Maturity Model Assessment of SMART Logistics for SMEs

Poti Chaopaisarn* and Manuel WoschankPublished Date : 2021-04-01

DOI : https://doi.org/10.12982/CMUJNS.2021.025

Journal Issues : Number 2, April-June 2021

Abstract The objective of this study is to propose and operationalise a maturity model assessment of SMART logistics for SMEs. Under the current substantial changes in business practices, the concept of Industry 4.0 (I4.0) has amplified the complexity of the business eco-system, especially for SMEs. Several SMEs have attempted to cultivate the benefits of the technological advancement under the I4.0 concept; however, due to the increasing complexity of technological capabilities and development of adequate strategies, a rising concern of uncertainty hinders the adaptation of new management practices such as SMART logistics. The current paper intends to contribute to fill the scientific ‘gap’ with the question on how SMEs may assess their readiness in adapting the I4.0 and how they could plan their activities and operations to heighten firms’ competitive advantage through SMART logistics in the current business environment. Overall, the authors have identified six dimensions and assigned 18 items for assessing the maturity of I4.0 for SMEs. The model has been transformed into a practical tool that can be used to test the readiness of firms in a real business environment.

Keywords: Indicator assessment, Maturity model, Measurement model, SMART logistics, SMEs

Funding: The project “SME 4.0 – Industry 4.0 for SMEs” has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie grant agreement No. 734713

Citation: Chaopaisarn, P., and Woschank, M. 2021. Maturity model assessment of SMART logistics for SMEs. CMUJ. Nat. Sci. 20(2): e2021025.

INTRODUCTION

With the growing attention of the so-called fourth industrial revolution (I4.0), modern companies are adding new intelligent technologies to create a network capable system and to urge a smarter and efficient workflow throughout the supply chain. Simultaneously, this has altered the way that a product is delivered from the production factory to a customer based on an array of SMART devices which potentially offers a cohesive and a highly visible logistics system. While the application of SMART devices on logistics activities presents a promising value-added proposition for companies to navigate through the complexity of supply chain, hurdles and bottlenecks may pose potential challenges for companies, especially for small and medium-sized enterprises (SMEs). Due to the nature of a competitive environment, SMEs are sensitive to the economic, social and political environment; therefore, developing a stable relational network would assist them to ensure business viability in their business eco-system (Thakkar et al., 2009). Furthermore, one of the main obstacles which hinder SMEs to integrate the concept of I4.0 in their business structure is the level of expected cost- benefit and attitude towards changes (Tu, 2018; Tu et al., 2018). Thus, the development of maturity model assessment is needed to evaluate the readiness of SMEs in the adaptation of I4.0.

Inspired by Capability Maturity Model Integration (CMMI), a maturity model is a structured collection of elements that describe the characteristics of an effective process at different stages of development (Wendler, 2012). The concept of maturity model was developed as a grid to not only measure software-related domains, but to analyse and measure quality management of activities and tasks. According to Battista and Schiraldi (2013), a maturity model highlights possible improvement through identification of appropriate actions to be taken to increase the processes in the industrial companies and allowing any user to easily and rapidly understand the more critical issues in terms of process immaturity. Other than the software engineering, the CMMI model can be found in supply chain performance (Estampe et al., 2013), fashion companies (Battista and Schiraldi, 2013), logistics processes (Benmoussa et al., 2014) and defence supply network (Bibby and Dehe, 2018).

In this paper, the authors attempt to develop a maturity assessment model to systematically assess SMEs’ capabilities of integrating SMART logistics in relation to the vision of I4.0. The contribution of the proposed maturity assessment model is twofold. Scientifically, it is aimed to collect data regarding the current state of firms’ strategy for I4.0 and to compare the key enablers of different countries. Practically, this paper is aimed to assist companies to evaluate the maturity of its I4.0 strategies in the scales of SMEs. The paper is structured as follows. In section 2, theory and methods of I4.0 in relation to SMEs are defined to state the foundation of this paper, which is followed by section 3 where dimensions of SMART Logistics are identified based on existing research. In section 4, the concept of readiness and maturity assessment models are reviewed with an introduction to the proposed maturity assessment model. Finally, in section 5, the authors conclude the usability of the model and limitations of the model with suggested future research.

MATERIALS AND METHODS

SMART Logistics

With the growing attention to the technological advancement in logistics, this has led to new innovative technologies such as SMART containers, SMART warehousing, SMART ports, SMART shelves, and SMART manufacturing (Tu, 2018). As concerns mount about the economic and environmental cost of logistics activities, SMART logistics address the precision, reliability, and efficiency of logistics execution through the improvement of information and capability of data utilisation. According to Weyer et al. (2015), a strong network of automated technologies has allowed higher flexibility of operations and interoperability in-between modules of the production line. With emerging technologies, traditional logistics activities which are human-operated are gradually replaced through a decentralised and self-organised cyber-physical system (CPS).

CPSs are identified as modular factory structures composed of smart devices that are connected in an IoT network. The production line will be flexible and modular so that even a small lot size can be produced under conditions of flexible mass production. This will allow SMEs to capture the diversification of customer needs, which may be considered as difficult for larger firms due to lack of economy-of-scale. With current available technological resources, SMART logistics have allowed firms to prevent empty runs on resources and attain higher efficiencies in real-time.

Industrial 4.0 and SMEs

The principle of the I4.0, is the implementation of the Internet of Things (IoT) and smart manufacturing, work in process products, components and production machine which collect and share data in real-time. This allows firms to shift from a centralised production plant to decentralised intelligence. Since the published report of I4.0 in 2013 by the German National Academy of Science and Engineering, comprehensive research and development have been quickly accelerated in both academia and industry professionals (Stock and Seliger, 2016). The German government initiated the computerisation of manufacturing industries in their I4.0 programme, while, in the United States, the Smart Manufacturing Leadership Coalition (SMLC) programme was promoted and other major manufacturing companies, such as in Japan, Korea and China, have also established national agenda on SMART manufacturing, warehousing and logistics programmes (Wang et al., 2015; Stock and Seliger, 2016).

Following an extensive search of the definition of SMEs, to the best of authors’ knowledge, a standard criterion for SME qualification does not exist. In accordance to industrial and cultural variance of different countries, various types of indicators are used to draw the line between multinational companies (MNC) and SMEs (OECD, 2017). However, it is worth noting that SMEs account for approximately 99 percent of all firms, which create 70 percent of jobs by, on average, generating 50 to 60 percent value added products and services. With the nexus of I4.0 and SMEs, SME companies are able to grow in a niche market segment and are able to gain competitive advantages through the exploitation of available technologies and to capture commercial opportunities in response to the growing diversification of customer needs (Chaopaisarn and Woschank, 2019).

RESULTS

Literature review

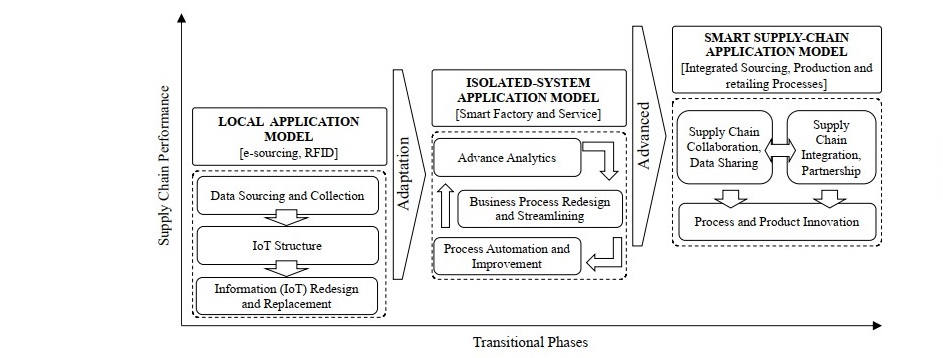

Chaopaisarn and Woschank (2019) proposed a SMART supply chain management implementation model with three distinct transitional phases, namely, local application model (LAM), isolated-system application model (IAM) and SMART supply-chain application model (SSAM). The aim of the model is to conceptualise the transitional phases and requirement of enabling SMART supply-chain management (SSCM) for SMEs. The model identifies key technological enablers for SMEs to elevate operational and managerial practice to encapsulate possible benefits of the I4.0 (Figure 1).

Figure 1. SMART Supply Chain Management Implementation Model.

According to Figure 1, a certain period of adaptation is needed for SMEs to advance themselves to integrate I4.0 activities into their business eco-system to proliferate overall supply chain performance. In the phases of the SSCM implementation model, SMEs would require empowering a selective range of information technologies to conduct operational decisions. Thus, it gives SMEs the abilities to access strategic resources which would be considered as critical for their competitiveness and allow rapid process and product innovations (Chaopaisarn and Woschank, 2019).

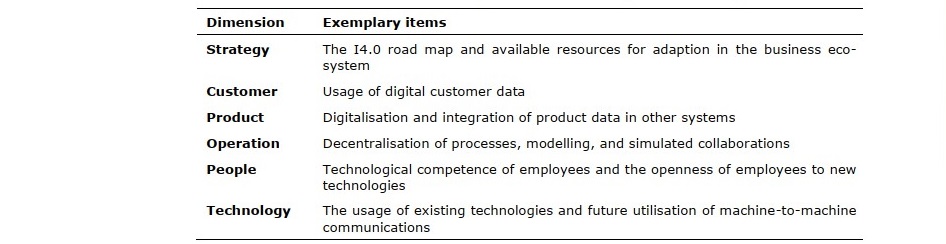

In the search of I4.0 dimensions, four assessment models that are widely used in the industry are selected and examined, namely, IMPLUS model, Empowered and Implementation strategy for Industry, Industry 4.0/Digital Operation Self-Assessment and The Connected Enterprise Maturity Model (Schumacher et al., 2016). One of the similarities among these models is the use of a maturity model as the main instrument to conceptualise and measure the maturity of a process regarding to some specific target state. However, most of these models have been used in the eco-design of manufacturing or lean manufacturing. One of the most commonly used models, IMPULS, has been widely accepted and served as the foundation of this research to formulate a suitable assessment model for SMEs. There are two reasons why the IMPULS model is selected. First, the model is well-grounded in its structure in explaining the usage of technologies in the organisation under a transparent manner. Second, the model offers a structured content in explaining the development process and assessment for detailed comparisons (IMPULS, 2016). Furthermore, the maturity model proposed by Schumacher et al. (2016) was adapted to further operationalise the model to allow it to be transparent and easy to use in a real industrial environment. In order to facilitate different analyses of I4.0 maturity phases, the proposed model includes a total of 18 maturity items which are grouped into six dimensions. Table 1 provides an overview of the dimensions used in this paper with exemplary items to support the understanding of the proposed groups. Each of the dimensions will undergo key enablers of the local application model (LAM) examined hereunder.

Table 1. Dimensions and Maturity Items of Industry 4.0 Maturity Model.

Local application model

Through the advancement of information systems and technology, the concept of supply chain and logistics has undergone a massive change and substantial investments have been spent to seize new opportunities and competitive advantages (Wu et al., 2016). According to Chaopaisarn and Woschank (2019), a certain period of adaptation and level of usage is needed for SMEs to obtain desired results. Referring to future research suggestions, as stated by Chaopaisarn and Woschank (2019), the main objective of this paper is to identify holistic assessment of SMART logistics integration in SMEs with operationalised indicators through maturity assessment theories. The phase that the authors will solely focus on is the LAM stage of the implementation model. The reason is twofold. First, the authors wish to operationalise the maturity assessment model for SMEs to identify shortcomings of adapting to I4.0. Second, to the best of the authors’ knowledge, this is one of the pioneer researches in assessing the adaptation of SMEs to the concept of I4.0.

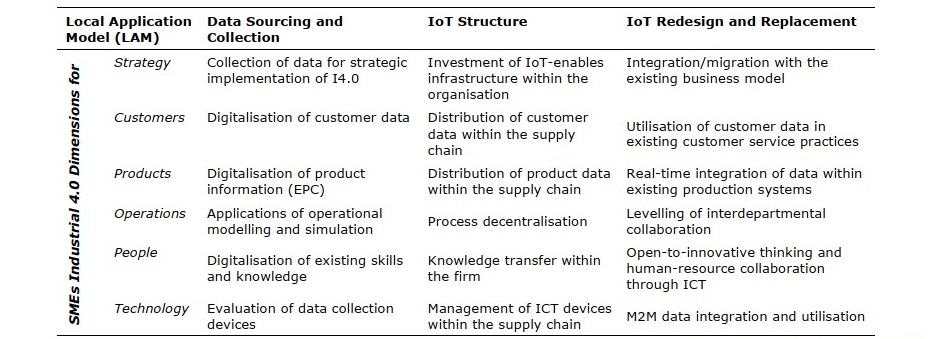

Three key enablers for LAM model are data sourcing and collection, then transmitting them in real-time through IoT structure and then, finally, redesigning and replacing the existing platform with new interphases to optimise the use of the collected data (Wu et al., 2016). The objective of this model is to highlight the use of data in the current phase of operational functions to IoT structural decision-based activities. Selected examples of these IoT structural decision-based activities are electronic product code (EPC), radio frequency identification (RFID) and Big Data. In order to use these indicators to assess the readiness of the SMEs in the early phase of I4.0 adaptation, a maturity assessment model is adapted and implemented. According to Table 2, a total of 18 measurement items are identified and are operationalised through the maturity model examined in the following section.

Table 2. Measurement Indicators of LAM for SMEs.

Maturity assessment model

A great deal of literature addresses various topics on the matter of maturity models which are commonly used to conceptualise and measure the development stages of computer software and quality management with the goal to capture the development process of desired future states (Schumacher et al., 2016). According to Schumacher et al. (2016), the difference between readiness and maturity assessment lies in the starting-point of the assessment process. For example, readiness assessment takes place before engaging in the maturity stage, while the maturity assessment captures the as-is state of the maturing stage. The evaluation of the maturity level of each item is conducted using standard Likert-scale reaching from 1 to 5, ranging from beginner to top performer. The evolution path of each maturity level is where the initial level describes the discipline process of the firm in learning new skills in information technology. The following levels respond to the consistency and experiences gained through the adaption phase of new information technology skills. The final two levels illustrate the continuous improvement process of the firm to gain the status from expert to top performer in the industry.

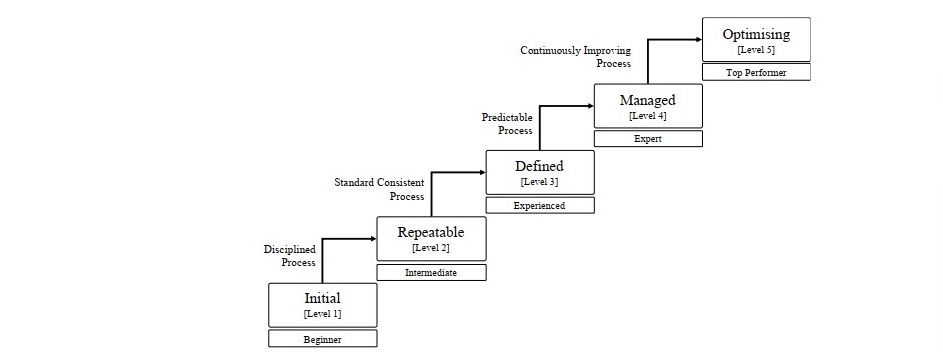

Figure 2. Capability Maturity Model of Industrial 4.0 for SMEs (CMMI-SMEs).

The proposed CMMI-SMEs model consists of five maturity levels, which are initial, repeatable, defined, managed and optimising. The maturity continuums are defined hereunder.

Initial: the starting point for the use of a new or undocumented process which might initially cause chaotic or unstable environment for the process. A highly anticipated learning curve is required to stabilise the process to capture the key benefits.

Repeatable: The processes are repeatable with possible constant results. This is unlikely to be rigorous whereby it may help to ensure that existing processes are maintained during the time of stress.

Defined: A set of defined and documented standard processes are established and subject to some degree of improvement over time. The processes may not have been systematically or repeatedly used but may become more competent or prove to be validated in a range of situations. This could consider a development stage with use in a wider range of conditions and user competence development of the process in the next level of maturity.

Managed: The use of processing metrics to quantitatively manage the process objectives through a range of operational conditions. The suitability of the improved process has been rigours tested in multiple environments and has been fully refined and adapted.

Optimising: The final level of the maturity model which focuses on the continuous improvement process through incremental and innovative technological changes and improvements.

It is important to stress that each individual level is a reflection of the respondent’s perspectives in the understanding of the concept of I4.0; therefore, an initial I4.0 knowledge session is suggested to gain a general understanding of the concept and to gain a representable insight and accuracy of the proposed capability maturity model.

DISCUSSION AND CONCLUSIONS

The research work presented here aimed for the development of a maturity model for assessing the I4.0 maturity of SMEs in development towards SMART Logistics. In contrast to other maturity model approaches, e.g. the frequently used CMMI (Wendler, 2012) the proposed CCMI-SMEs features the inclusion of SME- related perspectives aimed to gain a more comprehensive result.

However, the model is still at its development phase and more rigorous testing is required to provide a solid point of reference for further strategic measures. The implementation stage of the model would be focused on collection of questionnaire data from the industry. Based on the definition of SMEs by the Thai Ministry of Commerce, the questionnaires will be distributed based on the registered capital, number of employees and type of business (OECD, 2017). An equal distribution of data will be attempted to increase the generalisability of the model. From an academic standpoint, the conceptual model for assessing the maturity levels of the SMEs allows the researchers to collect data on firms across different industries and to identify additional success factors for effective implementation of I4.0 strategies (Dallasega et al., 2020).

Future research activities will mainly aim at identification of firms’ target state of data usage in the adaptation of SMART logistics and to examine distinctive patterns of SME operations to integrate the CCMI-SMEs into the decision-making process in a user- friendly way.

REFERENCES

Battista, C. and Schiraldi, M.M. 2013. The logistic maturity model: application to a fashion company. International Journal of Engineering Business Management. Special Issue on Innovations in Fashion Industry. 5: 1-11.

Benmoussa, R., Abdelkabir, C., Abd, A., and Hassou, M. 2014. Capability/maturity based model for logistics processes assessment: application to distribution processes. International Journal of Productivity and Performance Management. 64: 28-51.

Bibby, L. and Dehe, B. 2018. Defining and assessing industrial 4.0 maturity levels- case of the defence sector. Production Planning and Control: The Management of Operations.

Dallasega P., Woschank M., Zsifkovits H., Tippayawong K., Brown, C.A. 2020. Requirement analysis for the design of smart logistics in SMEs. In: Matt DT, Modrák V, Zsifkovits H, and Zsifkovits, H., editors. Industry 4.0 for SMEs. Cham: Springer. p. 147–162.

Estampe, D., Lamouri, S., Paris, J-C. and Brahim-Djelloul, S. 2013. A framework for analysing supply chain performance evaluation model. International Journal of Production Economics. 143: 247-258.

Chaopaisarn, P. and Woschank, M. 2019. Requirement analysis for SMART supply chain management for SMEs. Proceedings of the International Conference on Industrial Engineering and Operations Managementß. Bangkok, Thailand.

OECD. 2017. Enhancing the contributions of SMEs in a global and digitalized economy. Paris: OECD Publishing.

Schumacher, A., Erol, S., and Sihn, W. 2016. A maturity model for assessing Industrial 4.0 readiness and maturity of manufacturing enterprises. Procedia in Changeable, Agile, Reconfigurable and Virtual Production. 52: 161-166

Stock, T., and Seliger, G. 2016. Opportunities of sustainable manufacturing in Industry 4.0. 13th Global Conference on Sustainable Manufacturing – Decoupling Growth from Resource Use. 40: 536-541.

Thakkar, J., Kanda, A., and Deshmukh, S.G. 2009. Supply chain management for SMEs: A research introduction. Management Research News. 32: 970-993.

Tu, M. 2018. An exploratory study of Internet of Things (IoT) adoption intention in logistics and supply chain management: A mixed research approach. The International Journal of Logistics Management. 29: 131-151.

Tu, M., Lim, M.K., and Yang, M-F. 2018. IoT-based production logistics and supply chain system – Part 1: Modeling IoT- based manufacturing supply chain. Industrial Management & Data Systems. 118: 65-95.

Wang, L., Törngren, M., and Onori, M. 2015. Current status and advancement of cyber-physical systems in manufacturing. Journal of Manufacturing Systems. 37: 517-527.

Weyer, S., Schmitt, M. Ohmer, M., and Gorecky, D. 2015. Towards industry 4.0 – standardization as the crucial challenge for highly modular, multi-vendor production systems. International Federation of Automatic Control. 48: 579-584.

Wendler, R. 2012. The maturity of maturity model research: A systematic mapping study. Information and Software Technology. 54: 1317-1339.

Wu, L., Yue, X., Jin, A., and Yen, D.C. 2016. Smart supply chain management: a review and implications for future research. The International Journal of Logistics Management. 27: 395-417.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand https://cmuj.cmu.ac.th

Poti Chaopaisarn1,* and Manuel Woschank2

1 Center of Excellence in Logistics and Supply Chain Management, Chiang Mai University, Chiang Mai 50100, Thailand

2 Chair of Industrial Logistics, Montanuniversitaet Leoben, Leoben, Austria

Corresponding author: Poti Chaopaisarn, E-mail: poti@eng.cmu.ac.th

Total Article Views

Editor: Wasu Pathom-aree,

Chiang Mai University, Thailand

Article history:

Received: February 6, 2020;

Revised: May 12, 2020;

Accepted: May 27, 2020