The Optimal Drying Temperature and Moisture Content for Microwavable Job’s Tears Grains

Orathai Bunthawong and Somchai Jomduang*Published Date : 2019-08-23

DOI : 10.12982/cmujns.2016.00013

Journal Issues : Number2 ,May - August 2016

ABSTRACT

This research focused on the optimal drying temperature and moisture content for two forms – polished and unpolished – of microwavable, puffed, black husk variety, Job’s tears grains. Grains were prepared by overnight soaking and autoclave cooking at 15 psi for 20 minutes. All prepared grains were then dried in a tray dryer at five different temperatures (60, 70, 80, 90, and 100°C). After drying and overnight storage at room temperature, their moisture content was determined. The pretreated grains at different moisture contents were puffed by microwave oven at the maximum power of the machine (800 watts) for 1 to 3 minutes, or until they were completely expanded. If the expansion ratios of both forms of puffed products were greater than or equal to 1.5, the puffed products were accepted by taste panelists; accordingly, we selected the expansion ratio of 1.5 as the benchmark for these puffed products. At this benchmark expansion ratio, the optimal drying condition of pretreated Job’s tears grains was 90°C for 2 hours, resulting in 9.4% to 10.3% moisture content for polished and unpolished grains, respectively.

Keywords: Puffed Job’s tears grains, Microwavable puffed grains, Benchmark expansion ratio, Drying temperature, Moisture content

INTRODUCTION

Currently, marketed snack foods are mostly starch and fat, with little nutritional value. Overconsumption of crispy fried snacks leads to certain degenerative diseases, such as obesity, high blood pressure, diabetes, hypercholesterolemia, and osteoporosis (Woottiprasai and Maleehorm, 2007). Some consumers have been looking for healthier choices, driving a demand for new low-fat snacks.

Most snack products are made from cereal grains. One interesting grain is Job’s tears (Coix lacryma-jobi L.), which has the potential to be transformed into puffed snacks. Job’s tears has shown beneficial effects in the gastrointestinal tract and is used as a prebiotic because of its modifying effect on some intestinal bacteria (Chiang et al., 2000). The main components in the acetone extract of Job’s tears grains are four free fatty acids (palmitic, stearic, oleic, and linoleic acids) and coixenolide. Coixenolide was reported to have antitumor activity in sarcomas in mice (Tokuda et al., 1990; Numata et al., 1994; Shih et al., 2004; Yang et al., 2004) as well as prevent cancer and protect against viral infections (Hung and Chang, 2003). In addition, Job’s tears can reduce liver fat accumulation and prevent tumor-stimulating compounds (Chang et al., 2003; Yu et al., 2005). Furthermore, the polyphenolic substances in Job’s tears grains are good antioxidants and capture free radicals (Kuo et al., 2001, 2002).

Currently, puffed Job’s tears are commercially produced. However, they are fried in oil, which reduces shelf life, with a potentially rancid smell developing during storage. It would be advantageous to find a way to make Job’s tears expand besides oil frying. Puffing them in a household microwave oven is an interesting option, and an innovative method. Before microwaving, Bunthawong et al. (2012) prepared both unpolished and polished Job’s tears grains by soaking, autoclave cooking, and drying; the optimal pretreatment process after autoclave cooking was drying at 60°C for 5.5 to 6 hours until an 8.0% to 10.6% moisture content was achieved. This drying time was too long to be suitable for commercial manufacturing. Hence, the current study aimed to determine a better drying temperature and moisture content for production of puffed Job’s tears grains by microwave oven. The goal was to find the benchmark expansion ratio for these puffed products so that the result could be applied to commercial production of microwave-puffed Job’s tears grains.

MATERIALS AND METHODS

Preparation of two forms of Job’s tears grains

This study used the black husk variety of Job’s tears grains. The grains were dehusked, yielding unpolished black Job’s tears grains (UBJ). Polishing these yielded polished black Job’s tears grains (PBJ). Both forms were used as raw materials. All grains were purchased from CCP Northern Co., Ltd., Phayao, Thailand.

Study of the effect of drying temperature on the moisture content of pretreated Job’s tears grains

Each of the two forms – unpolished and polished – of Job’s tears grains were soaked overnight at room temperature and cooked in an autoclave at 15 psi for 20 minutes (modified method from Bunthawong et al., 2012). Then, the grains were separately dried in a tray dryer at five drying temperatures: 60, 70, 80, 90, and 100°C – temperatures typically used with agriculture products. Samples were randomly taken every 30 minutes, until the moisture content was less than 8.0%. After the sampling was completed, they were packed into tightly sealed aluminum foil bags and stored overnight at room temperature to balance the moisture content (Jomduang, 1994). After overnight storage, the moisture content of the pretreated grains was measured (AOAC, 2005). The relationship of drying times and moisture content of both grain types – unpolished and polished – was plotted and compared across drying temperatures.

Determination of the benchmark expansion ratio for puffed Job’s tears grains

Each form of Job’s tears grains – unpolished and polished – was separately examined to determine the benchmark expansion ratio for puffed Job’s tears. The pretreated grains from both forms of Job’s tears at different moisture contents provided from the previous study were puffed using a microwave oven (Samsung, ME712N model) at the maximum power of the machine (800 watts) for 1 to 3 minutes, until they expanded completely. The expansion ratios of the grains were determined using the sesame seed displacement method (Nath and Chattopadhyay, 2008).

The expansion ratios of both unpolished and polished grains were classified into several interval groups, and then each group was analyzed for physical and sensory qualities. Texture qualities consisted of hardness and crispness, as measured by a texture analyzer (Stable Micro Systems’ TA.XTPlus, USA). Sensory evaluation was conducted by 50 panelists using a 9-point hedonic scaling (1 = extremely dislike, 5 = neither like nor dislike, and 9 = extremely like). The panelists evaluated the sensory qualities of appearance, color, smell, texture (crispness), and overall liking. The experimental design was a randomized complete block design. The data obtained from the experiments were analyzed using analysis of variance and the means were compared using Duncan’s new multiple range test (P ≤ 0.05). The minimum expansion ratio that provided acceptable qualities of puffed products was selected and used as the benchmark expansion ratio for selecting the optimal moisture content in the next step of the study.

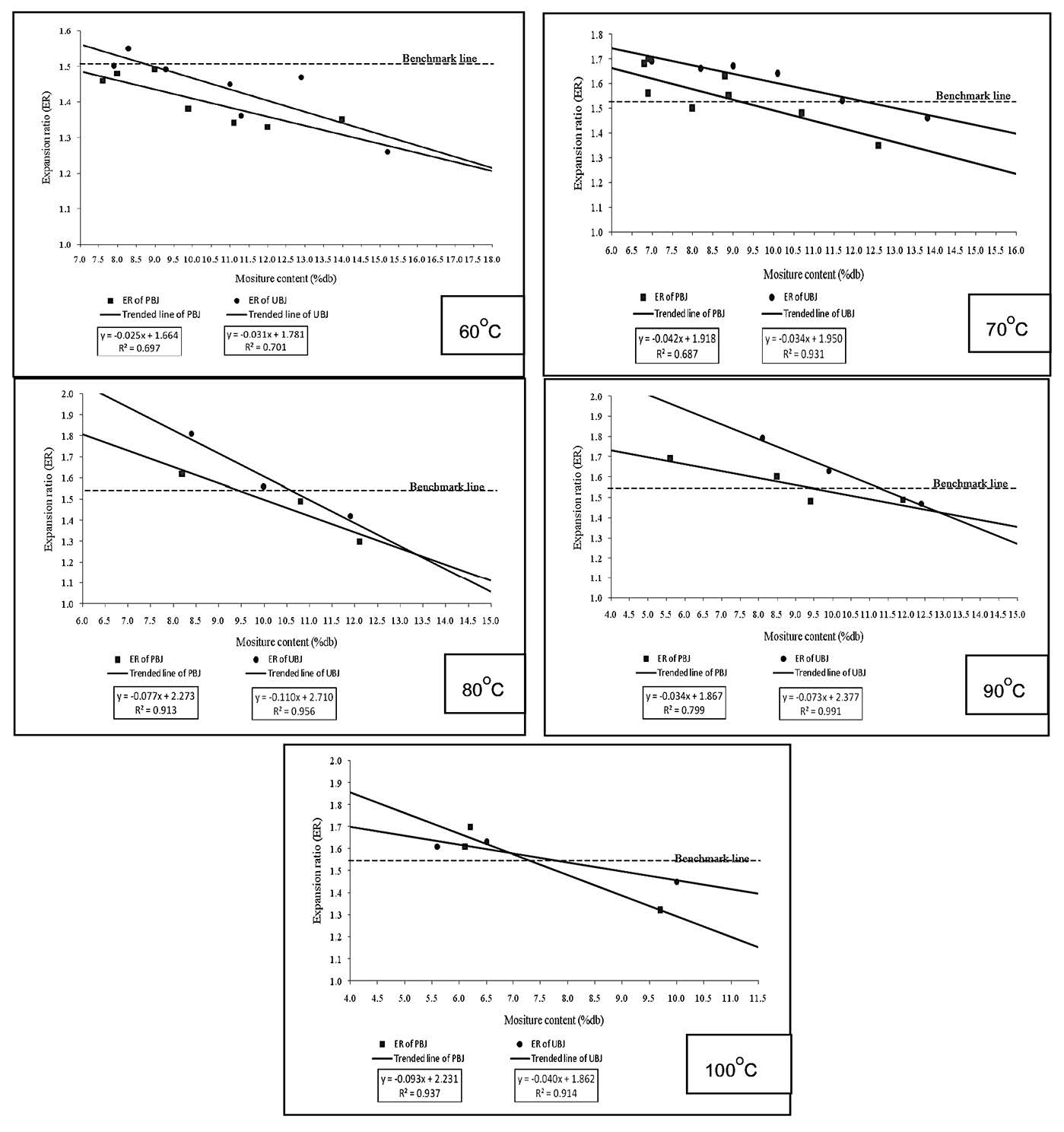

Study of the optimal drying temperature and moisture content for pretreated Job’s tears grains

Scatter graphs of the expansion ratios and moisture contents were created at each drying temperature from the earlier study. The linear trend line and linear line equation from each data group were created using packaged software. For each graph of the drying temperature, the selected benchmark expansion ratio line was used as the criteria for selecting the optimal moisture content range. The drying temperature was selected based on the expansion ratio of the puffed product that matched the benchmark expansion ratio. In addition, the cost efficiency of production at different drying temperatures and times was also used as a selection criterion in determining the optimal drying conditions (temperature and time).

RESULTS

Effect of the drying temperature on the moisture content of pretreated Job’s tears grains

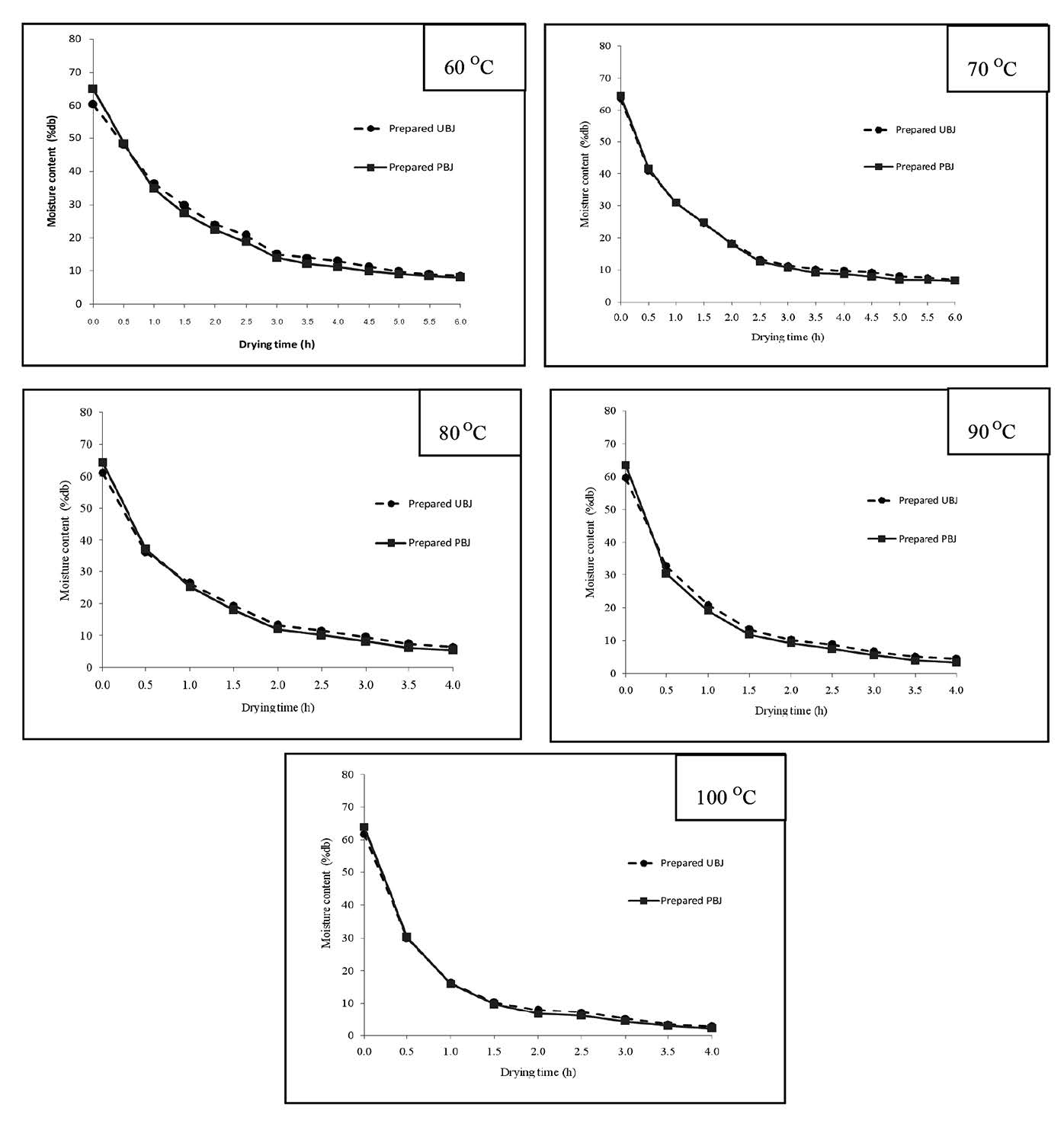

During the drying period of prepared Job’s tears grains at 60, 70, 80, 90, and 100°C, the moisture content of both the unpolished and polished grains decreased rapidly during the first 2 hours of drying time (Figure 1). After that, the moisture content reduced slowly. At a 70 to 100°C drying temperature for 4 hours, all forms of pretreated grains had less than 10% moisture content. However, at 60°C drying temperature for 4 hours, the moisture content remained above 10%. All prepared Job’s tears grains after drying were used as pretreated Job’s tears grains for the next steps.

Figure 1. The moisture content of unpolished (UBJ) and polished (PBJ) black Job’s tears at different drying temperatures.

The benchmark expansion ratio for puffed Job’s tears grains

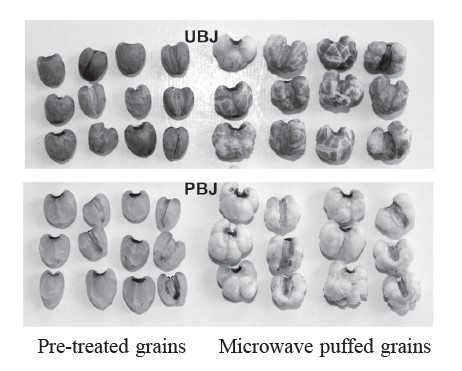

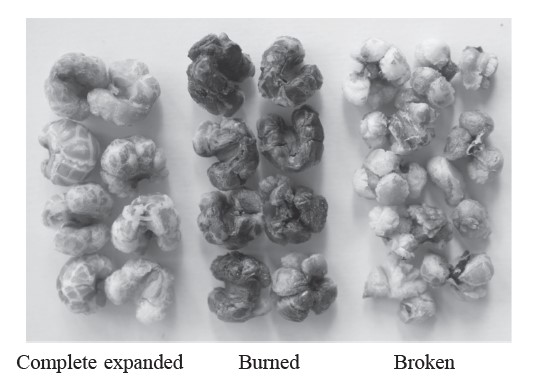

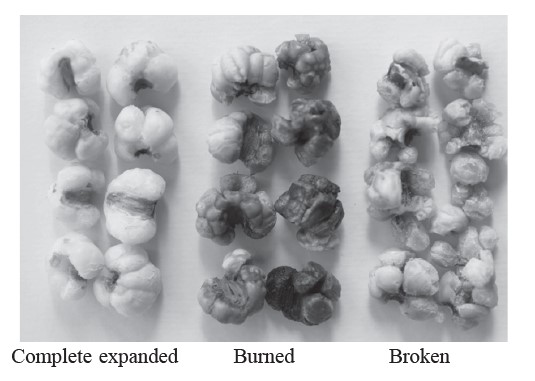

Each form – unpolished and polished – of the grains were separately investigated to determine the benchmark expansion ratio for puffed Job’s tears. The pretreated grains from the different drying conditions of the previous study were puffed by microwave oven until fully expanded (Figure 2).

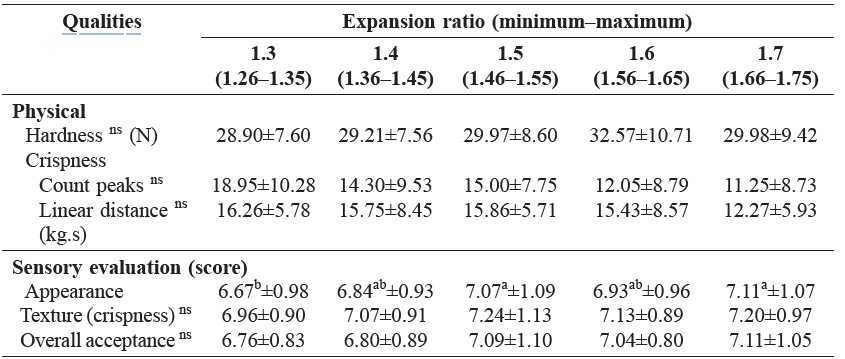

The expansion ratios of the puffed unpolished grains could be classified into five groups: 1.3 (1.26 to 1.35 interval), 1.4 (1.36 to 1.45 interval), 1.5 (1.46 to 1.55 interval), 1.6 (1.56 to 1.65 interval), and 1.7 (1.66 to 1.75 interval). The hardness and crispness did not differ significantly among the groups (P > 0.05) (Table 1). From the sensory evaluation, the texture and overall acceptance scores were not significantly different (P > 0.05), but the appearance scores at the 1.4, 1.5, 1.6, and 1.7 expansion ratios were significantly higher than at the 1.3 expansion ratio (P ≤ 0.05).

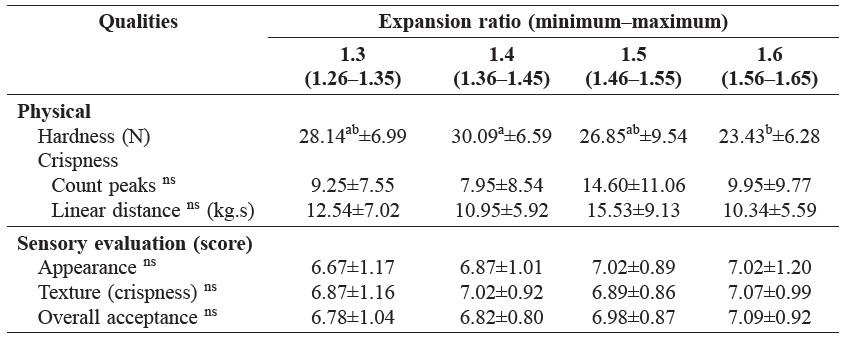

The expansion ratios of the puffed polished grains could be classified into only four groups: 1.3 (1.26 to 1.35 interval), 1.4 (1.36 to 1.45 interval), 1.5 (1.46 to 1.55 interval), and 1.6 (1.56 to 1.65 interval). All of their physical and sensory evaluation qualities, except for hardness, were not significantly different (P > 0.05) (Table 2). The hardness of the expansion ratios 1.3, 1.5, and 1.6 was low (28.14, 26.85, and 23.43 N, respectively), which differed significantly from that of the 1.4 expansion ratio (P ≤ 0.05).

With both unpolished and polished puffed grains, higher expansion ratios tended to generate higher sensory evaluation scores. In addition, if the expansion ratios of the puffed grains were greater than or equal to 1.4 in the unpolished grains and 1.5 in the polished grains, their physical and sensory evaluation qualities were similar. In practical applications, the benchmark expansion ratio of these puffed products should be the same value. Hence, the most suitable benchmark expansion ratio was 1.5

Figure 2. Appearance characteristics of unpolished (UBJ) and polished (PBJ) black Job’s tears grains.

The optimal drying temperature and moisture content for pretreated Job’s tears grains

After scatter diagrams between the expansion ratio and moisture content of each drying temperature were plotted, the linear trend lines and linear line equation were determined (Figure 3). The benchmark expansion ratio of 1.5, which was determined in the previous step, was used as a minimum criterion for moisture content selection. Only the puffed unpolished grains achieved the benchmark expansion ratio at 60°C, so this temperature was ruled out. With drying temperatures from 70 to 100°C, both forms of puffed Job’s tears grains achieved the benchmark expansion ratio. However, 70 and 80°C required 3 to 6 hours, too long for commercial applications (Table 3); and while 100°C required only 2 to 4 hours drying time, some puffed products were burned and broken into small pieces (Figures 4 and 5). At 90°C, the drying time was economically cost-effective for commercial production (2 to 4 hours). In addition, 90°C yielded a good expansion ratio and a low proportion of unexpanded grains. Thus, the 90°C drying temperature for 2 hours was the most suitable drying condition for pretreated grains of both forms – unpolished and polished, resulting in a moisture content of 9.4% to 10.3% (Table 3).

Table 1. Physical and sensory qualities of unpolished black Job’s tears grains at each expansion ratio.

Note: In each row, the different superscripts represent significant difference (P ≤ 0.05). ns = no significant difference (P > 0.05.)

Table 2. Physical and sensory quality of polished black Job’s tears grains at each expansion ratio.

Note: In each row, the different superscripts represent significant difference (P ≤ 0.05). ns = no significant difference (P > 0.05).

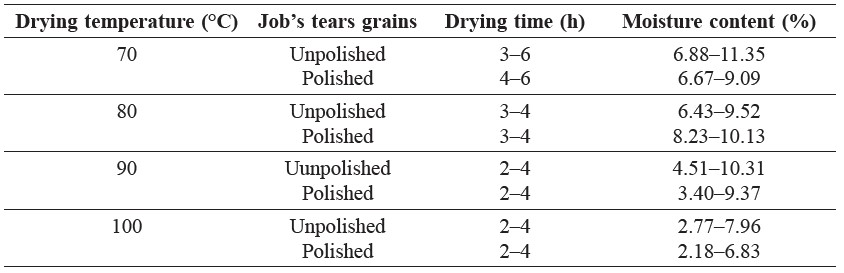

Table 3. Moisture content and drying time of various pretreated Job’s tears grains that provided an expansion ratio higher than 1.5.

Figure 3. The trend line of expansion ratios with different moisture contents of each form of Job’s tears grain (UBJ = unpolished and PBJ = polished).

Figure 4. Puffed unpolished Job’s tears grains using microwave oven.

Figure 5. Puffed polished Job’s tears grains using microwave oven.

DISCUSSION

Two forms of cooked Job’s tears grains – unpolished and polished – were dried by tray dryer at 60, 70, 80, 90, and 100°C to reduce moisture content. During the initial stage of drying, the higher the drying temperature, the more quickly the moisture content decreased. In this initial stage, the moisture quickly evaporated from the grains; as drying continued and less moisture remained, evaporation slowed and the moisture content changed little. The small quantity of moisture that remained was spread evenly over the surface (Chen and Mujumdar, 2008; Hui et al., 2008). At the final stage of drying, the higher the drying temperature, the lower the moisture content of the dried pretreated grains.

After puffing, the benchmark expansion ratio was investigated. The benchmark expansion ratio was the minimum value that provided a good expansion ratio, low proportion of unexpanded grains, and good sensory acceptance. With the unpolished grains, higher expansion ratios tended to deliver higher sensory scores. With the polished grains, higher expansion ratios led to lower hardness. This result corresponded to Fan et al. (1999), who found that snacks with high expansion ratios had low hardness. From the sensory evaluation, all expansion ratios had average scores of more than 6.7, corresponding to slightly to moderately like on the 9-point hedonic scale. In this study, the puffed products with expansion ratios of 1.5 or more from both the unpolished and polished grains had acceptable physical and sensory qualities; for this reason, an expansion ratio at 1.5 was selected as the benchmark.

The benchmark expansion ratio of 1.5 was used to investigate the optimal drying conditions. Both unpolished and polished forms of pre-treated Job’s tears grains yielded puffed products at all drying temperatures, except 60°C, at which only the unpolished grains achieved the benchmark expansion ratio. At 60°C, the water vapor moved out of grains slowly during the drying process, with low shrinkage, low surface film, and a high porous texture. When these pretreated grains were puffed by microwave oven, most of the water changed to water vapor very quickly, passing easily from inside the grain to the outer surface; as a consequence, the water vapor pressure was not high enough to expand the grain. In addition, 60°C took too long to adequately dry the grains for commercial application. When drying at 70 to 100°C, the water vapor rapidly moved out of the grains, causing high shrinkage, high surface film, and low porous texture. When these pretreated grains were puffed by microwave oven, the water vapor could not pass easily from the inner to outer grain; the water vapor pressure was high enough to expand the grains. Fast (1993) and Hoke et al. (2005) studied oven-puffing mechanisms; puffing was based on a sudden application of heat at atmospheric pressure, so that the water in the grain was vaporized in situ, thereby expanding the product.

The 70 and 80°C drying temperatures took too long for commercial use, and at 100°C some grains burned or were broken. The 90°C drying temperature for 2 hours was optimal, yielding a moisture content of 9.4-10.3% and providing a good expansion ratio, low proportion of unexpanded grains, and high sensory evaluation scores after puffing.

ACKNOWLEDGEMENTS

Special thanks to the Thailand Research Fund (TRF) and Maelek Food Product Limited Partnership for funding this research.

REFERENCES

AOAC. 2005. Official Methods of Analysis of AOAC (Association of Official Analytical Chemists) International. 18th ed. The United State of America, Arlington.

Buntawong, O., S. Pikasem, and W. Intanun. 2012. Effect of processing methods on products quality of Puffed Job’s tears snack. Hands-on Research and Development, Rajamangala University of Technology Lanna (RMUTL) report, Chang Mai, Thailand.

Chang, H.C., Y.C. Huang, and W.C. Hung. 2003. Antiproliferative and chemopreventive effects of adlay seed on lung cancer in vitro and in vivo. Journal of Agricultural and Food Chemistry. 51: 3656-3660.

Chen, X.D., and A.S. Mujumdar. 2008. Drying technology in food processing. Wiley-Blackwell, West Sussex, UK.

Chiang, W., C.Y. Cheng, M.T. Chaiang, and K.T. Chung. 2000. Effect of dehulled adlay on the culture of some microbiota and their metabolism in the gastrointestinal tract of rats. Journal of Agricultural and Food Chemistry. 48: 829-832.

Fan, S., F. Hsieh, and H. E. Huff. 1999. Puffing of wheat cakes using a rice cake machine. Applied Engineering in Agriculture. 15: 677-684.

Fast, R.B. 1993. Manufacturing technology of ready-to-eat cereals, in: R. B. Fast and E. F. Caldwell (Eds.). Breakfast Cereals and How They are Made. AACC Inc. USA.

Hoke, K., J. Housova, and A.M. Houska. 2005. Optimum conditions of rice puffing-Review. Czech J. Food Sci. 23: 1-11.

Hui, Y.H., C. Clay, M.M. Farid, O.O. Fasina, A. Noomhorm, and J. Welti-Chanes. 2008. Food drying science and technology: microbiology, chemistry, application.

DE stech Publications, Lancaster.

Jomduang, S. 1994. Modification and improvement of “Khao Kriap Waue” (A traditional Thai glutinous rice-based snack food). Ph.D. Dissertation. University Pertanian, Malaysia.

Kuo, C.C., M.C. Shih, Y.H. Kuo, and W.C. Chiang. 2001. Antagonism of free-radical-induced damage of adlay seed and its antiproliferative effect in human histolytic lymphoma U937 monocytic cells. Journal of Agricultural and Food Chemistry. 49: 1564-1570.

Kuo, C.C., W.C. Chiang, G.P. Liu, Y.L. Chien, J.Y. Chang, C.K. Lee, J.M. Lo, S.L. Huang, M.S. Shih, and Y.H. Kuo. 2002. 2,2-Diphenyl-1-picrylhydrazyl radical-scavenging active components from adlay (Coix lachrymal-jobi L. var. mayuen stapf) hulls. Journal of Agricultural and Food Chemistry. 50: 5850-5855.

Hung, W.C., and H.C. Chang. 2003. Methanolic extract of adlay seed suppresses COX-2 expression of human lung cancer cells via inhibition of gene transcription. Journal of Agricultural and Food Chemistry. 51: 7333-7337.

Numata, M., A. Yamamato, A. Moribayashi, and H.Yamada. 1994. Antitumor components isolated from the Chinese herbal medicine Coix lachrymal-jobi. Planta-media. 60(4): 356-359.

Shih, C.K., W. Chiang, and M.L. Kuo. 2004. Effects of adlay on azoxymethane-induced colon carcinogenesis in rats. Food and Chemical Toxicology. 42: 1339-1347.

Tokuda, H., T. Matsumoto, T. Konoshima, M. Kozuka, H. Nishino, and A. Iwashima. 1990. Inhibitory effects on Epstein-Barr virus activation and anti-tumor promoting activities of coix seed. Planta Medica 56: 653-654.

Woottiprasai, M., and S. Maleehorm. 2007. Snack products from nut. Bachelor Dissertation. Chiang Mai University, Chiang Mai, Thailand.

Yang, J.H., Y.H. Tseng, H.L. Chang, Y.L. Lee, and J.L. Mau. 2004. Storage stability of monascal adlay. Food Chemistry. 90: 303-309.

Yu, Y.T., T.J. Lu, M.T. Chiang, and W. Chiang. 2005. Physicochemical properties of water soluble polysaccharide enriched fractions of adlay and their hypolipidemic effect in hamsters. Journal Food and Drug Analysis. 13(4): 361-367.

Orathai Bunthawong and Somchai Jomduang*

Division of Food Science and Technology, Faculty of Agro-Industry, Chiang Mai University, Chiang Mai 50100, Thailand

*Corresponding author. E-mail: somchai.j@cmu.ac.th

Total Article Views