Effects of Plasma Treatment on Cooking and Physical Qualities of Pigmented Thai Rice

Metanee Noppakun, Srisuwan Naruenartwongsakul, Phisit Seesuriyachan,Yuthana Phimolsiripol, Dheerawan Boonyawan, and Pilairuk Intipunya*Published Date : 2020-12-17

DOI : https://doi.org/10.12982/CMUJNS.2021.004

Journal Issues : Number 1, January-March 2021

Abstract Plasma surface modification processes account for most of the commercial uses of surface modification because they are fast, efficient methods for improving the adhesion, wettability properties and other surface characteristics of a variety of materials. This research was aimed to investigate of surface modification of pigmented rice by plasma technique. Two rice varieties namely Kum Doi Saket and Hom Nil rice were used. The samples were subjected to plasma treatment with different gas types to determine suitable gas type. The types of gas for plasma treatment were argon, nitrogen and air. The output voltage of the plasma was 0.1428 W at the frequency of 110 Hz and treatment time of 40 min. It was found that plasma treatment with various gas types on the samples caused a reduction in cooking time and increase in water uptake ratio, length expansion ratio and volume expansion ratio, an increase in water absorption, a decrease in contact angles as compared to untreated sample. These results were related to etching of the bran layer of the rice grain which allowed better water transfer into the grain during cooking. It was also found that plasma production using plasma gas had more effect on texture of the rice grains, as compared to without plasma treatment.

Keywords: Plasma gas, Rice surface modification, Cooking quality, Physical property

Funding: This research was supported by grants funded by National Research Council of Thailand (NRCT) and the Graduate School of Chiang Mai University. The authors thank the Faculty of AgroIndustry, Chiang Mai University for providing instruments.

Citation: Noppakun, M., Naruenartwongsakul, S., Srisuriyajan, P., Pimolsiripol, Y., Boonyawan, D., and Intipunya, P. 2021. Effects of plasma treatment on cooking and physical qualities of pigmented Thai rice. CMUJ. Nat. Sci. 20(1): e2021004.

INTRODUCTION

Thailand is one of the most efficient producers and one of the world largest rice exporters (Forssell, 2009). There are many types of pigmented Thai rice that provide outstanding benefits such as Kum Doi Saket, Hom Nil, Riceberry and Sangyod. Normally, brown rice or unpolished rice is often considered healthier rice than white rice because of its higher nutritional value (Khamtong et al., 2014). Pigmented rice contains essential nutrients such as proteins, dietary fibers, vitamins, minerals, γ-oryzanol, gamma-aminobutyric acid (GABA), tocotrienol, octacosanol and carotenoid (Champagne, 2004; Chen et al., 2012). However, most people do not prefer cooked brown rice due to its poor cooking and eating qualities (Das et al., 2008). There are several reports on studies to reduce the cooking time of brown rice such as enzymatic treatment (Das et al., 2008; Somjai, 2015), germination (Chung et al., 2012; Cornejo et al., 2015; Li et al., 2018), and ultrasonic treatment (Cui et al., 2010; Zhang et al., 2015; Park and Han, 2016; Bonto et al., 2018). However, these treatments have some disadvantages such as being complicated processes, low quality appearance, undesirable texture and taste, unpleasant odors (Cui et al., 2010; Chen et al., 2012; Chen, 2014).

Plasma is the fourth state of matter besides solid, liquid, and gas. It is consisted of positive and negative ions, electrons, free radicals, atomic species, and UV photons with a net neutral charge (Gaunt et al., 2006; Kogelschatz, 2007). There are two types of plasma; thermal (hot plasma) and non-thermal (cold plasma) plasmas (Mantham, 2006). Many researches apply cold plasma treatment in both solid and liquid foods (Chen et al., 2012; Chen, 2014; Bahrami et al., 2016; Halee et al., 2016; Kovacevic et al., 2016; Thirumdas et al., 2017; Dixit et al., 2018) due to its ability to improve surface of material and does not require chemicals. Thus after plasma, there is no environmental pollution expelled (Dobrin et al., 2013). Furthermore, the plasma technology was successfully used to improve surface properties of non-food materials, for example, textiles and polymers (Kan et al., 1998; Laroussi, 2005; Pankaj et al., 2014; Wasy zia et al., 2014; Arolkar et al., 2015).

Plasma etching is one of the plasma processes. It can improve surface properties of a substrate. The particles occurred as plasma (ions, electrons, free radicals and other) during plasma generation will collide with the surface of the material exposed to the plasma. The surface is obtained with desired functions and geometries (Braithwaite, 2000). Plasma etching applies gases or gas combinations such as argon, nitrogen and oxygen. Some research found that the plant seed surface had discoloration, visible damages and a reduced germination by using of nitrogen and oxygen plasma which may be due to a degradation of surface polysaccharides (Selzuk, 2008), while increased germination rate was found when argon was used (Volin, 2000). Zou et al. (2004) reported that argon glow discharge plasma could be used to modified starch by generating cross linking between starch molecules. The loss of OH groups during the cross-linking of α-D-glucose is due to a collision of Are-species with hydroxyl group. Ar plasma can change the surface topography and surface chemistry of powders (Dixit et al., 2018). Thirumdas (2015) reported that low temperature plasma treatment can be used to improve cooking quality of basmati rice. The plasma treatment decreased contact angle and increased surface energy of the rice grains. The etching and the increase in surface energy of rice grains could be useful to reduce cooking time due to better water absorption into the grains. The cooking time, hardness and water contact angles of parboiled rice were reduced after plasma treatment. Also the cooked brown rice has a soft texture (Chen et al., 2012; Chen, 2014; Sarangapani et al., 2015; Lee et al., 2016).

This research was aimed to investigate the application of plasma technology for rice quality improvement by mechanism of surface modification. In this study, effects of plasma from different gasses on cooking, physical and chemical properties of rice were investigated, in order to find a suitable gas types for plasma surface modification of unpolished pigmented Thai rice.

MATERIALS AND METHODS

Rice sample

Kum Doi Saket and Hom Nil (Oryza sativa L.) were procured from Chiang Mai, Thailand, which grown in wet-season from June to August and harvest between October to December 2015. The samples were carefully dehusked and vacuum sealed in aluminum foil bags (150×250 mm) and stored at 4°C until further analysis within 1 week.

Plasma treatment

Samples of pigmented rice (2.5 g) were paste on double sided tissue tape, then placed on an alumina (4x4 cm) plate. The distance between the electrodes was 1 mm in all the experiments and exposure to plasma using dielectric-barrier discharge (DBD). The gases used for plasma generation were argon, nitrogen and air. The output voltage of the plasma was 0.1428 W with frequency of 110 Hz and treatment time of 40 min at gas flow rate of 2 L/min. From the preliminary experiment, it was found that a treatment time of 40 min could obviously influence the surface of brown rice. Therefore, the process time for this experiment was fixed at 40 min. The experiment was conducted in a complete randomized design (CRD) with 3 replications. Untreated rice samples were used as the control samples. The control samples and plasma-treated Kum Doi Saket and Hom Nil rice samples were analyzed for cooking quality, physical and chemical properties as follows:

Cooking properties measurement

Optimal cooking time (OCT). The OCT was determined using the method of Chen et al. (2012). Two grams (2 g) of sample was added to boiling water (20 mL). A few kernels were removed after 10 min of boiling and then at every 1 min interval during cooking. The kernels were pressed between two glass plates until no white core was present. The cooking time until the white core disappeared was noted as OCT.

Water uptake ratio (WUR). Rice samples (2 g) were cooked in 20 mL of distilled water for optimal cooking time in boiling water on a hotplate (MR 3001, Heidolph, Schwabach, Germany). The cooked samples were then accurately weighed and the WUR was calculated according to equation (1) (Somjai, 2015).

WUR = Weight of cooked rice / Weight of uncooked rice (1)

Length expansion ratio (LER). Length of each cooked grain was measured using a digital caliper (CD-6 CSX, Mitutoyo, Takatsu-ku, Kawasaki, Japan) (measuring range 0-150 mm or 0-6 inch). The lengths of ten cooked rice kernels were divided by lengths of 10 uncooked raw kernels and the result was reported as LER (Chen et al., 2012), as calculated using equation (2)

LER = Final grain length after cooking / Initial grain length before cooking (2)

Volume expansion ratio (VER). Two gram (2 g) samples were weighed into a test tube and 5 mL distilled water was added. Cooking was carried out by placing the sample test tube in boiling water and cooked until reaching OCT. The volume ratio of raw kernel and cooked was determined by water displacement method using a measuring cylinder. The VER was calculated using equation (3) (Verma et al., 2015).

VER = Volume of cooked rice / Volume of uncooked rice (3)

Water absorption behavior in soaking procedure

Water absorption was measured using the method of Chen et al. (2012) for up to 5 h. Samples of pigmented rice, approximately 5 g, were weighed to an accuracy of ±0.1 mg. The samples were transferred into 30 mL vessels with screw caps, large enough to prevent the kernels from touching each other. The flasks were then placed at room temperature. At specific times, the soaked rice was placed on a filter paper (1001-020, Whatman No.4, 110 mm). The kernels were quickly blotted with another filter paper (3-5 times) until they lost the glistening appearance associated with the presence of a surface film of water. After blotting, the grains were transferred into a prepared weighing bottle and weighed to an accuracy of ±0.1 mg. Percentage water absorption was calculated from the increased in weight of rice kernels after soaking. The water absorption was calculated using equation (4).

Water absorption (%) = Weight of soaked rice − Weight of unsoaked rice / Weight of unsoaked rice × 100 (4)

Water contact angle and surface energy

The effect of the plasma on the hydrophilicity of pigment rice was determined by water contact angle (Deshmukh and Bhat, 2003). A 0.5 ml droplet of water was applied on the surface of rice kernel with and without plasma treatment. The evolution of the droplet shape was recorded each 10 s by a video camera, image analysis software (Sessile drop, Plasma and Beam Physics, Thailand) was used to determine the contact angle evolution. The surface energy was calculated from water contact angle values, using Neumann's equation (equation 5) as described by Deshmukh and Shetty (2008);

S. E = A(θ) 3 − B(θ) 2 −C(θ) +γl (5)

where A, B, and C are constants, θ is angle of contact and γl is surface tension of a liquid (water). The constant values of A, B and C used for calculation of the surface energy were 2.9×10-5, -0.00652, and -0.1326, respectively (Ward and Neumann, 1974). Since the water contact angle was measured at 25oC, the corresponding water’s surface tension of 71.99±0.05 mN/m-1 was used in the equation (5) (Pallas and Harrison, 1990).

Microstructure of rice kernel surface

Surface morphology of rice kernel was examined using a scanning electron microscopy (SEM). The rice samples were sputter-coated with gold and observed by JEOL JSM- 5910LV, Japan (operating at 0.3 to 30 kV, spatial resolution of 4.5 nm) (Chen, 2014).

Proximate analysis

Chemical compositions of rice samples were analyzed according to AOAC (2000) standard methods. The moisture content of the rice sample was determined after drying at 105oC until a constant weight was attained. Protein was determined by combustion (LEGO EP-528, United States). Crude lipids were extracted with petroleum ether, using a soxhlet extraction unit (Tecator A Perstorp Analytical Company, Sweden). Ash and fiber contents were determined using gravimetric methods. The total crude carbohydrate was estimated by the equation (6).

Carbohydrate (%) = 100 − (%moisture + %protein + %lipids + %fiber + %ash ) (6)

Statistical analysis

The experiment was carried out using a complete randomized design (CRD) with 3 replications. Measurements were conducted in triplicates. The results were statistically analyzed by one-way ANOVA technique using SPSS and Duncan's multiple range test was used to determine significant differences between mean values. Statistical significance was declared at 95% confidential level (P≤0.05).

RESULTS

Effect of plasma treatment on cooking properties

Cooking quality parameters measured in terms of optimal cooking times (OCT), water uptake ratio, length expansion ratio and volume expansion ratio are shown in Table 1.

Table 1. Cooking properties of Kum Doi Saket and Hom Nil rice after treatment with plasmas from different gases.

|

Plasma gas |

Optimum cooking time (min) |

Water uptake ratio |

Length expansion ratio |

Volume expansion ratio |

|

|

Kum Doi Saket Untreated Argon Plasma |

40.0a 34.0b |

1.51b ± 0.04 1.64a ± 0.03 |

0.99b ± 0.01 1.06a ± 0.01 |

1.71a ± 0.00 1.89a ± 0.19 |

|

|

Nitrogen Plasma |

34.0b |

1.65a ± 0.07 |

1.08a ± 0.01 |

1.89a ± 0.10 |

|

|

Air Plasma Hom Nil Untreated Argon Plasma Nitrogen Plasma Air Plasma |

34.0b

30.0a 28.0b 28.0b 28.0b |

1.68a ± 0.06

1.73a ± 0.04 1.75a ± 0.10 1.75a ± 0.07 1.77a ± 0.06 |

1.05a ± 0.02

0.99c ± 0.01 1.04ab ± 0.02 1.06a ± 0.03 1.01bc ± 0.01 |

1.83a ± 0.00

1.81b ± 0.08 2.07a ± 0.11 2.00a ± 0.00 2.02a ± 0.03 |

|

Note: Values presented in the table are means + standard deviations. Different superscripts after the mean values in the same column indicate significant differences of means at 95% confidence level (P≤0.05).

After treatments with plasmas from different gases, the OCT of both rice varieties decreased as compared to those of the control samples (P≤0.05). The cooking times of Kum Doi Saket and Hom Nil samples were reduced by 16% and 6.67%, respectively. The water uptake ratios of both rice samples treated with plasma increased to the ratios of 1.64-1.68 and 1.75-1.77, respectively, as compared to untreated brown rice. The length expansion ratios of Kum Doi Saket and Hom Nil rice significantly increased (P≤0.05) for all plasma treated samples. They were in the ranges of 1.05-1.08, and 1.01-1.06, respectively. This conforms to water uptake ratios of both rice samples. The volume expansion ratio of Kum Doi Saket did not change significantly (P>0.05) after the plasma treatments, whereas that of Hom Nil significantly increased (P≤0.05) to the ratios 2.00-2.07 after the plasma treatment.

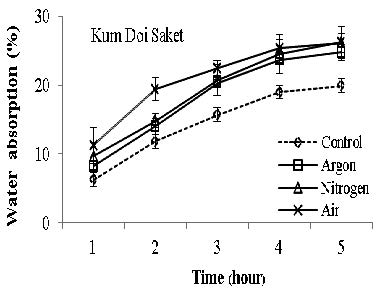

Effect of plasma treatment on water absorption behavior

From the study of water absorption characteristics of Kum Doi Saket and Hom Nil rice after treatments with plasmas of argon, nitrogen, and air, it was found that water absorption rate was significantly increased (P≤0.05) when compared with untreated samples (Figure 1). The rates of water absorption of Kum Doi Saket rice were in the ranges of 8.17 to 24.73%, 9.68 to 26.18%, and 11.23 to 26.23% after treatment with plasmas of argon, nitrogen and air, respectively. For Hom Nil rice, the rates of water absorption were in the ranges of 7.37 to 22.67%, 8.74 to 22.21%, and 10.03 to 22.98%, respectively, after the treatments.

(A) (B)

(A) (B)

Figure 1. Water absorption of pigmented rice after plasma treatments. (A) Water absorption of Kum Doi Saket rice, (B) Water absorption of Hom Nil rice.

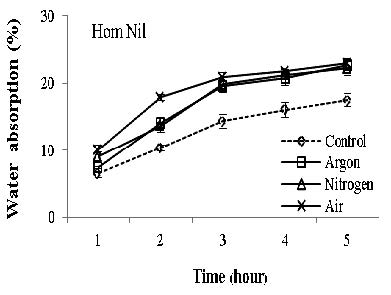

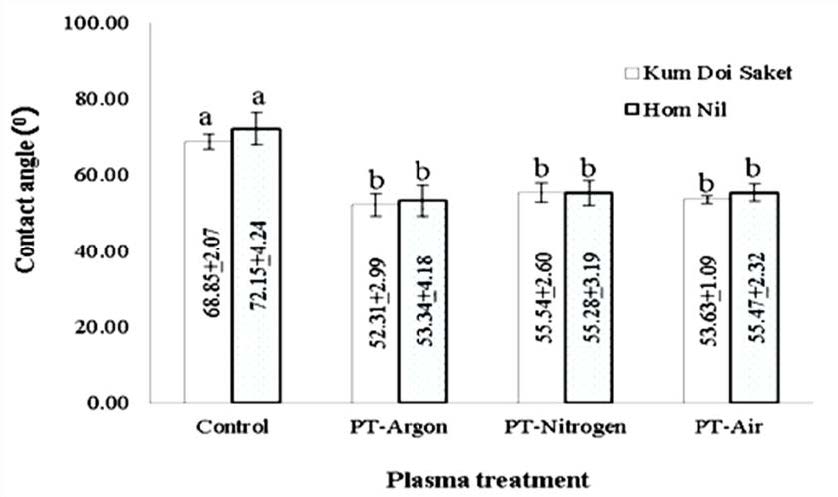

Effect of plasma treatment on contact angle

Results of contact angle measurements of both Kum Doi Saket and Hom Nil rice with and without plasma treated are shown in Figure 2. The contact angles of rice samples treated with argon, nitrogen, air plasmas and without plasma treatment were 52.31°, 55.54°, 53.63° and 68.85°, respectively, for Kum Doi Saket rice samples. The water contact angles were 53.34°, 55.28°, 55.47° and 72.15°, respectively, for Hom Nil rice samples. The surface energies of Kum Doi Saket rice samples treated with and without plasma were 47.18±2.16, 44.50±1.90, 46.14±0.78 and 31.96±1.86 mJ/m2, respectively. For Hom Nil rice, the surface energies were found to be 47.52±2.93, 44.69±2.76, 44.95±1.70 and 30.70±0.99 mJ/m2, respectively.

Figure 2. Water contact angles of pigmented rice after plasmas treatments.

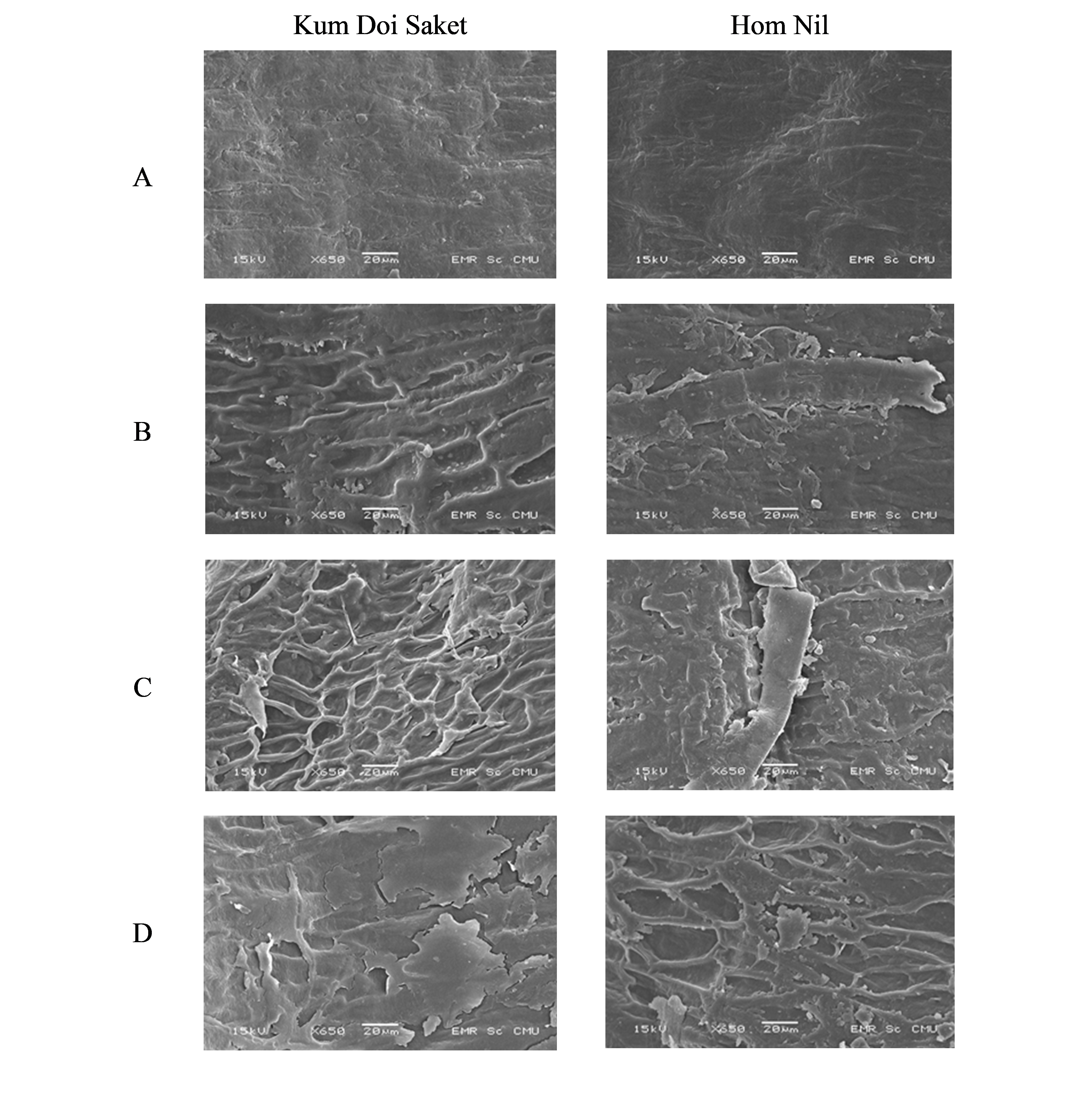

Effect of plasma treatment on microstructure

Figure 3 shows the surface structures of Kum Doi Saket and Hom Nil rice samples after treatment with plasmas from different gases. Surface changes were observed by scanning electron microscope at a magnification of 20 µm (650X).

Figure 3. SEM images (650X) of Kum Doi Saket and Hom Nil rice samples after treatments: (A) No treatment, Treatments with plasmas from (B) argon gas, (C) nitrogen gas, (D) air.

Chemical composition of rice samples

After treatment with plasmas from argon, nitrogen and air, the samples were subjected to proximate analysis and the results are shown in Table 2. The moisture contents of Kum Doi Saket rice samples were not significantly difference (P>0.05). Moisture contents of Hom Nil rice samples significantly decreased (P≤0.05) when compared to that of the control sample. The protein contents of Kum Doi Saket rice samples were 9.04, 9.17, and 9.09%, respectively, while those for Hom Nil rice samples were 8.62, 8.48, and 8.72% after treatments with argon, nitrogen and air plasma, respectively. Fat contents of Kum Doi Saket samples significant declined (P≤0.05) as compared to the control sample but no significant difference (P>0.05) amongst the plasma treatments was observed. Fat contents of Kum Doi Saket rice samples after treated with plasmas from argon, nitrogen and air were 3.65, 3.46, and 3.28%, respectively. Fat contents of Hom Nil rice samples were not significantly different (P>0.05) from that of the control. The fat contents were 3.86, 3.15, and 3.40%, respectively. The fiber contents of the two samples were significantly decreased (P≤0.05), compared to the untreated samples. The fiber contents of the Kum Doi Saket rice samples were 1.30, 0.93, and 1.59%, respectively, and 0.93, 0.63 and 0.86%, respectively, for Hom Nil rice samples. Kum Doi Saket rice samples had the ash contents of 1.77, 1.77, and 1.76%, respectively; whereas Hom Nil rice samples had the contents of 1.74, 1.74, and 1.71%, respectively. Carbohydrate contents of Kum Doi Saket rice were significantly increased (P≤0.05) as compared to the untreated samples but the type of plasma gas did not cause significant difference in carbohydrate contents (P>0.05). Carbohydrate contents of Hom Nil rice samples were significantly increased (P≤0.05) as compared to the untreated samples. The contents were found at 73.29, 73.80, and 75.27%, respectively.

Table 2. Chemical composition of Kum Doi Saket and Hom Nil rice samples without and with treatments using plasmas from different gases.

|

Proximate analysis |

Untreated |

Argon |

Nitrogen |

Air |

|

Kum Doi Saket Moiturens (%) Proteinns (%) Fat (%) Fiber (%) Ashns (%) Carbohydrate (%) Hom Nil Moiture (%) Proteinns (%) Fatns (%) Fiber (%) Ashns (%) Carbohydrate (%) |

12.25 ± 0.53 9.03 ± 0.05 4.55a ± 0.52 1.62a ± 0.15 1.77 ± 0.01 70.78b ± 0.34

12.48a ± 0.16 8.73 ± 0.15 4.15 ± 0.99 0.99a ± 0.09 1.74 ± 0.05 71.92c ± 0.67 |

11.21 ± 0.09 9.04 ± 0.02 3.65b ± 0.13 1.30b ± 0.10 1.77 ± 0.01 73.03a ± 0.11

11.57b ± 0.31 8.62 ± 0.11 3.8 ± 0.67 0.93a ± 0.05 1.74 ± 0.02 73.29b ± 0.76 |

11.13 ± 0.09 9.17 ± 0.15 3.46b ± 0.18 0.93c ± 0.03 1.77 ± 0.01 73.54a ± 0.13

11.97b ± 0.56 8.48 ± 0.12 3.15 ± 0.63 0.63b ± 0.12 1.74 ± 0.04 73.80b ± 0.81 |

11.11 ± 1.23 9.09 ± 0.13 3.28b ± 0.16 1.59a ± 0.04 1.76 ± 0.01 73.16a ± 0.23

10.27c ± 0.10 8.72 ± 0.03 3.40 ± 0.33 0.86ab ± 0.06 1.71 ± 0.00 75.27a ± 0.26 |

Note: Values presented in the table are means + standard deviations. Different superscripts after mean values in the same column indicate significant differences of means, and ns indicates non-significant difference at 95% confidence level (P≤0.05).

DISCUSSION

The decreases of OCT indicate that the application of plasma using all gas types could erode the grain’s bran layer, resulting in a better water absorption inside the grain. Similar results were reported that low pressure plasma treatment of brown rice could reduce the cooking time by 24-30% (Chen et al., 2012; Chen, 2014). Plasma treatment using argon, nitrogen and air caused the surface of the grain to erode. This affected the cooking properties of the rice grain. The OCTs were reduced to 34 min for Kum Doi Saket and 28 min for Hom Nil rice. The water uptake ratio, length expansion ratio and volume expansion ratio were increased as compared to the untreated samples. The increasing water uptake ratio also indicates increased rice softness (Mohapatra and Bal, 2006; Sommanee, 2011). The values obtained from plasma treatments using three types of gas were similar. This can be stated that all the experimented gas types of plasma were qualified for surface etching of rice grain. As a result, water can be absorbed into the grain easier, hence reducing cooking time while increasing water uptake rate, retention rates, and expansion volume rate (Chen et al., 2012; Chen, 2014; Thirumdas et al., 2015).

From the study of water absorption characteristics of Kum Doi Saket and Hom Nil rice after treatments with plasmas of argon, nitrogen, and air (Figure 1), it was found that water absorption rate was significantly increased (P≤0.05) when compared with untreated samples. Typically, brown rice kernel has bran containing protein, fat, fiber and ash, which prevents water from entering the seed (Khatoon and Gopalakrishna, 2004). Consequently, increasing water absorption rate after plasma treatment indicates that plasma eroded the surface of the grain, causing acceleration of the water absorption during immersion (Chen et al., 2012). The increase in water absorption characteristic was related to cooking property (Lee et al., 2016).

Figure 2 shows water contact angles of the samples treated for 40 min with frequency of 110 Hz using plasmas from different gases. Water contact angle is measured as change in droplet size or contact angle with respect to time and it is related to the wettability of the material (Yuan and Lee, 2013). From the results, the initial contact angles were higher for untreated rice samples. On the application of plasma treatment, significant differences (P≤0.05) in contact angles were observed. It was found that contact angles among the samples decreased. This may due to better absorption of water resulting in a decrease in contact angle (Andrade et al., 2005). The sharp decrease in water contact angles visualized for treated pigmented rice samples may be attributed mainly to the rapid absorption of the water. Parboiled rice with plasma treatment also showed a similar effect of reducing contact angle when compare to untreated rice samples (Sarangapani. et al., 2015).

The surface energy of rice grains was affected by plasma treatment and it is known to relate to the water contact angle. As plasma treatment caused the water contact angle to decreased, the calculated surface energy of rice grain was increased. The etching effects of plasma on the surface of rice grain generated rougher surface, increased surface area, and breaking of the bran layer (as shown in Figure 3); hence, more exposure of the inner layer’s hydrophilic compounds can be expected. Therefore, the surface energy could increase. The results were consistent with the research of Thirumdas et al. (2016) who studied the influence of low pressure cold plasma on cooking and textural properties of brown rice. Their results showed the increase in surface energy after the plasma treatment; and it was suggested to be as the result of an increase in hydrophilicity and surface area (Thirumdas et al. 2015; Thirumdas et al. 2016).

From the surface quality analysis of both rice samples, more eroded and rough surfaces were observed as compared with the untreated samples (Figure 3). The surface was eroded broadly but not very deep. Erosion occurs in the middle of the seed’s surface which was primarily exposed to plasma (Chen et al., 2012). The change in the structure of the surface was clearly shown at 650X. When examining the image of Kum Doi Saket grain’s surface structure, the surface roughness of the grain was clear when using plasmas of argon and nitrogen. Argon and nitrogen gas are very easy to ionize due to having larger number of electrons in the outer shell. Hence, argon and nitrogen atoms are available to respond on surface of Kum Doi Saket rice (Yepez and Keener, 2016). Selzuk et al. (2008) reported that the use of plasma from nitrogen gas resulted in seed surface discoloration and visible damages (Selzuk et al., 2008). Moreover, it was also reported that Ar+ in combination with reactive oxygen species such as *OH, *O and *O2 caused epidermis to degenerate guard cells (Grzegorzewski et al., 2011). The structure of the surface roughness of Hom Nil rice was clear when air plasma was used. Some research reported that air plasma is the source for reactive oxygen-based and nitrogen-based species, such as O, O2, O3, OH, NO, NO2 (Laroussi, 2009; Murakam et al., 2013). These plasma species can cause surface etching of parboiled rice (Sarangapani et al., 2015). Increasing water absorption rate and decreased OCT after plasma treatment showed that the surface of rice

grain responded well to the ionization of all plasma gases. Thus, plasma has ability to generate surface etching and subsequently influent most surface related properties, such as water absorption ability as found to be beneficial for improvement of rice cooking properties in this research.

For proximate analysis, the moisture content may be reduced due to the disintegration by the plasma when contact with the surface of the grain which causes water molecules on the surface to evaporate. A loss of moisture is specifically upon the surface that has been eroded (Zou et al., 2004; Thirumdas et al., 2015), which corresponds to the amount of moisture lowering in grain starches after a low pressure plasma treatment (Lii et al., 2002), while protein contents of both samples did not change (P>0.05). A slight reduction in fat contents may due to the breakdown of the outer cell wall by plasma or oxidation by free radical and unstable compounds, depending on factors such as different kind of energy, time and gas (Lii et al., 2002). Moreover, there is a report states that OH*-hydroxyl radical and O2*-superoxide anion caused by radiation may change the molecular properties of proteins and fats (Sarangapani et al., 2015). The fiber contents of the two samples were significantly decreased (P≤0.05), compared to the untreated samples. Crude fiber is the fiber from cell wall which forms the bran layer (Roberfroid, 1993). Erosion of the outer bran layer by plasma can lead to a reduction of fiber content. The ash contents of the two rice samples were not significantly affected (P>0.05) by plasma treatment. The sample treated with air was found to have the highest carbohydrate content. This might due to loss of more moisture from the surface of rice grains, giving a rise of the calculated carbohydrate content (Thirumdas et al., 2015).

CONCLUSION

Plasma treatment could significantly improve cooking qualities, texture and preserve major chemical composition of the unpolished, pigmented Thai rice. Reductions in cooking time and water contact angle; increases in water uptake ratio, length expansion ratio, volume expansion ratio and water absorption of the rice grains were observed after plasma treatment. These were caused by surface etching or erosion by plasma species, resulting in better water absorption and transfer inside the interior of the grain during cooking. Consequently, cooking quality and physical properties were improves, whereas chemical quality was not severely affected. Increasing surface roughness of the Kum Doi Saket rice grain was clearly shown when using argon and nitrogen plasmas, while the surface roughness of Hom Nil was clear when using air plasma. Plasmas from different gas types did not showed significant differences in most of the properties of rice. Plasma generated from argon gas had more effects on texture of the rice grains, as compared to nitrogen and air. Overall, plasmas from argon and nitrogen gases may slightly be better in improving cooking quality of the unpolished pigmented rice grains as compared to plasma generated from air. However, selection of the appropriate gas type for plasma treatment should include the results of chemical and other physical analyses, as well as the availability of the tool and cost of the gases for consideration. Therefore, air could appropriately be used for plasma treatment of rice grain due to it being readily available at no cost and no extra gas container requirement. Even though this research was conducted using a lab scale instrument, the data reported here can be further used for designing a larger scale system for industrial application.

REFERENCES

Andrade, C.T., Simao, R.A., Thire, R.M.S.M., and Achete, C.A. 2005. Surface modification of maize starch films by low-pressure glow 1-butene plasma. Carbohydrate Polymers. 61: 407-413.

Arolkar, G.A., Salgo, M.J., Kelkar-Mane, V., and Deshmukh, R.R. 2015. The study of air-plasma treatment on corn starch/poly(ε-caprolactone) films. Polymer Degradation and Stability. 120: 262-272.

AOAC. 2000. Official methods of the association of official analytical chemists. Washington D.C.: Association of Official Analytical Chemists.

Bahrami, N., Bayliss, D., Chope, G., Penson, S., Perehinec, T., and Fisk, I.D. 2016. Cold plasma: a new technology to modify wheat flour functionality. Food Chemistry. 202: 247-253.

Bonto, A.P., Camacho, K.S.I., and Camacho, D.H. 2018. Increased vitamin B5 uptake capacity of ultrasonic treated milled rice: a new method for rice fortification. LWT - Food Science and Technology. 95: 32-39.

Braithwaite, N.S.J. 2000. Introduction to gas discharges. Plasma Sources Science and Technology. 9: 517-527.

Champagne, E.T. 2004. Rice Chemistry and Technology. 3rd ed. United States. Eagan, Minnesota: Agricultural Research Service. Southern Regional Research Center: American Association of Cereal Chemists. p. 95-96.

Chen, H.H., Chen, Y.K., and Change, H.C. 2012. Evaluation of physicochemical properties of plasma treated brown rice. Food Chemistry. 135: 74-79.

Chen, H.H. 2014. Investigation of properties of long-grain brown rice treated by low-pressure plasma. Journal of Food Bioprocess Technology. 7: 2484-2491.

Chung, H-J., Cho, A., and Lim, S-T. 2012. Effect of heat-moisture treatment for utilization of germinated brown rice in wheat noodle. LWT - Food Science and Technology. 47: 342-347.

Cornejo, F., Caceres., P.J., Martínez-Villaluenga, C., Rosell, C.M., and Frias, J. 2015. Effects of germination on the nutritive value and bioactive compounds of brown rice breads. Food Chemistry. 173: 298-304.

Cui, L., Pan, Z., Yue, T., Atungulu, G.G., and Berrios, J. 2010. Effect of ultrasonic treatment of brown rice at different temperatures on cooking properties and quality. Cereal Chemistry. 87: 403-408.

Das, M., Banerjee, R., and Bal, S. 2008. Evaluation of physicochemical properties of enzyme treated brown rice (Part B). LWT- Food Science and Technology. 41: 2092-2096.

Deshmukh, R.R., and Bhat, N.V. 2003. The mechanism of adhesion and printability of plasma processed PET films. Materials Research Innovations. 7: 283-290.

Deshmukh, R.R., and Shetty, A.R. 2008. Comparison of surface energies using various approaches and their suitability. Journal of Applied Polymer Science. 107: 3707-3717.

Dixit, D., Bunk, S., Rane, R., and Ghoroi, C. 2018. Influence of Ar plasma treatment on the wetting behavior of pharmaceutical powders. Advanced Powder Technology. 29: 2928-2940.

Dobrin, D., Magureanu, M., and Mandache, N.B. 2013. The influence of non-thermal plasma treatment on wheat germination. Proceedings of 31st International Conference on Phenomena in Ionized Gases; 2013 July 14 19. Granada: International Organizinf Comminitee of ICRP and International Scientific Committee of ICPIG.

Forssell, S. 2009. Rice price policy in Thailand-policy making and recent developments [master’s thesis]. Sweden: University of Lund.

Gaunt, L. F., Beggs, C. B., and Georghiou, G. E. 2006. Bactericidal action of the reactive species produced by gas-discharge nonthermal plasma at atmospheric pressure: A review. IEEE Transactions on Plasma Science. 34: 1257-1269.

Grzegorzewski, F., Ehlbeck, J., Schlüter, O., Kroh, L.W., and Rohn, S. 2011. Treating lamb’s lettuce with a cold plasma-Influence of atmospheric pressure Ar plasma immanent species on the phenolic profile of Valerianella locusta. LWT-Food Science and Technology. 44: 2285-2289.

Halee, K.H., Kim, H-J., Woo, K.S., Jo, C., Kim, J-K., Kim, S.H., Park, H.Y.,

Oh, S-K., and Kim, W.H. 2016. Evaluation of cold plasma treatments for improved microbial and physicochemical qualities of brown rice. Food Science and Technology. 73: 442-447.

Kan, C.W., Chan, K., Yuen, C.W.M., and Miao, M.H. 1998. Surface properties of low-temperature plasma treated wool fabrics. Journal of Materials Processing Technology. 83: 180-184.

Khamtong, P., Mecmora, T., and Khuhasawanwech, S. 2014. Feasibility study of black jasmine rice (Hom Nil) production in Nongchok District, Bangkok. King Mongkut's Agricultural Journal. 32: 27-35.

Khatoon, S., and Gopalakrishna, A. 2004. Fat-soluble nutraceuticals and fatty acid composition of selected Indian rice varieties. Journal of the American Oil Chemists’ Society. 81: 939-943.

Kogelschatz, U. 2007. Twenty years of Hakone symposia: from basic plasma chemistry to billion dollar markets. Plasma Processes and Polymers. 4: 678-681.

Kovacevic, D.B., Putnik, P., Dragovic-Uzelac, V., Pedisic, S., Jambrak, A.R., and Herceg, Z. 2016. Effects of cold atmospheric gas phase plasma on anthocyanins and color in pomegranate juice. Food Chemistry. 190: 317-323.

Laroussi, M. 2005. Low temperature plasma-based sterilization: overview and state-of-the-art. Plasma Processes and Polymers. 2: 391-400.

Laroussi, M. 2009. Low-temperature plasmas for medicine. IEEE Transactions on Plasma Science. 37: 714-725.

Lee, K.H., Kim, H-J., Woo, K.S., Kim, S.H., Park, H.Y., Oh, S-K., and Kim, W.H. 2016. Evaluation of cold plasma treatments for improved microbial and physicochemical qualities of brown rice. LWT-Food Science and Technology. 73: 442-447.

Li, Y., Liu, K., Chen, F., and Cheng, Y. 2018. Comparative proteomics analysis reveals the effect of germination and selenium enrichment on the quality of brown rice during storage. Food Chemistry. 269: 220-227.

Lii, C.Y., Liao, C.D., Stobinski, L., and Tomasik, P. 2002. Behaviour of granular starches in low-pressure glow plasma. Carbohydrate Polymers. 49: 499-507.

Mantham, K. 2006. Improvement of paper quality by an atmospherric plasma system [master’s thesis]. Chiang Mai: Chiang Mai University.

Mohapatra, D., and Bal, S. 2006. Cooking quality and instrumental textural attributes of cooked rice for different milling fractions. Journal of Food Engineering. 73: 253-259.

Murakami, T., Niemi, K., Gans, T., O'Connell, D., and Graham, W.G. 2013. Chemical kinetics and reactive species in atmospheric pressure helium-oxygen plasmas with humidair impurities. Plasma Sources Science and Technology. 22: 1-29.

Pallas, N.R., and Harrison, Y. 1990. An automated drop shape apparatus and the surface tension of pure water. Colloids and Surfaces. 43: 169-194.

Pankaj, S.K., Carmen Bueno‐Ferrer, Misra, N.N., Paula Bourke, and Cullen, P.J. 2014. Zein film: Effects of dielectric barrier discharge atmospheric cold plasma. Journal of Applied Polymer Science. 131: 40803.

Park, D-J., and Han, J-A. 2016. Quality controlling of brown rice by ultrasound treatment and its effect on isolated starch. Carbohydrate Polymers. 137: 30-38.

Roberfroid M. 1993. Dietary fiber, inulin, and oligofructose: a review comparing their physiological effects. Critical Reviews in Food Science and Nutrition. 33: 103-148.

Sarangapani, C., Devi, Y., Thirundas, R., Annapure, U.S., and Deshmukh, R.R. 2015. Effect of low-pressure plasma on physico-chemical properties of parboiled rice. Journal of Food Science and Technology. 63: 452-460.

Selzuk, M., Oksuz, L., and Basaran, P. 2008. Decontamination of grains and legumes infected with Aspergillus spp. and Penicillum spp. by cold plasma treatment. Bioresource Technology. 99: 5104.

Somjai, C. 2015. Texture modification and production of microwavable quick cooking [master’s thesis]. Chiang Mai: Chiang Mai University.

Sommanee, S. 2011. Production and storage of texture modified brown rice. [master’s thesis]. Chiang Mai: Chiang Mai University.

Thirumdas, R., Deshmukh, R.R., and Annapure, U.S. 2015. Effect of low temperature plasma processing on physicochemical properties and cooking quality of basmati rice. Innovative Food Science and Emerging Technologies. 31: 83-90.

Thirumdas, R., Saragapani, C., Ajinkya, M.T., Deshmukh, R.R., and Annapure, U.S. 2016. Influence of low pressure cold plasma on cooking and textural properties of brown rice. Innovative Food Science and Emerging Technologies. 37: 53-60.

Thirumdas, R., Trimukhe, A., Deshmukh, R.R., and Annapure, U.S. 2017. Functional and rheological properties of cold plasma treated rice starch. Carbohydrate Polymers. 157: 1723-1731.

Verma, D.K., Mohan, M., Prabhakar, P.K., and Srivastav, P.P. 2015. Physico-chemical and cooking characteristics of Azad basmati. International Food Research Journal. 22: 1380-1389.

Volin, J.C., Denes, F.S., Young, R.A., and Park, S.M. 2000. Modification of seed germination performance through cold plasma technology. Crop Science. 40: 1706- 1718.

Ward, C.A., and Neumann, A.W. 1974. On the surface thermodynamics of a two-component liquid-vapor-ideal solid system. Journal of Colloid and Interface Science. 49: 286-290.

Wasy zia, A., Wang, Y‐Q., and Lee, S. 2014. Effect of physical and chemical plasma etching on surface wettability of carbon fiber–reinforced polymer composites for bone plate applications. Advances in Polymer Technology. 34: 21480.

Yepez, X.V., and Keener K.M. 2016. High-voltage atmospheric cold plasma (HVACP) hydrogenation of soybean oil without trans-fatty acids. Innovative Food Science and Emerging Technologies. 38: 169-174.

Yuan, Y., and Lee, T.R. 2013. Contact angle and wetting properties. Surface Science Techniques. 3-34.

Zhang, X., Wang, L., Cheng, M., Wang, R., Luo, X., Li, Y., and Chen, Z. 2015. Influence of ultrasonic enzyme treatment on the cooking and eating quality of brown rice. Journal of Cereal Science. 63: 140-146.

Zou, J.J., Liu, C.J., and Eliasson, B. 2004. Modification of starch by glow discharge plasma. Carbohydrate Polymers. 55: 23-26.

OPEN access freely available online

Chiang Mai University Journal of Natural Sciences [ISSN 16851994]

Chiang Mai University, Thailand

https://cmuj.cmu.ac.th

Metanee Noppakun1, Srisuwan Naruenartwongsakul1, Phisit Seesuriyachan1, Yuthana Phimolsiripol1, Dheerawan Boonyawan2, and Pilairuk Intipunya1*

1 Faculty of Agro-Industry, Chiang Mai University, Chiang Mai 50100, Thailand

2 Department of Physics and Materials Science, Faculty of Science, Chiang Mai University, Chiang Mai 50200, Thailand

Corresponding author: Pilairuk Intipunya, E-mail: pilairuk.intipunya@cmu.ac.th

Total Article Views

Editor: Wasu Pathom-aree,

Chiang Mai University, Thailand

Article history:

Received: March 31, 2020;

Revised: May 28, 2020;

Accepted: June 9, 2020