Smart SMEs 4.0 Maturity Model to Evaluate the Readiness of SMEs Implementing Industry 4.0

Nilubon Chonsawat and Apichat Sopadang*Published Date : 2021-04-01

DOI : https://doi.org/10.12982/CMUJNS.2021.027

Journal Issues : Number 2, April-June 2021

Abstract In the Industry 4.0 revolution, advanced manufacturing capabilities integrate technology and data to create intelligent production systems, such as automation, cloud computing, the Internet of Things and cyber-physical systems. Small and medium-sized enterprises, which are the backbone of economic growth, especially must apply the advanced technology in their business and operations so as to increase productivity. This paper empirically proposes the Smart SMEs 4.0 maturity model and its implementation for assessing the readiness of an organisation to enter the realm of smart manufacturing. The model is categorised into five dimensions as well as 43 sub-dimensions for evaluating SMEs 4.0 maturity. These dimensions are mainly composed of “manufacturing and operations”, “people capability”, “technology-driven process”, “digital support” and “business and organisation strategies”. Moreover, the model is implemented in two case studies for two companies in Thailand. The results imply that the model can evaluate an organisation’s readiness and also can guide companies to implement the Smart SMEs 4.0 efficiently.

Keywords: Evaluation, Industry 4.0, Implementation, Maturity model, Readiness, Smart manufacturing, Smart SMEs

Funding: This project has received funding from the European Union’s Horizon 2020 R&I programme under the Mari Skłodowska-Curie grant agreement No 734713 and Excellence Centre in Logistics and Supply Chain Management of Chiang Mai University.

Citation: Chonsawat, N., and Sopadang, A. 2021. Smart SMEs 4.0 maturity model to evaluate the readiness of SMEs implementing industry 4.0. CMUJ. Nat. Sci. 20(2): e2021027

INTRODUCTION

Global industries have declared a new revolution era, known as Smart Manufacturing or Industrial 4.0. Industrialised countries around the world have realised the importance of technology and innovation for improving operational efficiency. Notably, the introduction of technology increases production efficiency and cost.

This revolution involves high-state strategies (Pereira and Romero, 2017), which include smart machines, smart devices, smart products, cyber-physical systems, cloud computing, the Internet of Things (IoT), the Internet of Service and Big Data analysis (Bibby and Dehe, 2018). These integrate production processes and operations through intelligent work systems, such as automation, robotic devices and sensors.

Smart manufacturing systematically incorporates production technology, marketing, logistics and operation management. It can replace labour, paper and documentation, and it supports decision-making. An organisation that wants to transform into Industry 4.0 should be flexible. For example, the information can communicate based on the smart equipment (Reischauer, 2018) along with overall production and supply chains (Zhong et al., 2017).

In the Industry 4.0 revolution, small and medium-sized enterprises (SMEs), which are the backbone of economic growth, have been called Smart SMEs. Smart SMEs have the technology that can integrate from upstream to downstream, including raw material, production, logistics, data sharing, data flow and inventory management (Pereira and Romero, 2017). However, they still lack knowledge about technological applications in business, production and supply chain.

The purpose of this paper is to describe the results of the maturity model that we developed, the Smart SMEs model, in terms of Industry 4.0. This model shows the gap between current SMEs and the highest target of Industry 4.0. It can also guide small enterprises to improve their production efficiency.

The paper is structured as follows. Section 2 describes the background of existing research and related work. Section 3 introduces the Smart SMEs 4.0 maturity model. Section 4 describes model implementation. Finally, section 5 presents our results and conclusions.

MATERIALS AND METHODS

The maturity model

According to definitions of the maturity model, Pullen (2007) said that ‘a maturity model is a structured collection of elements that describe the characteristics of effective processes at different stages of development. It also suggests points of demarcation between stages and methods of transitioning from one stage to another’ (Pullen, 2007). The maturity model is the ‘the state of being complete, perfect or ready’ (Simpson and Weiner, 1989) and ‘the state of being mature; fullness or perfection of development or growth’, according to the Oxford English Dictionary (Wendler, 2012).

The capability maturity model evaluation can be classified into five major levels. In the first, Level 1–Initial, the operation is the chaotic and the individual. Production capability is basic and discontinuous and cannot combine with other departments. These organisations cannot adopt technology into their operations. On Level 2–Manage, the project determines the schedule planning. Cost structure, functionality and quality can be analysed. Process and progress are always assessed and controlled. However, these organisations still have low technological capability. Moreover, customer requirements are identified in the process development for Level 3–Defined, which concerns risk management as well. At Level 4–Qualitatively Managed, the process results in high performance and high quality. Organisations can manage projects and processes with a statistically logical decision. Level 5–Optimising is the highest level. These are the leader companies in developed countries. Defects are rapidly detected and removed, and the organisations identify and develop new tools, processes and products to meet customer needs.

The development of a Smart SMEs 4.0 maturity model

This research includes a review of the literature that examines models and frameworks published in 2015-2018 to find the gap and guideline for the Industry 4.0 readiness assessment.

The development model starts with a literature review of research involving organisations that do not understand how to or are not able to transform into Industry 4.0. Stock and Seliger (2016) suggest that the business model, equipment, human resources, value creation network, organisation, processes and product are the opportunity factors for an organisation in Industry 4.0 (Stock and Seliger, 2016). The IMPLUS (2015), which favoured evaluating Industrial 4.0 readiness, identified the components for assessing an organisation using five levels of the maturity model. They have six dimensions, including strategy and organisation, smart factory, smart operation, smart product, data-driven services and employees (Lichtblau et al., 2015).

Similarly, the University of Warwick (2015) has developed a maturity model for Industry 4.0 assessment. The model has five core dimensions, including ‘products and services, manufacturing and operations, strategy and organisation, supply chain, business model and legal considerations’ (Agca et al., 2105). All dimensions are categorised into four maturity levels.

Brooks et al. (2015) produced a framework for developing a business intelligence maturity model. Subsequently, a maturity model was developed to assess Industry 4.0 readiness by Schumacher et al. (2016). Similarly, Leyh et al. (2016) developed the integration maturity model in terms of Industry 4.0 in 2016.

In 2017, Industry 4.0 Readiness was developed for non-comparative organisations (Gokalp et al. 2017) (Viharos et al., 2017) also developed a capability maturity model of Industry 4.0 (Gokalp et al., 2017). Finally, Issa et al. (2017) developed the Industry 4.0 roadmap framework to evaluate and guide Industry 4.0 readiness from the capability maturity model.

Hence, the maturity model is widely used to measure organisational readiness for Industry 4.0. However, published research primarily assesses larger enterprises; furthermore, some principles are limited to small enterprises. For this reason, this research focuses on the smaller enterprises only. The researchers conducted previous studies that focused on the maturity model and readiness framework. This research extends the model based on “The Development of the Maturity Model to evaluate the Smart SMEs 4.0 Readiness” (Chonsawat and Sopadang, 2019), which developed the capability of the maturity model and the levels for SMEs. This model development presents the main categories and their characteristics in five levels. That is, 43 sub- dimensions can be grouped into five dimensions.

The next section describes the complete model development, which is defined by the dimensions and sub-dimensions, in order to evaluate organisational readiness.

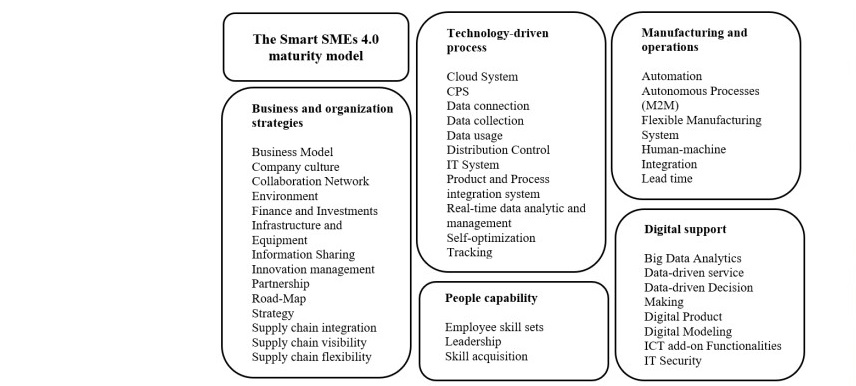

The Smart SMEs 4.0 maturity model

The concept of Smart SMEs from “The Development of the Maturity Model to evaluate the Smart SMEs 4.0 Readiness” (Chonsawat and Sopadang, 2019) classifies the factors used to evaluate an organisation’s readiness into five dimensions and 43 sub-dimensions. Figure 1 shows the five core dimensions, including Manufacturing and Operations, People Capability, Technology-driven Processes, Digital Support and Business and Organisation Strategies (Chonsawat and Sopadang, 2019).

Business and organisation strategies are the management and organisation strategies that support Industry 4.0 principles. They include the following sub- dimensions: Business Model, Company Culture, Collaboration Network, Environment, Finance and Investments, Infrastructure and Equipment, Information Sharing, Innovation Management, Road-map Strategy, Supply Chain Integration, Supply Chain Visibility and Supply Chain Flexibility.

Manufacturing and operations are production processes and operations that use advanced technology, including Automation, Autonomous Processes (M2M), Flexible Manufacturing Systems, Human–Machine Integration, Lead Time, Product Customisation and Risk.

Figure 1. Smart SMEs 4.0 maturity model.

Technology-driven processes involve the implementation of technology and information systems to support production activities. Examples of technology-driven processes include the following: Cloud System, CPS, Data Connection (Information Flow), Data Collection, Data Usage, Distribution Control, IT Systems (Internet of Things, Internet of Service and Industrial Internet), Product and Process Integration System, Real-time Analytics and Management, Real-time Data Management, Self-optimisation and Tracking (product and process).

Digital support is the digital technology of an organisation that supports corporate activities. There are eight sub-dimensions: Big Data Analytics, Data-driven Service, Data-driven Decision Making, Digital Products, Digital Modelling (transformation), ICT Add-on Functionalities, IT Security and Integration Marketing Channels.

People capability refers to personal development to achieve readiness for Industry 4.0. It also emphasises attitudes, knowledge and skills. Employee Skill Sets, Leadership and Skill Acquisition are grouped in this section.

The questionnaires for evaluation

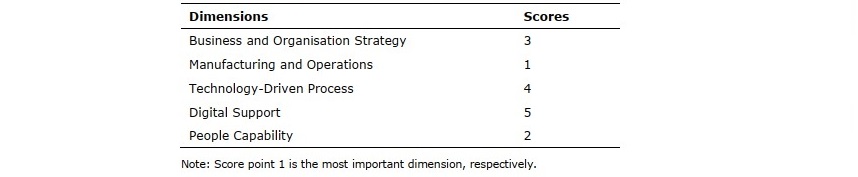

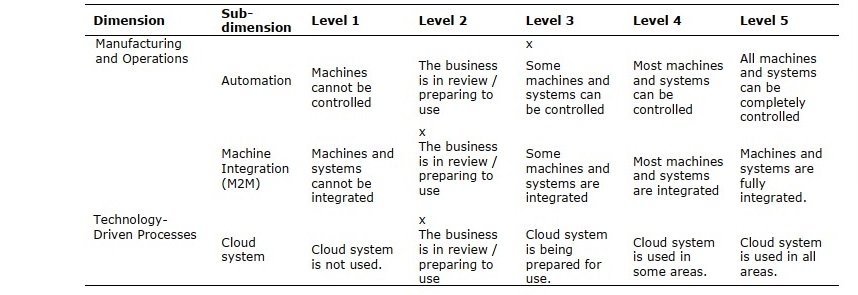

The researchers send the set of questionnaires to the companies by an e-mail. Table 1 shows an example of the questionnaire used to evaluate the important dimensions of the organisation.

Table 1. Example of questionnaire.

Figure 2 shows the weighting score by the rating score of the j dimension divided by the sum of all the i dimensions as in the following:

Where Di = dimension i, r = rating score at the i, j = sub-dimension, And i = dimensions 1,2,3,4 and 5.

Figure 2. Model scoring process.

The model can then be divided into sub-dimensions branched off from the main categories, that is, Manufacturing and Operations, People Capability, Technology-driven Processes, Digital Support and Business and Organisation Strategies. Organisations evaluate their readiness by selecting their capability level for each dimension using the evaluation rubric.

Table 2. Example of readiness questionnaire.

Table 2 displays the questionnaire implemented to evaluate the organisation’s capabilities. The questions are classified into five levels; each level includes different capabilities and companies choose the level that best reflects their capability level.

RESULTS

The two case studies from Thai companies examined implementation of this model. The first company (Company A) is a small enterprise in the plastics industry. Its products are waterproof plastic shoes. Company A’s customers and companies are based in Thailand. The second case study focuses on Company B, a medium enterprise. It is a worldwide company, located in Thailand, China, Japan, the United States, Australia and Singapore. Its products are conveyor and wire mesh made from stainless steel.

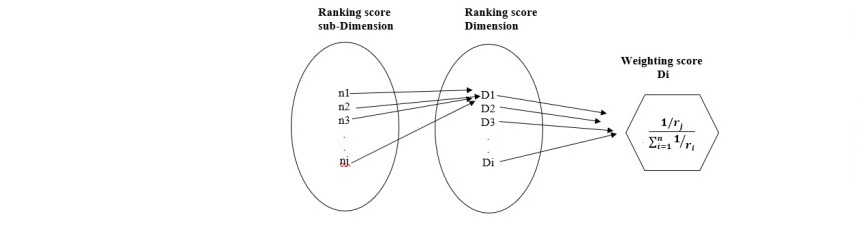

This section presents the results of the model implemented by the case studies. The results contain two parts, the first being the important dimension by weighting score. The highest score shows the most significant factors that require improvement before attempting Industrial 4.0 transformation.

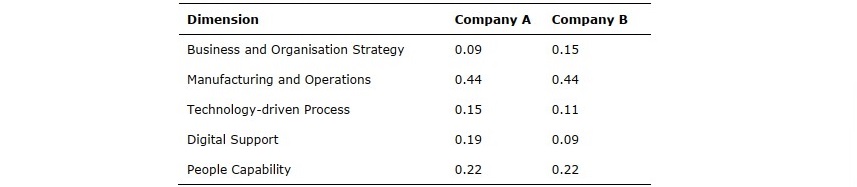

Table 3 shows the most important criteria (dimensions) from Company A and B. The Manufacturing and Operations dimension is the essential factor for company A. In descending order, the other factors by importance are People Capability, Technology- driven Processes, Digital Support and Business and Organisation Strategy. In Company B, Manufacturing and Operations is the most important dimension, while Business and Organisation Strategy, Technology-driven Processes, People Capability and Digital Support are of lesser importance, in descending order.

Table 3. Total score of the important dimensions.

As a result of the weighting score, Manufacturing and Operations and People Capability are the key dimensions for transformation into Industry 4.0 for both companies.

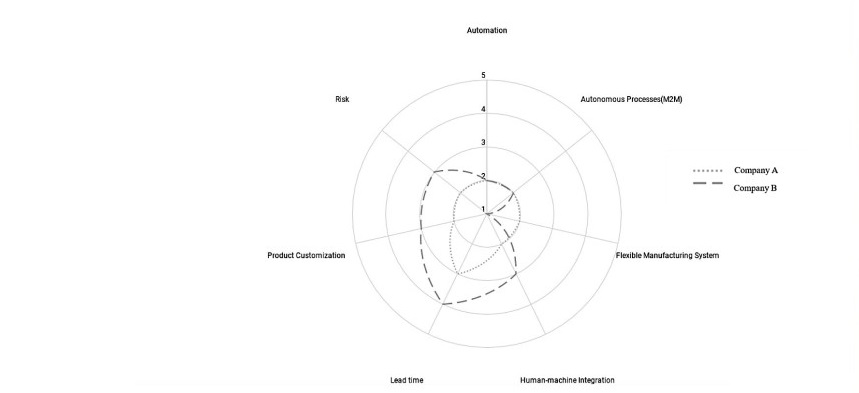

The second part of the results presents the organisation’s degree of readiness. An example of the results of Manufacturing and Operations is shown in Figure 3. In addition, the overall model results can be explained by each dimension.

Figure 3. Example results of the Manufacturing and Operations dimension.

Business and organisation strategies are the organisation’s strategies for supporting Industry 4.0 principles. Business Model, Innovation Management and Strategy are in level 1 for Company A. In addition, Company Culture, Environment, Finance and Investments, Infrastructure and Equipment, Road-map Strategy, Supply Chain Integration, Supply Chain Visibility and Supply Chain Flexibility are in level 2. Only Collaboration Network is in level 3.

Furthermore, the Strategy dimension is in level 1 of Company B. Business Model, Innovation Management and Road-map Strategy are in level 2. Company Culture, Environment, Supply Chain Integration, Supply Chain Visibility and Supply Chain Flexibility are identified in level 3. Finally, dimensions of Collaboration Network, Finance and Investments, Infrastructure and Equipment and Information Sharing are categorised in level 4.

Manufacturing and operations are production processes and operations that use advanced technology. From the model implementation, Company A has Lead Time in level 3. The dimensions of Automation, Flexible Manufacturing System, Autonomous Processes (M2M), Human–Machine Integration, Product Customisation and Risk are evaluated at level 2.

Company B lists Flexible Manufacturing in level 1. Automation and M2M are ranked in level 2. Human–Machine Integration, Product Customisation and Risk fall under level 3. Finally, Lead Time is classified in level 4.

Technology-driven processes refer to the implementation of technology and information systems to support production activities. Company A has Cloud System, CPS, IT Systems (Internet of Things, Internet of Service), Product and Process Integration System and Self-optimisation in level 1. Data Usage, Distribution Control, Real-time Analytic and Management and Real-time Data Management are sorted in level 2. The dimensions of Data Collection, Data Usage and Tracking (product and process) are identified in level 3.

Company B places the dimensions of CPS, Self-optimisation and Tracking in level 1. The Cloud System, Data Connection (Information Flow), Data Collection, Product and Process Integration System, Real-time Data Analytics and Management and IT Systems (Internet of Things, Internet of Service) are determined as level 3. Lastly, Data Usage and Distribution Control are in level 4.

Digital support is the digital technology used in an organisation’s management to support corporate activities. The capabilities of Company A in level 2 include Big Data Analytics, Data-driven Service, Data-driven Decision-Making and Integration Marketing Channels. In addition, the dimensions of Digital Product, Digital Modelling (Transformation), ICT Add-on Functionalities and IT Security are ranked in level 1.

Company B has Digital Product, Digital Modelling, ICT Add-on Functionalities and Integration Marketing Channels in level 2. Data-driven Service and IT Security are ranked in level 3. Finally, the dimensions of Big Data Analytics as well as Data-driven Decision-Making are grouped in level 4.

People capability refers to personal development to achieve readiness for Industry 4.0, which comprises attitudes, knowledge and skills. Employee Skill Sets and Skill Acquisition are in level 2 of Company A. Leadership is in level 3.

Company B has dimensions of Employee Skill Sets as well as Leadership in level 3 and Skill Acquisition is identified in level 2.

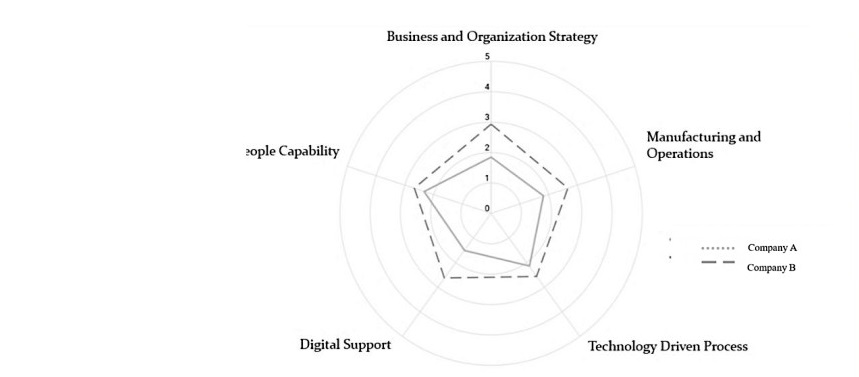

Figure 4 shows the capability degree in the Smart SMEs maturity model. First, Company A has Business and Organisation Strategy, Manufacturing and Operations and Digital Support in level 1. Level 2 includes Technology-driven Processes together with People Capability.

Company B has only Business and Organisation Strategy in level 3. Manufacturing and Operations, Digital Support, Technology-driven Processes and People Capability are grouped in level 2.

The overall potential of Company A was at Level 1–Initial, moving towards Level 2–Managed. The operation of Company A is the individual workstation. The production capability is basic and discontinuous and cannot combine with other departments. The organisation has no capability to adopt technology into its operations.

Company B is potentially in Level 3–Defined, that is to say, the project estimates the schedule planning. They always assess and control processes and progress. Cost structure, functionality and quality can be analysed. Nevertheless, the organisation still has low technological capabilities.

Finally, the model presents the gap between current capability and highest capability. It can be shown using the maturity model presented in the next section.

Figure 4. Results of the Smart SMEs maturity model.

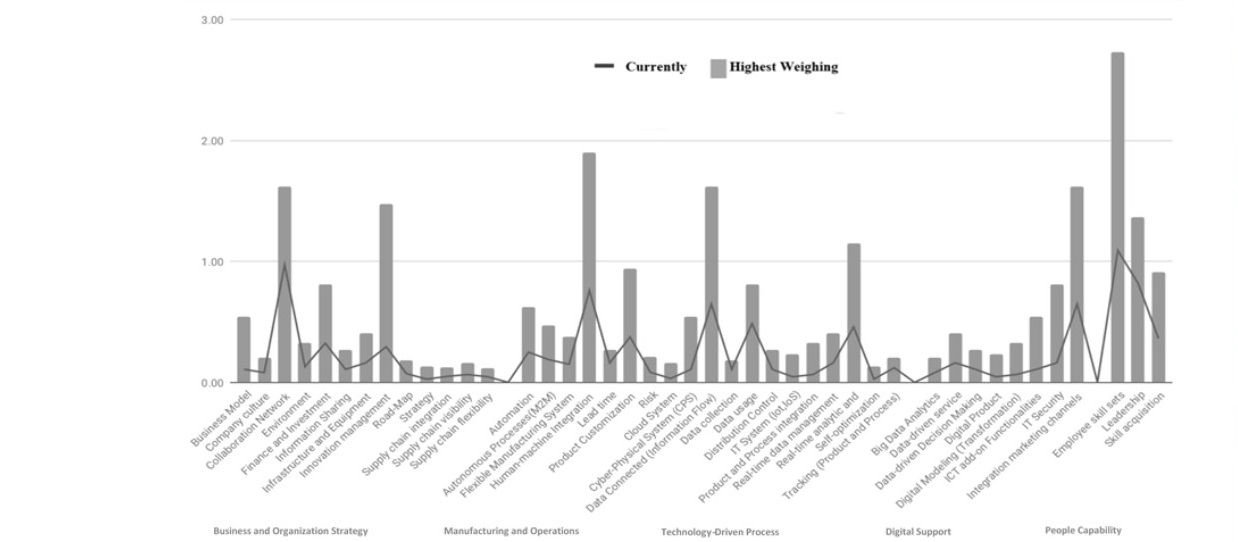

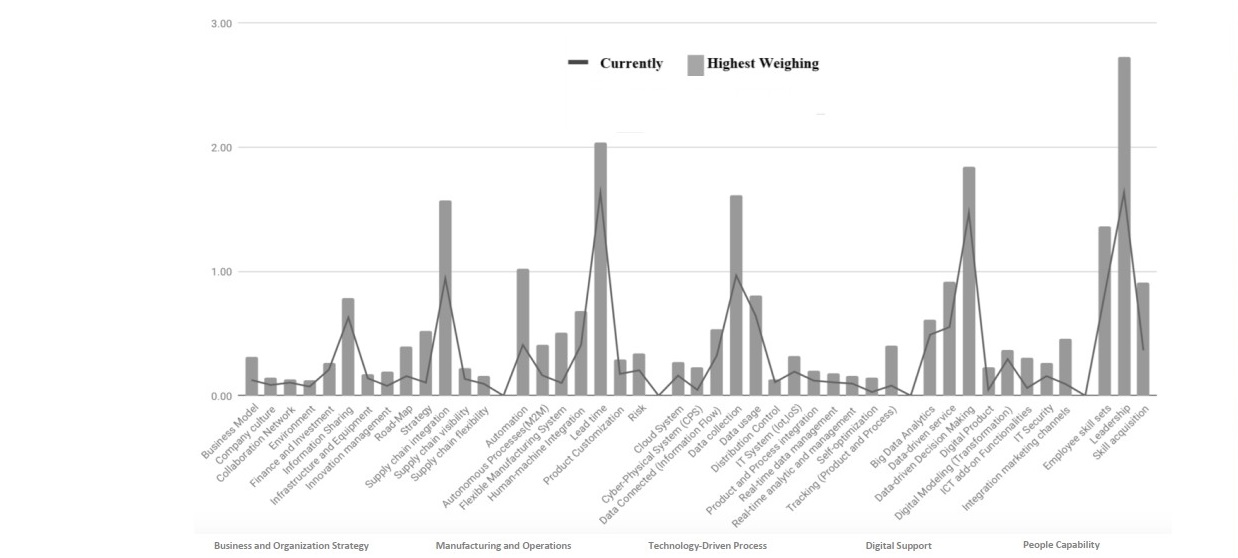

In Figure 5, a graph presents current capability compared to highest capability. It also shows the guideline and suggests Company A develop in five dimensions. The first one is the Business and Organisation Strategies dimension. Company A should improve in Collaboration Network, Innovation Management, Business Model and Finance and Investments.

The dimensions of Manufacturing and Operations, Human–Machine Integration, Product Customisation, and Automation are the most important to be adjusted.

The Technology-driven Processes dimension must be improved upon as it relates to Data Connected, Data Usage and Real-time Analytic and Management.

The dimension of Digital Support should be improved with regard to Integration Marketing Channels, IT Security, and ICT Add-on Functionalities.

Lastly, the dimension of People Capability is the Employee Skill Sets. Due to these factors, the dimensions for Company A reflect lower capability and Company A also has the most significant gap between current and highest capability level.

In the same way, the graph in Figure 6 presents each important dimension. Company B has the biggest gap of current capability and the highest level. The first dimension, Business and Organisation Strategies must be improved upon in Supply Chain Integration, Strategy and Road-map.

The dimension Manufacturing and Operation should be upgraded in Human– Machine Integration as well as Lead Time. Moreover, the dimension of Technology- driven Processes should be improved in Tracking and Process Integration System. The Digital Support dimension is Data-driven Service and Data-driven Decision Making. Finally, the People Capability dimension might be improved in the Leadership category.

The next section will be the discussions, conclusions and limitations and future work of this research.

Figure 5. Gap between the highest and current capability (Company A).

Figure 6. Gap between the highest and current capability (Company B).

DISCUSSION

The purpose of this research is to present the implementation of a maturity model for assessing the readiness for Smart SMEs 4.0 of small manufacturing enterprises. The research extends the model based on “The Development of the Maturity Model to evaluate the Smart SMEs 4.0 Readiness” by Chonsawat and Sopadang (2019), which includes five dimensions and 43 sub-dimensions. These main dimensions include Manufacturing and Operations, People Capability, Technology-driven Processes, Digital Support and Business and Organisation Strategies.

Two parts of the questionnaire are applied in the model implementation. In the first part, the most critical core dimensions are selected, followed by the sub- dimensions. Then, in the second part, the companies choose the level that best reflects their capabilities from the five main levels and their characteristics.

The results show that the model can evaluate the current level of an organization’s readiness and improve their potential. That the same as the readiness assessment model by IMPLUS (2015) and the University of Warwick (2015), however, they have a limitation for a small enterprise. Therefore, this research focuses on SMEs capability and can also help companies to implement Smart SMEs 4.0 efficiently.

The limitation of this model is that sub-dimensions have confusing meanings and some of the criteria are duplicated. Furthermore, the model gives an unclear definition level.

Future research is recommended to develop the model by clarifying the dimensions and sub-dimensions to reduce confusion and eliminating duplication of criteria. The model should improve by developing new indicators for supporting technological change and the future industrial revolution. Afterwards, the model will be sent to small enterprises to collect data and benchmark for SMEs.

REFERENCES

Agca, O., Gibson, J., Godsell, J., Ignatius, J., Davies, C. W. and Xu, O. 2015. An Industry 4 readiness assessment tool. International Institute for Product and Service Innovation University of Warwick. England: London.

Bibby, L. and Dehe, B. 2018. Defining and assessing industry 4.0 maturity levels – case of the defence sector. Production Planning & Control: 1–14.

Brooks, P., El-Gayar, O., and Sarnikar, S. 2015. A framework for developing a domain specific business intelligence maturity model: application to healthcare. International Journal of Information Management. 35: 337–345.

Chonsawat, N. and Sopadang, A. 2019. The development of the maturity model to evaluate the smart SMEs 4.0 readiness. Proceedings of the International Conference on Industrial Engineering and Operations Management. Bangkok: IEM Society International. p. 354-363

Gokalp, E., Şener, U. and Eren, P.E. 2017. Development of an assessment model for industry 4.0: Industry 4.0-MM. Software Process Improvement and Capability Determination: 128–142

Issa, A., Lucke, D., and Bauernhansl, T. 2017. Mobilizing SMEs towards industrie 4.0- enabled smart products. Procedia CIRP. 63: 670–674

Leyh, C., Bley, K., Schäffer, T., and Forstenhäusler, S. 2016. SIMMI 4.0-a maturity model for classifying the enterprise-wide it and software landscape focusing on Industry 4.0. In 2016 Federated Conference on Computer Science and Information Systems (FedCSIS). 1297-1302.

Lichtblau, K., Stich, V., Bertenrath, R., Blum, M., Bleider, M., Millack, A., Schmitt, K., Schmitz, E., and Schroter M. 2015. IMPULS - Industrie 4.0- Readiness. Impuls- Stiftung des VDMA. Aachen-Köln

Pereira, A.C. and Romero, F. 2017. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manufacturing. 13: 1206–1214.

Pullen, W. 2007. A public sector HPT maturity model. Performance Improvement. 46: 9–15.

Reischauer, G. 2018. Industry 4.0 as policy-driven discourse to institutionalize innovation systems in manufacturing. Technological Forecasting and Social Change. 132: 26–33

Schumacher, A., Erol, S., and Sihn, W. 2016. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp. 52: 161-166

Simpson, J. and Weiner, E. 1989. The Oxford English dictionary. 2nd ed. Oxford: Oxford University Press

Stock, T. and Seliger, G. 2016. Opportunities of sustainable manufacturing in industry 4.0. Procedia CIRP. 40: 536–541.

Viharos, Z.J., Soos, S., Nick, G., Vargedo, T., and Beregi, R. 2017. Non-comparative. industry 4.0 readiness evaluation for manufacturing enterprises. 15th IMEKO TC10 Workshop on Technical Diagnostics. Technical Diagnostics in Cyber- Physical Era. Hungary: Budapest.

Wendler, R. 2012. The maturity of maturity model research: a systematic mapping study. Information and Software Technology. 54: 1317–1339.

Zhong, R.Y., Xu, X., Klotz, E. and Newman, S.T. 2017. Intelligent manufacturing in the context of industry 4.0: a Review. Engineering. 3: 616–630.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand https://cmuj.cmu.ac.th

Nilubon Chonsawat1 and Apichat Sopadang2,*

1 Graduate Program in Industrial Engineering, Department of Industrial Engineering, Faculty of Engineering, Chiang Mai University, Chiang Mai 50200, Thailand

2 Department of Industrial Engineering, Excellent Center in Logistics and Supply Chain Management, Chiang Mai University, Chiang Mai 50200, Thailand

Corresponding author: Apichat Sopadang, E-mail: apichat@eng.cmu.ac.th

Total Article Views

Editor: Wasu Pathom-aree,

Chiang Mai University, Thailand

Article history:

Received: February 6, 2020;

Revised: May 12, 2020;

Accepted: May 27, 2020