Optimization of Oil Extraction from Gac (Momordica cochinchinensis Spreng) Aril Using a Screw Press

Suthida Akkarachaneeyakorn*, Apinya Boonrattanakom,Pornchanok Pukpin, Samaporn Rattanawaraha and Sutheera KhantaphantPublished Date : 2019-08-24

DOI : 10.12982/CMUJNS.2015.0087

Journal Issues : Number 3, September - December 2015

ABSTRACT

We extracted oil from the aril of Momordica cochinchinensis Spreng using a screw press to determine the optimal conditions and mathematical equations to predict the oil extraction efficiency; the β-carotene and lycopene contents; and the iodine, acidity, and peroxide values using a 2-factor, 5-level, central composite design. The two factors were compression length (1.18, 1.30, 1.60, 1.90, and 2.02 cm) and rotational speed (10.14, 11.30, 14.10, 16.90, and 18.06 rpm). The optimal conditions were those that maximized oil extraction efficiency, β-carotene and lycopene content, and iodine value and minimized acidity and peroxide values. Under the optimal conditions, the predicted values were 65±15% extraction efficiency, 15±5 mg of β-carotene per 100 g, 4±2 mg of lycopene per 100 g, 65±5% iodine value, and 2±2 mg potassium hydroxide per gram of acidity. The extraction efficiency increased with higher rotational speeds. Increasing both the compression length and rotational speed increased the iodine value, the β-carotene content, and the lycopene content. To validate the mathematical model, the predicted values were compared to experimental data; they deviated by less than 10%, indicating that the model predictions were very good. The L*, a*, b*, Hue angle, and viscosity of oil extracted from gac aril were 6.4, 23.0, 9.0, 21.25°, and 135 mPa.s, respectively.

Keywords: Aril, Gac fruit, Oil extraction, Optimization, Screw press

INTRODUCTION

Momordica cochinchinensis Spreng (gac) is a plant found in tropical Asian countries, including Vietnam, Laos, Thailand, China, Bangladesh, and India (Kubola et al., 2013; Kubola and Siriamornpun, 2011). Gac, a local vegetable, is a rich nutrient source, high in β-carotene and lycopene (Tinrat et al., 2014). Its aril contains sufficient quantities of β-carotene and lycopene (twice as much as the flesh) to help prevent coronary artery disease and some cancers, including prostate, lung, and stomach cancer. The aril of gac contains approximately 102 mg oil/g of edible portion, including up to 69% unsaturated fatty acids (Vuong et al., 2002). Unsaturated fatty acids are beneficial to carotenoid absorption, which helps to reduce cholesterol in the blood. Vuong et al. (2005) reported that gac aril was high in lycopene (408.4 μg/g) and β-carotene (83.3 μg/g).

Oil extraction by a screw press uses a compressive force and friction to produce oil. As this method is chemical-free, it is popular at both the community and industry levels (Khan and Hanna, 1983). Extraction efficiency depends upon sample preparation; if the sample is high in moisture, this reduces friction and thus the amount of oil obtained. Cooking the sample increases the amount of oil obtained, because cooking stops the growth of the cell wall, reduces oil viscosity, controls moisture content, prevents coagulation of proteins, and helps to inhibit both enzymes and microbial growth (Supakit et al., 2012).

Marcela et al. (2013) studied oil extraction from almond nuts using a screw press, varying the moisture content (4, 6, 8, 10, and 12%) and compression temperature (20, 40, and 60°C); the highest amount of oil (79.3%) was obtained at a moisture content of 8% by weight and 40°C. Kasote et al. (2013) studied the quality of oil extracted from ramie seeds using a screw press by extracting one, two, and three times. Extracting three times yielded the most product, while extracting twice yielded the most α-linoleic acid. The amount of fatty acids increased with the number of compressions, and three extractions yielded the most. Two extractions yielded the best quality oil, because of the high natural antioxidant content in the phenolic groups, which are beneficial to health. Supakit et al. (2012) studied rice bran oil extraction using a screw press by varying rotational speed (8.5, 11.3, 14.1, 16.9, and 19.8 rpm) and compression length (1, 1.3, 1.5, 1.7, and 1.9 cm); a rotational speed of 8.5 rpm and a compression length of 1.7 cm was the most efficient, yielding an oil to rice bran ratio (oil recovery) of 4.2%.

Experimental design using the response surface method and central composite design (CCD) is popular for finding optimal conditions in chemical and biological processes when studying the relationships between variables in manufacturing processes and the optimal conditions for production. Experimental design using CCD reduces the number of experiments, which in turn reduces experimental costs compared with a full factorial method (Montgomery, 2001).

Given the health benefits of the gac aril, we sought to identify the optimal conditions (the extraction efficiency percentage that produced the highest amounts of β-carotene, lycopene, and iodine values, and the lowest values of acidity and peroxide) for maximizing the nutritional value of oil extracted with a screw press, for which no reports exist in the literature.

MATERIALS AND METHODS

We extracted oil from gac aril using a screw press. The ripe gac fruit were collected from Nakornpathom Province, Thailand, six days after harvest (fully ripe; red color). We dried the gac aril in a microwave oven to aid the extraction efficiency, as Kha et al. (2013) found it improved the oil extraction efficiency and better retained the nutritional content relative to hot air. After drying, the gac aril was subjected to a steaming process and oil extraction using a screw press. A 2-factor (compression length and rotational speed), 5-level CCD was used. The accuracy of the mathematical model was verified by comparing with the experimental data. Physical properties of the oil extracted from the gac aril were studied, including the color and viscosity of the oil produced under optimal conditions.

Sample preparation

Drying and grounding process. To dry the gac aril, the method presented by Kha et al. (2013) was used, with slight modifications. First, 200 g of fresh gac aril was dried using a microwave (MW 7803, Severin, Germany) at 720 W for 20 ± 1 min. Then, 15 g of dried gac aril was blended with a blender (Model T30, Moulinex, China) for 15 min. Ground gac aril was stored in a zipper storage bag to prevent moisture gain and was stored away from sunlight at room temperature.

Steaming process. Steaming of ground gac aril was performed using the method explained by Kha et al. (2013). Five hundred g of ground gac aril was placed on a sheet of white cloth and spread out in a layer that was approximately 5 mm thick. Then, ground gac aril was steamed in a 20-cm-diameter cooker using 200 mL of water for 20 min, allowed to cool, and stored in a zipper storage bag and away from sunlight at room temperature.

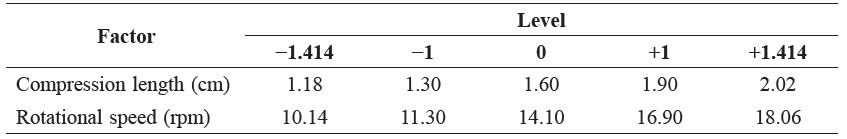

Oil extraction. Gac oil was extracted from steamed ground gac aril by using the screw press (Kasetsart University, Thailand). The compression lengths were varied at 1.18, 1.30, 1.60, 1.90, and 2.02 cm, and the rotational speeds were varied at 10.14, 11.30, 14.10, 16.90, and 18.06 rpm. Oil extract from gac aril was placed into a bottle, sealed, and stored away from sunlight at a temperature under 5°C until further analysis.

Analyses

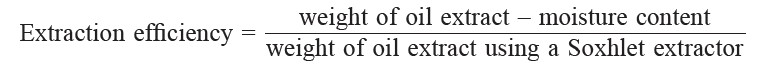

Extraction efficiency percentage. The efficiency of oil extraction was derived from the following formula:

Moisture content was measured using the Ca 2e-55 method (AOCS, 1997).

The total oil from gac was treated by a microwave before extraction and then analyzed using a BÜCHI extraction system (B-8118, BÜCHI, Switzerland) by weighing approximately 3 g of gac aril in a cellulose thimble and placing it in the extractor. Filtered petroleum ether (boiling point 60–90°C) was added to the weighed aluminum vessel, which was then connected to the extraction system. The temperature was set at 145°C and the extraction time was 120 min; the time required to wash out the remaining fatty acids was 20 min and the aluminum vessel used for storing the oil extract was dried for 20 min. The sample was dried in an oven at 100°C for 30 min until the weight was constant. The amount of oil in the sample was then used to calculate the weight.

Iodine values were measured according to AOCS using the 1d-92 method (1997). The acidity values were measured according to the AOCS Cd 3d-63 method (1997). The peroxide values were measured according to the AOCS Cd 8b-90 method (1997).

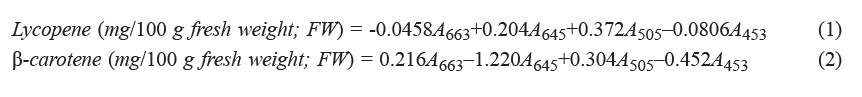

β-carotene and lycopene content. The method for determining the β-carotene and lycopene contents was modified from Nagata and Yamashita (1992). A 0.1 g sample of oil was added to a mixture of acetone:hexane at 4:6 (v/v) ratio and vortexed for 1 min. It was then diluted by a factor of 10, and the light absorption of the solution was subsequently determined using a UV-visible spectrophotometer at wavelengths of 663, 645, 505, and 453 nm, using an acetone:hexane solution at a 4:6 (v/v) ratio as a blank. The values were used to calculate the lycopene content with equation (1) and the β-carotene content with equation (2).

Color value. A 2 mL oil sample from gac was added to a sample container for color measurement. The measurement was performed in triplicate using a HunterLab ColorQuest 450 (Color Global Co., Ltd., USA) in a CIE lab system.

Apparent Viscosity. The apparent viscosity was measured using a Brookfield viscometer (RVDV-II, Brookfield, USA) with a No. 27 spindle at 100 rpm and room temperature, using 15 mL of oil.

Statistical analysis

To find the optimal conditions and an equation to predict the six factors (percentage extraction efficiency, β-carotene content, lycopene content, iodine, acidity, and peroxide values in the oil extract), experiments were designed by response surface methodology (RSM) using a CCD method with two factors. Each factor had five levels, as shown in Table 1, and the middle levels were repeated twice. There were thus six response values (Y), corresponding to the two factors listed above, and these were measured in triplicate. Data analysis was performed using the Minitab software version 16.2.2.0 at 95% confidence. A quadratic model was fitted to correlate the relationship between the independent variables and the responses to predict the optimal conditions.

Table 1. Factors and levels of each factor used in the experiments.

RESULTS

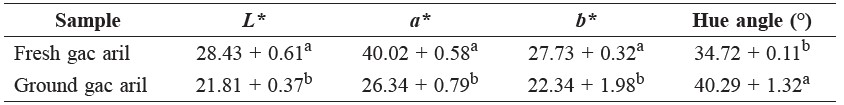

Color value analysis of gac aril and gac fruit dried in a microwave oven

The results in Table 2 show that the brightness of fresh gac aril was significantly different from that of ground, dried gac aril (P ≤ 0.05) and both the red and yellow color intensities of fresh gac aril reduced significantly (P ≤ 0.05) after drying. The hue angle can be calculated from the formula arctan (b*/a*), which shows the color (0° for red, 90° for yellow, 180° for green, and 270° for blue). The reduction in red color intensity for ground dried gac aril (P ≤ 0.05) was caused by the color change of carotenoid upon heating.

Table 2. Color value of fresh gac aril and ground dried gac aril.

Note: The average and standard deviation were based on triplicate experiments. a,bIn the same column indicates significant difference (P ≤ 0.05).

Optimal conditions for oil extraction from gac aril using a screw press

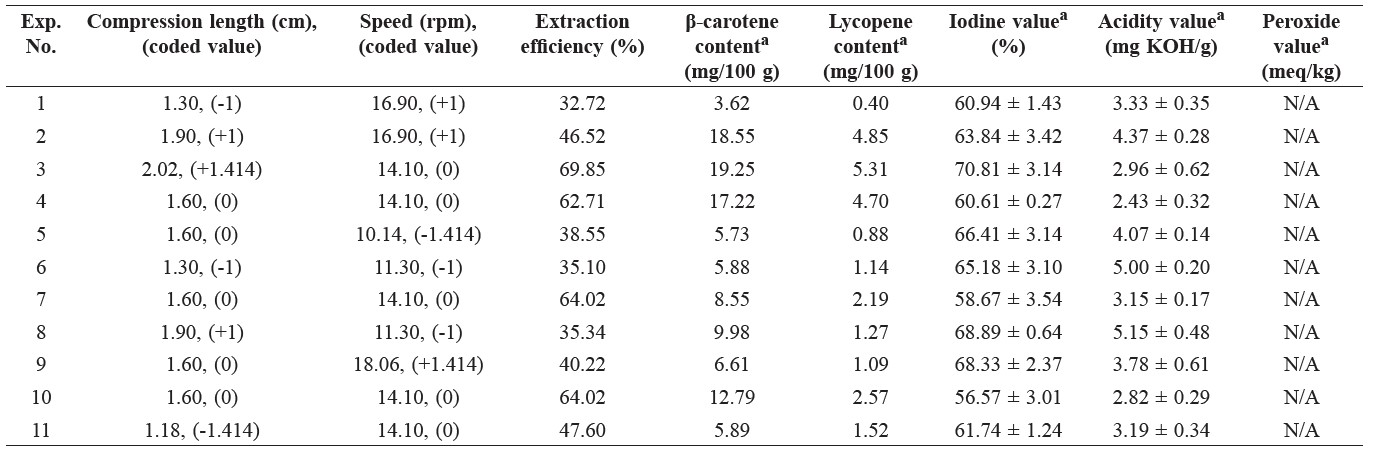

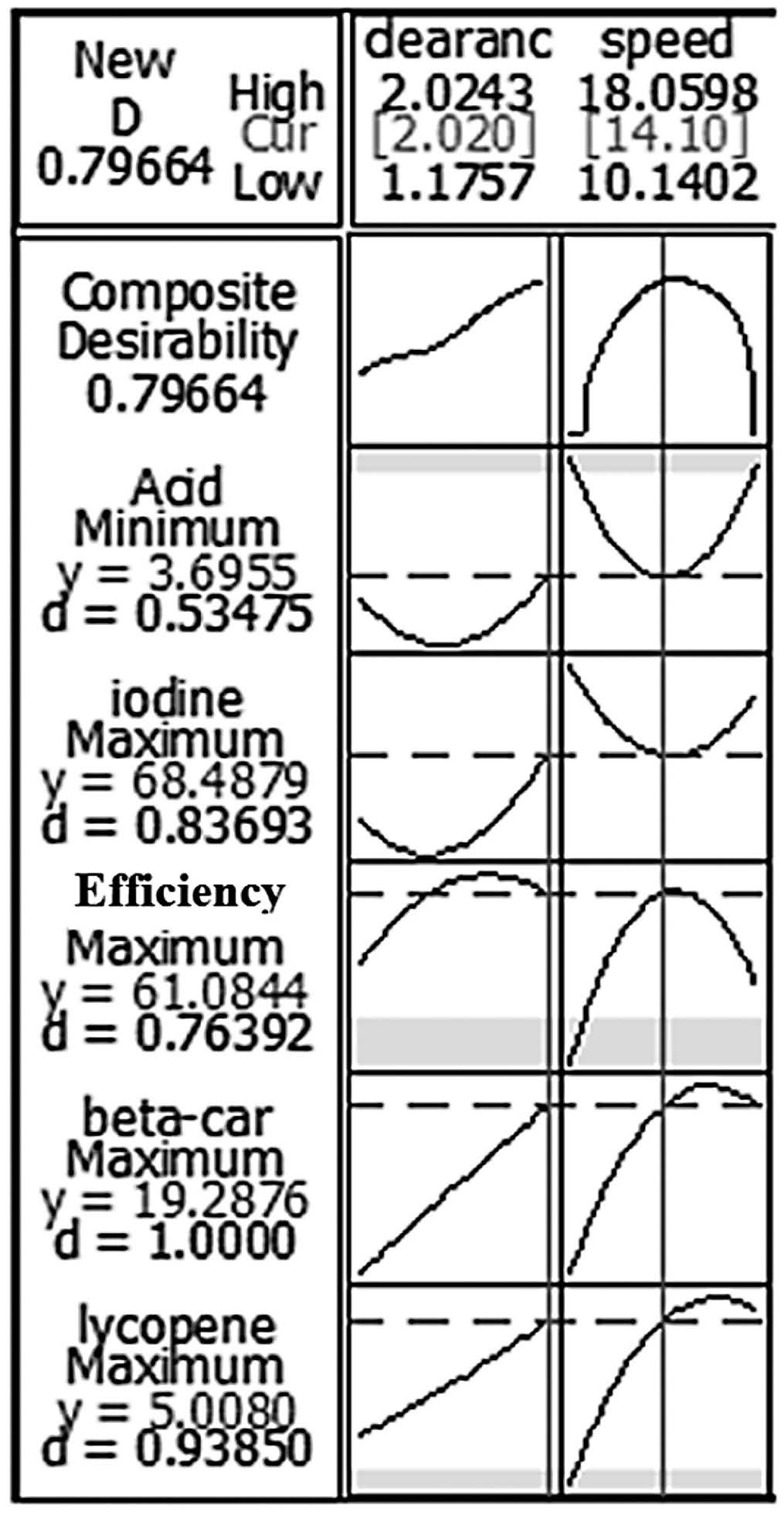

The results of experiments designed to determine the compression length and rotational speed for oil extraction of gac aril to obtain optimal extraction are shown in Table 3.

Extraction efficiency, β-carotene content, lycopene content, iodine value, acidity value, and peroxide value analysis of gac aril oil extracted under various conditions. In Figure 1(a), the black circle identifies the maximum oil extraction efficiency and the lower-intensity black colors show lower extraction efficiency. The two-dimensional graph shows the oil extraction efficiency of gac aril, the compression length, and rotational speed. In Figure 1(b), the black circle indicates the highest β-carotene content in oil and the less intense link indicates lower content. In Figure 1(c), the black circle indicates the highest lycopene content and the black intensity decreases for lower content. Figure 1(d) shows the iodine value of gac aril, compression length, and rotational speed; increasing compression length and rotational speed increased iodine values. In Figure 1(d), the black circle indicates a high iodine value and the white colors indicate lower iodine values in gac aril oil. Figure 1(e) shows the acidity values for oil extracted from gac aril under various conditions. As the compression length decreased, the acidity value increased, because high compression generated heat and caused the acidity value to increase. In Figure 1(e), the black circle represents acidity values below 3 mg potassium hydroxide per gram, and color changes from black to white represent higher acidity values. The acidity values of oil from gac aril were between 2.43 and 5.15 mg potassium hydroxide per gram, as shown in Table 3.

Table 3. Central composite design with six independent variables of oil extraction from gac aril by screw press.

Note: aMean and standard deviations are shown (n=3). N/A: not detected.

Figure 1. Two-dimensional graph of oil extraction efficiency for gac aril: (a) β-carotene content, (b) lycopene content, (c) iodine value, (d) acidity value, (e) at various compression lengths (X1) and rotational speeds (X2), and optimal conditions for oil extraction from gac aril using a screw press (f).

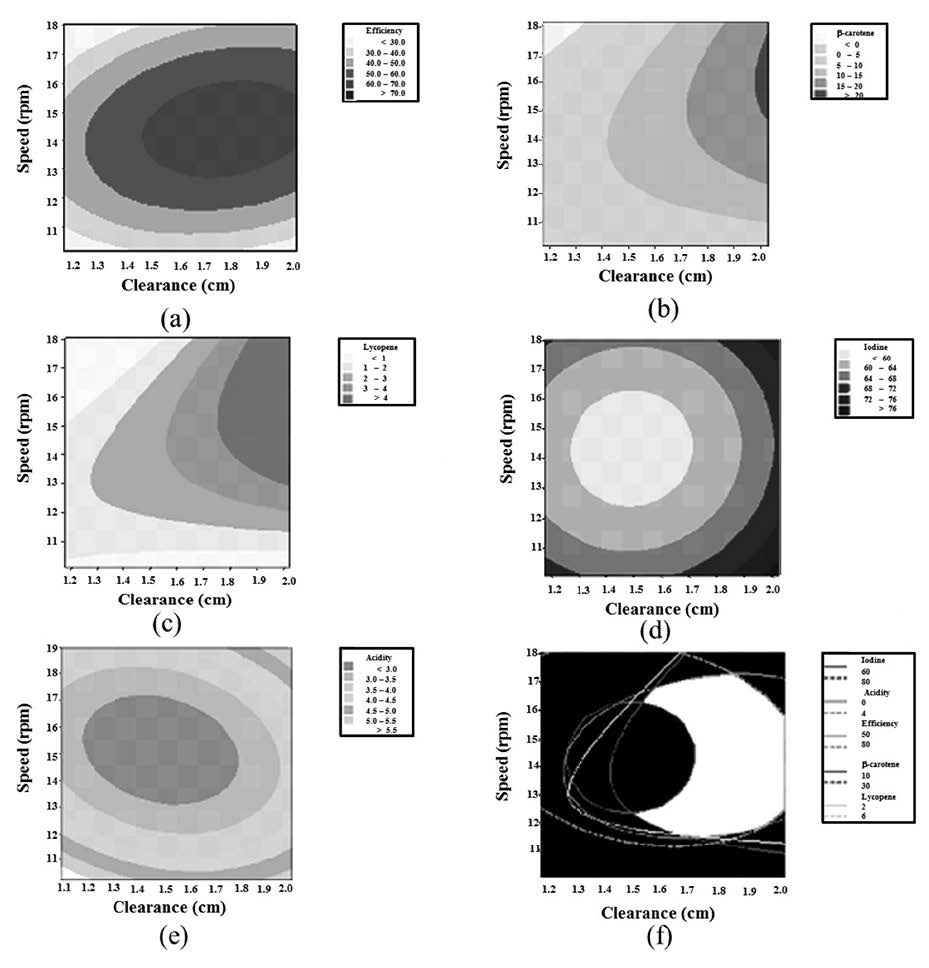

Analysis of the optimal conditions for oil extraction from gac aril using a screw press. The optimal conditions were identified for efficient extraction and maximizing β-carotene, lycopene, and the iodine value as well as minimizing the acidity value, using the response optimizer function in Minitab software, version 16.2.2.

The results from this search for optimal conditions are shown in Figure 1(e), which shows the compression length and rotational speed that resulted in extraction efficiencies between 50 and 80%, 10-20 mg of β-carotene per 100 g, 2-6 mg of lycopene per 100 g, 60-70% iodine values, and 0-4 mg potassium hydroxide per gram acidity. The white area shows the optimal conditions.

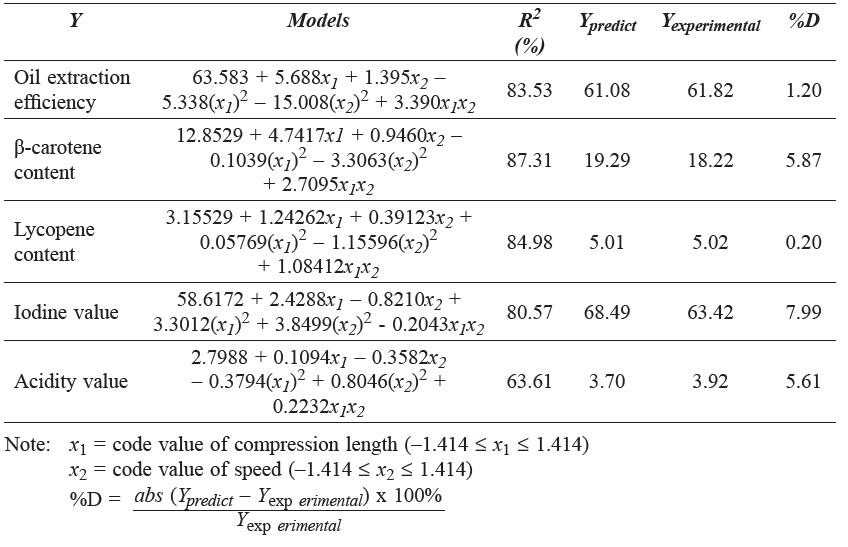

Validity test of the mathematical model for screw press extraction

The validity of the mathematical model for screw press extraction was tested by comparing the predicted values with experimental data for a compression length of 2.02 cm and a rotational speed of 14.10 rpm, using the response optimizer function of Minitab software, as shown in Figure 2. The predicted values were 61.1% efficiency, 19.3 mg β-carotene per 100 g, 5.0 mg lycopene per 100 g, 68.5% iodine value, and 3.7 mg potassium hydroxide per g acidity. The experimental data is shown in Table 4. To compare the values, % D is determined, where % D is the comparative value between percentage obtained from the experiment and the prediction. A low % D value indicates that the model is accurate and useful.

Figure 2. Finding optimal conditions for oil extraction from gac aril using real values.

From Table 4, the % D values of extraction efficiency, β-carotene content, lycopene content, iodine value, and acidity value were less than 10%, indicating that the mathematical model is accurate and useful.

Table 4. Models, the R2 and % D value of oil extraction efficiency, β-carotene and lycopene content, iodine value, and acidity value in coded units.

Physical properties of the gac aril oil extracted at the optimal conditions

The optimal conditions for oil extraction of gac aril using a screw press were a compression length of 2.02 cm and a rotational speed of 14.10 rpm, which yielded L* of 6.4, a* of 23.0, b* of 9.0, Hue angle of 21.25°, and viscosity of oil extracted from gac aril of 135 mPa.s. The color of the oil product when encapsulated in clear and colorless gelatin capsules was orange.

DISCUSSION

Analysis of gac aril oil extracted under various conditions

In Figure 1(a), a short compression length caused excessive compression and resulted in a clog during the extraction, reducing the amount of oil obtained (Supakit et al., 2012). Extraction efficiency also increased with increased rotational speed. However, if the rotational speed was too high, the extraction efficiency decreased, because this resulted in lower compression of the sample, reducing the amount of oil obtained. Additionally, oil extraction efficiency depended on the characteristics of the extraction samples.

β-carotene and lycopene analysis of oil extract from gac aril under various conditions

The results showed that as the compression length and rotational speed increased, the β-carotene content (Figure 1(b)) and lycopene content (Figure 1(c)) increased, because high compression caused high friction between the thread and the wall of the cylinder, increasing the temperature. Heat and oxygen caused the loss of carotenoid (Kha et al., 2013). When the rotational speed was too low, the time for compression was prolonged and the extraction samples stuck together so that the screw could not compress the sample (Supakit et al., 2012), creating heat and longer compression times, which resulted in a loss of carotenoid. Nhung et al. (2010) found that the ratio of lycopene to β-carotene in the gac aril was very high, but was nine times lower in an oil extract. However, the gac aril oil maintained the amounts of the two substances better than gac juice.

Iodine value analysis

Iodine value is the amount in grams of iodine involved in the halogenation reaction with double bonds in unsaturated fatty acids per 100 g of fat or oil. It, therefore, indicates the amount of unsaturated fatty acids in fat or oil. Unsaturated fatty acids are beneficial to metabolism and help reduce blood cholesterol. The iodine values of gac aril oil were between 56.6 and 70.8%, as shown in Table 3; these are similar to those reported by Kha et al. (2013), who found that gac aril had total unsaturated fatty acids of 70%, of which 50% were polyunsaturated fatty acids. Betty et al. (2004) found that fatty acids in gac aril were 22% by weight, of which oleic acid was 32%, palmitic acid 29%, and linoleic acid 28%. Therefore, the oil from gac aril contains high levels of unsaturated fatty acids.

Acidity value analysis

Acidity is the amount in milligrams of potassium hydroxide that reacts with free fatty acids in a sample. The obtained value can be used to calculate the amount of free fatty acids, which indicates the quality of oil and fat. More specifically, it indicates the amount of triglyceride, which is the main component of fat and oil that is produced when cleaved by hydrolysis using lipase and heat, giving glycerol and free fatty acids as products and increasing the acidity of oil and fat. The acidity values of oil from gac aril were between 2.43 and 5.15 mg potassium hydroxide per gram, as shown in Table 3. According to the Notification of the Ministry of Public Health, Thailand No. 205 B.E. 2543 (2000), the acidity value must not exceed 4.00 mg potassium hydroxide per gram. Peroxide value analysis

Peroxide value is the amount in milligrams equivalent of peroxide oxygen

in 1 kg of fat or oil. If the peroxide value is high, the fat or oil readily becomes rancid, a disadvantage in oily or fatty foods. According to the Notification of the Ministry of Public Health, Thailand No. 205 B.E. 2543 (2000) regarding oil and fat, the peroxide value must not exceed 10 mg equivalent of peroxide oxygen per 1 kg of oil. Oil from gac aril contained undetectable amounts in mg equivalent of peroxide, as shown Table 3, which agreed with Vuong and King (2003), who found that oil from gac aril contained 334 μg/g vitamin E, 69% unsaturated fat, and 35% polyunsaturated fatty acids. Vuong et al. (2005) found that gac aril had 76.3 ± 22.2 μg/mL of α-tocopherol, a derivative of vitamin E, a fat-soluble vitamin. Vitamin E helps to protect cells in the body from free radical attack by inhibiting oxidation reactions. This can prevent rancidity, because vitamin E is easily oxidized and, therefore, becomes oxidized in preference to other substances, preventing consumed unsaturated fat from combining with oxygen to create free radicals. Vitamin E also prevents the hardening of blood vessels and helps to reduce clogging by cholesterol. The peroxide value in oil from gac aril was below detectable levels, because it contained vitamin E, which helped prevent rancidity.

CONCLUSION

A Central Composite Design was applied to determine the optimal process for extraction of oil from the gac aril to give the maximum value of oil extraction efficiency, β-carotene, lycopene, and iodine value, while minimizing the acidity and peroxide values. Under the optimal conditions, the predicted values were 65±15% extraction efficiencies, 15±5 mg of β-carotene per 100 g, 4±2 mg of lycopene per 100 g, 65±5% iodine values, and 2±2 mg potassium hydroxide per gram acidity. % D values for these factors were below 10%, indicating that the mathematical model is accurate and useful for practical applications.

ACKNOWLEDGEMENTS

We are grateful to the Faculty of Applied Science, King Mongkut’s University of Technology North Bangkok for funding the research (5844101). The authors would also like to thank Asst. Prof. Dr. Supakit Sayasoonthorn and Mr. Prin Kongchop, Department of Farm Mechanics, Faculty of Agriculture, Kasetsart University, for providing the screw press oil extractor.

REFERENCES

American Oil Chemists’ Society Press. 1997. Official Methods and Recommended Practices of the AOCS, 5th ed. Champaign. Illinois.

Betty, K., T. Charlotta, H. Mary, and A. Thomas. 2004. Fatty acid and carotenoid composition of Gac (Momordica cochinchinensis Spreng) fruit. Journal of Agricultural and Food Chemistry. 52: 274-279. doi: 10.1021/jf030616i

Kasote, D.M., Y.S. Badhe, and M.V. Hegde. 2013. Effect of mechanical press oil extraction processing on quality of linseed oil. Industrial Crops and Products. 42: 10-13. doi:10.1016/j.indcrop.2012.05.015

Kha, T.C., M.H. Nguyen, P.D. Roach, and C.E. Stathopoulos. 2013. Effect of Gac aril microwave processing condition on oil extraction efficiency, and β–carotene and lycopene contents. Journal of Food Engineering. 117: 486-491. doi:10.1016/j.jfoodeng.2012.10.021

Khan, L. M., and M. A. Hanna. 1983. Expression of oil from oilseeds – A Review. Journal of Agricultural Engineering Research. 28: 495-503.

Kubola, J., and S. Siriamornpun. 2011. Phytochemical and antioxidant activity of different fruit fraction (Peel, pulp, aril and seed) of thai gac (Momordica cochinchinensis spreng). Food Chemistry. 127(3): 1138-1145. doi: 10.1016/j.foodchem.2011.01.115

Kubola, J., N. Meeso, and S. Siriamornpun. 2013. Lycopene and beta carotene concentration in aril oil of gac (Momordica cochinchinensis Spreng) as influenced by aril-drying process and solvents extraction. Food Research International. 50: 664-669. doi:10.1016/j.foodres.2011.07.004

Marcela, L.M., P. Ma. Cecilia, M. Ma. Andrea, D.R. Pablo, and M. Damian. 2013. Screw press extraction of almond (Prunus dulcis (Miller) D.A. Webb): Oil recovery and oxidative stability. Journal of Food Engineering. 119: 40-45. doi:10.1016/j.jfoodeng.2013.05.010

Montgomery, D.C. 2001. Design and Analysis of Experiments. 17th ed. Wiley. New York.

Nagata, M., and I. Yamashita. 1992. Simple method for simultaneous determination of chlorophyll and carotenoids in tomato fruit. The Japanese Society for Food Science and Technology. 39: 925-926. doi: 10.3136/nskkk1962.39.925

Nhung, D.T.T., P.N. Bung, N.T. Ha, and T.K. Phong. 2010. Changes in lycopene and beta carotene contents in aril and oil of gac fruit during storage. Food Chemistry. 121(2): 326-331. doi: 10.1016/j.foodchem.2009.12.032

Supakit, S., S. Kaewrueng, and P. Patharasathapornkul. 2012. Rice bran oil extraction by screw press method: Optimum operating setting, oil extraction level and press cake appearance. Rice science. 19(1): 75-78. doi:10.1016/S1672-6308(12)60024-9

Tinrat, S., S. Akkarachaneeyakorn, and C. Singhapol. 2014. Evaluation of antioxidant and antimicrobial activities of Momordica Cochinchinensis Spreng (Gac fruit) ethanolic extract. International Journal of Pharmaceutical Sciences and Research. 5(8): 3163-3169.

Vuong, L.T., and J.C.A. King. 2003. A method for preserving gac fruit oil, a rich source of beta-carotene and essential fatty acid in North Vietnam. Food and Nutrition Bulletin. 24(2): 224-230.

Vuong, L.T., S.R. Dueker, and S.P. Murphy. 2002. Plasma beta-carotene and retinol concentrations of children increase after 30-d supplementation with the fruit Momordica cochinchinensis (gac). American Journal of Chemical Nutrition. 75(5): 872-829.

Vuong, L.T., A.A. Franke, L.J. Custer, and S.P. Murphy. 2005. Momordica cochinchinensis Spreng (gac) fruit carotenoids reevaluated. Journal of Food Composition and Analysis. 19(6-7): 664-668. doi:10.1016/j.jfca.2005.02.001

Suthida Akkarachaneeyakorn*, Apinya Boonrattanakom, Pornchanok Pukpin, Samaporn Rattanawaraha and Sutheera Khantaphant

Department of Agro-Industrial, Food, and Environmental Technology, Faculty of Applied Science, King Mongkut’s University of Technology, North Bangkok, Bangkok 10800, Thailand

*Corresponding author. E-mail: suthida.a@sci.kmutnb.ac.th

Total Article Views