Physicochemical and Nutritional Properties of Nixtamalized Quality Protein Maize Flour and its Potential as Substitute in Philippine Salt Bread

Dianne Jane A. Sunico*, Felicito M. Rodriguez, Arvin Paul P. Tuaño, Lotis E. Mopera, Liezl M. Atienza, and Clarissa B. JuanicoPublished Date : 2021-04-01

DOI : https://doi.org/10.12982/CMUJNS.2021.035

Journal Issues : Number 2, April-June 2021

Abstract Nixtamalization is an ancient method of processing corn that is said to enhance the nutritional value of maize by improving protein quality, increasing calcium and niacin bioavailability, and reducing phytic acid levels, thus increasing iron digestibility and biovailability. The main objective of this study was to determine the effect of different nixtamalization processes on the physicochemical and nutritional properties of quality protein maize (QPM) flour and evaluate its potential and acceptability as a flour substitute in Philippine salt bread baking, determined through sensory analysis. Three processes of nixtamalization were employed, namely, traditional, classic, and ecological. Nixtamalized QPM flours, combined with wheat flour in 30:70 ratio, were used in the product development and sensory evaluation of Philippine salt bread. Results revealed that nixtamalization contributed significantly in the pH, color, and particle size of nixtamalized QPM flours. There was a significant increase (P ≤0.05) in the moisture, crude protein, crude fiber, crude ash, calcium, iron, niacin, lysine, tryptophan, total starch, amylose, amylopectin, resistant starch, and soluble fiber contents and a significant decrease in the crude fat, nitrogen-free extract (NFE), phytate, and insoluble fiber contents of QPM flours after nixtamalization. No significant difference was found in the zinc and total dietary fiber contents among the samples. The Philippine salt bread produced using nixtamalized QPM flours had a high overall acceptability based on two-step sensory analysis. QPM is greatly improved by the ancient technology of nixtamalization and nixtamalized QPM flour showed desirable contributions in terms of the nutritional value and sensory attributes of Philippine salt bread when used as a flour substitute or blend.

Keywords: Flour, Nixtamalization, Nutritional value, Philippine salt bread, Physicochemical properties, Quality protein maize.

Funding: This research was supported by grants provided by the Department of Science and Technology Accelerated Science and Technology Human Resource Development Program (DOST- ASTHRDP) scholarship and the Department of Agriculture-Bureau of Agricultural Research (DA-BAR).

Citation: Sunico, D.J.A., Rodriguez, F.M., Tuaño, A.P.P., Mopera, L.E., Atienza, L.M., and Juanico, C.B. 2021.Physicochemical and nutritional properties of nixtamalized quality protein maize flour and its potential as substitute in philippine salt bread. CMUJ. Nat. Sci. 20(2): e2021035.

INTRODUCTION

For centuries, corn, or more technically accepted as maize (Salazar et al., 2016), has been known as a very important crop and is widely consumed in the Philippines alongside rice (Gerpacio et al., 2004). Not only eaten as an alternative to rice, corn is even considered as the major staple in some parts of the country such as in Visayas and Mindanao according to Labios et al. (2016). Unfortunately, solely consuming corn as principal part of the diet has been partnered with issues of malnutrition, particularly in children (Katz et al., 1974; Maya-Cortes et al., 2010). Still, it cannot be denied that corn being a major staple did not pose any threat in providing proper nutrition in other countries, such as in Mexico (Wacher, 2003). Thus, it has been hypothesized that there must be a difference in the way corn is normally consumed or prepared in the Philippines as compared to other countries which might be the reason why Filipinos have not yet maximized the full nutritional potential and benefited from consumption of Philippine corn.

Nixtamalization, a well-known pre-treatment technique in the tortilla industry, is an ancient method of processing corn and is widely used in various countries around the world, especially in Central America (Wacher, 2003). This process is said to enhance the nutritional value of maize by improving protein quality, increasing calcium and niacin bioavailability, and reducing phytic acid levels, thus also increasing iron digestibility and biovailability (Suri and Tanumihardjo, 2016). According to Wacher (2003), cooking maize in alkaline solution softens the kernels and alters its grain structure, thereby releasing bound nutrients to make them more available for use by the body upon consumption. To date, there are three types of nixtamalization processes being used, namely, traditional, classic, and ecological. Lime or calcium hydroxide is used in the traditional method as alkali source whereas wood ash and calcium salts are used for the classic and ecological methods, respectively. Different effects on the various nutritional contents of maize can be observed depending on the nixtamalization process employed (Pappa et al., 2010; Campechano-Carrera et al., 2012; Bello Perez et al., 2015; Mariscal-Moreno et al., 2015).

Quality protein maize (QPM) contains the opaque-2 gene which has caused significant advances in the agronomic performance and nutritional superiority of maize (Prassana et al., 2001). This has been adapted by plant breeders in the Philippines which has led to the development of a white flint-type corn variety with highly acceptable grit quality called IPB var 6, released in 2006. It is a high-yielding maize variety in the country which possesses improved nutritional value as compared to the other corn varieties with typical protein quality (Magpantay et al., 2014; Salazar et al., 2016; Labios et al., 2016). It also contains high amounts of tryptophan and lysine which may be further enhanced during nixtamalization (Trejo-Gonzales et al., 1982; Suri and Tanumihardjo, 2016). Moreover, its attributes, having hard endosperm texture and clean white color, suits the preferences of processors on the type of corn ideal for use in nixtamalization (Rooney and Suhendro, 1999).

Philippine salt bread, more locally known as pan de sal, is the most popular bread in the Philippines. It is highly accepted and widely consumed in any time of the day by most Filipinos (Cabalda et al., 2009). Wheat flour is typically used in the production of pan de sal. However, to increase food crops utilization and decrease food losses in the Philippines, wheat flour is being substituted or blended with many other agricultural crops as flour source (e.g. sweet potato and saba banana) in producing pan de sal (Lizardo et al., 2017). QPM is also being incorporated in composite flours to supplement wheat flour for bread preparation due to its ability to be transformed into edible products without deterioration in terms of quality and acceptability (Magpantay et. al., 2014; Tandzi et al., 2017). On the other hand, the use of nixtamalized maize flour in other countries is increasingly becoming popular due to its convenience and significant nutritional contributions (Serna-Saldivar, 2016). Hence, utilization of nixtamalized maize flour from QPM as partial substitute for wheat flour may yield pan de sal with improved nutritive value and unique yet acceptable sensory quality. The main objective of the study was to determine the effect of different nixtamalization processes on the physicochemical and nutritional properties of QPM (Zea mays L. cv. IPB var 6) flour and its potential as substitute in Philippine salt bread (pan de sal).

MATERIALS AND METHODS

Materials

Quality Protein Maize (QPM) (Zea mays L. cv. IPB var 6) was obtained from the Institute of Plant Breeding, College of Agriculture and Food Science, University of the Philippines Los Baños in 2018. Samples were stored at freezer temperature (-10°C to 0°C) prior to use in nixtamalization, food preparation, and further analyses. Calcium hydroxide [Ca(OH)2] (powder, USP, FCC, J.T.Baker), calcium carbonate (CaCO3) (powder, USP, FCC, J.T.Baker), and wood ash from mango tree wood were used as alkali sources for nixtamalization. The mango tree wood was obtained from a local barangay near the university and prepared in the laboratory to produce wood ash.

Nixtamalization methods

Traditional nixtamalization. The traditional method was adapted from the procedure used by Campechano-Carrera et al. (2012) with some modifications. One kilogram of maize was cooked with two liters of distilled water with 1.0% (w/w) of calcium hydroxide at 94°C for 30 minutes. The cooked grains were steeped in the same solution for 16 hours at room temperature before the cooking liquor (nejayote) was decanted (Bello-Perez et al., 2015; Mariscal-Moreno et al., 2015; 2017).

Classic nixtamalization. The method used by Pappa et al. (2010) and Mariscal Moreno et al. (2015; 2017) for classic nixtamalization was followed with some modifications. One kilogram of maize was cooked with four liters of distilled water containing 1% (w/w) wood ash at 94°C for 60 minutes. The cooked grains were steeped in the same solution for 16 hours at room temperature before the cooking liquor (nejayote) was decanted.

Ecological nixtamalization. The new method patented by Figueroa et al. (2013) (Patent Mex PA⁄a⁄2005⁄011797) was followed for ecological nixtamalization with some modifications. Lime was replaced with calcium carbonate as solute in the alkaline solution. One kilogram of maize was cooked at 94°C for 30 minutes with two liters of distilled water having 1% (w/w) calcium carbonate. The cooked grains were steeped in the same solution for 16 hours at room temperature. The pericarp-free cooking water/liquor (nejayote) was decanted and separated from the grains.

Production of nixtamalized QPM flour

Each resulting nixtamal from the different nixtamalization processes employed above were dried in a cabinet oven-drier at 50-55°C overnight until the maize kernels were dry enough (i.e. having <10% moisture) to be ground into flour using a multi- functional high-speed disintegrator. Ground nixtamalized maize were passed through a 0.5 mm (80 mesh) sieve, packed in polyethylene bags, and stored at 4°C until use (Rodriguez-Mendez et al., 2013; Das et al., 2016). Dry-milled maize flour of same variety was used as non-nixtamalized control instead of wet-milled maize flour since it is already commercially available at the same source of QPM raw materials and have been previously used in making pan de sal. A total of four types of QPM flour, namely, from traditional nixtamalization process (TNP), classic nixtamalization process (CNP), ecological nixtamalization process (ENP), and non-nixtamalized (NN) flour were produced and subjected to physicochemical and nutritional properties analyses.

Physicochemical properties determination

pH. The pH values were determined using a pH meter (Sartorious pH Bio Kit) initially calibrated at room temperature with three different standard buffers (J.T. Baker standard buffers pH 4, pH 7, pH 10). A 5-g sample of corn flour was placed in a beaker containing 45 ml distilled water and stirred to form a slurry. The pH electrode was immersed in the suspension and pH readings were taken in three replicate samples.

Color. Colorimetric measurements of the dry flour samples were conducted using a chromameter CR-410 (Minolta Camera Co Ltd, Osaka, Japan). The instrument was initially calibrated with a standard white tile and psychrometric color terms L (lightness) and b (yellowness-to-blueness) were recorded. Samples were individually placed in the granular attachment and three color readings for each flour sample were obtained to minimize surface color differences (Afoakwa and Aidoo, 2006).

Particle size distribution. Percent pass through was determined using the Particle Size Retsch AS200 equipment. The instrument was pre-weighed and operating conditions were set. The pan and the sieves (80-mesh, 100-mesh, 120-mesh) were weighed and placed into the instrument. Fifty grams of each flour sample were weighed, placed on the top sieve, and sieved for 5 minutes. Each sieve was reweighed and percent pass through was calculated. Particle size distribution determination was done in triplicates.

Nutritional properties determination

Proximate composition. The moisture content of nixtamalized maize flours was measured using oven-drying method. Crude fat content was measured using the Soxhlet apparatus and protein content was analyzed via the Kjeldahl method using a conversion factor of 6.25 for cereals. The amount of crude fiber was determined by sequential acid and base extraction and the ash content was determined with the use of a high temperature muffle furnace. Nitrogen-free extract (NFE) or carbohydrate content was estimated by the difference of the % moisture, % crude fat, % crude protein, % crude fiber, and % ash from 100%. All analyses were performed in triplicates (AOAC, 2010).

Minerals, niacin, essential amino acids, and phytate. Flour samples for mineral analysis were prepared through dry-ashing and analyzed for calcium, iron, and zinc contents using atomic absorption spectroscopy as described in AOAC method 968.08 (1998) (Fernandez-Muñoz et al., 2002; Maya-Cortes et al., 2010). Analysis of niacin content was done through high-performance liquid chromatography (HPLC) using a C18 column and UV detection at 264 nm. Lysine and tryptophan contents were analyzed using protein hydrolysis and colorimetric assays at 390 nm and 545 nm, respectively (Opienska-Blauth et al., 1963). Phytate content was determined by colorimetric Wade reagent method read at 500 nm as described in the AOAC (1980).

Carbohydrate profile. Total starch content was analyzed using the anthrone method while analysis of amylose content was done colorimetrically based on amylose- iodine complex formation (Hoover and Ratnayake, 2001). Percent amylopectin was determined by subtracting % amylose from % total starch. Resistant starch was quantified using the K-RSTAR resistant starch assay kit (Megazyme International Ireland, Wicklow A98 YV29) based on AOAC Method 2002.02 (Mariscal Moreno et al., 2015; 2017; Santiago-Ramos et al., 2015; 2017). The soluble and insoluble dietary fiber (DF) contents were determined using K-TDFR total dietary fiber assay kit from Megazyme based on AACC method 32-05.01 and AOAC Method 985.29. Total DF was calculated from the sum of soluble DF and insoluble DF. All analyses were performed in triplicates.

Preparation of Philippine salt bread (pan de sal)

Flour mixtures were prepared by substituting wheat flour with nixtamalized and non-nixtamalized maize flours at 70:30 wheat-to-QPM flour ratio based on the results of Magpantay et al. (2014) in the production of pan de sal using QPM of the same variety (IPB var 6) in which the 70:30 wheat-to-corn ratio was found to have the highest corn flour proportion that is acceptable to consumers. Philippine salt bread was prepared in a local bakery in Los Baños, Laguna with a reference formulation of 200 g sugar, 8 g salt, 25 g yeast, 100 g lard, 1 kg flour blend, and 500 ml water. The dry ingredients were weighed and manually mixed to form the dough. The dough was kneaded until gluten was fully developed and then set aside for 20-30 minutes. Then, the dough was cut into portions approximately weighing 35-40 g per piece and then rounded and rolled on bread crumbs. Cut dough samples were put in baking trays, set aside for 1-1.5 hours to give a final proof, and baked at 175-180°C for 10-12 minutes. Finished products were removed from the oven and were placed in a cooling rack.

Sensory evaluation

Two separate sensory analyses were conducted for this study: descriptive test and consumer acceptability test. In the quantitative descriptive test, fifteen trained panelists were gathered to evaluate the quality attributes of the Philippine salt bread samples ( Heymann et al., 2012). The panelists were composed of male and female graduate students and university staff with ages ranging from 18-60 years old (Bibat et al., 2014). Sensory attributes evaluated were appearance, corn aroma, texture, corn flavor, mouthfeel, and overall acceptability using a modified sensory evaluation score sheet based on a 9-point hedonic scale. The following continuum was used in the interpretation of data for overall acceptability: 8.10–9.00 Liked extremely, 7.20–8.09 Liked very much, 6.30–7.19 Liked moderately, 5.40–6.29 Liked slightly 4.50–5.39, Neither like nor dislike, 3.60–4.49 Disliked slightly, 2.70–3.59 Disliked moderately, 1.80–2.69 Disliked very much, and 0.90–1.79 Disliked extremely (Mabesa, 1986). Five samples of pan de sal with different flour blends in 30:70 ratio were evaluated, i.e., TNP:wheat flour, CNP:wheat flour, ENP:wheat flour, NN:wheat flour, and pure wheat flour (control). Warm pan de sal pieces were served to the sensory panelists alongside water to cleanse the palate before evaluating the next samples. This sensory test was carried out in the sensory laboratory of the Institute of Food Science and Technology, College of Agriculture and Food Science, UP Los Baños.

On the other hand, 100 panelists of different age groups were included in the conduct of the consumer acceptability test following the procedure of Lawless and Heymann (2010). Only the Philippine salt bread formulation with the highest acceptability based on the preceding descriptive sensory test was evaluated. This sensory test was conducted among consumers within the University of the Philippines Los Baños campus. Ethics clearance for the study was approved by the University of San Agustin Research Ethics Review Committee with validity until May 26, 2020.

Statistical analysis

Data obtained from the physicochemical and nutritional properties analyses of nixtamalized maize flours and sensory evaluation of Philippine salt bread were subjected to analysis of variance (ANOVA) at 5% level of significance. Fisher-LSD and Tukey’s HSD statistical tests were used as post-hoc statistical treatments. All operations were performed on R version 3.5.3 statistical software. Results were expressed as mean value ± standard deviation (Fox and Leanage, 2016).

RESULTS

Physicochemical properties of nixtamalized QPM flour

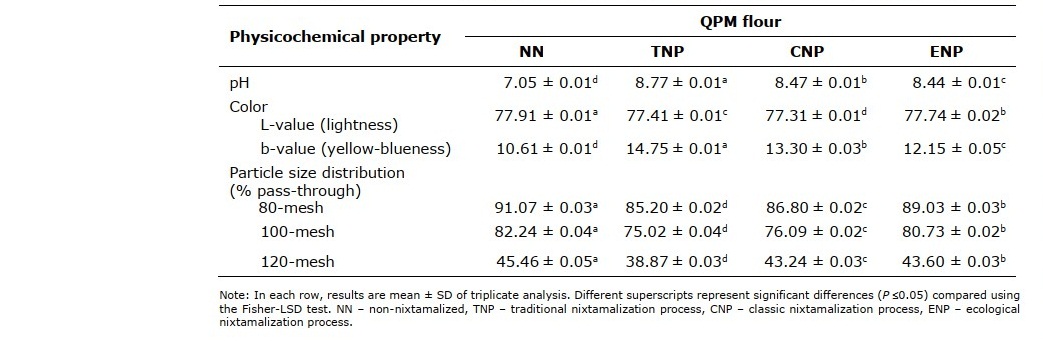

Table 1 shows the values for some physicochemical properties of the different nixtamalized and the non-nixtamalized QPM flours. A general observation is that significant differences can be found among samples in all of the properties listed below at P ≤ 0.05. QPM exhibited an alkaline pH after nixtamalization. The TNP flour had the most basic pH among the samples (8.77 ± 0.01) followed by CNP flour (8.47 ± 0.01) and then ENP flour (8.44 ± 0.01). Nixtamalization has been shown to add color to the QPM flours with significant differences in the L-value (lightness). The highest value for L among the nixtamalized flours analyzed was observed in ENP flour (77.74 ± 0.02) followed by TNP flour (77.41 ± 0.01) and CNP flour (77.31 ± 0.01).The b-value representing “yellowness to blueness” was highest in TNP (14.75 ± 0.01) followed by CNP (13.30 ± 0.03), and ENP (12.15 ± 0.05). Meanwhile, particle size distribution was evaluated by determining the % pass-through. TNP flour was found to have the lowest percent yield after passing through 80, 100, and 120-mesh (85.20 ± 0.02, 75.02 ± 0.04, 38.87 ± 0.03, respectively). It can be deduced that all flour samples complied with the general granulometry standard in which 75% of the flour must pass through a 60-mesh (250 mm) screen.

Table 1. Physicochemical properties of nixtamalized Quality Protein Maize (QPM) flours.

Proximate composition of nixtamalized QPM flours

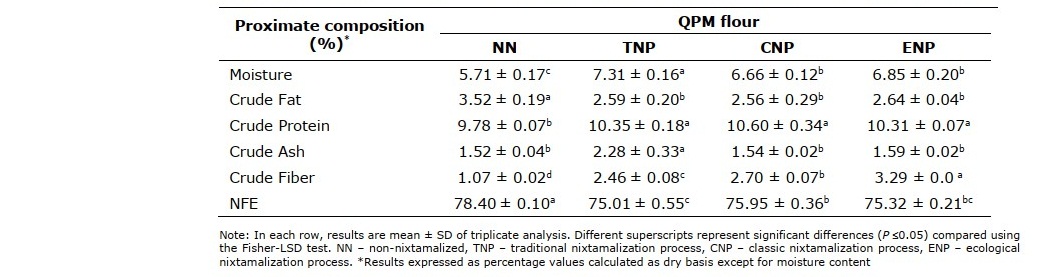

Nixtamalization caused a significant increase (P ≤0.05) in the moisture content of QPM flour as shown in Table 2. Among all the samples, TNP flour had the highest moisture content (7.31 ± 0.16%) followed by ENP flour (6.85 ± 0.20%) and CNP flour (6.66 ± 0.12%). The moisture content of all the flour samples did not exceed 15% and thus, may be considered as good quality flour (Ozola et al., 2012). Also, nixtamalization significantly decreased (P ≤0.05) the crude fat and NFE contents and significantly increased (P ≤0.05) the crude protein and crude fiber contents of the QPM flours. ENP flour had the highest crude fiber content (3.29 ± 0.06%), followed by CNP (2.70 ± 0.07%) and TNP flours (2.46 ± 0.08%), respectively. On the other hand, no significant differences (P ≤0.05) were found in the crude fat and crude protein contents among all nixtamalized flour samples. In addition, majority of the crude ash values were found to be similar with each other (P ≤0.05), with only the TNP flour having a significantly higher crude ash content (2.28 ± 0.33%).

Table 2. Proximate composition of nixtamalized Quality Protein Maize (QPM) flours.

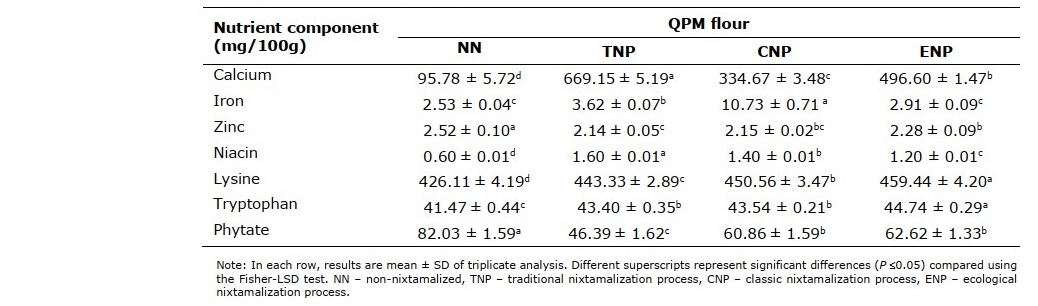

Minerals, niacin, essential amino acids, and phytate contents of nixtamalized QPM flours

After nixtamalization, the calcium content of the QPM flours had a highly significant increase (P ≤0.05) of up to 7 times the calcium content of non-nixtamalized flour counterpart as seen on Table 3. The calcium content of each nixtamalized flour sample was found to be significantly different (P ≤0.05) from each other. Among all the samples, the TNP flour was observed to have the highest calcium content followed by the ENP and CNP flours, respectively, due to their alkali sources. In addition, CNP flour had the highest iron content (10.73 ± 0.71 mg/100g) followed by TNP flour (3.62 ± 0.07 mg/100g) and ENP flour (2.91 ± 0.09 mg/100g). Iron contents differed significantly (P ≤0.05) among the three nixtamalized corn flour samples. However, the value for ENP was found to have no significant difference with that of the control. On the other hand, a significant decrease at P ≤0.05 was found in the zinc contents of the flours after nixtamalization with the TNP flour (2.14 ± 0.05 mg/100g) having the highest significant decrease followed by CNP (2.15 ± 0.02 mg/100g) and ENP flours (2.28 ± 0.09 mg/100g).

Table 3. Minerals, niacin, essential amino acids, and phytate contents of nixtamalized Quality Protein Maize (QPM) flours.

Niacin content (Table 3) increased significantly after nixtamalization of QPM and was found to be significantly different among all samples at P ≤0.05. Highest niacin increase was observed in TNP flour (1.6 ± 0.01 mg/100g) followed by CNP flour (1.4 ± 0.01 mg/100g) and ENP flour (1.2 ± 0.01 mg/100g). Moreover, nixtamalization processes caused a significant increase in the lysine and tryptophan contents of the QPM flours at P ≤0.05. The highest lysine and tryptophan contents were both found in the ENP flour followed by CNP and TNP flours. Results were also found to be significantly different from each other except for the CNP and TNP flour tryptophan levels. In contrast, statistical analysis revealed that QPM flour samples decreased significantly (P≤0.05) in terms of phytate content after the nixtamalization. The largest decrease was observed in TNP flour with ~43% decrease relative to the control, NN.

Carbohydrate profile of nixtamalized QPM flours

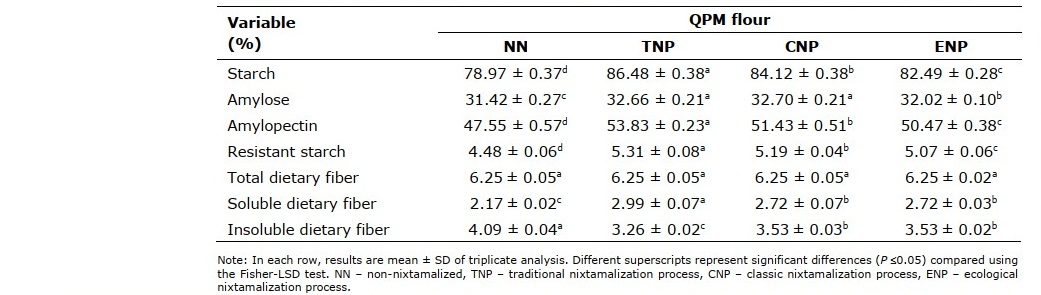

Statistical analysis revealed that total starch, amylose, amylopectin, and resistant starch contents of the QPM flours increased significantly (P ≤0.05) after nixtamalization as reported in Table 4, in which TNP flour had the highest total starch, amylopectin, and resistant starch contents followed by CNP and ENP flours, respectively. On the other hand, TNP and CNP flours did not significantly differ in amylose content.

Table 4. Carbohydrate profile of nixtamalized Quality Protein Maize (QPM) flours.

The soluble dietary fiber contents of QPM flours (Table 4) significantly increased (P ≤0.05) while the insoluble dietary fiber contents significantly decreased after nixtamalization. The highest soluble dietary fiber content (2.99 ± 0.07%) and insoluble dietary fiber content (3.26 ± 0.02%) were both observed in TNP flour, significantly higher than the other nixtamalized QPM flours. Nonetheless, the total dietary fiber contents did not differ significantly (P ≤0.05) between nixtamalized and non- nixtamalized QPM flours with values obtained consistently at around 6.25 ± 0.02%.

Sensory evaluation of Philippine salt bread produced using different nixtamalized QPM flour blends

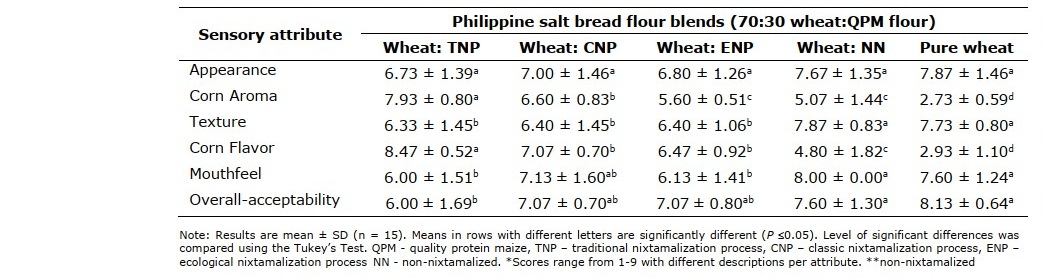

In the descriptive test, the appearance of the Philippine salt bread samples was evaluated based on the degree of likeness of its color, shape, and size of product (9- liked extremely, 1-disliked extremely). No significant difference was found in the degree of likeness in the appearance of the different pan de sal samples at P ≤0.05. Aroma was evaluated based on the extremity of perceived corn aroma in pan de sal (9-highly perceptible, 1-not perceptible). Based on the results, there has been a significant difference between sample scores at P ≤0.05. Corn aroma was highly perceptible in pan de sal made from wheat:TNP flour blend (7.93 ± 0.80) followed by that of wheat:CNP flour blend (6.60 ± 0.83), and that of wheat:ENP flour blend (5.60 ± 0.51) and wheat:NN flour blend (5.07 ± 1.44). Pan de sal made from pure wheat had a corn aroma perceptibility of low to none (2.73 ± 0.59). Same trend was found in the perceptibility of corn flavor having the same basis for evaluation with the corn aroma. Texture scores were determined based on the softness of pan de sal (9-extremely soft; 1-extremely firm). It can be deduced from the results that the pan de sal made from wheat:NN flour blend (7.87 ± 0.83) and pure wheat flour (7.73 ± 0.80) had significantly higher values for softness. Scores for mouth feel were determined on the basis of the texture of pan de sal in the mouth (9-extremely smooth, 1-extremely rough/grainy) in which the pan de sal made from wheat:NN flour blend obtained the highest score (8.00±0.00), however, not significantly different from that made from pure wheat flour and wheat:CNP flour pan de sal at P ≤0.05 (Table 5). On the other hand, pan de sal samples made using the different nixtamalized QPM flours proportioned with wheat flour were found to have statistically similar average scores from each other. The overall acceptability was evaluated based on the degree of likeness (9-liked extremely, 1-disliked extremely) of the overall quality of the pan de sal samples regardless of appearance, aroma, texture, flavor, and mouthfeel (Table 5). Although pan de sal produced using the conventional pure wheat flour still obtained the highest overall acceptability score (8.13 ± 0.64), pan de sal with CNP and ENP flours (7.07 ± 0.70, 7.07 ± 0.80, respectively) were found to have no significant difference (P ≤0.05) as compared with the pure wheat and wheat:NN pan de sal.

In terms of correlation, there was a high inverse relationship between the scores for overall-acceptability and corn aroma (r = -0.73, P ≤0.05) and corn flavor perceptibility (r = -0.86, P ≤0.05). Overall acceptability has a moderate correlation with mouthfeel (r = 0.66, P ≤0.05), texture (r = 0.59, P ≤0.05), and appearance (r = 0.50, P ≤0.05). Based on the results of overall acceptability, two types of pan de sal, namely, wheat:CNP and wheat:ENP flour proportions, were then subjected to consumer acceptability test.

Table 5. Comparison of the mean scores* for various sensory attributes and overall acceptability of Philippine salt bread (pan de sal) with different flour blends.

In the consumer acceptability test, the degree of likeness of each sample was evaluated using a 5-point hedonic scale (5-Like extremely, 1-Dislike extremely). Based on the statistical analysis (Fisher-LSD, P ≤0.05), the pan de sal with ENP flour had a significantly higher score of 4.57 ± 0.54 as compared to pan de sal with CNP flour having a score of 4.33 ± 0.74. Nevertheless, both samples can be considered acceptable by consumers since scores fell in the range “liked very much” (4.20-5.00).

DISCUSSION

The increase in pH is due to the alkaline solution in which the maize kernels were cooked. The lowest lightness value in the CNP flour may be associated to the wood ashes added in the cooking solution which imparted a slightly dark coloration. According to Serna-Saldivar (2016), the addition of lime or calcium hydroxide leads to a yellowish end-product which caused the increase in b-value of nixtamalized QPM flours especially for TNP. Also, flour particles tend to become thicker in surface area, hence the increase in particle size after nixtamalization. This is due to the accumulation of solids such as minerals coming from the alkali source, especially for the nixtamalized flour produced using the traditional process (Gutierrez-Cortez et al., 2013).

Increase in moisture content is due to the increase in water uptake upon soaking maize in alkaline solutions (Pappa et al., 2010, Campechano et al., 2012; Mariscal- Moreno et al., 2015). The authors noted that pH plays a role in water uptake through the destruction of the seed coat. These claims show correlation with the pH values presented above for the nixtamalized QPM flours in which it was determined that the TNP flour had a significantly higher pH compared to ENP and CNP flours. Moreover, increase in solute concentration from the alkali source may have also contributed to the increase in water uptake of the grains. On the other hand, it was hypothesized by Mariscal-Moreno et al. (2015) that the alkaline pH in the nixtamalized QPM flours hydrolyzed the lipid ester linkages and the free fatty acids were lost in the nejayote, hence the lower crude fat content. Lower levels of crude fat in flour can be beneficial in terms of prolonging its shelf life (Olaoye et al., 2007). In terms of crude protein, nixtamalization improved the protein content of maize compared to the initial grain which may be attributed to a concentration effect on nitrogen content (Rojas-Molina et al., 2008; Ocheme and Mikailu, 2011). Increase in ash content may be attributed to the alkali source used in cooking. Campechano et al. (2012) indicated that relatively higher ash losses in nejayote can be observed using the ecological nixtamalization process than the traditional process as observed in the present results. Lower values for crude fiber content of the TNP and CNP flours relative to ENP flour were due to the relatively less basic pH hence, a higher retention of the pericarp and external layers, which contain mainly fiber, of the maize grains in the ENP during cooking and steeping (Mariscal- Moreno et al., 2017).

Ash content is an index of the inorganic components of the sample. Higher percent crude ash indicated a higher mineral content of the nixtamalized QPM flours. Although, maize is generally not a good source of calcium, nixtamalization caused an increase in the calcium contents of the QPM flours attributed to the utilization of calcium salts in alkaline cooking (Bressani, et al., 2002). Calcium increase can also be associated with alkalinity increase since higher pH accelerates the removal of pericarp material, thereby promoting calcium interaction with the maize endosperm (Bressani et al., 2004; Rodríguez-Miranda et al., 2011). TNP flour showed a significantly higher crude ash content as compared to ENP flour which is mainly attributed to the calcium source used during alkaline-cooking (Pappa et al., 2010; Mariscal-Moreno et al., 2017). Both TNP and ENP used 1% (w/w) of alkali source but of different molecular weights: MW= 74 g/mol for calcium hydroxide and MW= 100 g/mol for calcium carbonate. Thus, already higher amounts of calcium were contained in the TNP alkaline solution as compared to ENP at the beginning of the process. CNP flour was found to have the least yet still significant increase in calcium content among the nixtamalized QPM flours which may be due to a lower level of calcium ions from wood ash. The endosperm is said to contain the majority of the iron in the maize kernel of about 76% while 18% in the germ (Bressani et al., 2002). Hence, there was an observed increase in iron concentration after the removal of pericarp during nixtamalization. Some studies reported that steeping for over five hours resulted in small but statistically significant losses in zinc and longer holding time of nixtamal may cause a loss of up to 11% of zinc as compared to initial content of the grain which may explain the results in this study for zinc content (Bressani et al., 2002; Morales and Zepeda, 2017).

According to the reviews of some authors (Wacher, 2003; Suri and Tanumihardjo, 2016), the amount of free niacin, which is usually found in the aleurone, germ, and endosperm, is said to increase after nixtamalization due to its release from bound form during the process. This explains the results in the study. It can be assumed that calcium hydroxide which is used in the traditional nixtamalization process is more effective in extracting the bound niacin to its free form as compared to wood ash and calcium carbonate. Calcium hydroxide has long been used to liberate niacin from cereals, meat, and other foods by alkaline digestion (Ward and Trenerry, 1997).

Moreover, aside from improving the protein content of maize due to increase in protein fraction, nixtamalization is also said to enhance its protein quality, hence the increase in lysine and tryptophan contents. Traditional nixtamalization has a more destructive effect on the maize kernels thereby causing the leaching out of proteins (Santiago-Ramos et al., 2015). In effect, higher amounts of amino acids may have been lost in the nejayote during traditional nixtamalization as compared with the classic and ecological processes.

On the other hand, the reduction in phytic acid content may be due to the degradation of phytic acid complexes by the enzyme phytase which is usually activated during soaking of maize in alkaline solution (Ocheme and Mikailu, 2011). It can be inferred from the results that lime or calcium hydroxide is more effective in reducing the phytic acid content of maize relative to wood ash and calcium carbonate. Differences may be due to the variation of the pH of the soaking solution or nejayote in which a more alkaline pH of 11.2 was found in calcium hydroxide solution whereas a pH of 8.6 and 8.4 was found in wood ash solution and calcium carbonate solution, respectively. In effect, the reduction in phytic acid levels may improve the bioavailability of calcium, iron, and zinc since it tends to form complexes with these minerals in the intestine (Bressani et al., 2004).

The starchy endosperm of maize is surrounded by the pericarp and a single layer of cells known as the aleurone layer (Scott and Emery, 2016). The pericarp and aleurone layer are both removed during nixtamalization process hence liberating the starchy endosperm and increasing the total starch content (Mariscal-Moreno et al., 2015). Since both the pericarp and the aleurone layer are rich in fiber (Scott and Emery, 2016), reported high contents of crude fiber may be an indication that the pericarp and aleurone layer of maize have not been completely removed which yielded lower starch concentrations. This observation is supported by the values reported for crude fiber in which higher contents were found in ENP than in CNP and TNP. The variations on the obtained starch levels for TNP, CNP, and ENP flours may be due to the differences in the alkalinity of the cooking solution, in particular with the nixtamalization process used. Traditional nixtamalization provides a more alkaline medium relative to the two other processes which promotes faster hydrolysis and removal of pericarp and outer layers of maize kernel (Santiago-Ramos et al., 2018).

Starch granules are composed of two polysaccharides: amylose and amylopectin (Scott and Emery, 2016). Increase in amylose and amylopectin contents is due to the release of starch after nixtamalization (Mariscal-Moreno et al., 2015). Significantly lower amylose and amylopectin contents were found in ENP flour due to its milder effect in terms of hydrolysis and removing the maize pericarp as compared to CNP and TNP flours brought about by a less alkaline solution. The increase in resistant starch is attributed to the heat treatments during the process’ steps that promote the interaction of the starch with proteins, lipids, and its own components, making it less susceptible to enzyme hydrolysis (Mariscal-Moreno et al., 2015). Moreover, Santiago-Ramos et al. (2015) and Mariscal-Moreno et al. (2017) specified that this increase corresponds mainly as a consequence of amylopectin retrogradation and the formation of amylose- lipid complexes. This explication matches the results for amylose and amylopectin contents in which relatively higher values were found in TNP flour than in other nixtamalized flours.

The significant increase in the soluble dietary fiber contents of QPM and the significant decrease in insoluble dietary fiber contents after nixtamalization is mainly due to the elimination of the seed coat during alkaline cooking. Most insoluble dietary fiber can be found in the pericarp (Mora-Escobedo et al., 2004). The trend in which the highest increase for soluble dietary fiber content as well as the highest decrease for insoluble dietary fiber content as observed in TNP flour among all nixtamalized flours reflecting the effect of salts on the hydrolysis of pericarp components. This is also true with the results of Mariscal-Moreno et al. (2017) in which the authors stated that hydrolysis by OH− anions as compared to other anions results in higher pericarp losses in the nejayote. Salts used in the ecological and classic processes reduce the pericarp hydrolysis, thereby retaining most of them in the whole grain even after cooking and steeping.

According to Sharif et al. (2017), developed products need to be evaluated by trained panelists to guarantee that they exhibit the desired characteristics. When the final product formulation has been decided, specifying the exact ingredients and preferred methods of production, the product must be tested on large-scale to determine consumer acceptability. Hence, a two-step sensory analysis was conducted in which the first step is descriptive test (quality scoring) followed by the consumer acceptability test.

In the descriptive test, general observations for appearance include a more aerated volume for pure wheat pan de sal as compared to other samples. This is mainly due to higher content of gluten which is responsible for the characteristic structure of yeast bread (Guadarrama-Lezama et al., 2016). Lime or calcium hydroxide contributes to the development of aroma in nixtamalized corn (Wacher, 2003; Serna-Saldivar, 2016) and hence, a significantly higher perceptibility of corn aroma in pan de sal with TNP flour. A significantly softer and more pliable texture of pan de sal made from wheat:NN flour blend and pure wheat flour may be due to the relatively lower water absorption capacity of nixtamalized maize flours (Milan-Carrillo et al., 2004) resulting to a firmer texture. Also, the decrease in the amount of gluten present in wheat flour in pan de sal substituted with nixtamalized QPM flours resulted in the decrease in viscoelastic properties of bread (Guadarrama-Lezama et al., 2016). Same with the evaluation of corn aroma scores, the significantly high perceptibility of corn flavor in pan de sal with TNP flour was due to the presence of calcium hydroxide which is known to release the characteristic alkaline taste evident in tortillas (Wacher, 2003; Milan-Carillo et al., 2004). These factors have contributed to the significantly lower overall acceptability score for pan de sal with TNP flour.

Pan de sal with ENP and CNP flours, having no significant difference with pure wheat pan de sal in terms of overall acceptability, were used in the consumer acceptability test. A total of 100 judges were asked to evaluate the pan de sal which consisted of thirty-eight percent males and sixty-two percent females. Panelists came from different age groups: 18% were 19 years old and below, 48% were 20-39 years old, 24% were 40-59 years old, and 10% of the population were 60 years old and above. When asked whether the consumers recognized if there was a difference between the two pan de sal samples, 75% of the population answered “yes” while 25% answered “no”. When asked if they will buy the evaluated products given the opportunity that it will be sold in the market, 98% answered “yes” while the remaining 2% answered “no”. When asked whether they tasted the maize in the pan de sal samples, 45% of the respondents answered “yes” while 55% answered “no”. Those who answered “yes” were asked if they liked the taste of corn in the pan de sal and 83% of them answered “yes” while 17% answered “no”. Lastly, when the respondents were asked if they were open to purchasing and consuming the pan de sal with nixtamalized maize flour, a majority of 98% answered “yes”. Since both samples may be considered acceptable to consumers with scores within the range “liked very much” in the consumer acceptability test and a positive evaluation of the test samples, there could be a high potential for the marketability of pan de sal produced with these nixtamalized QPM flours.

CONCLUSION

The quality of QPM was greatly improved by the ancient technology of nixtamalization. It induces favorable contributions in its nutritional value and sensory attributes such as in Philippine salt bread. There could be a high potential for Philippine salt bread produced with nixtamalized QPM flour in terms of consumer acceptability and marketability aside from its improved nutritional significance. All three nixtamalization processes have their own advantages and drawbacks, hence, choosing the appropriate nixtamalization process to be used in the development of a specific product will depend on the nutrient of interest to be enhanced.

ACKNOWLEDGEMENTS

The technical assistance provided by the University of the Philippines Los Baños’ Institute of Food Science and Technology, Institute of Plant Breeding, and Institute of Human Nutrition and Food Analytical Laboratories, specifically by Ms. Elena B. Palenzuela, is hereby acknowledged.

REFERENCES

Afoakwa, E.O. and Aidoo, P.R. 2006. Changes in souring development, nutritional and functional properties during fermentation of cowpea-fortified nixtamalized maize. International Journal of Food Engineering. 2: 1-17

Association of Official Analytical Chemists (AOAC). 1980. The Official Methods of Analysis. Washington DC. Pergamon Press.

Association of Official Analytical Chemists (AOAC). 2010. Official Methods of Analysis of Association of Official Analytical Chemists. 18th Edition, Washington, DC.

Bello-Perez, L.A., Flores-Silva, P.C., Camelo-Mendez, G.A., Paredes-Lopez, O., and Figueroa-Cardenas, J.D. 2015. Effect of the nixtamalization process on the dietary fiber content, starch digestibility, and antioxidant capacity of blue maize tortilla. Cereal Chemistry. 92: 265–270.

Bibat, M.A.D.R., Del Rosario, O.M., Mopera, L.E., Collado, L.S., and Flores,F.P. 2014. Characterization of alkaline-cooked quality protein maize as raw material for noodle processing. Philippine Science Letters. 7: 413-419.

Bressani, R., Turcios, J.C., and Colmenares-De Ruiz, A.S. 2002. Nixtamalization effects on the contents of phytic acid, calcium, iron and zinc in the whole grain, endosperm and germ of maize. Food Science and Technology International. 8: 81-86.

Bressani, R., Turcios, J.C., Colmenares-De Ruiz, A.S., and Palacios-De Palomo, P. 2004. Effect of processing conditions on phytic acid, calcium, iron, and zinc contents of lime-cooked maize. Journal of Agriculture and Food Chemistry. 52: 57-62.

Cabalda, A.B., Tengco, L.W., Solon, J.A.A., Sarol, J.N.J., Rayco-Solon, P., and Solon, F.S. 2009. Efficacy of pandesal baked from wheat flour fortified with iron and vitamin A in improving the iron and anthropometric status of anemic schoolchildren in the Philippines. Journal of the American College of Nutrition. 28: 591-600.

Campechano-Carrera, E.M., Figueroa-Cardenas, J.D., Arambula-Villa, G., Martinez-Flores, H.E., Jimenez-Sandoval, J.S., and Luna-Barcenas, J.G. 2012. New ecological nixtamalisation process for tortilla production and its impact on the chemical properties of whole corn flour and wastewater effluents. International Journal of Food Science and Technology. 47: 564–571.

Das, A.K., Bhattacharya, S., and Singh, V. 2016. Bioactives-retained non-glutinous noodles from nixtamalized dent and flint maize. Food Chemistry. 217: 125-132.

Fernandez-Muñoz, J.L., Acosta-Osorio, A.A., Zelaya-Angel, O., and Rodriguez-Garcia, M.E. 2002. Effect of calcium content in the corn flour on RVA profiles. Food Engineering. 102: 100-103.

Figueroa, J.D., Veles-Medina, J.J., Hernandez-Landaverde, M.A., Aragon-Cuevas, F., Gaytan-Martinez, M., Chavez-Martinez, E., Palacios, N., and Wilcox, M. 2013. Effect of annealing from traditional nixtamalization process on the microstructural, thermal, and rheological properties of starch and quality of pozole. Journal of Cereal Science. 58: 457-464.

Fox, J. and Leanage, A. 2016. R and the journal of statistical software. Journal of Statistical Software. 73: 1-13.

Gerpacio, R., Labios, J., Labios, R., and Diangkinay, E. 2004. Maize in the Philippines: production systems, constraints and research priorities. International Maize and Wheat Improvement Centre (CIMMYT), Texcoco, Mexico. 1-37

Guadarrama-Lezama, A.Y., Carrillo-Navas, H., Vernon-Carter, E.J., and Alvarez-Ramirez, J. 2016. Rheological and thermal properties of dough and textural and microstructural features of bread obtained from nixtamalized corn/wheat flour blends. Journal of Cereal Science. 69: 158-165

Gutiérrez-Cortez, E., Rojas-Molina, J.I., Zambrano-Zaragoza, M.L., Quintanar-Guerrero, D., González-Reza, R.M., Rojas-Molina, A., and Espinosa-Arbeláez, D.G. 2013. Effect of processing conditions on the production of nixtamalized corn flours by the traditional method. Journal of Food. 11: 46-53

Heymann, H., Machado, B., Torri, L., and Robinson, A.L. 2012. How many judges should one use for sensory descriptive analysis?. Journal of Sensory Studies. 27: 111-122. Hoover, R. and Ratnayake, W.S. 2001. Determination of Total Amylose Content of

Starch. Current Protocols in Food Analytical Chemistry. 00: E2.3.1–E2.3.5.

Katz, S.H., Hediger, M.L. and Valleroy, L.A. 1974. Traditional maize processing techniques in the new world. Science. 184: 765-73.

Labios, R.V., Manguiat, P.H., Labios, J.D., and Malayang, D.B.N. 2016. Considering farmers’ preferences in the breeding and dissemination of white corn varieties as staple food. Philippine Agricultural Scientist. 99: 379–390.

Lawless H., and Heymann H. 2010. Introduction. In: Sensory Evaluation of Food. Food Science Text Series. Springer, New York, NY. 1-18.

Lizardo, R.C.M., Castillo-Israel, K.A.T., Dizon, E.I., Mejico, M.I.F., and Jubinal C.M.D. 2017. Development of high-value food products from selected indigenous and underutilized crops to increase food utilization and reduce food loss. Journal of Developments in Sustainable Agriculture. 12: 1-12.

Mabesa, L.B. 1986. Sensory Evaluation of Foods: Principles and Methods. College of Agriculture University of the Philippines Los Baños: College, Laguna, Philippines. Magpantay, R.B., Diones, J.A., Diaz, M., Solivas, S., Salazar, A., and Hurtada, W. 2014.

Comparative nutrition of normal maize (Zea mays L.) quality protein maize and wheat (Triticum spp.) flour and blends for 'pan de sal' making. Philippine Journal of Crop Science. 39: 1-13.

Mariscal-Moreno, R.M., Figueroa, J.D.C., Santiago-Ramos, D., Arambula-Villa, G., Jimenez-Sandoval, S., Rayas-Duarte, P., Veles-Medina, J.J., and Martinez- Flores, H.E. 2015. The effect of different nixtamalisation processes on some physicochemical properties, nutritional composition, and glycemic index. Journal of Cereal Science. 65: 140-146.

Mariscal-Moreno, R.M., Figueroa-Cardenas, J.D.C., Santiago-Ramos, D., Rayas-Duarte, P., Veles-Medina, J.J., and Martinez-Flores, H.E. 2017. Nixtamalization process affects resistant starch formation and glycemic index of tamales. Journal of Food Science. 82: 1110-1115.

Maya-Cortes, D.C., Figueroa-Cardenas, J.D., Garnica-Romo, M.G., Cuevas-Villanueva, R.A., Cortes-Martinez, R., Veles-Medina, J.J., and Martinez-Flores, H.E. 2010. Whole-grain corn tortilla prepared using an ecological nixtamalisation process and its impact on the nutritional value. International Journal of Food Science and Technology. 45: 23–28.

Milan-Carrillo, J., Gutierrez-Dorado, R., Cuevas-Rodriguez, E.O., Garzon-Tiznado, J.A., and Reyes-Moreno, C. 2004. Nixtamalized flour from quality protein maize (Zea mays L.): optimization of alkaline processing. Plant Foods for Human Nutrition. 59: 35–44.

Morales, J.C. and Zepeda, R.A.G. 2017. Effect of different corn processing techniques in the nutritional composition of nixtamalized corn tortillas. Journal of Nutrition and Food Sciences. 7: 1-7.

Mora-Escobedo, R., Osorio-Diaz, P., Garcia-Rosas, M.I., Bello-Perez, A., and Hernandez-Unzon, H. 2004. Changes in selected nutrients and microstructure of white starch quality maize and common maize during tortilla preparation and storage. Food Science and Technology International. 10: 79–87.

Ocheme, O.B. and Mikailu, E.G. 2011. Effect of alkaline soaking and cooking on the proximate, functional and some anti-nutritional properties of sorghum flour. AU Journal of Technology.14: 210-216.

Olaoye, O.A, Onilude, A.A., and Oladoye, C.O. 2007. Breadfruit flour to biscuit making: effects on product quality. African Journal of Food Science. 1: 20-23.

Opienska-Blauth, J.M., Charenzinski, M., and Berbec, H. 1963. A new rapid method of determining tryptophan. Analytical Biochemistry. 6: 69-76.

Ozola, L., Straumile, E., Galoburda, R., and Klava, D. 2012. Application of extruded maize flour in gluten-free bread formulations. World Academy of Science, Engineering and Technology. International Journal of Nutrition and Food Engineering. 6: 176-181.

Pappa, M.R., Palacios De Palomo, P., and Bressani, R. 2010. Effect of lime and wood ash on the nixtamalization of maize and tortilla chemical and nutritional characteristics. Plant Foods for Human Nutrition. 65: 130-135.

Prasanna, B.M., Vasal, S.K., Kassahun, B., and Singh, N.N. 2001. Quality protein maize.

Current Science. 81(10): 1308-1319.

Rodriguez-Mendez, L.I., Figueroa-Cardenas, J.D., Ramos-Gomez, M., and Mendez- Lagunas, L.L. 2013. Nutraceutical properties of flour and tortillas made with an ecological nixtamalization process. Journal of Food Science. 78: 1529-1534.

Rodríguez-Miranda, J., Ruiz-López, I.I., Herman-Lara, E., Martínez-Sánchez, C.E., Delgado-Licon, E., and Vivar-Vera, M.A. 2011. Development of extruded snacks using taro (Colocasiaesculenta) and nixtamalized maize (Zea mays) flour blends. Journal of Food Science and Technology. 44: 673-680.

Rojas-Molina, I., Gutierrez, E., Cortes-Acevedo, M.E., Falcon, A., Bressani, R., Rojas, A., Ibarra, C., Pons-Hernandez, J.L., Guzman-Maldonado, S.H., Cornejo- Villegas, A., and Rodriguez, M.E. 2008. Analysis of quality protein changes in nixtamalized qpm flour as a function of the steeping time. Cereal Chemistry. 85: 409–416.

Rooney, L.W. and Suhendro, E.L. 1999. Perspectives on nixtamalization (alkaline cooking) of maize for tortillas and snacks. Cereal Foods World. 44: 466-470.

Salazar, A.M., Pascual, C.B., Caasi-Lit, M.T., Pentecostes, K.Z., Dumalag, P.Y., Ladia,

V.A. Jr., and Paril, J.F. 2016. Breeding potential of Philippine traditional maize varieties. Sabrao Journal of Breeding and Genetics. 48: 154-161.

Santiago-Ramos, D., Figueroa, J.D.C., Veles-Medina, J.J., Mariscal-Moreno, R.M., Reynoso-Camacho, R., Ramos-Gomez, M., Gaytan-Martinez, M., and Morales- Sanchez, E. 2015. Resistant starch formation in tortillas from an ecological nixtamalization process. Cereal Chemistry. 92: 185–92.

Santiago-Ramos, D., Figueroa, J.D.C.,Veles-Medina, J.J., and Mariscal-Moreno, R.M. 2017. Changes in the thermal and structural properties of maize starch during nixtamalization and tortilla-making processes as affected by grain hardness. Journal of Cereal Science. 74: 72-78.

Santiago-Ramos, D., Figueroa, J.D.C., Mariscal-Moreno, R.M., Escalante-Aburto, A., Ponce-Garcia, N., and Veles-Medina, J.J. 2018. Physical and chemical changes undergone by pericarp and endosperm during corn nixtamalization: a review. Journal of Cereal Science. 81: 108-117.

Scott, M.P. and Emery, M. 2016. Maize: overview. Reference Module in Food Sciences.

Elsevier Ltd. IA: Iowa State University, Aimes. 1-6.

Serna-Saldivar, S.O. 2016. Maize: Foods from Maize. Reference Module in Food Sciences. Elsevier Ltd. Tecnologico de Monterrey, Monterrey, Mexico. 1-12.

Sharif, M., Butt, M., Sharif, H., and Nasir, M. 2017. Sensory evaluation and consumer acceptability. Handbook of Food Science and Technology: Sensory Evaluation and Consumer Acceptability. 2017: 362-386.

Suri, D.J. and Tanumihardjo, S.A. 2016. Effects of different processing methods on the micronutrient and phytochemical contents of maize: from A to Z. Comprehensive Reviews in Food Science and Food Safety. 15: 912-926.

Tandzi, L.N., Mutengwa, C.S., Ngonkeu, E.L.M., Woin, N., and Gracen, V. 2017. Breeding for quality protein maize (QPM) varieties: a review. Journal of Agronomy. 7: 80.

Trejo-Gonzalez, A., Feria-Morales, A., and Wild-Altamirano, C. 1982. The role of lime in the alkaline treatment of corn for tortilla preparation. In: Feeney RE, Whitaker JR, editors. Modification of Proteins: Foods, Nutritional and Pharmacological Aspects, Advances in Chemistry Serial No 198. Washington, DC: American Chemical Society. 245-262.

Wacher, C. 2003. Nixtamalization, a Mesoamerican technology to process maize at small-scale with great potential for improving the nutritional quality of maize based foods. 2nd International Workshop. Mexico: Food-based Approaches for A Healthy Nutrition. 735-743.

Ward, C.M. and Trenerry, V.C. 1997. The determination of niacin in cereals, meat and selected foods by capillary electrophoresis and high performance liquid chromatography. Food Chemistry. 60: 667-67.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand https://cmuj.cmu.ac.th

Dianne Jane A. Sunico1,*, Felicito M. Rodriguez1, Arvin Paul P. Tuaño1, 2, Lotis E. Mopera3, Liezl M. Atienza1, and Clarissa B. Juanico1

1 Institute of Human Nutrition and Food, College of Human Ecology, University of the Philippines Los Baños, College, Laguna 4031, Philippines

2 Institute of Chemistry, College of Arts and Sciences, University of the Philippines Los Baños, College, Laguna 4031, Philippines

3 Institute of Food Science and Technology, College of Agriculture and Food Science, University of the Philippines Los Baños, College, Laguna 4031, Philippines

Corresponding author: Dianne Jane A. Sunico, E-mail: dasunico@up.edu.ph

Total Article Views

Editor: Wasu Pathom-aree,

Chiang Mai University, Thailand

Article history:

Received: May 12, 2020;

Revised: July 1, 2020;

Accepted: October 12, 2020