Radio Frequency Heat Treatment for Controlling Rice Weevil n Rough Rice cv. Khaoe Dawk Mali 105

Wornwimol Wangspa , Yaowaluk Chanbang* and Suchada VearasilpPublished Date : 2019-08-24

DOI : 10.12982/CMUJNS.2015.0081

Journal Issues : Number 2, May - August 2015

ABSTRACT

The rice weevil (Sitophilus oryzae Linnaeus) is one of the most serious stored-grain pests worldwide. The immature insects grow rapidly within grain. This study analyzed the effectiveness of radio frequency (RF) heat treatment for killing rice weevils in rough rice cv. Khao Dawk Mali 105. Rough rice at 14% moisture content was blended with 30 individuals of each stage (egg, larva, pupa, adult) of the rice weevil, and exposed to RF heat treatment at 50°C for 180 seconds. The mortality rates of egg, larva, pupa and adult were 100.00, 96.50 ± 2.3, 80.90 ± 7.3 and 79.69 ± 5.1%, respectively (P>0.05). To then determine the most efficient combination of temperature and duration for RF heat treatment, the adults (representative of the most RF heat-tolerant stages) were treated with 50, 55, 60, 65 and 70oC for 90, 120, 150 and 180 seconds (20 combinations of treatment). RF heat treatment at 55°C for 180 seconds, 60°C for 150 seconds or more, and 65 and 70°C for 120 seconds or more all caused 100% mortality. Of these, the RF treatment of 65°C for 120 seconds used the least energy (0.391 kW).

Keywords: Sitophilus oryzae, tolerance, temperature, radio frequency heat treatment

INTRODUCTION

In Thailand, rice is a major grain crop, with 55% of production consumed domestically and the remainder exported; Khao Dawk Mali 105, or jasmine rice, is important for both (Business Process Analysis Guide to Simplify Trade Procedures, 2011; Phare Rice Seed Center, 2011). Khao Dawk Mali 105 is the most popular aromatic rice variety in Thailand, due to its good cooking quality and aroma (Sareepuang et al., 2008).

Stored rice is susceptible to many insect pests. These can multiply rapidly, causing serious damage and loss by direct feeding on grains, as well as lead to contamination with storage fungi. The rice weevil (Sitophilus oryzae Linnaeus) is one of the most problematic stored-grain pests worldwide.

The most effective method to control rice weevil and other stored-grain insects is fumigation with methyl bromide (MeBr). However, MeBr is being phased out in 2015 due to its environmental and health effects. Phosphine gas is the other chemical commonly used to control stored-grain insects, but many of the pests have developed phosphine resistance (Benhalim et al., 2004). One alternative is radio frequency (RF) heat treatment, which can effectively and quickly control rice weevils, while consuming less energy than conventional heat treatment. Moreover, RF heat treatment avoids the surface overheating of traditional surface-heating methods (Lagunas-Solar et al., 2005).

The objectives of this study were 1) to study the effectiveness of radio frequency for killing rice weevils, and 2) to find the specifications for RF heating for controlling rice weevils that minimizes damage to rough rice cv. Khao Dawk Mali 105.

MATERIALS AND METHODS

Mass rearing of test insect

Rough rice (cv. Khao Dawk Mali 105) was stored at -21°C for 2-3 days to kill any insects in the rough rice. The moisture content of the rice kernels was adjusted to 18%. Then adult rice weevils (Sitophilus oryzae) were added to 200 g of the rough rice and reared, about 100-200 insects per plastic container, under laboratory conditions at 28°C and 70% relative humidity (R.H.). The insects were allowed to lay eggs for three days inside the kernels and then the adult insects were separated and discarded from the egg-infested rice. From this egg-infested rice (maintained at 28°C and 70% R.H.), eggs, larvae, pupae and adults were harvested at 4, 11, 28, and 35 days, respectively (Takang, 2011).

RF tolerance of rice weevil stages

This experiment determined the most tolerant stage (egg, larval, pupal and adult stages) of rice weevil to RF heat treatment. Rough rice of Khao Dawk Mali 105 with 14% initial moisture content (300 g) was used in all experiments. Rough rice containing each stage of the insect was exposed to the heat treatment with RF at 27.12 MHz at a temperature of 50°C for 180 seconds. Rice weevil eggs were prepared by thoroughly selecting the rice kernels with egg plugs that could be seen under stereo microscope. Egg-infested kernels were selected two days after the rice weevil had laid the eggs. Larval- and pupal-stage kernels were collected from the kernels with egg plugs after 14-18 days and 24-28 days, respectively. About two-week-old adults were used in all experiments. Thirty infested rice kernels representing the various stages were combined with milled rice and exposed to RF as described above. After exposing to the RF heat treatments, the moribund and live insect mortality were evaluated when the surviving insects in each stage developed into the adult stage (4-6 weeks).

The live insects that survived the previous treatments were reared under normal conditions in milled rice. The rice weevils were paired in each vial and the number of eggs and hatching capability were observed. The rate of survival of the progeny was counted after an additional six weeks.

Effectiveness of RF heat treatment for completely killing rice weevil

The objective of this study was to find the combination of minimal temperature and time that completely killed the most tolerant stage of rice weevils as found from Experiment 1. Infested rough rice with the most tolerant stage of rice weevil was exposed to RF heat treatment at 27.12 MHz with temperatures of 50, 55, 60, 65 and 70°C and durations of 90, 120, 150 and 180 seconds (20 combinations of treatment). Thirty insects were used in each combination of treatment. Since the egg, larval and pupal stages of the rice weevil were inside the rough rice kernels, insect mortality was assessed after emergence of surviving insects. The F1 progeny was counted after an additional six weeks. The electrical energy (Eel Wh) of the different RF heat treatments was calculated as the product of electrical power (Pel W) and time (t).

Statistical analysis

Insect mortality was counted and the percentage mortality was calculated using Abbott’s formula (Abbott, 1925). All data were analyzed by analysis of variance (ANOVA) using Statistix version 8.0 (Analytical Software, USA) to determine the treatment effects. The means of the difference of the treatments were compared by least significant difference (LSD). Differences were considered significant for p < 0.05 for all comparisons.

RESULTS

RF tolerance of rice weevil stages

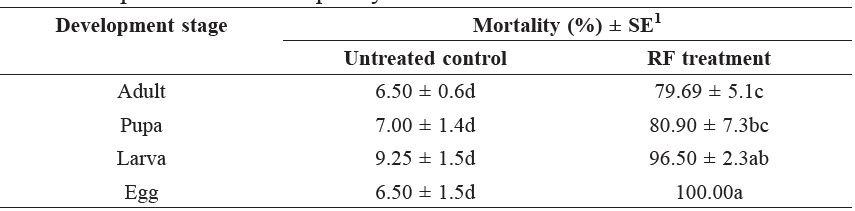

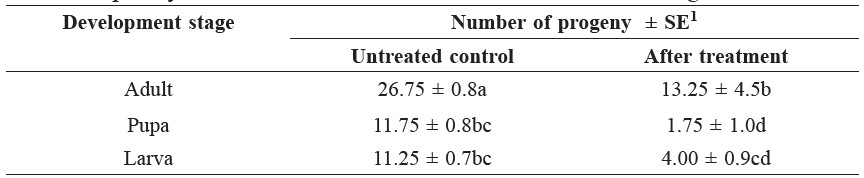

After exposure to RF heat treatment at 50°C for 180 seconds, complete mortality was found only in the egg stage. Mortality rates in the adult, pupal and larval stages were 79.7 ± 5.1, 80.9 ± 7.3 and 96.5 ± 2.3%, respectively. The mortalities of egg, larval, pupal and adult stages were significantly different (P<0.05) when compared with the untreated control (Table 1). The number of F1 progeny of the adult, pupa and larva that survived the RF heat treatment – 13.3 ± 4.5, 1.8 ± 0.1 and 4.0 ± 0.9 insects, respectively – was significantly less than the number of progeny in the untreated control (Table 2).

Table 1. Average mortality of rice weevil at various development stages when exposed to radio frequency at 50°C for 180 seconds.

Note: 1Means within the same column and row followed by different letters are significantly different at 95% confidence level (P<0.05) by Least Significant Difference (LSD) comparison.

Table 2. Average of progeny of rice weevil treated with 27.12 MHz radio frequency at 50°C for 180 seconds after 6 weeks of storage.

Note: 1Means within the same column and row followed by different letters are significantly different at 95% confidence level (P<0.05) by Least Significant Difference (LSD) comparison.

Responses of rice weevil to RF heat treatment

The pupal and adult stages of the rice weevil were the most RF-tolerant stages. Because the adults were easier to handle than the pupae, the adult stage was chosen to find the minimally effective combination of temperature and duration that completely killed the rice weevils.

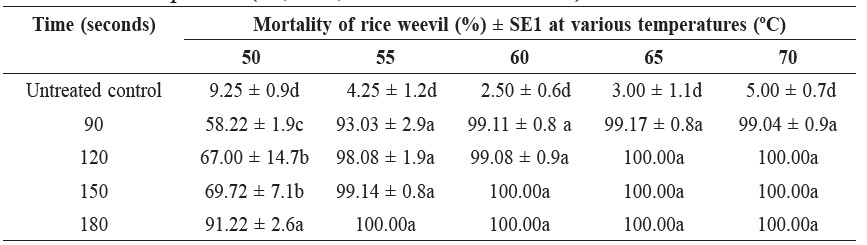

RF heat treatments of 55°C for 180 seconds, 60°C for 150 seconds or more, and 65 and 70°C for 120 seconds or more all caused 100% mortality in adult stage rice weevils (Table 3).

Table 3. Average mortality of adult rice weevils when exposed to radio frequency heat treatment at combinations of temperature (50, 55, 60, 65 and 70°C) and exposure (90, 120, 150 and 180 seconds).

Note: 1Means within the same column and row followed by different letters are significantly different at 95% confidence level (P<0.05) by Least Significant Difference (LSD) comparison.

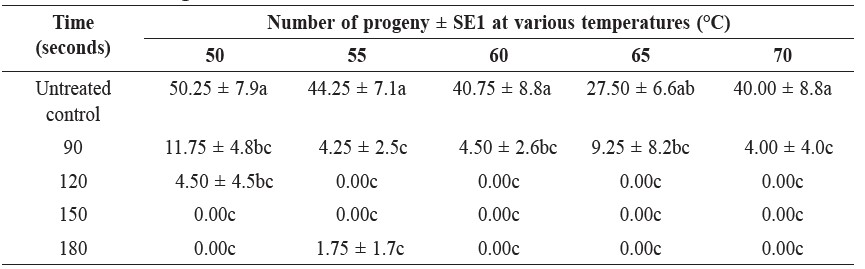

For those treatments that did not kill 100% of the adults, the survivors of RF heat treatment laid eggs that survived to adulthood in significantly fewer numbers than untreated control (Table 4).

Table 4. Average number of progeny of rice weevils when exposed to radio frequency heat treatment at combinations of temperature (50, 55, 60, 65 and 70 ºC) and exposure (90, 120, 150 and 180 seconds) after 6 weeks of storage.

Note: 1Means within the same column and row followed by different letters are significantly different at 95% confidence level (P<0.05) by Least Significant Difference (LSD) comparison.

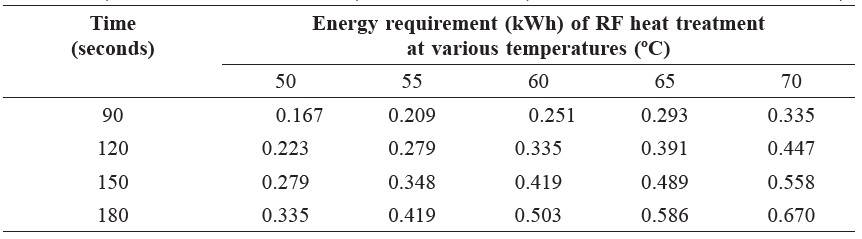

The energy requirement for the RF heat in the various combination treatments was calculated as shown in Table. 5. The energy consumed increased with increasing exposure time and temperature. Of the combination treatments that resulted in 100% mortality, 65°C for 120 seconds required the least energy (0.391 kWh) and 70°C for 180 seconds the most energy (0.670 kWh).

Table 5. Energy requirement (kWh) of RF heat treatment at various temperatures (50, 55, 60, 65 and 70ºC) and durations (90, 120, 150 and 180 seconds).

DISCUSSION

The pupa and adult were the most RF-tolerant stages of the rice weevil. Sumetha et al. (2009) found similar results with the lesser grain borer, Rhyzopertha dominica; the adult was the most tolerant stage to RF treatment of 27.12 MHz at 50°C for 180 seconds, followed by the pupal, larval and egg stages. Moreover, Faikrajaypuan et al. (2011) showed that adult maize weevils, Sitophilus zeamais, were more tolerant to RF treatment than the other stages. Insects with a higher moisture content heat more quickly when exposed to RF heat treatment (Ryynänen, 1995; Mitcham et al., 2004). However, the moisture content of each stage of a rice weevil has not been determined. RF heat treatment causes fast heating because of the direct interaction between the RF energy and the material, so that the temperature inside the material rises quickly, whereby the dielectric properties of the commodity is influenced by moisture content and the degree of water binding with the constituent of the commodity (Wang et al., 2005; Nelson and Trabelsi, 2009). However, Chapman (1998) and Yoder et al. (2009) reported that Coleopteran insects (which include rice weevils) with their hard, joined exoskeleton or cuticle have a low percentage of body water content, which makes adults more heat tolerant than the larvae and pupae.

In this experiment, some of the adult rice weevils that survived the RF-exposure were capable of reproduction, but the number of progeny was significantly lower than that in the untreated control. Buapud et al. (2012) found that the F1 progeny of Angoumois grain moths, Sitotroga cerealella (Olivier) in rough rice at 14% water content exposed to 49.6±0.1°C RF heat treatment were fewer than untreated controls. Rai et al. (1974) also reported that 39 MHz heat-treated yellow mealworm (Tenebrio molitor) showed lower fecundity. Rai et al. (1974; 1977) concluded that when insects were exposed to heat, their sperm cells, ovarian tissue and spermatozoa were damaged.

In our experiment, many combinations of temperature level and time period were able to completely kill all rice weevils. Of these, the combination of RF applied for 65°C for 120 seconds consumed the least energy. This is a similar or lower temperature and duration than for other insect pests in rough rice. The Angoumois grain moth at pupal stage, its most RF-tolerant stage, required 72.1±0.4°C for 220 seconds to kill all insects (Buapud et al., 2012). The rice moth, Corcyra cephalonica, required 60°C for 180 seconds (Luechai et al., 2008). The lesser grain borer required RF heat treatment of at least 70°C for 180 seconds. In this way, an RF treatment of at least 73°C for a minimum of 220 seconds would treat all of these pests in rough rice.

RF technology has advantages over other heat treatments. Wiset et al. (2001) reported that conventional hot-air drying has many disadvantages, such as high energy consumption, low drying efficiency and a detrimental effect on product quality. Fluidized bed dryers, which provide higher heat for a shorter duration, are less damaging than conventional heat. However, fluidized bed dryers are most effective when the moisture content in the grains is above 18% (Cheenkachorn, 2007). Taweerattanapanish et al. (1999) reported that when fluidized bed heat was used for drying rough rice with high inlet air temperature at 140 and 150°C, head rice yield increased to a maximum value at a range of paddy moisture content of 19 to 22%; at less than 19%, head rice yield was less. However, at the higher moisture contents for which the fluidized bed dryers are more effective, rice is not safe from insect reinfestation and other spoilages (Prakash and Rao, 1995). As stored rough rice in Thailand has a typical moisture content of 14% (National Bureau of Agricultural Commodity and Food Standards, 2010), RF heat treatment offers an effective means of controlling pests, and an alternative to chemicals.

ACKNOWLEDGEMENTS

We thank the Postharvest Technology Research Institute and Postharvest Technology Innovation Center, Chiang Mai University, Thailand for supplying the scientific instruments. We also thank The Graduate School, Chiang Mai University for its research grant.

REFERENCES

Abbott, W.S. 1925. A method of computing the effectiveness of insecticide. Journal of Economic Entomology 18: 265-267.

Benhalim, H., M.Q. Chaudhry, K.A. Mills, and N.R. Price. 2004. Phosphine resistance in stored-product insects collected from various grain storage facilities in Morocco. Journal of Stored Products Research 40: 241-249.

Buapud, A., Y, Chanbang, and S. Verasilp. 2012. Effects of radio frequency heating on Sitotroga cerealella (Olivier) and milling quality of rice cv. Khao Dawk Mali 105. Journal of Agriculture 28(2): 137-144.

Chapman, R. F. 1998. The Insect Structure and Function. 4th ed. The United Kingdom at the University Press, Cambridge. 770 pp.

Cheenkachorn, K. 2007. Drying of rice paddy using a microwave-vacuum dryer. Paper Presented at European Congress of Chemical Engineering (ECCE-6), Copenhagen September 16-20, 2007. 7 pp.

Faikrajaypuan, W., Y. Chanbang, and S. Verasilp. 2011. Effect of heat radiofrequency on maize weevil (Sitophilus zeamais). Agricultural Science Journal (Suppl.): 392-395.

Janhang, P., N. Krittigamas, W. Lücke, and S. Vearasilp. 2005. Using radio frequency heat treatment to control the insect Rhyzopertha dominica (F.) during storage in rice seed (Oryza sativa L.). Paper Presented at the Conference on International Agricultural Research for Development. October 11-13, 2005. Stuttgart-Hohenheim, Germany. 4 pp.

Lagunas-Solar, M. C., J. S. Cullor, N. X. Zeng, T. D. Truong, T. K. Essert, W. L. Smith, and C. Piña. 2005. Disinfection of dairy and animal farm waste water with radiofrequency power. Journal of Dairy Science 88(11): 4120-4131.

Luechai, N., Y. Chanbang, and N. Krittigamat. 2008. Radio frequency treatment for controlling rice moth, Corcyra cephalonica (Stainton) and its effects on quality of milled rice cv. Khao Dawk Mali 105. Agricultural Science Journal. 39:3(Suppl.): 347-350.

Mitcham, E.J., R.H. Veltman, X. Feng, E. de Castro, J.A. Johnson, T.L. Simpson, W.V. Biasi, S. Wang, and J. Tang. 2004. Application of radio frequency treatments to control insects in in-shell walnuts. Postharvest Biology and Technology 33 : 93-100.

National Bureau of Agricultural Commodity and Food Standards. 2010. Good Manufacturing Practices for rice mill. Thai Agricultural TAS 4403-2010.

The Royal Gazette Vol. 127 Section 150D Special, Ministry of Agriculture and Cooperatives, Thailand. 36 p.

Nelson, S.O., 1996, Review and assessment of radio-frequency and microwave energy for stored-grain insect control, Transactions of the ASAE 39(4): 1475-1484.

Nelson, S.O., and Samir Trabelsi. 2009. Influence of water content on RF and microwave dielectric behavior of foods. Journal of Microwave Power & Electromagnetic Energy 43(2)

Phare Rice Seed Center. 2011. Rice Thailand. [Online]. Available: http://pre-rsc.ricethailand.go.th/ knowledge/6.htm (July 22, 2011).

Prakash, A., and J. Rao. 1995. Insect Pest Management in Stored Rice Ecosystem. pp. 709-736. In: D. S. Jayas, N. D. G. White, and W.E. Muir, (eds) In Stored grain ecosystem. Marcel Dekker, Inc. New York.

Rai, P. S., H. J. Ball, S. O. Nelson, and L. E. Stetson. 1974. Cytopathological effects of radiofrequency electric fields on reproductive tissue of adult Tenebrio molitor (Coleoptera: Tenebrionidae). Annals of the Entomological Society of America 67(4): 687-690.

Rai, P. S., H. J. Ball, S. O. Nelson, and L. E. Stetson. 1977. Spermatozoan activity and insemination in Tenebrio molitor following radiofrequency electrical treatment (Coleoptera: Tenebrionidae). Annals of the Entomological Society of America 70(2): 282-284.

Ryynänen, S. 1995. The electromagnetic properties of food materials: A review of the basic principles. Journal of Food Engineering 26: 409-429.

Sareepuang, K., S. Siriamornpun, L. Wiset, and N. Meeso. 2008. Effect of soaking temperature on physical, chemical and cooking properties of parboiled fragrant rice. World Journal of Agricultural Sciences 4(4): 409-415.

Sumetha, K.,Y. Chanbang, V. Hengsawad, and N. Krittigamas. 2009. Effect of radio frequency on Rhyzopertha dominica (Fabricius) (Coleoptera: Bostrichidae) and quality of rice cv. Khao Dawk Mali 105 Paper Presented at 6th Conference of Agricultural Graduate Research. March 12-13, 2009. Chiang Mai University. Thailand.

Taweerattanapanish, A., S. Soponronnarit, , S. Wetchakama, N. Kongseri, and S. Wongpiyachon. 1999. Effects of drying on head rice yield using Fluidisation Technique. Drying Technology: An International Journal 17(1-2): 346-353.

Wang, S., M. Monzon, Y. Gazit, J. Tang, E. J. Mitcham, and J. W. Armstrong. 2005. Temperature-dependent dielectric properties of selected subtropical and tropical fruits and associated insect pests. Transactions of the ASAE 48(5): 1873-1881.

Wiset, L., G. Srzednicki, R. Driscoll, C. Nimmuntavin, and P. Siwapornrak. 2001. Effects of high temperature drying on rice quality. Agricultural Engineering International: the CIGR Journal of Scientific Research and Development. 01 003(3): 1-10.

Work, Power and Energy. no date. [Online]. Available: http://recursostic.educacion.es/newton/web/materiales_didacticos/work/aulawork.pdf. (September 9, 2013)

Yoder, J. A., M.J. Chambers, J.L.Tank, and G. D. Keeney. 2009. High temperature effects on water loss and survival examining the hardiness of female adults of the spider beetles, Mezium affine and Gibbium aequinoctiale. Journal of Insect Science 9: 1-8.

Wornwimol Wangspa1, Yaowaluk Chanbang1,2* and Suchada Vearasilp1,3

1 Postharvest Technology Research Institute / Postharvest Technology Innovation Center, Chiang Mai University, Chiang Mai 50200, Thailand

2 Department of Entomology and Plant Pathology, Faculty of Agriculture, Chiang Mai University, Chiang Mai 50200, Thailand

3 Department of Plant Science and Natural Resources, Faculty of Agriculture, Chiang Mai University, Chiang Mai 50200, Thailand

*Corresponding author. E-mail: lukksu@hotmail.com

Total Article Views