Evaluation of The Physicochemical, Sensorial and Antioxidant Properties of Functional Ale Beer Brewed with Rice and Fruit by-Products

Wichien Sriwichai*, Pakkawat Detchewa, and Patcharee PrasajakPublished Date : 2021-04-01

DOI : https://doi.org/10.12982/CMUJNS.2021.031

Journal Issues : Number 2, April-June 2021

Abstract Functional beer brewed with a high bioactive compound ingredients is beneficial to prevent many diseases. Rice and fruit by-products are rich in bioactive compounds and have a potential for functional beer production. The aim of the present work was to assess the physicochemical, nutritional and sensorial properties of the beer brewed with rice and fruit by-products. The five formulas of beer investigated were the dried malt extract, Phitsanulok paddy rice powder, riceberry powder, banana peel and coffee pulp. The ratio of the dried malt extract and the other alternative ingredients was 80:20. The contents in reducing sugar, total phenolic compounds, flavonoid, chlorogenic acid, caffeine and dietary fiber were evaluated. The correlations between the physicochemical, sensorial, antioxidant properties and acceptability of beers were assessed by the Principal Component Analysis. The results showed that beers were differed in color density and have a low alcohol content. Among beer formula, beers brewed with coffee pulp was the richest in total phenolic and beers brewed with banana peel was the richest in flavonoid content (278.82 mg gallic acid equivalent/ L beer and 69.18 mg catechin equivalent/ L respectively). The antioxidant capacity was the highest in banana peel beer formula (76.64%). The Principal Component Analysis revealed that beers brewed with the two varieties of rice powder formula were in the same group of beer control (dried malt extract formula). These beers were characterized by a high note of appreciation from consumer. Whereas, a high correlation between the antioxidant capacity and total polyphenolic, flavonoid content was observed in beer fruit by-products formulas. The incorporation of two varieties of rice powder or fruit by-products was feasible in brewing process to produce a functional ale beer appreciated by customer and having a noticeable antioxidant capacity.

Keywords: Antioxidant capacity, Fruit by-products, Functional ale beer, Physicochemical properties, Rice

Citation: Sriwichai, W., Detchewa, P., and Prasajak, P. 2021. Evaluation of the physicochemical, sensorial and antioxidant properties of functional ale beer brewed with rice and fruit by-products. CMUJ. Nat. Sci. 20(2): e2021031.

INTRODUCTION

Beer is one of the oldest world’s brewing alcoholic beverage that is widely consumed. It is obtained from water, barley malt, and hops (Humulus lupulus L.), then fermented by yeast. Beer production both in artisanal or mass scale is one of the most important sector which can stimulate the world socio-economic. The moderate beer consumption has been reported to reduce the risks of coronary diseases, heart attack, diabetes and counters atherosclerosis, both in laboratory animals and human trial (Britton and McKee, 2000; Hines and Rimm, 2001; Mann and Folts, 2004). The claimed health benefits are attributed to the hydrophilic and hydrophobic vitamins, amino acids, dietary fibers and phenolic compounds from barley malt and hops.

Innovation is the key driver in the brewing industry since the consumers are looking for new products with health benefits. Nowadays, functional beers incorporating new ingredients increase in consumer’s demands towards innovative products. Malted barley is a basically raw material for beer production but other raw materials can be used as well (e.g., wheat, maize, rice, sorghum, rye and oat). Barley is sometime hardly cultivated in some countries and is not available in many area. Substituting an alternative cereals like rice, worldwide available, is interesting to produce a beer-like beverage. Over the last decade, the paddy rice and the pigmented rice (e.g., brown rice and riceberry) gain the attention for consumer. Since many researches showed that the husk and bran layers of these rice contain some phenolic acids (e.g., ferulic acid, P- coumaric and diferulate) having a high antioxidant capacity against scavengers of singlet oxygen responsible of many diseases (Adom and Liu, 2002; Lee et al., 2003; Butsat and Siriamornpun, 2010).

Even though, the production of a beer-like 100% rice beverage is not possible because of the lack of starch-degrading enzymes in the rice to yield soluble sugars in beer. Moreover, a high gelatinization temperature of the rice starch is a main cause of an incomplete saccharification during mashing. Supplementing the commercial exogenous enzymes to the rice beer is not neither possible, since the rice protein could not be degraded by synthetic enzymes. Consequently, the protein was not solubilized in the wort (Ceppi and Brenna, 2010; Steiner et al., 2012). Despite many effort of research on the production of a beer-like 100% rice beverage, by using different varieties of rice, or modifying the process of brewing, the sensory characteristic of some rice beer is still unexplored (Mayer et al., 2014; Mayer et al., 2016).

Fruit by-products could be added to produce beer rich in bioactive compounds which have a potential to prevent diseases (e.g., functional beer). Among different types of fruit by-products, coffee pulp and banana peel were worldwide produced in a high quantity. Around 81.2 Mtons of banana peel was produced a year and 1.0 tons of the coffee pulp were obtained from two tons of coffee fruits. Vijayalaxmi et al., (2015) suggested that these two by-products have a potential to valorize in food industry because these two by-products were reported to have a noticeable amount of carbohydrates, proteins, pectins and polyphenols contents (Murthy and Madhava Naidu, 2012; Murthy and Naidu, 2012; González-Montelongo et al., 2010).

The enrichment of beer with fruit or fruit by-products may add new flavors, but also increase the content of bioactive compounds and the oxidative stability of the beer. Many types of fruit were enriched in beer such as Cornelian cherry (Cornus mas L.) and Goji berries (Lycium barbarum) giving a new flavors and increasing the concentration of bioactive compounds, then enhancing the antioxidant capacity (Ducruet et al., 2017; Kawa-Rygielska et al., 2019).

To our knowledge, the mixture of barley malt in powder state brewed with the Phitsanulok paddy rice powder, riceberry powder, banana peel and coffee pulp has never been investigated. The physicochemical, sensorial characteristic and the antioxidant capacity of these beers have never been either elucidated. The aim of the present work was to assess the physicochemical, nutritional and sensorial properties of the beer brewed with rice and fruit by-products. The five formulas of beer investigated were the dried malt extract, Phitsanulok paddy rice powder, riceberry powder, banana peel and coffee pulp. The acceptability in term of sensorial characteristic by consumer was also evaluated. The correlations between the physicochemical, nutritional, sensorial properties and acceptability of the five beers were assessed by the Principal Component Analysis.

MATERIALS AND METHODS

Materials and chemicals

Dried malt extract was delivered from NassenceTM (Shanghai, China). Saccharomyces cerevisiae Safale US-05 yeast from the Fermentis company (Lesaffre, France) were used for wort fermentation. Huell Melon Hops were obtained from Germany. Two types of rice, varieties of O. sativa L. namely Phitsanulok2 paddy rice and riceberry were purchased from local market (Nakhonnayok, Thailand). They were grounded and sieved on 80 mesh, the powder were rapidly stored in an aluminum bag. Cavendish bananas peel (Musa acuminata) and coffee pulp (Coffea arabica L. var. typica) cultivated in Thailand were used in brewing process. Bananas peel and coffee pulp were hot air dried (Binder, USA) at 65°C for 8 h, Aw of final product is 0.65. Then they were grounded (Phillips, China) and sieved on 80 mesh, the powder were rapidly stored in an aluminum bag for further brewing process or chemical analysis.

Dichloromethane, petroleum ether, ethanol and methanol were from Fisher Chemical (England) and acetone was from Aldrich (St. Louis, MO, USA). Folin– Ciocalteu’s reagent and other chemicals were from VWR (France). DPPH (2, 2-diphenyl- 1-picryhydrazyl) and caffeine were purchased from Sigma Chemical Co. (St. Louis, MO, USA). Chlorogenic acid was form Acros Organics (India). All other chemicals were from Merck.

Concept design of experiment

The dried malt extract (DME), paddy rice (PR), riceberry (RB), coffee pulp (CP) and banana peel (BP) powder were evaluated their total phenolic, flavonoids, AIRs, pectin and reducing sugar content in raw state. The mixture of DME and the four alternative ingredients (PR, RB, CP and BP), on the ratio 80:20 was chosen for the present study. This ratio had the highest note among the other ratio (60:40, 70:30 and 90:10) using Just About Right and 9-Point Hedonic scale test from our pre-experimental research. The sensory analysis of 9-point hedonic scale test was also applied to determine the sensorial acceptability of each formulas after three weeks of the fermentation. For each formula of beer was then evaluated their total phenolic and flavonoid content, antioxidant capacity, as well as their physicochemical properties. The statistical significant attributes at the 5% significance level for the sensory analysis, physicochemical and nutritional of functional beer were subjected to statistical analysis, a Principal Component Analysis (PCA), on correlation matrix. A characterization of the beers was evaluated using a classification with significant descriptors at 20%.

Beer processing

Beer brewing process was adapted from Kawa-Rygielska et al., (2019). All beer formulas were mashed by using DME and the alternative ingredients (8.2% (W/W)) and 3 L of water. Infusion mashing was conducted on water 65 °C and heated until the temperature of liquid reached 75°C. The mash was firstly filtrated through colander and then by Whatman filter paper (N°4). Dried hops (170 mg/L) were added to resultant wort and boiled at 100°C for 1 h, then rapidly cooled down to a temperature of 25°C. Saccharomyces cerevisiae yeasts (1.7 g) was rehydrated in pure water for 30 min at 25°C, then were added to all wort formulas. Fermentation was carried out in 5 L glass fermentation flasks for three weeks.

Dry matter determination

The dry matter (DM) contents were determined by drying the samples 24 h at 105°C. Samples were then weighted precisely on a OHAUS (EP412101C) balance, Switzerland.

Determination of total phenolic content

Total phenolic content was determined by Folin-Ciocalteu Assay (Pękal and Pyrzynska, 2014). Approximately 1 g of dried samples were mixed to 0.1 mL of Folin- Ciocalteu’s reagent and 0.9 mL of water in test tube respectively. Samples were left for 5 min and 1 mL Na₂Co₃ (7%, w/v), 4 mL of water were added. The mixture were stabilized for 30 min until blue color appeared. The measurement wavelength absorption at 765 nm against blank sample. Gallic solution was used as standard curve. The data were expressed in milligram of gallic acid equivalent per 100 g food sample or 1 L of beer.

Determination of flavonoid content

Dried samples (rice, fruit peel) were sieved to obtain the particle size 60 mesh. An appropriate dried sample (0.1-0.5 g) were diffused in 50 mL of freshly boiled water for 10 min. After the infusion time, the samples were cooled for 5 min and then centrifuged at 4,000 g for 5 min at 4°C. Sample solution or liquid sample (beer), 1 mL were used for flavonoid and total phenolic determination as previously described procedure of Pękal and Pyrzynska, (2014) with minor modification. All determinations were carried out in triplicate.

The flavonoid content was analyzed according to spectrophotometric methods based on the formation of aluminum-flavonoid complexes. Tested solution (1 mL of standard or sample), was mixed with 0.3 mL of NaNO2 (5%, w/v) and incubated for 5 min. After 0.5 mL of AlCl3 (2%, w/v) was added and sample was mixed and incubated again for 6 min. Then, sample solution were neutralized with 0.5 mL of 1 M NaOH solution. The mixture was left for 10 min at room temperature and finally subjected the spectral analysis using spectrophotometer (Optima, SP-300, Japan) against the blank, where AlCl3 solution was substituted by water. The measurement were assessed for the maximum wavelength of flavonoid absorption at 510 nm using catechin as standard.

Determination of caffeine and chlorogenic acid content

The caffeine and chlorogenic acid content were quantified in all ingredients according to the method of Belay et al., (2008). Sample was weighed approximately 0.6 g and mixed to 25 mL of water for 1 h. The mixtures were filtered through Whatman paper No.4 on suction pump to separate the extracted filtrate containing the caffeine and chlorogenic acid. The caffeine were extracted by using dichloromethane extraction in the ratio of filtrate and solvent 1:1. The mixture was left or 10 min and washed by water 4 times. Finally, the caffeine extracted by dichloromethane at each round and the chlorogenic acid in water was collected and measured by UV/vis spectrophotometer against the corresponding reagent blank. The measurement were assessed for the maximum wavelength of caffeine absorption at 274 nm and maximum wavelength of chlorogenic acid absorption 324 nm.

Determination of Alcohol-insoluble residues (AIRs) and pectin content

The rice, banana peel and coffee pulp powder were firstly isolated by precipitation in boiling ethanol to remove low-molecular-weight components (Selvendran, 1975). Sample (containing 1 part of water) were combined with boiling ethanol (4 parts) and grounded for 1 min (Buono, Germany). The mixture was boiled for 15 min and then filtered on a funnel of porosity 3 μm (DURAN®, Wertheim, Germany). The residue was extensively washed with ethanol, acetone, and ether, one after the other, and finally dehydrated in a vacuum oven (55°C; 24 h) and weighed. The dehydrated powder on a funnel represented the alcohol-insoluble residues (AIRs) or crude fiber content.

The pectin contents of the cell walls were determined by galacturonic acid content without preliminary desesterification by the m-phenylphenol procedure (Ahmed and Labavitch, 1978; Blumenkrantz and Asboe-Hansen, 1973).

Determination of reducing sugar content

The colorimetric technique was used to quantify the reducing sugar contents of the raw ingredients by using the dinitrosalicylic acid method (DNS). Approximately 1 g of sample was weighed and 1 mL of the DNS reactive was added. The pH was brought to 10. The mixture was boiled for 5 min, then cooled to room temperature. The volume of sample is completed with 8 mL of distilled water. Sample was finally homogenized and read at 540 nm in a spectrophotometer. Glucose solution was used as standard, and the results were expressed in mg glucose equivalent/ 100 g DM.

Determination of DPPH radical scavenging activity

The DPPH assay was used to determine antioxidant capacity according to the method described by Ditrych et al., (2015). The working solution was prepared by dissolving 0.0025 g of DPPH reagent in 100 mL of methanol. A 0.3 mL sample diluted 10-fold was added to 6 mL of DPPH working solution and placed in the dark for 30 min at room temperature. The absorbance (A30) was measured at a wavelength of λ = 515 nm against a methanol solution (A0). The percent of DPPH scavenged by the end of the reaction time was calculated according to the equation: % Reduction DPPH

= [1 – (A30/A0)] × 100%

Physicochemical analysis of the beer

The samples from each beer formulas were analyzed in triplicate. The pH of beer samples were measured using a pH Meter, Apera Instrument (USA) and the total soluble residues using a hand held refractometer. The alcohol concentration of beer samples were determined by using ebulliometer instrument (Dujardin-Salleron, France). Color measurement were evaluated based on L* (lightness), a* (redness, + or greenness, -), b* (yellowness, + or blueness, -) values of the beer using a Hunter Lab (USA). Turbidity was measured with a WTW Turb® 550 turbidimeter (Berlin, Germany). Viscosity was evaluated with Brookfield viscometer (Middleboro, MA, USA).

Sensory analysis

The sensory analysis of the beers was performed with the freshly prepared beer samples and served in the covered glasses (20 mL) at the same time, at 5°C. Water was provided for mouth rinsing between the beer samples tastings. All the tests were conducted at the testing room, and were evaluated by 20 volunteer panelists selected from the students training from the faculty of Agro-Industry, King Mongkut’s University of Technology North Bangkok, Prachinburi campus, Thailand. The sensory profile analysis of the beers was carefully evaluated. The attribute of the profile analysis was defined and evaluated its intensity by the judges. A linear scale was applied starting from 0 at the left end (none) to 9 at the right end (very intensive). The following stage was to measure the consumers’ preferences evaluated by 20 participants. Consumers noted the global appreciation of each beer on a structured 9-point hedonic scale anchored with ‘dislike extremely’ and ‘like extremely’.

Statistical analysis

All the chemical, physicochemical analysis and antioxidant properties of the beers were evaluated in triplicate. Results were reported as means ± standard deviations. A one way ANOVA and a post-hoc Duncan test were applied to test, significance was accepted at probability P <0.05. Concerning sensory analysis, a one way ANOVA with product factor and a Fisher’s Least Significant Difference (LSD) test were performed. The significant attributes (P <0.05) for the sensory profile analysis of the beers were used to realize a Principal Component Analysis (PCA) on correlation matrix using SPSS statistical software (Virginia, USA). The normal linear correlation, using Person correlation significant (2-tailled) at the 0.05 level was evaluated the correlation between data set.

RESULTS

Chemical composition of the raw ingredients for functional ale beer production

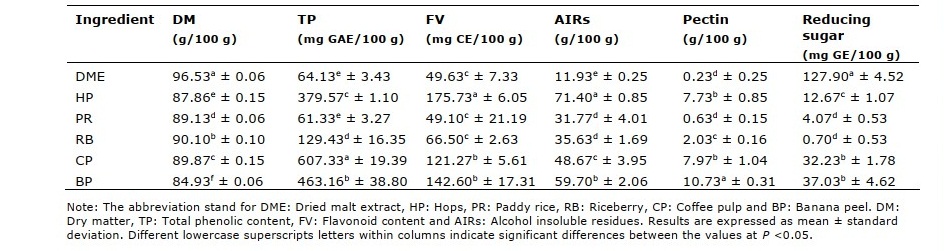

The chemical composition of the raw ingredients using in beer production could affect the nutritional and sensorial quality of the final products. The dry matter comprised of all the total soluble or insoluble residues (e.g., alcohol insoluble residues, pectin and reducing sugar content) might increase the turbidity, alcohol content and viscosity of the beer. The total phenolic and flavonoid content of the raw ingredients could change the color, density, and also increase the antioxidant capacity of the beer. The chemical compositions of raw ingredients are shown in Table 1.

Table 1. The total phenolic, flavonoids, AIRs, pectin and reducing sugar content in 100 g dry weight of raw ingredients

The raw ingredients used for ale beer brewing were in powder state. Their dry matter contents ranged from 89.87% to 96.53% (Table 1). The total phenolic content of the raw ingredients were significantly different between their nature types (e.g., cereal or fruit by-products). The highest total phenolic content was found in fruit by-products which is coffee pulp (607.33 ± 19.39 mg GAE/100 g DM). The flavonoid content in raw ingredients ranged from 49.10 - 175.73 mg CE/100 g DM, the highest content was in hops. The caffeine and chlorogenic acid content were detected only in coffee pulp, which was 8.93 ± 0.63 g/100 g DM and 0.24 g ± 0.18 g/100 g DM respectively (data not shown).

In addition, the hops were the richest in alcohol insoluble residues (71.40 ± 0.85 g/100 g DM), which was 7 folds higher than in the lowest one, dried malt extract (11.93 ± 0.25 g/100 g DM). The banana peel, coffee pulp and hops contained a high amount of pectin content which were 10.73, 7.97 and 7.73 g/100 g DM respectively. The dried malt extract was identified to have the highest reducing sugar content (127.90 ± 4.52 mg glucose equivalent/100 g DM). The lowest reducing sugar content was in 2 varieties of rice, which was less than 5 mg GE/100 g DM.

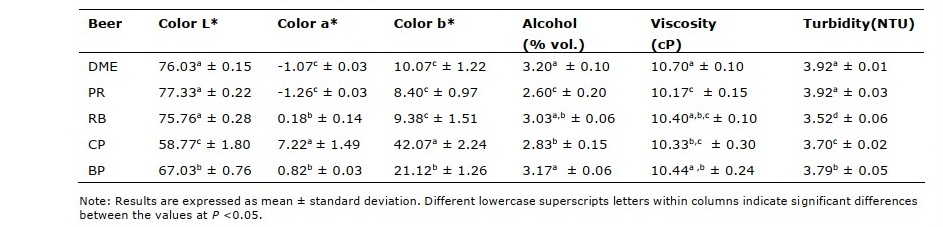

Physicochemical characteristic of the beers

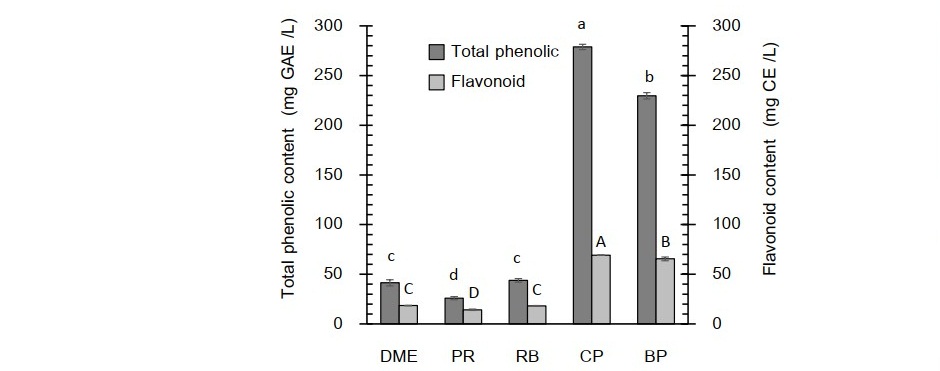

The color parameters, alcohol content, viscosity and turbidity of the five beers were shown in table 2 and the total phenolic and flavonoid content were presented in figure 1.

Table 2. Color parameters (L*: lightness, a*: greenness/redness and b*: blueness/yellowness), alcohol content, viscosity and turbidity of the five beers.

After three weeks of the fermentation of the five beers, beer coffee pulp had the lowest value of lightness (L*) and the highest values of (a*) and (b*). The beer revealed its darkest color with highest proportion of red and yellow color. Contrariwise, the beer dried malt extract, beer paddy rice, beer riceberry were the brightest in color (L* >75). They had a low value of a* and b*, less than 1 and 22 respectively, that indicate they were rather redness and yellowness.

All beers were low in an alcohol content (<3.5% vol.) and the lowest one was found in the paddy rice beer (2.60% vol.). The viscosity of beer was significantly different between beer formulas but were in the same range, varied from 10.17 ± 0.15 to 10.70 ± 0.10 cP. The beer dried malt extract (Beer control) had the highest viscosity content (10.70 cP) and turbidity value 3.92 ± 0.01 NTU. The lowest turbidity value was in beer coffee pulp (3.70 ± 0.02 NTU).

Figure 1. Total phenolic and flavonoid content of the 5 beers. Different lowercase and uppercase letters within bar graph indicate significant differences of the total phenolic and flavonoid content, respectively, between the beer formulas at P <0.05.

Total phenolic and flavonoid content were identified overall types of beers. The beer brewed with the fruit by-products formulas (e.g., coffee pulp and banana peel) contained the highest total phenolic content, 278.82 ± 2.68 and 229.67 ± 3.22 mg GAE/ L of beer respectively. They contained also the highest flavonoid content (65.51-69.18 mg CE/ L beer) which was approximately 4 folds higher than that in the beer dried malt extract, beer paddy rice and beer riceberry.

The antioxidant capacity of beers ranged from 35.42 to 76.64%. The highest one was in beer banana peel (76.64± 0.46%) and beer coffee pulp (75.53 ± 1.11%). The antioxidant capacity of these two beers were in average 2 folds higher than those in the beer dried malt extract (40.92 ± 1.09%), beer riceberry (35.42 ± 3.16%) and beer paddy rice (31.82 ± 0.46%) (Data not shown).

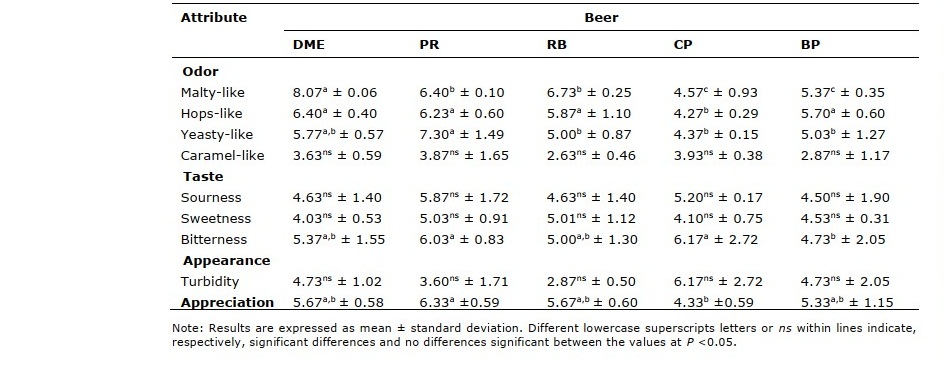

Sensory evaluation of beers

The sensory analysis of the similarity of beers in terms of odor, taste and appearance was evaluated, the results were shown in table 3. According to the judges, the beer dried malt extract, beer paddy rice and beer riceberry were characterized by a moderate notes for malt–like, hops-like and yeasty-like odor. On the contrary, the notes of caramel-like odor as well as the sourness and sweetness of all beer were not significantly different. While beer coffee pulp and paddy rice were noted to have the highest intensity in bitterness taste than the other ones. All the beer were defined by a low rating of turbidity in appearance with no statistically significant different. Besides the beer coffee pulp, the beers were rated in hedonic score as ‘Like slightly’ in the global appreciation.

Table 3. Sensorial attributes of five beers for odor, taste and appearance (minimum score = 0 and maximum score = 12) evaluated by a training panel (n = 20). The appreciation values result from a consumer test (n = 12) applying a hedonic scale (minimum score = 1 and maximum score = 9).

Correlation of the physicochemical, sensorial and antioxidant properties of beers

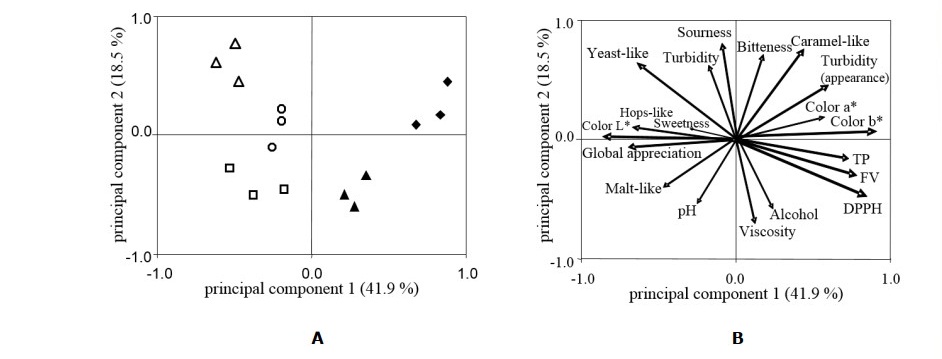

The total phenolic and flavonoid content, alcohol content, antioxidant capacity, color parameters, viscosity and the turbidity of the five beers were subjected to a Principal Components Analysis (PCA). The caffeine and chlorogenic acid were not included in the PCA analysis since it was detected only in the coffee pulp. All the sensorial attributes were taken into account for the PCA analysis to evaluate the correlation between the physicochemical and sensorial attributes of the beers.

Figure 2. Principal Component Analysis of the sensory descriptors and analytic parameter of the 5 beer. PCA plot of individual different type of beers (A). Correlation of physicochemical, sensorial and antioxidant properties plot of beers (B). (Ο) DME, (Δ) PR, (□) RB, (♦) CP and (▲) BP.

The representation of the variables with the Principal Component Analysis accounted for 60.54% of the variability of the data (Figure 2). The first axis of the PCA represents 41.90% of the overall variation. In the analytic parameter, the total phenolic and flavonoid content, antioxidant capacity and the color a* and b* of the beers were positively correlated. In contrast, they were negatively associated to the color L* of the beers. The global appreciation of consumer was positively associated to the color L*, hops-like odor, malty-like odor and sweetness taste. Nonetheless it was negatively correlated to the turbidity (appearance) of the tested beers. Pearson's correlation showed a highly significant negative correlation at 0.01 probability level between color L* and AIRs (r = -0.685), color L* and pectin content (r = -0.824) of the beers. The viscosity and alcohol content of the beers were moderately positively correlated to the reducing content in raw material of the beers (r = 0.656 and r = 0.549) respectively (data not shown).

DISCUSSIONS

The total phenolic, flavonoid, caffeine, chlorogenic acid, AIRs, pectin and reducing sugar content of coffee pulp and other ingredients in the present work were in the same range with the previous studies (Murthy and Naidu, 2012; Prangthip et al., 2013; Vijayalaxmi et al., 2015). Murthy and Madhava Naidu, (2012) reported the composition of total fiber, total polyphenols, total sugars, pectic substance, chlorogenic acid and caffeine in coffee pulp which were, respectively, 60.5%, 1.5%, 14.4%, 6.5%, 2.4%, and 1.5%. Butsat and Siriamornpun, (2010) found that rice bran fraction from three different growth sites in northeastern of Thailand had the highest value of total phenolic content ranged from 2.5 to 2.7 mg GAE/g. Although, in the present study, banana peel and hops were the richest in the total phenolic and flavonoid content. However, the contents might vary depend on the type and variety of ingredients (Liu et al., 2007; Walter and Marchesan, 2011).

Since the dried malt extract was obtained by freeze drying a soluble malt wort which was almost soluble in water, consequently the ratio of alcohol insoluble residues content or insoluble high molecular weight molecules were the lowest one. The plant based raw ingredients (e.g., the banana peel, coffee pulp and hops) contained a higher alcohol insoluble residues content than the paddy rice and riceberry. In fact the alcohol insoluble residues, hetero-polysaccharide (pectin), phenolic compounds and glycoproteins are the main composition of plant cell wall compared to the rice (Sandhu et al., 2009). Although, the other micronutrients and fibers are presented in the rice bran layer of the cereal, a noticeable amount were usually reported. Among the two different rice cultivars, the fiber content was identified as higher in the pigmented rice compared to those in unpolished rice. In the present study, the two variety of rice were pigmented and consisted of the whole rice bran layer. Therefore, they were high in fibers. The results obtained were in agreement with the study of Moongngarm et al., (2012) who reported a high amount of protein (13.66%), lipid (18.80%) and fiber (12.48%), as well as the other phytochemical compositions in rice germ fraction.

Generally, the starch from barley could be converted to a reducing sugar during the mashing of the brewing process. The hydrolysis is occurred by the α-amylase and β-amylase enzyme from malt, and activated by heating temperature. The α-amylase breaks down a large, insoluble starch molecules into soluble sugars, soluble molecules for the β-amylases. Contrariwise, rice starch does not completely degrade into soluble sugars. An insufficiency of starch-degrading enzymes, and a high gelatinization temperature of the rice starch cause an incomplete saccharification in the rice malt. These could explain the lowest reducing sugar content in 2 varieties of rice compared to the other ingredients. However, despite a high reducing sugar in some type of beers, a short period of partial fermentation (three weeks) might result in a low alcohol content in beers. In the present study, the pectin content in the ingredients was generally positively associated with the viscosity of the beers. The pectin is a soluble compounds which could be swollen once in contact with water during the brewing process. Consequently, it led to increase the viscosity of the beers. The lightness of the beers was also reduced. The beers become then more turbid and yellowish. The same phenomena was observed when the beers contained a high amount of the total phenolic and flavonoid content, the beer become more red yellowish and less lightness.

The beer brewed with the paddy rice, riceberry, banana peel and coffee pulp had a remarkable amount of the total phenolic and flavonoid content. The total phenolic and flavonoid can be better extracted and diffused in an alcoholic beer during the fermentation. The antioxidant capacity increased when a high amount of the total phenolic and flavonoid were in beer. Furthermore, the latter compounds in the beer increase the redness and yellowness color and decreased the lightness of the beers.

After three weeks of the fermentation, the beers were evaluated their sensorial characteristic for the odor, taste and appearance. The beer brewed with the cereal ingredients had a notable malt–like, hops-like and yeasty-like odor. More than 600 molecules of the volatile compounds are contributed to the aroma of beers. The main aroma-active odorants has been recently reported in Bavarian wheat beer and rice malt beer respectively (Langos et al., 2013; Ceccaroni et al., 2019). The rice beers might consist of the volatile compounds contributing to a more perceptive malt–like, hops-like and yeasty-like odor than fruit by-products beers. The bitter taste of the beer was conferred by the hops (Stevens and Page, 2004). In the present study, since all beers formula were brewed by incorporation the same quantity of hops. The polymeric phenolic compounds content such as tannins in coffee pulp, possibly gave a highest intensity in the bitterness taste of the beer coffee pulp. Moreover, the latter taste may be produced by the caramelization reaction occurring during the drying process of coffee pulp preparation.

The Principal Component Analysis (PCA) revealed the correlation of the physicochemical, sensorial and antioxidant properties of beers. The beers were grouped according to their common chemical characteristics. The beers coffee pulp and banana peel were in the same group. These beers were characterized by a high total phenolic and flavonoid content, as well as the antioxidant capacity. As mentioned above, the flavonoid and phenolic compounds could increase the color density and the bitterness taste of the beers. Therefore, beers coffee pulp and banana peel were described to have a red yellowish color, more turbid in appearance, pronounced in caramel-like and bitterness taste. The other group of beer were beer dried malt extract, beer paddy rice and beer bice berry. These beers were intense in the malt–like, hops-like and yeasty-like odor. They were also characterized by a sweetness and lightness intensity close to a common beer that consumers are used to drinking, thus had the highest of the appreciation note (overall like).

CONCLUSIONS

The evaluation of the physicochemical and sensorial properties and antioxidant capacity of the five beer formulas were achieved in the present study. The mixture of dried malt extract and alternative ingredients (80:20) gave a beer in different physicochemical and sensory characteristic. The beer brewed with the two varieties of rice powder had a noticeable malt–like, hops-like and yeasty-like odor. They were classified to have a high density of lightness color and sweetness taste similar to the beer control. The beer brewed with fruit by-products had a red yellowish color, more turbid in appearance. They were also pronounced in caramel-like and bitterness taste. It is possible to produce the functional ale beers by using paddy rice and riceberry powder with good consumer acceptability. Using the fruit by-products is feasible to produce the beers rich in the total phenolic and flavonoid content. Despite some particularity of the sensory characteristic, the beer brewed with fruit by-products had a noticeable antioxidant capacity beneficial to prevent many diseases. However, the study was conducted on a ratio of mixture, the future study on the variation of the quantity of the mixture is needed to increase the bioactive compounds level and being accepted in term of sensory by consumers. In addition, brewing beer with a pure gluten-free ingredients, more nutritious, but having a physicochemical property comparable to barley malt, can be a good alternative to produce a gluten-free functional ale beer.

ACKNOWLEDGEMENTS

The authors thank, Faculty of Agro-Industry, King Mongkut's University of Technology North Bangkok for providing instruments. The authors thank also Supakorn Thongaram and Ponsakorn Sasoonthorn for their technical assistance. The authors report no conflicts of interest. The authors alone are responsible for the content and writing of the paper.

REFERENCES

Adom, K.K. and Liu, R.H. 2002. Antioxidant activity of grains. Journal of Agricultural and Food Chemistry. 50: 6182–6187.

Ahmed, A.E.R. and Labavitch, J.M. 1978. A Simplified method for accurate determination of cell wall uronide content. Journal of Food Biochemistry. 1: 361– 365.

Belay, A., Ture, K., Redi, M., and Asfaw, A. 2008. Measurement of caffeine in coffee beans with UV/vis spectrometer. Food Chemistry. 108: 310–315.

Blumenkrantz, N. and Asboe-Hansen, G. 1973. New method for quantitative determination of uronic acids. Analytical Biochemistry. 54: 484–489.

Britton, A. and McKee, M. 2000. The relation between alcohol and cardiovascular disease in Eastern Europe: explaining the paradox. Journal of Epidemiology and Community Health. 54: 328.

Butsat, S. and Siriamornpun, S. 2010. Antioxidant capacities and phenolic compounds of the husk, bran and endosperm of Thai rice. Food Chemistry. 119: 606–613.

Ceccaroni, D., Sileoni, V., Marconi, O., De Francesco, G., Lee, E.G., and Perretti, G. 2019. Specialty rice malt optimization and improvement of rice malt beer aspect and aroma. LWT - Food Science and Technology. 99: 299–305.

Ceppi, E.L.M. and Brenna, O.V. 2010. Brewing with rice malt — A gluten-free alternative. Journal of the Institute of Brewing. 116: 275–279.

Ducruet, J., Rébénaque, P., Diserens, S., Kosińska-Cagnazzo, A., Héritier, I., and Andlauer, W. 2017. Amber ale beer enriched with goji berries – The effect on bioactive compound content and sensorial properties. Food Chemistry. 226: 109–118.

Ditrych, M., Kordialik-Bogacka, E., and Czyżowska, A. 2015. Antiradical and reducing potential of commercial beers. Czech Journal of Food Sciences. 33: 261–266.

González-Montelongo, R., Gloria Lobo, M., and González, M. 2010. Antioxidant activity in banana peel extracts: Testing extraction conditions and related bioactive compounds. Food Chemistry. 119: 1030–1039.

Hines, L.M. and Rimm, E.B. 2001. Moderate alcohol consumption and coronary heart disease: a review. Postgraduate Medical Journal. 77: 747.

Kawa-Rygielska, J., Adamenko, K., Kucharska, A.Z., Prorok, P., and Piórecki, N. 2019. Physicochemical and antioxidative properties of Cornelian cherry beer. Food Chemistry. 281: 147–153.

Langos, D., Granvogl, M., and Schieberle, P. 2013. Characterization of the key aroma compounds in two Bavarian wheat beers by means of the sensomics approach. Journal of Agricultural and Food Chemistry. 61: 11303–11311.

Lee, S.C., Kim, J.H., Jeong, S.M., Kim, D.R., Ha, J.U., Nam, K.C., and Ahn, D.U. 2003.

Effect of far-infrared radiation on the antioxidant activity of rice hulls. Journal of Agricultural and Food Chemistry. 51: 4400–4403.

Liu, Y., Gu, X.-H., Tang, J., and Liu, K. 2007. Antioxidant activities of hops (Humulus Lupulus) and their products. Journal of the American Society of Brewing Chemists. 65: 116–121.

Mann, L.B. and Folts, J.D. 2004. Effects of ethanol and other constituents of alcoholic beverages on coronary heart disease: a review. Pathophysiology. 10: 105–112.

Mayer, H., Marconi, O., Regnicoli, G.F., Perretti, G., and Fantozzi, P. 2014. Production of a saccharifying rice malt for brewing using different rice varieties and malting parameters. Journal of Agricultural and Food Chemistry. 62: 5369–5377.

Mayer, H., Ceccaroni, D., Marconi, O., Sileoni, V., Perretti, G., and Fantozzi, P. 2016. Development of an all rice malt beer: A gluten free alternative. LWT - Food Science and Technology. 67: 67–73.

Moongngarm, A., Daomukda, N., and Khumpika, S. 2012. Chemical compositions, phytochemicals, and antioxidant capacity of rice bran, rice bran layer, and rice germ. APCBEE Procedia. 2: 73–79.

Murthy, P.S., and Madhava Naidu, M. 2012. Sustainable management of coffee industry by-products and value addition - A review. Resources, Conservation and Recycling. 66: 45–58.

Murthy, P.S. and Naidu, M.M. 2012. Recovery of phenolic antioxidants and functional compounds from coffee industry by-products. Food Bioprocess Technol. 5: 897– 903.

Pękal, A. and Pyrzynska, K. 2014. Evaluation of aluminium complexation reaction for flavonoid content assay. Food Analytical Methods. 7: 1776–1782.

Prangthip, P., Surasiang, R., Charoensiri, R., Leardkamolkarn, V., Komindr, S., Yamborisut, U., Vanavichit, A., and Kongkachuichai, R. 2013. Amelioration of hyperglycemia, hyperlipidemia, oxidative stress and inflammation in steptozotocin-induced diabetic rats fed a high fat diet by riceberry supplement. Journal of Functional Foods. 5: 195–203.

Sandhu, A.P.S., Randhawa, G.S., and Dhugga, K.S. 2009. Plant cell wall matrix polysaccharide biosynthesis. Molecular Plant. 2: 840–850.

Selvendran, R.R. 1975. Analysis of cell wall material from plant tissues: Extraction and purification. Phytochemistry 14, 1011–1017.

Steiner, E., Auer, A., Becker, T., and Gastl, M. 2012. Comparison of beer quality attributes between beers brewed with 100% barley malt and 100% barley raw material. Journal of the Science of Food and Agriculture. 92: 803–813.

Stevens, J.F. and Page, J.E. 2004. Xanthohumol and related prenylflavonoids from hops and beer: to your good health! Phytochemistry. 65: 1317–1330.

Vijayalaxmi, S., Jayalakshmi, S.K., and Sreeramulu, K. 2015. Polyphenols from different agricultural residues: extraction, identification and their antioxidant properties. Journal of Food Science and Technology. 52: 2761–2769.

Walter, M. and Marchesan, E. 2011. Phenolic compounds and antioxidant activity of rice. Brazilian Archives of Biology and Technology. 54: 371–377.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand https://cmuj.cmu.ac.th

Wichien Sriwichai1,*, Pakkawat Detchewa2, and Patcharee Prasajak2

1 Department of Innovation and Product Development Technology, Faculty of Agro-Industry, King Mongkut’s University of Technology North Bangkok, Prachinburi 25230, Thailand

2 Department of Agro-Industry Technology and Management, Faculty of Agro-Industry, King Mongkut’s University of Technology North Bangkok, Prachinburi 25230, Thailand

Corresponding author: Wichien Sriwichai, E-mail: Wichien.s@agro.kmutnb.ac.th

Total Article Views

Editor: Wasu Pathom-aree,

Chiang Mai University, Thailand

Article history:

Received: May 12, 2020;

Revised: July 1, 2020;

Accepted: October 12, 2020