Reduction of Insertion Torque on Orthodontic Mini-screw Implant by means of Reduced Friction

Chavin Jongwannasiri, Taksid Charasseangpaisarn*, Shuichi WatanabePublished Date : 2021-04-01

DOI : https://doi.org/10.12982/CMUJNS.2021.060

Journal Issues : Number 3, July-September 2021

Abstract In this article, the reduction of insertion torque on the orthodontic mini-screw implants (OMI) was studied. Three types of diamond-like carbon (DLC) films (DLC, Si-DLC, and F-DLC) were deposited on the OMIs by plasma-based ion implantation technique. The maximum insertion torque (MIT) value was measured using a physiodispenser during insertion on a mandibular pig jaw. Ten OMIs of each condition were used to evaluate the MIT values compared to the Ti-6Al-4V typed OMI. The statistical analysis of data was analyzed by One-way analysis of variance (ANOVA) and Tukey HSD. The results indicated that the Ti-6Al-4V showed the highest MIT but not significantly different from the F-DLC (P >0.05). DLC and Si-DLC showed a significant reduction in MIT comparing to the Ti-6Al-4V (P <0.05). However, the Si-DLC showed the lowest MIT among groups (P <0.05). This phenomenon was due to the decreasing friction coefficient during OMI's insertion on a mandibular pig jaw. Therefore, the DLC coating, especially Si-DLC, could reduce the MIT value of OMI. It is thought that the lowering friction coefficient yields the lowering of MIT value.

Keywords: Diamond-like carbon, Friction, Insertion torque, Mini-screw implant

Funding: The authors declare that there is no research funding for this article.

Citation: Jongwannasiri, C., Charasseangpaisarn, T., and Watanabe, S. 2021. Reduction of insertion torque on orthodontic mini-screw implant by means of reduced friction. CMUJ. Nat. Sci. 20(3): e2021060.

INTRODUCTION

Over the past few decades, commercially pure titanium (cp Ti) is widely used in the aspect of orthodontic mini-screw implants (OMIs) owing to its good mechanical and biological properties (Aparicio et al., 2003; Latysh et al., 2006). However, cp Ti has lower fatigue strength than that of titanium alloys. Ti-6Al-4V can be used to overcome this limitation (Latysh et al., 2006; Hanawa, 2004). Nevertheless, one of the factors affecting OMI's stability is the excessive torques applied during the insertion into the bone. The excessive torques can cause necrosis around the bone and hinder osseointegration (Büchter et al., 2005; Serra et al., 2008). Therefore, it is necessary to know what a certain level of maximum insertion torque (MIT) value is suitable for physiology to assure these implants' stability. MIT is measured from frictional resistance between the OMI and bone during the insertion and is defined in Newton centimeters (Ncm). To achieve osseointegration, a degree of implant stability that occurs after insertion should be considered. This final result is associated with two terms, namely, primary and secondary implant stability. The former is a mechanical stabilization immediately after insertion, while the latter results from new bone-forming at the implant interface (Hembree et al., 2009). To fulfill primary stability, a certain MIT level is essential to understand (Ivanoff et al., 1996; Motoyoshi et al., 2006).

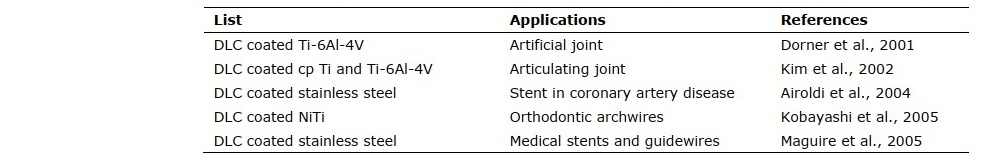

To decrease the frictional resistance and to accomplish the initial stability, surface modification is one of the best ways to solve this problem. Diamond-like carbon (DLC) has been vastly studied as protective coatings for many tribological applications (Robertson, 2002). Such examples related to DLC coated biomaterials for medical and tribological applications are given in Table 1. Moreover, both silicon- and fluorine- incorporated DLCs have shown their outstanding tribological properties, presenting a very low friction coefficient (Park et al., 2004; Rubio-Roy et al., 2009). Thus, DLC coatings on the OMIs may be an effective method to reduce MIT. We set the hypothesis that the lower friction coefficient generating between the OMI and bone surfaces yields the lower MIT during the insertion. Therefore, three types of DLC coating, namely DLC, Si-DLC, and F-DLC, were deposited on OMIs. A previous study showed that the Si-DLC and F-DLC films deposited at a gas flow rate ratio of 2:1 had shown the lower friction coefficients among all the compositions of DLCs (Jongwannasiri et al., 2019b). Consequently, both of them were selected to study in this experiment.

This study aimed to identify the effect of reduced friction on OMI's insertion torque in a mandibular pig jaw.

Table 1. Examples of DLC coated biomaterials for medical and tribological applications.

MATERIALS AND METHODS

Surface coating of OMI

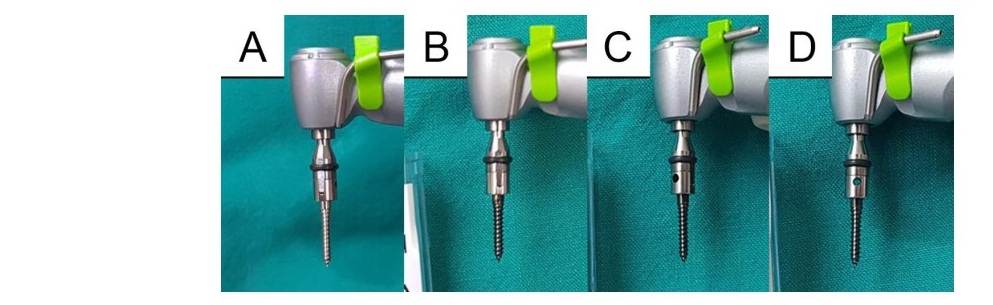

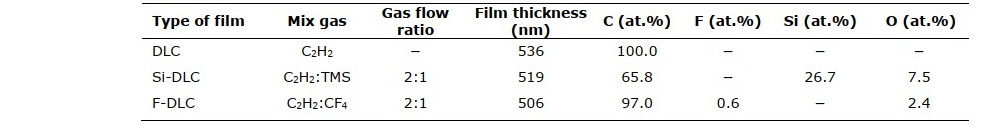

The plasma-based ion implantation (PBII) technique was used in this experiment. A schematic diagram of the apparatus and details of the sample preparation were previously described in the literature (Jongwannasiri et al., 2016). The DLC, Si-DLC, and F-DLC films were deposited on an OMI (Ti-6Al-4V, conical shape, ∅1.8 mm and 10 mm in length, OSSTEM IMPLANT Co., Ltd.) by utilizing a gases mixtures containing acetylene (C2H2), tetramethylsilane (Si(CH3)4 or TMS) and carbon tetrafluoride (CF4) in a vacuum chamber using the parameters shown in Table 2. A negative-pulsed bias voltage of 5 kV was used for the deposition, and the total thickness of each film is shown in Table 2. The deposition pressure was also set to 2 Pa. After the deposition, the films’ relative atomic content was measured by Auger electron spectroscopy (JAMP-7800F). The details of film compositions are shown in Table 2. The characters of OMIs after the deposition are also shown in Figure 1.

Figure 1. The characters of OMIs in the control group (A), after surface coating with DLC (B), Si-DLC (C), and F-DLC (D).

Insertion torque measurement

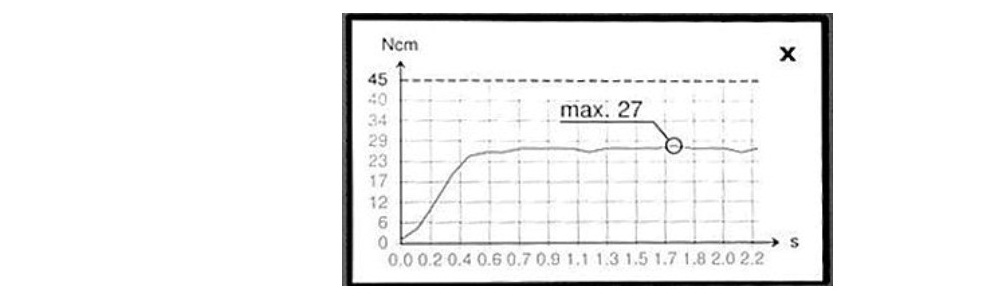

In this study, we used ten OMIs of each condition to evaluate the MIT values during the insertion on a mandibular pig jaw. An experimental study was based on the mandibular pig jaw of an already dead animal. There is no killing of the animal in this experiment, and the mandibular pig jaws were supplied from a butcher (slaughterhouse waste). The MIT values of the OMIs were measured using a physiodispenser (Implantmed, W&H Dentalwerk Bürmoos GmbH, Austria), as shown in Figure 2. MIT was automatically measured and shown in the graph on the physiodispenser, as shown in Figure 3. All MIT values were recorded. The data was also analyzed by One-way ANOVA and Tukey HSD at 95% confidence level with SPSS Statistics software version 22.0 (IBM Corp., Chicago, IL).

Figure 2. The physiodispenser, which shows the torque values digitally.

Figure 3. An example of recorded insertion torque when it reaches the maximum value.

Table 2. The parameter and relative atomic content of carbon, fluorine, silicon, and oxygen in the films.

RESULTS

Effect of surface coating on maximum insertion torque

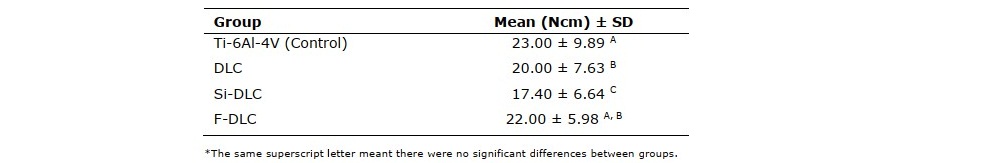

Three types of DLC coated OMIs were tested in the pig's mandible to obtain the MIT values compared to the Ti-6Al-4V (Control). The results showed that the MIT values of those DLCs coated OMIs were lower than that of Ti-6Al-4V, especially the Si-DLC coating (Table 3). For the statistical analysis, 1-Komolgorov smirnov test was performed and showed the normal distribution in each group. The Levene test also showed the variance between groups but was not significantly different. Thus, One-way ANOVA and Tukey HSD were performed and showed that mean insertion torque was significantly different between groups, as shown in Table 3. The control group showed the highest MIT values but no difference from the F-DLC group (P >0.05). The DLC and F-DLC group showed no significantly different MIT values (P >0.05). However, the Si-DLC group showed the significantly lowest MIT values among groups (P <0.05).

Table 3. Mean insertion torque and standard deviation of each group.

DISCUSSION

As mentioned in the introduction, the Si and F doped DLC films (at a ratio of 2:1) were the best condition of each element incorporation. All of them possessed lower friction coefficients than the others. Besides, Si and F doped DLC films exhibited excellent biocompatibility because there was no difference in L929 fibroblast cells' viability (approximate 90 - 110%) between groups comparing to Ti-6Al-4V and DLC (Jongwannasiri et al., 2019a). There was no implication that DLC films were dissolved to the L929 fibroblast or osteoblast-like cells because there was no loss of cell integrity due to the film coating (Jongwannasiri et al., 2012; Bendavid et al., 2007; Randeniya et al., 2009). Those are the reasons why we chose two of them for coatings on OMIs to evaluate the MIT values during the insertion on a mandibular pig jaw.

The previous study reported that DLC, Si-DLC, and F-DLC films' friction coefficients were 0.18, 0.03, and 0.16, respectively (Jongwannasiri et al., 2019b). The decreasing friction coefficient of the F-DLC film was due to the formation of repulsive forces with F atoms. Repulsive forces reduce the shear strength of the contact, causing a weaker lateral friction force, thus lowering the friction coefficient (Zhang et al., 2015). However, the friction coefficient of F-DLC was slightly lower than that of DLC. Thus, MIT values of both DLC and F-DLC coated OMIs showed no statistically significant difference between the two groups. Moreover, a very low friction coefficient of Si-DLC film was attributed to the formation of silica-gel-like layers between the contact surfaces, generating the low friction coefficient (Oguri et al., 1991, 1992). Therefore, the MIT values of Si-DLC coated OMIs presented statistically significant differences among groups. These MIT values are consistent with the results of two findings (Lim et al., 2008; Giri et al., 2020).

In this study, the MIT obtained from animal bones was 17-23 Ncm. On the contrary, the insertion torque value derived from human bones was lower than mentioned above. An insertion torque value from 5 to 10 Ncm is acceptable for the stability of the self-tapping type suggested by Motoyoshi et al., (2006). They also reported an instability or screw breakage because excessive insertion torque can cause necrosis between the bone and implant interfaces. However, the high MIT value in this experiment was concerned with the type of screw insertion (self-drilling type) and the animal bone's physical characteristics, which differ from the human bone.

Further studies need to be carried out with a large number of OMIs inserting into the human bones. It will gain a better understanding of the effect of DLC coated OMIs. Moreover, long-term studies are also required to investigate the osseointegration and integrity of DLC coated OMIs in clinical research.

CONCLUSION

Three types of coating, namely DLC, Si-DLC, and F-DLC, were successfully deposited on OMIs using the PBII technique. The different DLCs coated OMIs were investigated to determine the MIT values during the insertion on the mandibular pig jaw, comparing to the Ti-6Al-4V typed OMIs. At least 23 Ncm of MIT value is required to insert the Ti-6Al-4V implants on the mandibular pig jaw. After modifying implants by DLC coatings, the required MIT value has reduced, especially Si-DLC coated OMIs that showed the lowest MIT value of approximately 17.5 Ncm. This behavior was due to the reduced friction mechanism of DLC films. This finding is consistent with our hypothesis that the decreasing friction coefficient exhibited the lowering of MIT value. Therefore, DLC coatings can be considered to be beneficial in prolonging the performance of OMIs.

ACKNOWLEDGEMENTS

The authors thank College of Dental Medicine, Rangsit University for providing instruments.

AUTHOR CONTRIBUTIONS

Chavin Jongwannasiri assisted in designed and conducted the experiments and wrote the manuscript. Taksid Charasseangpaisarn designed and conducted all of the experiments, performed the statistical analysis, data visualization and wrote the manuscript. Shuichi Watanabe assisted in conducting the experiments and wrote the manuscript. All authors have read and approved of the final manuscript.

CONFLICT OF INTEREST

The authors declare that they hold no competing interests.

REFERENCES

Airoldi, F., Colombo, A., Tavano, D., Stankovic, G., Klugmann, S., Paolillo, V., Bonizzoni, E., Briguori, C., Carlino, M., Montorfano, M., et al. 2004. Comparison of diamond-like carbon-coated stents versus uncoated stainless steel stents in coronary artery disease. Am J Cardiol. 93: 474-477.

Aparicio, C., Gil, F.J., Fonseca, C., Barbosa, M., and Planell, J.A. 2003. Corrosion behavior of commercially pure titanium shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials. 24: 263-273.

Bendavid, A., Martin, P.J., Comte, C., Preston, E.W., Haq, A.J., Magdon Ismail, F.S., and Singh, R.K. 2007. The mechanical and biocompatibility properties of DLC- Si films prepared by pulsed DC plasma activated chemical vapor deposition. Diam Relat Mater. 16: 1616-1622.

Büchter, A., Wiechmann, D., Koerdt, S., Wiesmann, H.P., Piffko, J., and Meyer, U. 2005. Load-related implant reaction of mini-implants used for orthodontic anchorage. Clin Oral Implants Res. 16: 473-479.

Dorner, A., Schürer, C., Reisel, G., Irmer, G., Seidel, O., and Müller, E. 2001. Diamond- like carbon-coated Ti6Al4V: influence of the coating thickness on the structure and the abrasive wear resistance. Wear. 249: 489-497.

Giri, M., Sabapathy, K., Govindasamy, B., and Rajamurugan, H. 2020. Evaluation of insertion torque and surface integrity of zirconia-coated titanium mini screw implants. J World Fed Orthod. 9: 13-17.

Hanawa, T. 2004. Metal ion release from metal implants. Mater Sci Eng C. 24: 745- 752.

Hembree, M., Buschang, P.H., Carrillo, R., Spears, R., and Rossouw, P.E. 2009. Effects of intentional damage of the roots and surrounding structures with miniscrew implants. Am J Orthod Dentofacial Orthop. 135: e281-289.

Ivanoff, C.J., Sennerby, L., and Lekholm, U. 1996. Influence of initial implant mobility on the integration of titanium implants. An experimental study in rabbits. Clin Oral Implants Res. 7: 120-127.

Jongwannasiri, C. and Watanabe, S. 2016. Tribological behavior of O2 and CF4 plasma post-treated diamond-like carbon films under dry air and in a high relative humidity environment. Surf Coat Technol. 306: 200-204.

Jongwannasiri, C., Charasseangpaisarn, T., and Watanabe, S. 2019a. Preliminary testing for reduction of insertion torque of orthodontic mini-screw implant using diamond-like carbon films. J Phys Conf Ser. 1380: 012062.

Jongwannasiri, C., Moolsradoo, M., Khantachawana, A., Kaewtatip, P., and Watanabe, S. 2012. The Comparison of Biocompatibility Properties between Ti Alloys and Fluorinated Diamond-Like Carbon Films. Adv Mater Sci Eng. 2012: 1-8.

Jongwannasiri, C., Yoshida, S., and Watanabe, S. 2019b. Effects of fluorine and silicon incorporation on tribological performance of diamond-like carbon films. Materials Sciences and Applications. 10: 170-185.

Kim, DH., Kim, HE., Lee, KR., Whang, CN., and Lee, IS. 2002. Characterization of diamond-like carbon films deposited on commercially pure Ti and Ti–6Al–4V. Mater Sci Eng C. 22: 9-14.

Kobayashi, S., Ohgoe, Y., Ozeki, K., Sato, K., Sumiya, T., Hirakuri, KK., and Aoki, H. 2005. Diamond-like carbon coatings on orthodontic archwires. Diam Relat Mater. 14: 1094-1097.

Latysh, V., Krallics, G., Alexandrov, I. and Fodor, A. 2006. Application of bulk nanostructured materials in medicine. Curr Appl Phys. 6: 262-266.

Lim, S.A., Cha, J.Y., and Hwang, C.J. 2008. Insertion torque of orthodontic miniscrews according to changes in shape, diameter and length. Angle Orthod. 78: 234- 240.

Maguire, PD., McLaughlin, JA., Okpalugo, TIT., Lemoine, P., Papakonstantinou, P., McAdams, ET., Needham, M., Ogwu, AA., Ball, M., and Abbas, GA. 2005. Mechanical stability, corrosion performance and bioresponse of amorphous diamond-like carbon for medical stents and guidewires. Diam Relat Mater. 14: 1277-1288.

Motoyoshi, M., Hirabayashi, M., Uemura, M., and Shimizu, N. 2006. Recommended placement torque when tightening an orthodontic mini-implant. Clin Oral Implants Res. 17: 109-114.

Oguri, K. and Arai, T. 1991. Tribological properties and characterization of diamond- like carbon coatings with silicon prepared by plasma-assisted chemical vapour deposition. Surf Coat Technol. 47: 710-721.

Oguri, K. and Arai, T. 1992. Two different low friction mechanisms of diamond-like carbon with silicon coatings formed by plasma-assisted chemical vapor deposition. J Mater Res. 7: 1313-1316.

Park, S.J., Lee, K.R., and Ko, D.H. 2004. Tribochemical reaction of hydrogenated diamond-like carbon films: a clue to understand the environmental dependence. Tribol Int. 37:913-921.

Randeniya, L.K., Bendavid, A., Martin, P.J., Amin, Md.S., Preston, E.W., Magdon Ismail, F.S., and Coe, S. 2009. Incorporation of Si and SiOx into diamond-like carbon films: Impact on surface properties and osteoblast adhesion. Acta Biomater. 5: 1791-1797.

Robertson, J. 2002. Diamond-like amorphous carbon. Mater Sci Eng R. 37: 129-281. Rubio-Roy, M., Corbella, C., Bertran, E., Portal, S., Polo, M.C., Pascual, E., and Andújar, J.L. 2009. Effects of environmental conditions on fluorinated diamond- like carbon tribology. Diam Relat Mater. 18: 923-926.

Serra, G., Morais, L.S., Elias, C.N., Meyers, M.A., Andrade, L., Muller, C., and Muller, M. 2008. Sequential bone healing of immediately loaded mini-implants. Am J Orthod Dentofacial Orthop. 134: 44-52.

Zhang, L., Wang, F., Qiang, L., Gao, K., Zhang, B. and Zhang, J. 2015. Recent RSC Adv. 5: 9635-9649.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand https://cmuj.cmu.ac.th

Chavin Jongwannasiri1, Taksid Charasseangpaisarn2,*, Shuichi Watanabe3

1 Faculty of Medicine and Public Health, HRH Princess Chulabhorn College of Medical Science, Chulabhorn Royal Academy, Bangkok 10210, Thailand

2 Department of Prosthodontics, College of Dental Medicine, Rangsit University, Pathum Thani 12000, Thailand

3 Department of Applied Chemistry, Faculty of Fundamental Engineering, Nippon Institute of Technology, Saitama 345-8501, Japan

Corresponding author: Taksid Charasseangpaisarn, E-mail: taksid.c@rsu.ac.th

Total Article Views

Editor: Korakot Nganvongpanit, Chiang Mai University, Thailand

Article history:

Received: December 29, 2020;

Revised: February 5, 2021;

Accepted: February 8, 2021;

Published online: March 18, 2021