effect Size of the data using OpenMEE software (Wallace et al., 2017). The data collected from the selected journals are the mean, standard deviation or standard error, and the number of repeated attempts. SMD with a corresponding 95% CI, pooled using a random-effects model. According to Higgins (2016), if the exploration of heterogeneity across studies is carried out using an index of I^2 (I^2> 50% indicates good heterogeneity). The moderator variables for analysis for the sub-groups were food, place, and prebiotic properties. Meta-analysis was carried out using OpenMEE software with the output in the form of forest plots for analysis.

RESULTS

Study Library Selection

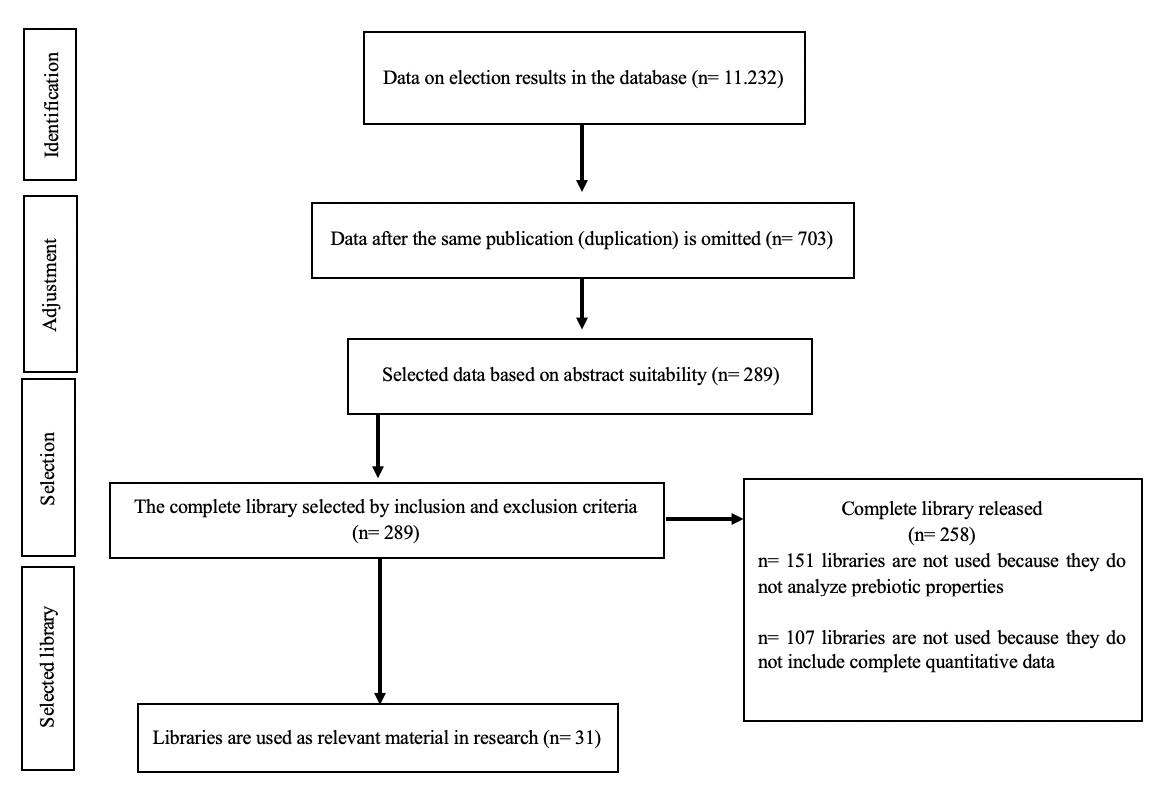

The references obtained from the selection process in the database are 11,232 references. Overall, the input references into Zotero software is to remove the same duplicate references and get 703 references, then proceed with selection based on the abstracts obtained by 289 references. The results of the next selection removed 258 references because they did not analyze prebiotic properties and did not include complete quantitative data in the form of resistant starch content data before microwave treatment (control data) and after microwave treatment (experimental data). Library selection is also carried out based on literature published from reputable international journals. The selected references are also the result of primary data research published in the last 10 years (2011-2021) and are limited to studies using heat moisture treatment techniques. A total of 31 complete libraries were used as relevant material in the meta-analysis study as shown in Figure 1.

Figure 1. The process of selecting literature/study articles for further meta-analysis.

Data analysis of the content of indigestible starch from each selected library was obtained up to 31 data. Table 1 summarizes the data for each study. The entire data is then processed in the OpenMEE worksheet to determine the Effect Size value, heterogeneity/inconsistency value (I^2), and p-value. Effect Size values from each study were re-analyzed using OpenMEE to determine the combined effect measurement value with a 95% confidence interval (CI) with a significance level of 0.05. The Effect Size value is the Hedges'd (Standardized Mean Difference/SMD) value to analyze the treatment effects that have a relationship.

Table 1. Data on changes in levels of resistant starch in foodstuffs.

|

No. |

Foodstuffs |

Control resistant starch (%) |

Resistant starch after modification (%) |

Changes in resistant starch (%) |

Literature review |

|

|

1 |

Millet starch |

14.50 |

17.95 |

3.45 |

Zheng et al.,(2019) |

|

|

2 |

Caltrop starch |

16.06 |

44.93 |

28.87 |

Wei et al.,(2020) |

|

|

3 |

Potato |

5.89 |

9.96 |

4.06 |

Narwojsz et al., (2020) |

|

|

4 |

Bananas |

19.88 |

29.54 |

9.66 |

Sánchez-Rivera |

|

|

5 |

Corn starch |

22.29 |

22.65 |

0.36 |

||

|

6 |

Rice starch |

3.00 |

34.95 |

31.94 |

Li et al., (2019) |

|

|

7 |

Corn starch |

22.00 |

58.78 |

36.78 |

Wang et al., (2019) |

|

|

8 |

Potato starch |

22.28 |

57.88 |

35.60 |

||

|

9 |

Jasmine brown rice |

3.00 |

3.87 |

0.87 |

Krongworakul et al., (2020) |

|

|

10 |

Rice ADT-46 |

11.23 |

20.95 |

9.72 |

Kanagaraj et al., (2019) |

|

|

11 |

Barnyard millet CO2 |

12.45 |

22.62 |

10.18 |

||

|

12 |

Lentil Green (CDC Greenland) |

5.46 |

7.40 |

1.93 |

Nongmaithem et al., (2017) |

|

|

13 |

Lentil Red (CDC Maxim) |

4.66 |

9.69 |

5.03 |

||

|

14 |

Buckwheat |

6.59 |

19.69 |

13.11 |

Wang et al.,(2017) |

|

|

15 |

Tuber |

17.63 |

41.11 |

23.48 |

Barua et al., (2021) |

|

|

16 |

Bulbs |

9.05 |

47.09 |

38.04 |

Chen et al., (2016) |

|

|

17 |

Chinese yams |

16.35 |

40.67 |

24.31 |

Chen et al., (2017) |

|

|

18 |

Taro tubers |

14.77 |

96.84 |

82.08 |

Deka et al., (2016) |

|

|

19 |

Chinese yams |

13.57 |

26.23 |

12.67 |

Duang et al., (2020) |

|

|

20 |

Barley |

11.20 |

20.30 |

9.10 |

Emami et al., (2012) |

|

|

21 |

Brown rice |

1.58 |

14.35 |

12.78 |

Haung et al., (2021) |

|

|

22 |

Potato tubers |

8.67 |

22.99 |

14.32 |

Larder et al., (2019) |

|

|

23 |

Japonica rice |

16.00 |

57.46 |

41.45 |

Li et al., (2014) |

|

|

24 |

Indica rice |

23.42 |

49.48 |

26.06 |

Li et al., (2020) |

|

|

25 |

Sorghum (LML1) |

5.61 |

30.84 |

25.24 |

Li et al., (2021) |

|

|

26 |

Sorghum (LZ13) |

8.56 |

28.01 |

19.45 |

||

|

27 |

Sorghum (HN) |

8.38 |

28.04 |

19.66 |

||

|

28 |

Faba bean |

8.55 |

30.15 |

21.60 |

Liu et al., (2020) |

|

|

29 |

Lentil |

10.65 |

33.25 |

22.60 |

||

|

30 |

Pea |

14.45 |

30.80 |

16.35 |

||

|

31 |

Cassava starch |

24.13 |

39.26 |

15.13 |

Sumardiono et al., (2018) |

|

|

32 |

Corn starch (Hylon VII) |

35.58 |

42.07 |

6.49 |

Mutlu et al., (2018) |

|

|

33 |

Breadfruit |

20.57 |

37.43 |

16.86 |

Otemuyiwa et al., (2021) |

|

|

34 |

Canna starch |

12.67 |

41.63 |

28.96 |

Zhang et al., (2010) |

|

|

35 |

Sago starch |

12.61 |

34.40 |

21.78 |

Zailania et al., (2022) |

|

|

36 |

Indica rice |

20.11 |

42.04 |

21.93 |

Liu et al., (2021) |

|

|

37 |

Rice |

62.83 |

72.14 |

9.31 |

Thuengtung et al., (2019) |

|

|

38 |

Canna starch |

22.61 |

59.61 |

37.00 |

Wu et al., (2020) |

|

|

39 |

Sago starch |

11.89 |

32.99 |

21.09 |

Zailani et al., (2021) |

|

|

Note: The average levels of control resistant starch (n= 39); 15% (n= 39); 15 % |

|

|||||

|

The average content of resistant starch after modification (n= 39); 34.87 % |

|

|||||

|

The average increase in resistant starch (n= 39); 77.930 % |

|

|||||

Data analysis

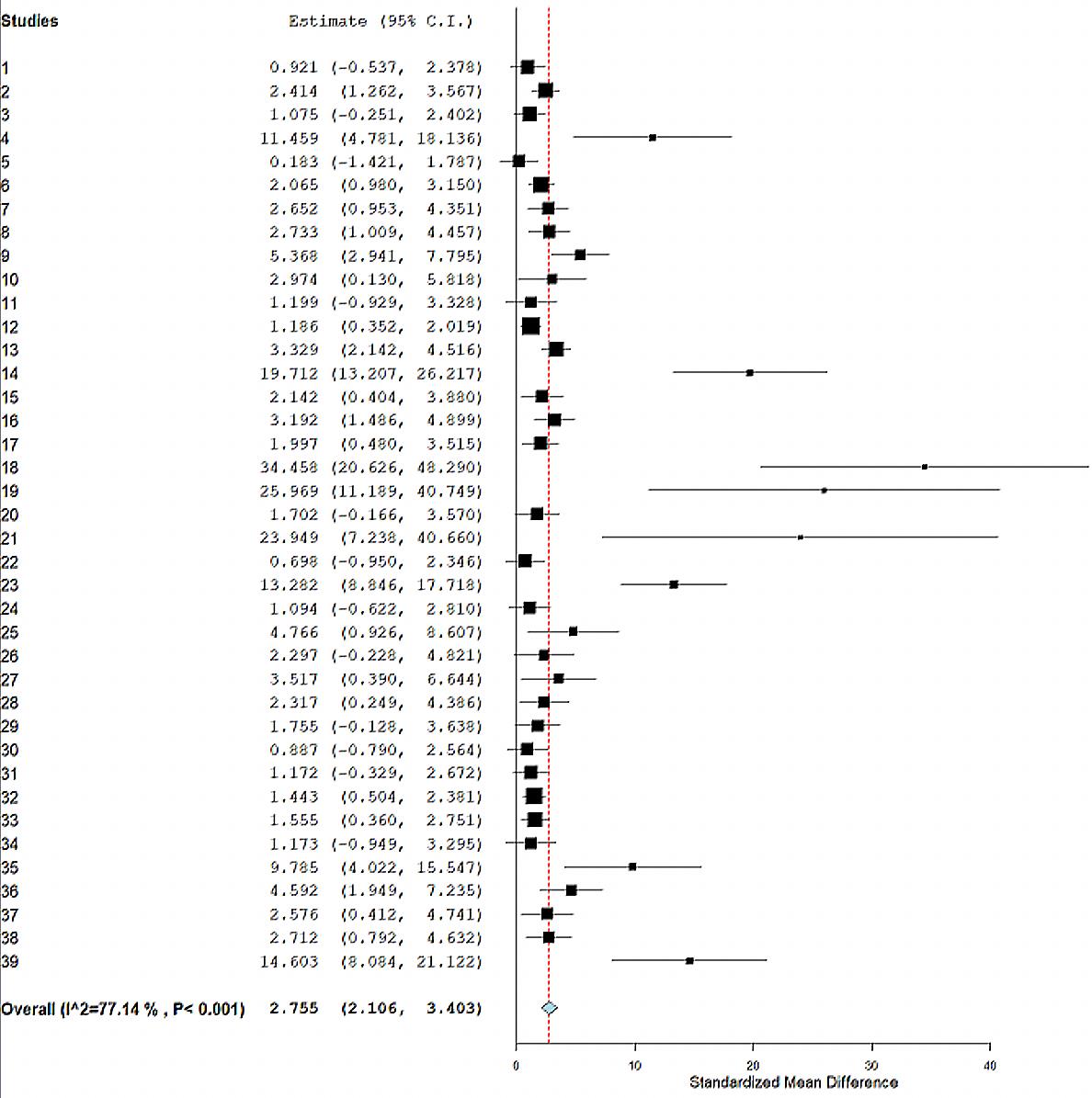

The results of the forest plot meta-analysis using OpenMEE (Figure 2) showed that there was a significant effect in the microwave heat treatment process on increasing levels of resistant starch, with a combined SMD effect value of 2.755 with 95% CI (2.106 to 3.403) P

Figure 2. Forest plot of the results of the meta-analysis study of all data.

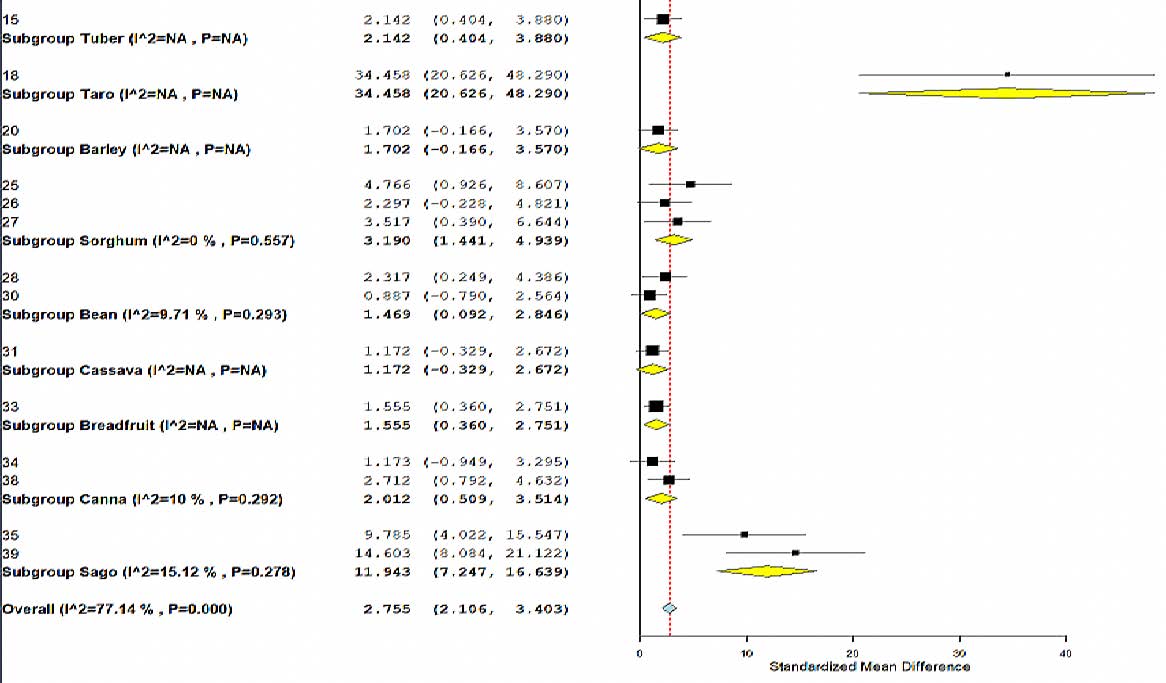

Figure 3. Forest plot of the results of the meta-analysis of the study of the effect of different types of carbohydrate foods on increasing resistance starch levels.

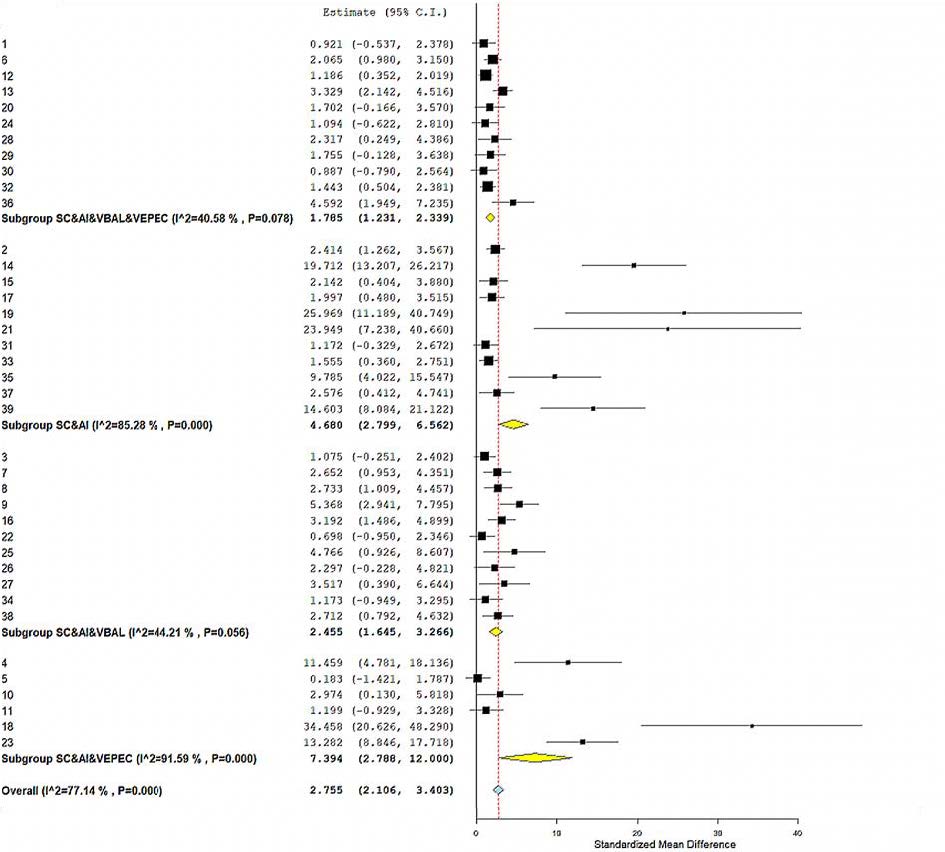

Note: Information: SC: Starch Composition, AI: Amylose Interaction, VBAL: Viability BAL, VEPEC: Viability EPEC

Figure 4. Forest plot of the results of the meta-analysis of the study of the effect of carbohydrate foods on prebiotic properties.

The Effect of Different Carbohydrate Foodstuffs on Increasing Resistance Starch Levels

Forest plot data analysis results from the effect of different types of carbohydrate foods are presented in Figure 3. The results of the forest plot showed that high-carbohydrate foods had a significant effect on increasing levels of resistant starch with an SMD effect value of 2.775 with 95% CI (2.106 to 3.403) P

Effect Size value data indicate that in general the results of the meta-analysis support the theory that the relationship between modified microwave heat treatment techniques and increased levels of resistant starch is interrelated. There are 12 data on food materials whose levels of resistant starch did not increase significantly, namely millet starch, potato, corn starch, tuber, barley, potato tubers, indica rice, sorghum (LZ13), lentil, pea, cassava starch, canna starch.

Effect of Carbohydrate Foodstuffs on Prebiotic Properties

Further research was conducted to determine how the effect of the type of carbohydrate food on the prebiotic properties. Each prebiotic trait test was divided into the starch composition (SC), amylose interaction (Al), lactic acid bacteria viability (VBAL), enteropathogenic Escherichia coli (VEPEC) viability in the literature were analyzed and forest plot data were obtained as shown in Figure 4. Based on the results in the forest plot, the type of carbohydrate food had a significant effect on the prebiotic properties with an SMD effect value of 2.775 with a 95% CI (2.106 to 3.403) P

DISCUSSION

Physical modification techniques with microwave treatment for high-carbohydrate foods have a significant effect on increasing resistant starch levels by interpreting the data on the significant value of the effect of increased resistant starch levels (SMD 2.755; 95% CI): 2.106 to 3,403; P

The microwave heat treatment technique was carried out using the influence of temperature and treatment time which showed that heating starch or flour to >100°C helped to produce functionality equivalent to that obtained by chemical crosslinking (Lim et al., 2002). Starch with normal amylose content is known that cooking at a temperature >100°C can increase the yield of type RS 3 (Sajilata et al., 2006). The hypothesis tested in the meta-analysis study was that the greater the increase in the levels of resistant starch, the higher the effect of the modified microwave heat treatment technique on the food ingredients.

Signs of decreased levels of resistant starch were related to the degradation process of RS1 and RS2 after modification, with the degradation process of RS1 and RS2 being more dominant due to a decrease due to overheating and causing a decrease in the percentage of distribution chain with a degree of polymerization (DP) 25-30. In the starch gelatinization process, if excess water is added and heated for a certain time and temperature, the birefringence properties of the starch granules will be lost, and the starch granules will swell and cannot return to their original state (irreversible) (Zabar et al. al., 2008). Heating the starch suspension above the gelatinization temperature can cause hydrogen bonds to occur.

The type of food high in carbohydrates had a significant effect on increasing prebiotic properties (P <0.001) with an SMD effect value of 4.045 with 95% CI. Li et al., (2014) reported that in the microwave heating treatment of rice starch, in vitro starch digestibility was measured by the simulative digestion method. In vitro and micromorphology obtained by SEM. Microwave-heated rice starch has a larger swell and smaller gap between starch granules when compared to conductive heating. The concentration of digestibility of reducing sugars and glucose in vitro was higher in rice starch cooked by microwave heating. Amylose and amylopectin levels of modified starch were also influenced by several factors such as reducing sugar content, starch digestibility, starch composition, fiber content, starch gelatinization, and starch retrogradation (Afolabi et al., 2018).

CONCLUSION

This meta-analysis concluded that microwave treatment had a significant effect with a 95% confidence level in increasing the levels of resistant starch and increasing the prebiotic properties of high-carbohydrate foods. Limitations of this meta-analysis need to study more deeply about the location of high-carbohydrate foods.

ACKNOWLEDGEMENTS

The author would like to deepest thank all parties who have helped in the completion of this research.

AUTHOR CONTRIBUTIONS

All authors (Muhammad Isra, Dimas Andrianto, and R. Haryo Bimo Setiarto) had equal contributions as the main contributors to this manuscript paper.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

REFERENCES

Afolabi, T.A., Opara, O.A., and Kareem, O.S. 2018. In vitro digestibility of hydrothermally modified bambara groundnut (Vigna subterranean l.) starch and flour. Food Science & Nutrition. 6: 36-46.

Barua, S., Rakshit, M., and Srivastav, P. 2021. Optimization and digestogram modeling of hydrothermally modified elephant foot yam (Amorphophallus paeoniifolius) starch using hot air oven, autoclave, and microwave treatments. LWT- Food Science and Technology. 145: 111283.

Bemiller, J.N. and Huber, K.C. 2015. Physical modification of food starch functionalities. Annual Review of Food Science and Technology. 6: 19-69.

Bilbao-Sáinz, C., Butler, M., Weaver, T., and Bent, J. 2007. Wheat starch gelatinization under microwave irradiation conduction heating. Carbohydrate Polymers. 69: 224–232.

Borenstein, M., Hedges, L.V., Higgins J.P.T., and Rothstein, H.R. 2009 Fixed-Effect Versus Random-Effects Models. in Introduction to Meta-Analysis. John Wiley & Sons Ltd. Hoboken NJ USA: 77-86. ISBN: 978-0-470-05724-7.

Chen, X., Li, X., Mao, X., Huang, H., and Jing, M. 2016. Study on the effects of different drying methods on physicochemical properties, structure, and in vitro digestibility of Fritillaria thunbergii Miq. (Zhebeimu) flours. Food and Bioproducts Processing. 98: 266-274.

Chen, X., Li, X., Mao, X., Huang, H., Wang, T., Qu, Z., Miao, J., and Gao, W. 2017. Effects of drying processes on starch-related physicochemical properties, bioactive components and antioxidant properties of yam flours. Food Chemistry. 24: 224-232.

Deka, D., and Sit, N. 2016. Dual modification of taro starch by microwave and other heat moisture treatments. International Journal of Biological Macromolecules. 92: 416-422.

Duang, X., Han, H., Deng, R., and Wu, P. 2020. Drying treatments on Chinese yam (Dioscorea spp.) prior to wet milling influence starch molecular structures and physicochemical properties. Food Hydrocolloids. 102: 105599.

Emami, S., Perera, A., Meda, V., and Tyler, R.T. 2012. Effect of microwave treatment on starch digestibility and physico-chemical properties of three barley types. Food Bioprocess Technology. 5: 2266-2274.

Fan, D., Ma, W., Wang, L., Huang, J., Zhang, F., and Zhao, J. 2013. Determining the effects of microwave heating on the or- dered structures of rice starch by NMR. Carbohydrate Polymers. 92: 1395–1401.

Fan, Z. 2014. Structure, physicochemical properties, and uses of millet starch. Trends in Food Science and Technology. 36: 68–78.

Higgins, J.P. and Thompson, S.G. 2016. Quantifying Heterogeneity in A Meta-Analysis. Statistics in Medical. 21: 1539-1558.

Huang, W., Song, E., Lee, D., Seo, S., Lee, J., Jeong, J., Chang, Y., Lee, Y., and Hwang, J. 2021. Characteristics of functional brown rice prepared by parboiling and microwave drying. Journal of Stored Products Research. 92: 101796.

Kanagaraj, S.P., Ponnambalam, D., and Antony, U. 2019. Effect of dry heat treatment on the development of resistant starch in rice (Oryza sativa) and barnyard millet (Echinochloa furmantacea). Journal of Food Processing and Preservation. 43: e13965.

Krongworakul, N., Naivikul, O., Boonsupthip, W., and Wang, Y. 2020. Effect of conventional and microwave heating on physical and chemical properties of Jasmine brown rice in various forms. Journal of Food Process Engineering. 43: e13506.

Larder, C.E., Baeghbali, V., Pilon, C., Iskandar, M.M., Donnelly, D.J., Pacheco, S., Godbout, S., Ngadi, M.O., and Kubow, S. 2019. Effect of non-conventional drying methods on in vitro starch digestibility assessment of cooked potato genotypes. Foods. 8: 382.

Lewandowicz, G., Jankowski, T., and Fornal, J. 2000. Effect of micro-wave radiation on Physico-chemical properties and structure of cereal starches. Carbohydrate Polymers. 42: 193–199.

Li, J., Han, W., Xu, J., Xiong, S., and Zhao, S. 2014. Comparison of morphological changes and in vitro starch digestibility of rice cooked by microwave and conductive heating. Starch/Stärke. 66: 549-557.

Li, N., Cai, Z., Gou, Y., Xu, T., Qiao, D., Zhang B., Zhao S., Huang, Q., Nui, M., Jia, C., et al. 2019. Hierarchical structure and slowly digestible features of rice starch following microwave cooking with storage. Food Chemistry. 295: 475-483.

Li, N., Wang, L., Zhao, S., Qiao, D., Jia, C., Niu, M., Lin, Q., and Zhang, B. 2020. An insight into starch slowly digestible features enhanced by microwave treatment. Food Hydrocolloids. 103: 105690.

Li, R., Dai, L., Peng, H., Jiang, P., Liu, N., Zhang, D., Wang, C., and Li, Z. 2021. Effects of microwave treatment on sorghum grains: Effects on the physicochemical properties and in vitro digestibility of starch. Journal of Food Process Engineering. 44: e13804.

Li, Y., Zhang, A.R., Luo, H.F., Wei, H., Zhou, Z., Peng, J., and Rus, Y.J. 2015. In vitro and in vivo digestibility of corn starch for weaned pigs: effects of amylose: amylopectin ratio, extrusion, storage duration, and enzyme supplementation. Journal Animal Science. 93: 3512-8790.

Lim, S.T., Han, J.A., Lim, H.S., and BeMiller, J.N. 2002. Modification of starch by dry heating with ionic gums. Cereal Chemistry. 79: 601-606.

Liu, T., Zhang, B., Wang, L., Zhao, S., Qiao, D., Zhang, L., and Xie, F. 2021. Microwave reheating increases the resistant starch content in cooked rice with high water contents. International Journal of Biological Macromolecules. 184: 804-811.

Liu, Y., Ragaee, S., Marcone, M.F., and Abdel-Aal, E.M. 2020. Effect of different cooking methods and heating solutions on nutritionally-important starch fractions and flatus oligosaccharides in selected pulses. Cereal Chemistry. 97: 1216-1226.

Lombu, W.K., Ni, A.A.I., and Wiadnyani, S. 2018. Differences in Chemical Characteristics and Digestibility of Corn Starch and Corn Sprout Flour (Zea mays L.). Journal of Food Science and Technology. 7: 43-51.

Mutlu, S., Kahraman, K., Severcan, S., and Öztürk, S. 2018. Modeling the effects of debranching and microwave irradiation treatments on the properties of high amylose corn starch by using response surface methodology. Food Biophysics. 13: 263-273.

Narwojsz, A., Borowska, E.J., Polak-Śliwińska, M., and Danowska-Oziewicz, M. 2020. Effect of different methods of thermal treatment on starch and bioactive compounds of potato. Plant Foods for Human Nutrition. 75: 298-304.

Nongmaithema, R. and Meda, V. 2017. Optimization of microwave vacuum drying parameters for germinated lentils based on starch digestibility, antioxidant activity and total phenolic content. International Journal of Food Studies. 6: 44-55.

Otemuyiwa, I.O. and Aina A.F. 2021. Physicochemical properties and in-vitro digestibility studies of microwave-assisted chemically modified breadfruit (Artocarpus altilis) starch. International Journal of Food Properties. 24: 140-151.

Oyeyinka, S.A., Umaru, E., Olatunde, S.J., and Joseph, J.K. 2019. Effect of short microwave heating time in the physicochemical and functional properties of Bambara groundnut starch. Food Bioscience. 28: 36–41.

Sajilata, M.G., Singhal, R.S., and Kulkarni, P.R. 2006. Resistant starch - A review. Comprehensive Reviews Food Science and Food Safety. 5: 1-17.

Sánchez-Rivera, M.M., Almanza-Benitez, S., Bello-Perez, L.A., Mendez-Montealvo, G., Núnez-Santiago, M.C., Rodriguez-Ambriz, S.L., and Gutierrez-Meráz, F. 2013. Acetylation of banana (Musa paradisiaca L.) and corn (Zea mays L.) starches using a microwave heating procedure and iodine as a catalyst: II. Rheological and structural studies. Carbohydrate Polymers. 93: 1256-1261.

Sumardiono, S., Budiarti, G., and Kusmiyati. 2018. Conversion of cassava starch to produce glucose and fructose by enzymatic process using microwave heating. In 24th Regional Symposium on Chemical Engineering (RSCE 2017). 156: 01024.

Thuengtung, S., Matsushita, Y., and Ogawa, Y. 2019. Comparison between microwave-cooking and steam-cooking on starch properties and in vitro starch digestibility of cooked pigmented rice. Journal of Food Process Engineering. 12: e13150.

Wallace, C.B., Lajeunesse, J.M., Dietz, G., Dahabreh, J.I., Trikalinos, A.T., Schmid, H.C., and Gurevitch, J. 2017. OpenMEE: Intuitive, Open-Source Software for Meta-Analysis in Ecology and Evolutionary Biology. Methods in Ecology and Evolution. 8: 941-947.

Wang, L. and Bai, X. 2017. The Producing Technology of Resistant Starch (RS) from Buckwheat Using Microwave Treatment. Sustainability in Environment. 2: 301-308.

Wang, M., Sun, M., Zhang, Y., Chen, Y., Wu, Y., and Ouyang, J. 2019. Effect of microwave irradiation-retrogradation treatment on the digestive and physicochemical properties of starches with different crystallinity. Food Chemistry. 298: 125015.

Wang, R. Y., Ji, X., Lu, P., Liu, M. X., Xu, Y., Wang, L., and Qiao, Z.J. 2017. Analysis of genetic diversity in common millet (Panicum miliaceum) using fluorescent SSR in China. Acta Agronomica Sinica. 43: 530–548.

Wang, R., Wang, H., Liu, X., Ji, X., Chen, L., Lu, P., and Qiao, Z. 2018. Waxy allelic diversity in common millet (Panicum miliaceum L.) in China. Crop Journal. 6: 377–385.

Wei, H., Liang, B., Chai, Y., Xue, L., Wang, X., and Yin, X. 2020. Effect of different heat treatments on physicochemical properties and structural and digestibility of water caltrop starch. Starch – Stärke. 72: 1900275.

Wu, C., Sun, R., Zhang, Q., and Zhong, G. 2020. Synthesis and characterization of citric acid esterified canna starch (RS4) by semi-dry method using vacuum-microwave-infrared assistance. Carbohydrate Polymers. 250: 116985.

Xie, Y., Yan, M., Yuan, S., Sun, S., and Huo, Q. 2013. Effect of microwave treatment on the physicochemical properties of potato starch granules. Chemistry Central Journal. 7: 1–7.

Yang, Q., Qi, L., Luo, Z., Kong, X., Xiao, Z., Wang, P., and Peng, X. 2017. Effect of microwave irradiation on internal molecular structure and physical properties of waxy maize starch. Food Hydrocolloids. 69: 473–482.

Zabar, S., Shimoni, E., and Bianco-Peled, H. 2008. Development of Nanostructure in Resistant Starch Type III During Thermal Treatments and Cycling. Macromolecular Bioscience. 8: 163-170.

Zailani, M. A., Kamilah, H., Husaini, A., and Sarbini, S.R. 2021. Physicochemical properties of microwave heated sago (Metroxylon sagu) starch. CyTA-Journal of Food. 19: 596-605.

Zailani, M.A., Kamilah, H., Husaini, A., Seruji, A.Z.E.A., and Sarbini, S.R. 2022. Functional and digestibility properties of sago (Metroxylon sagu) starch modified by microwave heat treatment. Food Hydrocolloids. 122: 107042.

Zeng, S.X., Chen, B.Y., Zeng, H.L., Guo, Z.B., Lu, X., and Zhang, Y. 2016. Effect of microwave irradiation on the physicochemical and digestive properties of lotus seed starch. Journal of Agricultural & Food Chemistry. 64: 2442–2449.

Zhang, J., Chen, F., Lui, F., and Wang, Z. 2010. Study on structural changes of microwave heat-moisture treated resistant Canna edulis Ker starch during digestion in vitro. Food Hydrocolloids. 24: 27-34.

Zheng, M., Xiao, Y., Yang, S., Liu, H., Liu, M., Yaqoob, S., Xu, X., and Liu, J. 2019. Effects of heat–moisture, autoclaving, and microwave treatments on physicochemical properties of proso millet starch. Food Science & Nutrition. 8: 735-743.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand

https://cmuj.cmu.ac.th

Muhammad Isra1, Dimas Andrianto1 and R. Haryo Bimo Setiarto2,*

1 Department of Biochemistry, IPB University, Bogor, 16680, Indonesia

2 Research Center for Biology, National Research and Innovation Agency (BRIN) Jl. Raya Jakarta-Bogor Km 46, Cibinong Science Center, Bogor, 16911, West Java, Indonesia.

Corresponding author: R. Haryo Bimo Setiarto, E-mail: haryobimo88@gmail.com

Total Article Views

Editor: Veerasak Punyapornwithaya,

Chiang Mai University, Thailand

Article history:

Received: January 16, 2022;

Revised: March 5, 2022;

Accepted: March 7, 2022;

Published online: March 8, 2022