Effect of Foam-Mat Drying Conditions on Antioxidant Activity, Total Phenolic Compound, Anthocyanin Content and Color of Purple-Fleshed Sweet Potato Powder

Nattakan Jakkranuhwat* and Patcharee KunchansombatPublished Date : 2021-04-01

DOI : https://doi.org/10.12982/CMUJNS.2021.045

Journal Issues : Number 2, April-June 2021

Abstract This research was aimed to study chemical properties (antioxidant activity, total phenolic compound and anthocyanin content) and color of foam-mat dried purple-fleshed sweet potato powder affected by 2 drying methods (tray drying and vacuum drying) and 3 drying temperatures (50, 60 and 70°C). The foaming process of purple-fleshed sweet potato used carboxymethyl cellulose (1%) mixed with hydroxy propylcellulose (1%) as a foaming agent. The results showed that different drying methods and temperatures affected qualities of foam-mat dried purple-fleshed sweet potato powder significantly (P <0.05). Vacuum drying method at 70°C showed antioxidant activity, total phenolic compound and anthocyanin content in foam-mat vacuum-dried powder than tray- dried one at 70°C. The results also showed that increasing temperature led to an increase in anthocyanins and antioxidant activities of the samples (P <0.05) because low oxygen and drying time condition could avoid the oxidation reaction. Therefore, their low phytochemical content loss during vacuum drying could be considered from the high intense of purple color (low b* value). Results of this study suggested that foam-mat drying by vacuum method at 70°C could retain higher quality of purple-fleshed sweet potato powder, in terms of phytochemical content as well as antioxidant capacities. This study has indicated that, under the experimental conditions, obtain for highly nutrition powder characteristics and applying for food ingredients.

Keywords: Antioxidant activity; Anthocyanin content; Foam-mat drying; Purple-fleshed sweet potato powder; Total phenolic compound

Funding: The authors wish to thank the King Mongkut’s University of Technology North Bangkok. The contract no. KMUTNB-62-NEW-12 for financial support.

Citation: Jakkranuhwat, N. and Kunchansombat, P. 2021. Effect of foam-mat drying conditions on antioxidant activity, total phenolic compound, anthocyanin content and color of purple-fleshed sweet potato powder. CMUJ. Nat. Sci. 20(2): e2021045.

INTRODUCTION

Sweet potato (Ipomoea batatas) is an excellent source of ß-carotene, vitamins (B1, B2, C and E), dietary fiber, minerals and polysaccharides that may provide special health benefits. Purple-fleshed sweet potato contains enriched anthocyanin and high stability during cooking (Suda et al., 2003; Kano et al., 2005) when compared with white or orange-fleshed sweet potato. Anthocyanins are phenolic compounds responsible for the red, blue and purple color of fruits and vegetables such as red grapes, blueberries and purple-fleshed sweet potatoes (Khoo et al., 2017). The several food processing such as juice concentration and powder could add value and extend shelf-life for purple-fleshed sweet potatoes. Moreover, the phytochemical content of purple-fleshed sweet potatoes has been found to change under thermal processing. Foam mat drying is new drying technique and alternative method for preventing the nutritional compound and resulting dried powders, which allows the dehydration under low temperature and short drying time to maintaining the product quality with convert liquid or semi-solid food to stable foam by cooperation with foaming agents or stabilizing agents (Franco et al., 2015). The porous foam structure and the large surface area exposed to the drying air and the mass transfer rates increasable, leading to short dehydration and therefore a dried product with higher quality. Moreover, there has been no reported study on foam-mat drying technique applied to purple-fleshed sweet potato. Thus, the objective of this study was to determine the foam-mat by 2 drying method on quality of purple-fleshed sweet potato.

MATERIALS AND METHODS

Materials

Purple-fleshed sweet potato puree. Purple-fleshed sweet potato (Ipomoea batatas) was obtained from fresh market at Prachinburi province and transported to Faculty of Agro-Industry, King Mongkut's University of Technology North Bangkok- Prachinburi Campus, Thailand. Purple-fleshed sweet potato were washed with clean water, streamed for 30 minute and chopped into small pieces. The small sample were blended with water at a ratio of 1:1.5 (%w/v) for 1 minute to obtain purple-fleshed sweet potato puree.

Foaming agent. Carboxymethyl cellulose (CMC) mixed with hydroxypropyl methylcellulose (HPMC) with the mixing ratio of two substances (a mix ratio by weight of 1:1, dissolving in water to receive the concentration of 1% by weight), which were used as the foaming agent.

Foamed purple-fleshed sweet potato. The foam agent was added to the purple-fleshed sweet potato puree at a ratio of 2:1 (% by weight). The purple-fleshed sweet potato puree with foaming agent were whipped in a mixer (KitchenAid USA.) at a maximum speed of 294 rpm for 30 minute. Foamed purple-fleshed sweet potato puree was spread uniformly into 20x30x0.3 cm (length x width x thickness) on an aluminum tray.

Effect of drying method and drying time on quality of purple- fleshed sweet potato powder

The foamed purple-fleshed sweet potato puree was dehydrated by two methods: tray drying (50, 60 and 70°C) and vacuum drying (50, 60 and 70°C at 70 mbar). The moisture content at the designated intervals was determined until the moisture of the sample was below 10%. Then, all dried purple-fleshed sweet potato samples were ground and sieved (100 mesh) to obtain fine powder. Each foam-mat dried powder was packed into aluminum foil bags under vacuum condition and stored at a temperature of under -18°C for further analysis.

Purple-fleshed sweet potato powder quality

Moisture content. The moisture content was determined according to the method of AOAC (2012). The 3 g of sample, which was heated at 105 ± 3 °C in a hot air oven (Memmert, England) for a minimum of 14 h or until the heated sample reached a constant weight (Toan and Anh, 2018). The amount of water in the sample was then calculated using following equations for:

Moisture (%wet basis) = (M1-M2) / M1 (1)

Where M1 = weight (g) of sample before drying and M2 = weight (g) of sample after drying

Total phenolic compound. Total phenolic compound were performed by the methods involving Folin-Ciocalteu reagent (Singleton et al. (1999) with slight modification. The 400 μl of extracts solution was mixed with 200 μl of Folin- Ciocalteu reagent. After 4 min, 5% of Na2CO3 in 600 μl was added, vortexed for 1 min and incubated in dark for 30 min at room temperature. Absorbance was measured at 765 nm. The content of total phenolic compounds was expressed as mg of gallic acid equivalents per g dry matter (mg GAE. g-1DM)

Antioxidant activity. 2,2-Diphenyl-1-picrylhydrazyl (DPPH) radical scavenging capacity was used to determine antioxidant activity. DPPH were determined by the slightly modified method of Brand-Williams et al. (1995). The 600μl of 0.8mM DPPH solution in ethanol was mixed with 5,200 µL of extract solution (5 g foam-mat dried purple-fleshed sweet potato powder added in 20 ml ethanol), vortexed for 1 min and incubated in dark for 30 min at room temperature. Absorbance was measured at 517 nm. The antioxidant activity were expressed as Trolox equivalent (mg trolox/100g sample).

Anthocyanin content. Anthocyanin content according to the method described by Abdel-Aal and Hucl (1999). The 2 g foam-mat dried purple-fleshed sweet potato powder were extracted with 20 ml methanol acidified with 1.0 N HCl (85:15, v/v) and shake on a shaker at 1 °C for 15 min, the supernatants were collected. The 2 ml solution and its absorbance were measured at 535nm wavelength using a spectrophotometer. Calculate anthocyanin concentration, expressed as cyanidin-3-5- diglucoside equivalents, as follows:

C = (A/ε) x (Vol/1.000)×MW×(1/sample weight) x 10g6 (2)

Where C = concentration of total anthocyanin (mg/kg); A = reading of absorbance; e = molar absorptivity (cyanidin 3-5-diglucoside = 25.965 L/mol); Vol = total volume of anthocyanin extract in 50 ml flask and MW = the weight of the molecules of cyanidin 3-5-diglucoside (449)

Color measurement. Color was determined by using a Hunter Lab Colorflex EZ colorimeter (Hunter Associates Laboratory, Inc., USA). The results were expressed as Hunter color values of L* (lightness), a* (redness and greenness), and b* (yellowness and blueness), were used to calculate total Chroma (C*) and hue angle (h°) by using the following equations.

C* = (a*2 + b*2)1/2 (3)

h° = tan-1 (b*/a*) (4)

Statistical analysis

The data were reported as the means and standard error of triplicate measurements. Statistical analyses were carried out with Duncan’s multiple test (P <0.05) using SPSS V.25 software for window (SPSS Institute Inc., Chicago, USA).

RESULTS

Effect of Foam-mat Drying Condition on Quality of Purple- Fleshed Sweet Potato Powder

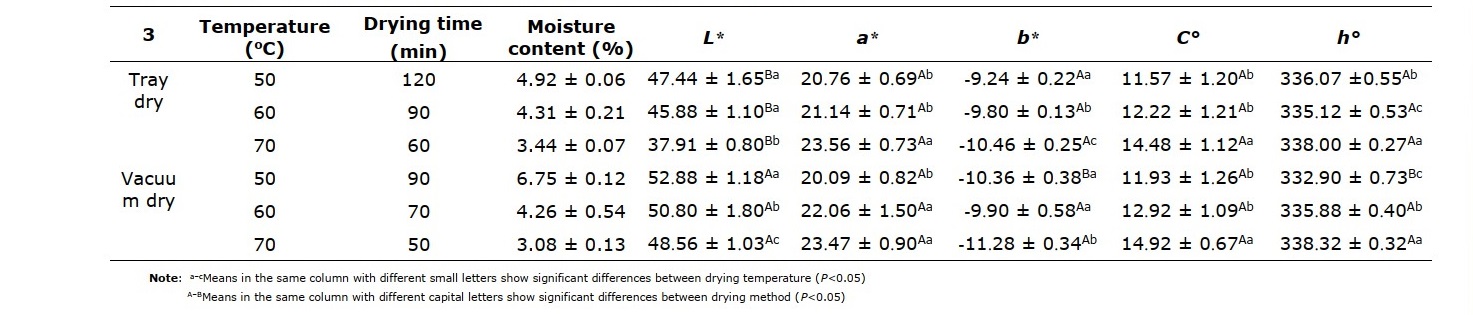

The moisture contents of foam-mat dried purple-fleshed sweet potato powder were indicated in table 1. For tray drying, the moisture content of samples was 4.92 ± 0.06 %, 4.31 ± 0.21 % and 3.44 ± 0.07 % at 50, 60 and 70°C, respectively (the moisture content of sample below 10%). While the moisture content of the vacuum-dried sample decreased with the increased temperature (the moisture content of dried sample was 6.75 ± 0.12 %, 4.26 ± 0.54 % and 3.08 ± 0.13 % at 50, 60 and 70°C, respectively).

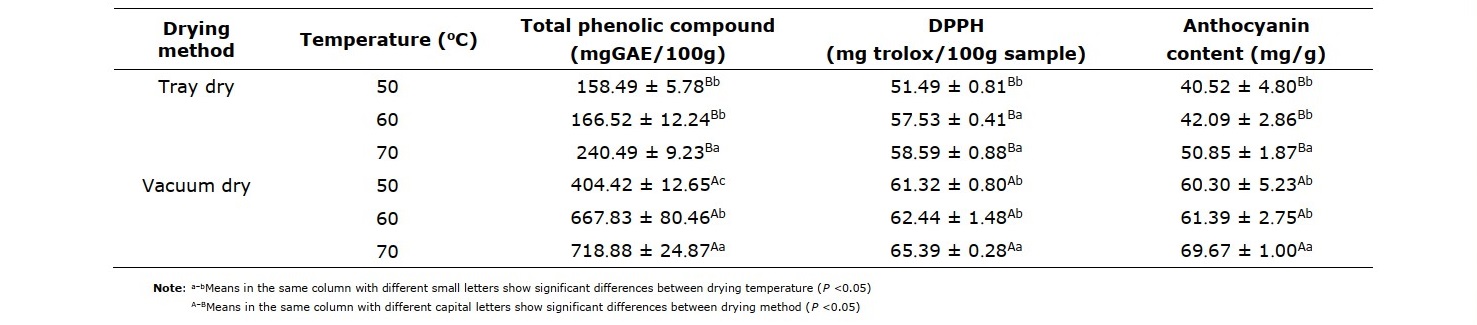

In table 2 showed the drying method affected chemical quality of foam-mat dried purple-fleshed sweet potato powder significantly (P <0.05). The total phenolic compound of vacuum-dried powders higher retained when compared with tray-dried sample (total phenolic content were obtained between 158.49 to 240.49 mg GAE/100 g for vacuum drying method and between 404.42 to 718.88 mg GAE/100 g for tray drying method).

The foam-mat dried purple-fleshed sweet potato powder were showed the phenolic compound correlates with antioxidant activity. In table 2, the foam-mat drying methods and drying temperatures affected DPPH radical scavenging of purple-fleshed sweet potato powder (P <0.05). The highest antioxidant activities found in the foam- mat dried purple-fleshed sweet potato powder by vacuum drying method at 70°C (antioxidant activity was 65.39 ± 0.28 mg trolox/100g sample) and samples were dried by tray drying at 50°C shows lowest antioxidant activity (51.49 ± 0.81 mg trolox/100g sample). Moreover, the antioxidant activity of samples was increased when drying temperature increase which DPPH of purple-fleshed sweet potato powder report value ranged from 51.49 to 61.32 mg trolox/100g sample, 57.53 to 62.44 mg trolox/100g sample and 58.59 to 65.39 mg trolox/100g sample at 50, 60 and 70°C, respectively.

Results showed that the anthocyanin content of purple-fleshed sweet potato powder was significantly increased (P <0.05) at foam-mat vacuum drying and high drying temperature condition. Vacuum drying can preserve anthocyanin of foam-mat dried powder better than tray drying (the anthocyanin content ranged from 40.52 mg/g to 50.85 mg/g and 60.30 mg/g to 69.67 mg/g for tray-dried and vacuum-dried samples, respectively). In addition, this experimental shows the anthocyanin content was increased when drying temperature increased (table 2).

Color in fruits is related to pigment content, the values and rates of color obtained are presented in table 1. The results of L* a* and b* were influenced by drying methods and drying temperatures (P <0.05). For drying method, the intensity of purple color of foam-mat dried purple-fleshed sweet potato powder by vacuum dry were higher than that of tray-dried samples (low b* and high a*). However, all foam-mat dried sample showed a purple shade color as indicated by the hue angle values (°h). This was the result of higher anthocyanin retention in vacuum-dried fleshed sweet potato powder as presented by an increase in negative (-) b* value and higher °h.

Table 1. Moisture content and color of purple-fleshed sweet potato powder.

Table 2. Total phenolic content antioxidant activities and anthocyanin content of purple-fleshed sweet potato powder.

DISCUSSIONS

This study reports both tray drying and vacuum drying seem to have similar influence on the purple-fleshed sweet potato powder. During vacuum drying, evaporation rate of the liquid increases and as the boiling point of water is reduced. In addition, the rate of heat transfer to the particles is greater at high temperatures. The driving force for moisture evaporation increased (Kelly et al., 2014; Aeimsard et al., 2015), thereby the moisture content was decreasing rapidly in increased temperature which reduced the drying time. The drying behavior of the purple-fleshed sweet potato powder in this study was according to Supakarn et al. (2018) who showed the vacuum drying tended to increase the equilibrium moisture content of Shiitake mushrooms and the relative humidity as the drying temperature decreased including the drying temperature decreased, the equilibrium moisture content increased.

Foam-mat drying is one of the rapid drying method at low temperature which the transformation of liquid material to stable foam by adding foaming agent, which enhances the quality of purple-fleshed sweet potato powder. Higher drying temperatures brought about higher degradation of phenolic compounds. Vacuum drying has more total phenolic compound retention that may arise from lower drying temperature and higher drying rate (Ozcan-sinir et al., 2019), resulting in reduced boiling point of water. Moreover, loss of total phenolic during oven-drying may be attributed to enzymatic processes by polyphenol oxidases (Lim and Murtijaya, 2007). Mbondo et al. (2018) reported that phenolic content of African eggplant decreased to 35% and 56% in the samples dried at 50°C in vacuum-drying and oven-drying, respectively. In addition, total phenolic content of the foam-mat dried purple-fleshed sweet potato powder significantly increased (P <0.05) with the increased drying temperature. This result can be explained by the heat treatment damage cell structures of sweet potato flesh tissues and resulted in more easy extraction of phenolic constituents (Ruttarattanamongkol et al., 2016). Moreover, foam-mat technique increased the drying rate significantly and could prevent the oxidative and thermal degradation of the phenolic compounds according to Naknaen et al. (2016) who showed the phenolic content of foam-mat dried banana powders decreased when compared with unfoam-mat dried sample.

The results of high antioxidant activities found in the foam-mat dried purple- fleshed sweet potato powder by vacuum drying suggest that the vacuum condition may allow water to evaporate at lower temperatures and the absence of oxygen in the environment helps to reduce potential oxidation resulting in the preservation of antioxidant components (Rabeta and Lai, 2013). Moreover, the antioxidant activity of samples was increased when temperature increase which DPPH of purple-fleshed sweet potato powder. Accordingly, Madrau et al. (2010) who reported that antioxidant activities of prunes (Prunus domestica L.) obtained from drying at 85°C were significantly higher than those at 60 °C. It demonstrated that high drying temperature might affect the oxidation reaction inactive (such as browning reaction) (Carvalho et al., 2017).

Anthocyanins are phenolic compounds and the natural pigments in plant foods, have been associated with antioxidant activity. There are unstable compounds and are easily degraded during thermal treatment. Zhou et al. (2017) suggested vacuum drying could preserve cyaniding 3-O-glucoside and cyaniding 3-O-rutinoside (the major anthocyanin found in most of the plants) in mulberry because they are more sensitive to heat. In addition, this experimental results indicated that increment in the anthocyanin content was related to the high temperature and short processing time, this may possibly be due to a combination with foam-mat technique in raise to the loss of moisture rates during drying. Studies conducted by Abbasi and Azizpour (2016) on anthocyanin content of cherry dried reported that total anthocyanin content of foam- mat dried sour cherry dried at 65°C (drying time 230 min) was considerably higher than that at 50°C (drying time 165 min). This was because decreasing drying time resulted in a lower anthocyanin degradation.

The results of chemical qualities of purple-fleshed sweet potato powder could explain in color term. The cyanidin-based anthocyanin pigment contributed to the blue and red hues of purple-fleshed sweet potatoes (Truong et al., 2010). Ruttarattanamongkol et al. (2016) indicated that the change in color values of purple- fleshed sweet potato flour after drying is consistent with associated higher phenolic and anthocyanin content. According to Firgianti et al. (2019), purple-fleshed sweet potato flour should have a low level of lightness and yellowness because the desired quality of product is deep purple color.

CONCLUSION

Foam-mat drying conditions showed a significantly effect on changes the total phenolic compound, antioxidant activity, anthocyanin content and color property of purple-fleshed sweet potato powder. The dehydration under low temperature and short drying time to maintain the phytochemical of dried powder. The optimum drying condition was vacuum drying and tray drying at 70°C, which retains the quality property for foam-mat purple-fleshed sweet potato powder.

ACKNOWLEDGEMENTS

The authors would like to thank Boonyakorn Boonyathan, Peerapol Jongjinakul and Sukanya Sangsukdee for their technical assistance in this study. The authors thank also Faculty of Agro-Industry, King Mongkut's University of Technology North Bangkok for providing instruments. The authors report no conflicts of interest.

REFERENCES

Abdel-Aal, E.S.M. and Hucl, P. 1999. A rapid method for quantifying total anthocyanins in blue aleuone and purple pericarp wheats. Cereal chemistry. 76: 350-354.

Abbasi, E. and Azizpour, M. 2016. Evaluation of physicochemical properties of foam mat dried sour cherry powder. LWT-Food Science and Technology. 68: 105-110.

AOAC. 2012. Official Methods of Analysis. 19th ed. Gaithersburg, Md: Association of Official Analytical Chemists.

Aeimsard, R., Thumthanaruk, B., Jumnongpon, R., and Lekhavat, S. 2015. Effect of drying on total phenolic compounds, antioxidant activities and physical properties of palm sugar. Journal of Food Science and Agricultural Technology. 1: 126-130

Brand Williams W., Cuvelier, M.E., and Berset C. 1995. Use of a free radical method to evaluate antioxidant activity. Food Science and Technology. 28: 25-30.

Carvalho, T.I.M.D., Nogueira, T.Y.K., Mauro, M.A., Gómez-Alonso, S., Eleni, G., Roberto, D.S., Hermosín-Gutiérrez, I., and Ellen, S.L.V. 2017. Dehydration of jambolan [Syzygium cumini (L.)] juice during foam mat drying: Quantitative and qualitative changes of the phenolic compounds. Food Research International. 108: 32-42.

Firgianti, G., Sunyoto, M., and Nurhadi, B. 2019. The effect of size reduction and steaming duration on the characteristics of purple sweet potato as the initial process of annealing flour making. International Journal of Food Science and Nutrition. 4: 26-31.

Franco, T.S., Perussello, C.A., Ellendersen, L.D.S.N., and Masson, M.L. 2015. Foam mat drying of yacon juice: Experimental analysis and computer simulation. Journal of Food Engineering. 158: 48-57.

Kano, M., Takayanagi, T., Harada, K., Makino, K. and Ishikawa, F. 2005. Antioxidative activity of anthocyanins from purple sweet potato, Ipomoera batatas cultivar ayamurasaki. Bioscience, Biotechnology, and Biochemistry. 69: 979-988.

Kelly, G. M., O’Mahony, J.A., Kelly, A.L. and o’Callaghan, D.J. 2014. Physical characteristics of spray-dried dairy powders containing different vegetable oils. Journal of Food Engineering. 122: 122-129.

Khoo, H.E., Azlan, A., Tang, S.T., and Lim, S.M. 2017. Anthocyanidins and anthocyanins: colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food and Nutrition Research. 61: 1361779.

Lim, Y.Y. and Murtijaya, J. 2007. Antioxidant properties of Phyllanthus amarus extracts as affected by different drying methods. LWT-Food Science and Technology. 40: 1664-1669.

Madrau, M.A., Sanguinetti, A.M., Caro, A.D., Fadda, C., and Piga, A. 2010. Contribution of melanoidins to the antioxidant activity of prunes. Journal of Food Quality. 33: 155–170.

Mbondo, N.N., Owino, W.O., Ambuko, J., and Sila, D.N. 2018. Effect of drying methods on the retention of bioactive compounds in African eggplant. Food Science & Nutrition. 6: 814–823

Naknaen, P., Charoenthaikij, P., and Kerdsup, P. 2016. Physicochemical properties and nutritional compositions of foamed banana powders (Pisang Awak, Musa sapientum L.) dehydrated by various drying methods. Walailak Journal of Science and Technology. 13: 177-191.

Ozcan-sinir, G., Ozkan-karabacak, A., Tamer, C.E., and Copur, O.U. 2019. The effect of hot air, vacuum and microwave drying on drying characteristics, rehydration capacity, color, total phenolic content and antioxidant capacity of Kumquat (Citrus japonica). Food Science and Technology. 39: 475-784.

Rabeta, M.S. and Lai, S.Y. 2013. Effects of drying, fermented and unfermented tea of Ocimum tenuiflorum Linn. on the antioxidant capacity. International Food Research Journal. 20: 1601-1608.

Ruttarattanamongkol, K., Chittrakorn, S., Weerawatanakorn, M., and Dangpium, N. 2016. Effect of drying conditions on properties, pigments and antioxidant activity retentions of pretreated orange and purple-fleshed sweet potato flours. Journal of Food Science and Technology. 53: 1811-1822.

Singleton, V.L., Orthofer, Orthofer, R., and Lamuela-Raventós, R.M. 1999. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin- Ciocalteu reagent. Methods in Enzymology. 299: 152-178.

Suda, I., Oki, T., Masuda, M., Kobayashi, M., Nishiba, Y., and Furuta, S. 2003. Physiological functionality of purple-fleshed sweet potatoes containing anthocyanins and their utilization in foods. Japan Agricultural Research Quarterly. 37: 167-173.

Supakarn, S., Theerakulpisut, S. and Artnaseaw, A. 2018. Equilibrium moisture content and thin layer drying model of shiitake mushrooms using a vacuum heat-pump dryer. Chiang Mai University Journal of Natural Sciences. 17: 1-12.

Toan N.V. and Anh, N.V.Q. 2018. Preparation and improved quality production of flour and the made biscuits from purple sweet potato. Journal of Food and Nutrition Research. 4: 1-14.

Truong, V.H., Deighton, N., Thompson, R.T., McFeeters, R.F., Dean, L.O., Pecota, K.V. and Yencho, G.C. 2010. Characterization of anthocyanins and anthocyanidins in purple-fleshed sweetpotatoes by HPLCDAD/ ESI-MS/MS. Journal of Agricultural and Food Chemistry. 58:404–410.

Zhou, M., Chen, Q., Bi, J., Wang, Y. and Wu, X. 2017. Degradation kinetics of cyanidin 3-O-glucoside and cyanidin 3-Orutinoside during hot air and vacuum drying in mulberry (Morus alba L.) fruit: A comparative study based on solid food system. Food Chemistry. 229: 574-579.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand https://cmuj.cmu.ac.th

Nattakan Jakkranuhwat* and Patcharee Kunchansombat

Department of Agro-Industry Technology and Management, Faculty of Agro-Industry, King Mongkut's University of Technology North Bangkok (Prachinburi Campus), Prachinburi 25230, Thailand

Corresponding author: Nattakan Jakkranuhwat, E-mail: nattakan.c@agro.kmutnb.ac.th

Total Article Views

Editor: Wasu Pathom-aree,

Chiang Mai University, Thailand

Article history:

Received: May 12, 2020;

Revised: July 1, 2020;

Accepted: October 12, 2020