The Effect of Heat-Cured Clear Acrylic Coating on the Color of Artificial Iris

Bongkot Sirinirund and Panarat Kodkeaw*Published Date : March 21, 2025

DOI : https://doi.org/10.12982/NLSC.2025.034

Journal Issues : Number 2, April-June 2025

Abstract The effect of heat-cured acrylic resin coating on the color of artificial irises fabricated using oil painting, laser printing, and inkjet printing was investigated. Sixty artificial irises (30 brown, 30 blue) were created on paper and measured using the CIELAB color system before and after coating. Color changes were evaluated using the CIEDE2000 formula. Results revealed significant color changes in all groups, influenced by fabrication technique and color. For brown irises, laser printing exhibited the lowest color change, followed by oil painting and inkjet printing. For blue irises, inkjet printing displayed the lowest color change, while oil painting and laser printing showed no significant difference. Overall, heat-cured acrylic resin coating affects iris color, with laser printing being preferred for brown irises and all techniques suitable for blue irises.

Keywords: Ocular prosthesis, Artificial eye, Color changes, Printed artificial iris, Office printer.

Funding: The authors are grateful for the research funding provided by Faculty of Dentistry, Chiang Mai University, Thailand.

Citation: Sirinirund, B. and Kodkeaw, P. 2025. The Effect of Heat-Cured Clear Acrylic Coating on the Color of Artificial Iris. Natural and Life Sciences Communications. 24(2): e2025034.

INTRODUCTION

Different fabrication techniques mastering ocular prosthesis have been developed to achieve better imitation of the missing eye. Realistic appearance and coloration of the ocular prostheses are some of the features required to achieve standard requirements, thus polymethyl methacrylate or PMMA is used due to its satisfactory properties (Erpf, 1953).

The fabrication of artificial iris is a challenging task to replicate the appearance and details of the remaining eye. Hence, numerous techniques of fabricating artificial iris have been proposed. These include direct painting with oil paint on substrates (such as paper, aluminum disc, acrylic disc), and reverse painting using prefabricated ocular buttons. Recently, digital technology was introduced to facilitate this process (Goiato et al., 2014; Pricop et al., 2016). The printed photographs of patient’s eye were transferred to fabricate an artificial iris for the missing eye through laser printing (Artopoulou et al., 2006; Chamaria et al., 2017), inkjet printing (Jauregui Ulloa et al., 2021; Walshaw et al., 2018; Zoltie et al., 2021), and 3D printing (Calis, 2022; Ko et al., 2019; Sedlak et al., 2020).

The process of creating an artificial eye involves attaching an artificial iris to the sclera base and then applying a layer of transparent acrylic coating. Discoloration of the artificial iris is a concern during this process. However, there is limited literature available on the color change of digitally printed artificial irises (Goiato et al., 2010; Goiato et al., 2011b; Bunker et al., 2023).

The objective of this study was to investigate the color changes of artificial iris after the process of heat-cured clear acrylic coating. The null hypothesis was that an artificial iris (brown and blue color) created from oil paint technique and digital printing techniques (laser printing and ink-jet printing) will not show significant differences in color changes after being coated with heat-cured clear acrylic resin.

MATERIALS AND METHODS

Six groups of samples (n=10) were fabricated and classified by their fabrication techniques and the colors used. Sample size calculation was performed using the G*Power program (University of Heinrich-Heine, Düsseldorf, Germany) based on our pilot study.

The control group consisted of hand-painted paper discs (150 GSM: Papawin, Nonthaburi, Thailand) using oil paint, Burnt umber for brown color and Cobalt blue hue for blue color (Winsor and Newton). The experimental groups included printings on photo paper (Photo paper 150 GSM: Papawin, Nonthaburi, Thailand) using a laser printer (ApeosPort-IV C3375, Fuji Xerox) and an inkjet printer (PIXMA iP2770 inkjet printer, Canon).

Specimen preparation

Hand painting irises

Oil paint (brown and blue color) was applied to a 12 mm-diameter paper disc using paintbrushes (SEKAI No.2 round Artist Brush: DG Art & Craft Ltd., Bangkok, Thailand). The procedure was carried out during the same period of time and under the same light condition. The specimens were left to dry for 5 days in a well-ventilated room (25-30 °C, humidity 40-50%) away from direct sunlight.

Printing irises

The photographic process was used to transfer color from the control groups to the experimental groups. A professional digital camera (Canon EOSRP Digital Rebel, Canon) equipped with a macro lens (Canon Macro Lens EF 100mm f/2.8 UMS, Canon) and a ring flash (Macro Ring Flash ML-150, Godox) was used to capture photos of iris specimens randomly selected from the control group. The camera settings were adjusted to have a shutter speed of 1/125 seconds, an aperture of f/16, and a sensitivity of ISO 640. A color correction chart (ColorChecker Passport Photo 2, Calibrite LLC, Wilmington, DE) was used for calibrating color and brightness of the taken photos.

The RAW file from the camera was edited in Adobe Lightroom Classic (Adobe). The shades gathered from the center of the iris photo were utilized to print the irises for the experimental groups. The printed irises were then punched to achieve 12 mm-diameter paper discs.

Specimen assembly

The artificial iris was fixed to the pre-fabricated white acrylic disc (22 mm in diameter and 3 mm in thickness) using a monopoly coating agent. Three layers of fixative spray (Win Acrylic Lacquer, TOA Paint, Samutprakan, Thailand) were applied afterward and left to dry in a well-ventilated environment for at least 24 hours. The specimens were stored in a dark and well-ventilated container (25-30 °C, humidity 40-50%) while awaiting the initial color measurement.

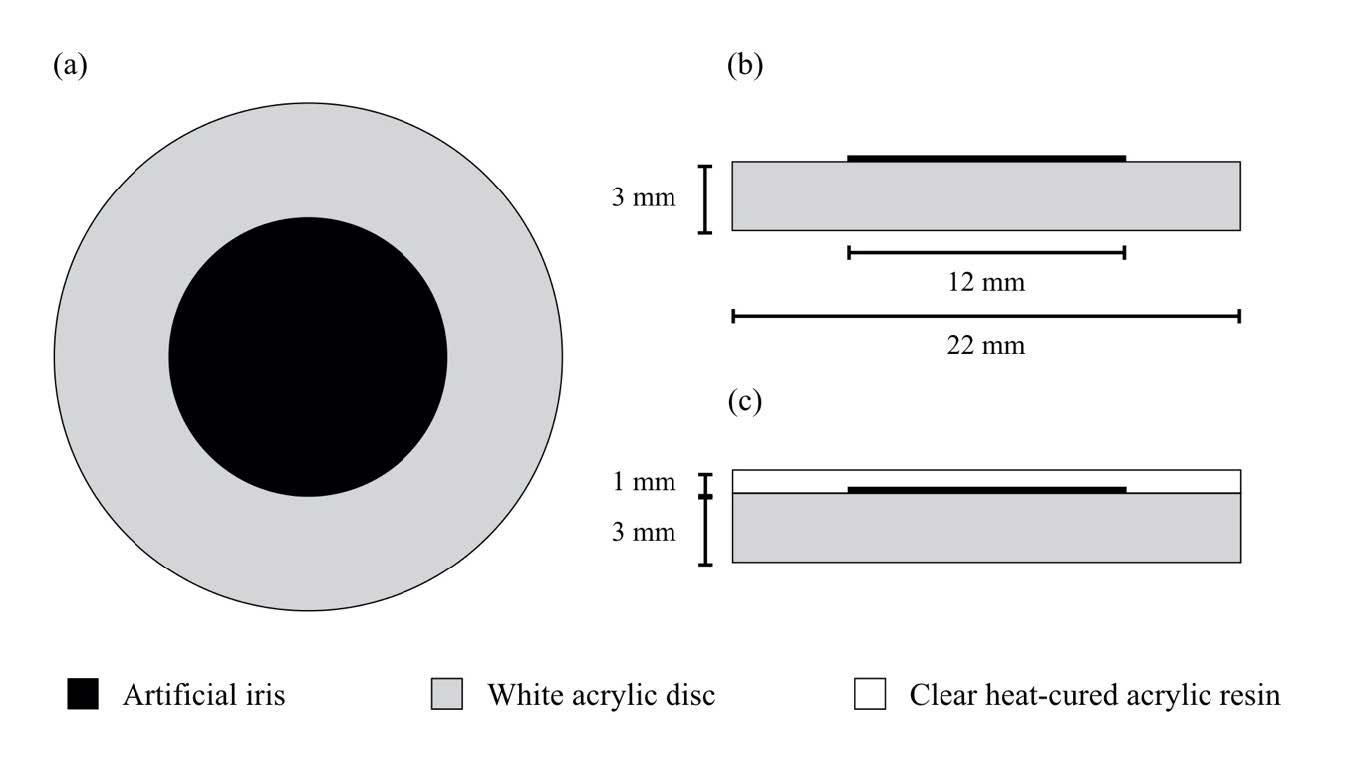

After collecting the initial color data measurements, the lost wax casting technique was used to apply the clear acrylic. Polymerization of the heat-cured clear acrylic (Heat Cure shade 01 clear, Meliodent) was accomplished using the manufacturer’s recommended rapid-curing cycle (Boil water in a water bath. Insert the flask into the boiling water bath. Remove the heat source for 15 minutes. Return the water bath to a boil and maintain the boil for 20 minutes. Finally, allow the flask to cool down completely within the water bath). Follow deflasking, the specimens were trimmed, and the testing surfaces were finished using a series of waterproof abrasive silicon carbide papers (grits #600-#7000) equipped in an automatic grinding and polishing machine (LaboPol-20, Struers). When the overall thickness of the specimens reached 4 mm, they were finally polished with a cloth polishing wheel. The specimens were stored in a dark and well-ventilated container (25-30 °C, humidity 40-50%) while awaiting the second color measurement. A schematic of the specimen is presented in both top view and cross-sectional view in Figure 1.

Figure 1. A schematic representation of the specimen’s dimension in the top view (a) and side views (b and c).

Measurement of color and calculation of color changes

The color reading was obtained using an ultraviolet-visible reflection spectrophotometer (CM-5, Konica Minolta). The specimens were positioned at the center of the reading opening. The color measurement was based on CIELAB color system with standard illumination of D65 and aspect angle of 10°. This color system allows the perception of colors to be specified in three dimensions, consisting of L*, a*, and b* values (Fernandes et al., 2009; Goiato et al., 2011b; Moreno et al., 2014). L* represents brightness or luminosity, ranging from 0 (black) to 100 (perfect white), a* represents red (positive) or green chroma (negative value), and b* represents yellow (positive) or blue chroma (negative value).

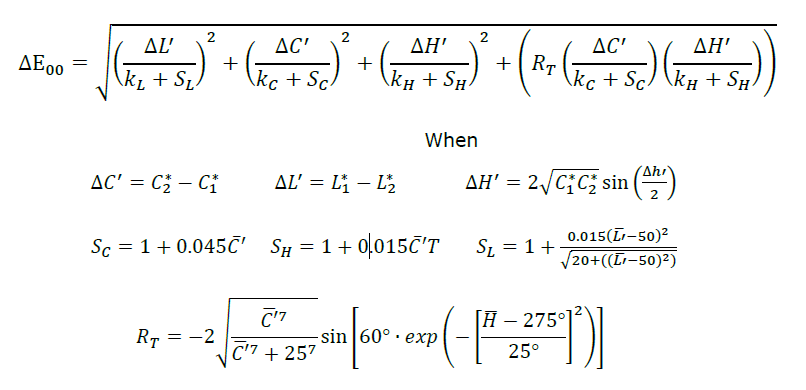

The initial and second color values of each specimen were calculated to determine the color changes value using the CIEDE2000 color difference formula (∆E00). This formular was recommended by the International commission on illumination (CIE) in 2001 and is currently regarded as the ISO/CIE (ISO IOS-J03) standard (Gómez-Polo et al., 2020; Sharma et al., 2005). The equation is as follow:

Statistical analysis

The color of the specimen was assessed before and after the clear acrylic coating process. The data were analyzed using SPSS software (version 25, IBM). A two-way ANOVA was used to determine the effect of artificial iris fabrication techniques and iris colors on the color changes after the process of heat-cured clear acrylic coating. The Tukey honestly significant difference (HSD) test was used to compare means between groups. The alpha level of significance was established at 0.05.

RESULT

ANOVA analysis showed a statistically significant difference between the technique and the color used (P < 0.05, Table 1). Table 2 displays the average values of the color changes observed in the artificial irises. Spectrophotometry analysis revealed that color changes were presented in all groups (∆E00>0). The color changes of brown and blue were significantly different, with the laser printing technique resulting in superior color stability compared to the other methods. For brown-colored artificial irises, the inkjet printing technique exhibited the lowest color stability, followed by the oil painting technique and finally the laser printing technique. Conversely, for blue-colored artificial irises, the inkjet printing technique exhibited the highest color stability, while no significant difference was observed between the oil painting technique and the laser printing technique.

Table 1. Result of two-way ANOVA.

|

Factors |

df |

SQ |

MQ |

F |

p |

|

Color |

1 |

97.64 |

97.64 |

123.24 |

<0.00 |

|

Technique |

2 |

36.27 |

18.13 |

22.89 |

<0.00 |

|

Color × |

2 |

135.67 |

67.84 |

85.62 |

<0.00 |

|

Error |

54 |

42.78 |

0.79 |

|

|

|

Total |

59 |

312.36 |

|

|

|

Note: P <0.05 indicates a statistically significant difference.

Table 2. Average and standard deviation of color change (∆E00) values.

|

Technique |

Color |

|

|

Brown |

Blue |

|

|

Oil painting |

6.98 ± 1.69Aa |

4.33 ± 0.83Ab |

|

Laser printing |

3.26 ± 0.51Ba |

4.44 ± 0.39Ab |

|

Inkjet printing |

8.38 ± 0.65Ca |

2.19 ± 0.60Cb |

Note: Different uppercase letters in columns and different lowercase letters in rows indicate P <0.05 based on the Tukey HSD test.

The average L*, a*, and b* values measured on the artificial iris specimens before and after the heat-cured clear acrylic coating process are shown in Table 3. According to the CIELAB color system, the decrease in L* value in all groups indicates that the artificial iris appeared darker after the clear acrylic coating procedure. The brown-colored specimens, created using oil painting and inkjet printing techniques, shifted to red and yellow tones, while the iris printed from the laser printer shifted to green and yellow tones. For blue-colored specimens, those created using the oil painting technique shifted to green and blue tones, those printed from the laser printer shifted to red and yellow tones, and those printed from the inkjet printer shifted to red and blue tones.

Table 3. Average values of ∆L*, ∆a*, and ∆b* before and after heat-cured clear acrylic coating process.

|

Color |

Iris fabrication |

Time |

L* |

a* |

b* |

|

Brown |

Oil-painting |

Before After |

20.04 12.62 |

4.68 8.66 |

4.55 9.11 |

|

Brown |

Laser-printing |

Before After |

23.91 20.52 |

-2.50 -3.49 |

-1.32 0.34 |

|

Brown |

Inkjet-printing |

Before After |

26.54 24.14 |

-2.01 3.51 |

-4.68 -3.11 |

|

Blue |

Oil-painting |

Before After |

22.13 16.48 |

2.84 0.27 |

-29.78 -30.99 |

|

Blue |

Laser-printing |

Before After |

26.19 21.04 |

-5.57 -2.13 |

-35.48 -28.15 |

|

Blue |

Inkjet-printing |

Before After |

25.78 24.62 |

-3.21 -0.78 |

-26.48 -27.61 |

DISCUSSION

The null hypothesis was rejected. The color of artificial irises significantly changed after being coated with heat-cured clear acrylic resin. The cause of color changes should be the interaction of polymer composition between the paint/ink/toner and uncured mixture of heat cured acrylic resin (Wheeler and Yeates, 2016; Verma et al., 2018; Pizzimenti et al., 2021). Despite the coating spray was applied to prevent direct contact with the unreacted acrylic resin mixture, the reaction remained continued and promoted the rupture of chemical bonds in the paint/ink/toner during the polymerization process of acrylic resin (Goiato et al., 2011a, 2011b; Bannwart et al., 2013).

The degree of conversion in heat-cured resins is influenced by their polymerization process. Lower degrees of conversion result in higher residual monomer content within the acrylic, which may affect the color stability of the artificial iris over time. Regarding different polymerization methods, conversion values for the rapid-cure technique, while statistically significantly lower in weight percent cure, exhibited similar residual monomer levels to those achieved with other polymerization techniques, such as conventional (long-cycle) and microwave methods (Bartoloni et al., 2000).

Color changes on oil painting technique

For oil color paint, the linseed oil which serves as a volatile binder component was considered as a cause of color changes. The evaporation of linseed oil occurred during drying process. Its remaining should be interacted with the unreacted acrylic resin mixture. To reduce the color changes after the polymerization of heat-cured clear acrylic coating, the drying process and the surface protection should be considered (Moreno et al., 2015).

Color changes on digital printing technique

To create print media, a digital file displayed in the RGB color model on a monitor is converted into the CMYK color model, allowing printers to utilize a combination of ink plates containing cyan, magenta, yellow, and black (Johansson et al., 2011; Wheeler and Yeates, 2016). The printed artificial irises were created by combining specific amounts of colors to produce brown and blue shades.

As well as laser printers and inkjet printers, they imprint color on substrates in distinctive ways. Laser printers generate an electric charge that attracts the polymer powder toner, which is then fused to the substrate using a combination of heat and pressure. Inkjet printers dispersed micro-sized aqueous-base ink droplets onto the substrate. Color fading on the substrate printed using both kinds of printers was triggered by exposure to high temperature and/or prolonged exposure time to heat (Hladnik et al., 2008)

Ink and toner

Generally, inkjet printers utilize pigment-based ink for black shades to ensure that the printed black areas truly appear black, while dye-based ink is used for colors to give the printed regions a vibrant appearance. Compared to pigment-based ink, dye-based ink is more susceptible to color changes caused by moisture (Wheeler and Yeates, 2016). Moisture retention in the stone mold during the process of the clear acrylic coating may increase humidity within the specimens. This could result in dye migration, which typically appears as a hue shift (Bugner and Gordon, 2013).

Toner consists primarily of resin, which act as a binder to adhere the toner to the substrate. Common binder materials include styrene, methacrylate polymers, and epoxy. In the toner production process, the toner mixture is heated to a homogeneous liquid, cooled, and then ground into the specified particle size (Shara et al., 2013; Yordanova et al., 2014). The pigment/dye should be stabilized within the binder, so that minimized color changes caused by moisture and heat during the clear acrylic coating process.

Color differences calculation

Over decades, formulas have been introduced to measure color difference. This study used the CIEDE2000 (∆E00) formula to calculate color difference. The formula provides a more accurate representation of human perception of color difference than the traditional Euclidean formula (∆Eab), as reported in both color science and dentistry (Luo et al., 2001; Paravina et al., 2019; Gómez-Polo et al., 2020). Color match quality between two objects can be evaluated using perceptibility threshold (PT) and acceptability threshold (AT). PT is the smallest noticeable color changes, while AT is the acceptable level of color differences before correction is required.

Perceptibility threshold and acceptability threshold in dentistry

While PT and AT have been extensively studied in various dental materials such as tooth-colored materials, dental ceramics, and skin-colored silicones (Paravina et al., 2009; Ghinea et al., 2010; Ren et al., 2015; Paravina et al., 2019), no publication focusing on PT and AT investigation of color stability in ocular prosthesis materials has been found. Moreover, due to inconsistencies in research methodology, there is no consensus on the determination of PT and AT values for artificial irises. Some studies have utilized values defined by the National Bureau of Standards (Nimeroff, 1968; Moreno et al., 2015) or derived from earlier researches on esthetics dental restorations (Reis et al., 2008; Mundim et al., 2012) or ocular prosthesis materials (Fernandes et al., 2009; Goiato et al., 2011b).

According to the National Bureau of Standards, color changes is considered clinically noticeable or reaching between PT and AT when ∆Eab>1 and ≥3, and clinically unacceptable when ∆Eab >3 (Nimeroff, 1968). A review on the PT and AT for color differences in various dental materials and natural teeth or soft tissues reported that PT and AT values between teeth and tooth-colored materials were PT = 1.2 and AT = 2.7. For gingival and gingiva-colored materials, PT and AT values were PT = 1.7 and AT = 3.7. Finally, PT and AT values were PT = 1.1 and AT = 3 for light skin and corresponding skin-colored materials, and PT = 1.6 and AT = 4.4 for dark skin-colored materials (Paravina et al., 2019).

Literatures regarding color changes in ocular prostheses were found, using color change values greater than 3.7 as clinically unsatisfactory (Bannwart et al., 2013; Goiato et al., 2011b). It is important to mention that this threshold value was also employed from other dental materials. Thus, based on prior reviews, the perceptibility and acceptability thresholds vary depending on different subjects and their color. Thresholds appear to be higher in the darker shades compared to tooth-colored shades (such as gingiva/skin), and it has been reported that specimen with darker shades are less sensitive to human observers when perceiving color differences (Paravina et al., 2009). Considering that the artificial iris may have higher perceptibility and acceptability thresholds.

Limitation

The limitation of this study is that the procedures used to fabricate the specimens differed from the protocols of the other authors, and only a few studies have documented color changes after the polymerization process of heat-cured clear acrylic resin. The color instability of the pigments in the paint/toner/ink used in this study can be attributed to various factors, including the additives used and the different chemical composition, which provide the paint/toner/ink with specific physical and chemical properties.

Ocular prostheses reside within the moist environment of the ocular cavity. Moisture is recognized as a significant factor that can alter the refractive index of acrylic materials. This change in refractive index would subsequently affect the appearance of the artificial iris color. However, to isolate and study the color changes specifically following the polymerization process, the study intentionally avoided exposing the specimens to high humidity or moisture unless absolutely necessary.

Other factors influencing the visual aspects of the artificial iris include surrounding elements such as the porosity of the clear acrylic coating layer, the object’s surface, and the luminosity of the color-measuring device (Lee et al., 2004). Therefore, more comprehensive understanding of the factors contributing to the color changes in printed artificial iris remains necessary.

Clinical implication

The color differences values in the study were relatively high compared to the prior study of PT and AT. However, with the exception of brown-colored artificial irises printed with the inkjet printing technique, minor color changes were noticed clinically. The laser printing technique demonstrated a lower trend in color changes values for both colors. Therefore, using laser printing for artificial iris fabrication may be beneficial, as it produces good color stability and consistency despite differences in color.

The process of creating esthetically acceptable and healthy-looking ocular prostheses involves more than matching the color of the artificial iris. Raizada and Rani (Raizada and Rani, 2007) identified elements to consider when customizing an ocular prosthesis, including sclera color, iris position, iris size, pupil size, and curvature of the artificial cornea. These factors not only influence the appearance of the prosthesis but also highlight the importance for the clinician to consider the contralateral eye among the factors previously mentioned.

CONCLUSIONS

Within the limitations of this study, it can be concluded that the heat-cured clear acrylic resin coating process affected the changes of color of artificial irises. Laser printing was preferred for brown color, while all techniques could be used for blue color. Factors that might have affected the color changes of the artificial irises included the types of paint/ink/toner used, porosity of clear acrylic coating, and polished surface of the ocular prostheses.

ACKNOWLEDGEMENTS

I would like to express my gratitude to Thanapat Sastraruji for the guidance which made this research possible.

CONFLICT OF INTEREST

The authors declare that they hold no competing interests.

REFERENCES

Artopoulou, I.I., Montgomery, P.C., Wesley, P.J., and Lemon, J.C. 2006. Digital imaging in the fabrication of ocular prostheses. The Journal of Prosthetic Dentistry. 95(4): 327-330.

Bannwart, L.C., Goiato, M.C., dos Santos, D.M., Moreno, A., Pesqueira, A.A., Haddad, M.F., Andreotti, A.M., and de Medeiros, R.A. 2013. Chromatic changes to artificial irises produced using different techniques. Journal of Biomedical Optics. 18(5): 58002.

Bartoloni, J.A., Murchison, D.F., Wofford, D.T., and Sarkar N.K. 2000. Degree of conversion in denture base materials for varied polymerization techniques. Journal of Oral Rehabilitation. 27(6): 488-493.

Bugner, D.E., and Gordon, S.T. 2013. Factors to consider in the design and evaluation of commercial printing inks and substrates for permanence and durability. Technologies for Digital Photo Fulfillment. 4: 25–30.

Bunker, E., Kazlauciunas, A., Zoltie, T., Walshaw, E., Bartlett, P., Archer, T., and Gout, T. 2023. Colour stability during production of printed ocular prostheses. Coloration Technology. 139(5): 596-609.

Calis, I. 2022. A digital workflow for 3d printed full-colour ocular prosthetics. Master Thesis. Delft University of Technology, Landbergstraat, Delft, Netherlands.

Chamaria, A., Aras, M., Chitre, V., and Bhushan, P. 2017. Ocular defect rehabilitation using digital photography. International Journal of Orofacial Research. 2(1): 32-35.

Erpf, S.F. 1953. Comparative features of plastic and/or glass in artificial-eye construction. AMA Archives of Ophthalmology. 50(6):737-744.

Fernandes, A.Ú.R., Goiato, M.C., Batista, M.A.J., and dos Santos, D.M. 2009. Color alteration of the paint used for iris painting in ocular prostheses. Brazilian Oral Research. 23: 386-392.

Ghinea, R., Pérez, M.M., Herrera, L.J., Rivas, M.J., Yebra, A., and Paravina, R.D. 2010. Color difference thresholds in dental ceramics. Journal of Dentistry. 38: e57-e64.

Goiato, M.C., Bannwart, L.C., Haddad, M.F., dos Santos, D.M., Pesqueira, A.A., and Miyahara, G.I. 2014. Fabrication techniques for ocular prostheses--an overview. Orbit. 33(3): 229-233.

Goiato, M.C., Fernandes, A., dos Santos, D.M., Hadadd, M.F., Moreno, A., and Pesqueira, A.A. 2011a. Alteration of blue pigment in artificial iris in ocular prosthesis: Effect of paint, drying method and artificial aging. Contact Lens and Anterior Eye. 34(1): 22-25.

Goiato, M.C., Moreno, A., dos Santos, D.M., de Carvalho Dekon, S.F., Pellizzer, E.P., and Pesqueira, A.A. 2010. Effect of polymerization and accelerated aging on iris color stability of ocular prosthesis. Contact Lens and Anterior Eye. 33(5): 215-218.

Goiato, M.C., dos Santos, D.M., Moreno, A., Gennari-Filho, H., and Pellizzer, E.P. 2011b. Evaluation of the color stability of two techniques for reproducing artificial irides after microwave polymerization. Journal Applied Oral Science. 19(3): 200-203.

Gómez-Polo, C., Montero, J., Gómez-Polo, M., and Casado, A.M. 2020. Comparison of the cielab and ciede 2000 color difference formulas on gingival color space. Journal of Prosthodontics. 29(5): 401-408.

Hladnik, A., Cernic, M., and Bukosek, V. 2008. Role of paper coating pigments and additives in darkfastness of ink jet prints. Journal of Imaging Science and Technology. 52(1): 010507-1-010507-7.

Jauregui Ulloa, J., Salazar-Gamarra, R., Mesquita, A.M.M., Aguirre, F., and Dib, L.L. 2021. A digital method to fabricate the ocular portion of an orbital prosthesis with a smartphone camera, color calibration and digital printing. Journal of Prosthodontics. 30(1): 91-94.

Johansson, K., Lundberg, P., and Ryberg, R. 2011. A Guide to Graphic Print Production, Third edition. John Wiley & Sons, New Jersey.

Ko, J., Kim, S.H., Baek, S.W., Chae, M.K., and Yoon, J.S. 2019. Semi-automated fabrication of customized ocular prosthesis with three–dimensional printing and sublimation transfer printing technology. Scientific Reports. 9: 2968.

Lee, Y.K., Lim, B.S., and Kim, C.W. 2004. Influence of illuminating and viewing aperture size on the color of dental resin composites. Dental Materials. 20: 116-123.

Luo, M.R., Cui, G., and Rigg, B. 2001. The development of the CIE 2000 colour-difference formula: CIEDE2000. Color Research and Application. 26(5): 340-350.

Moreno, A., Goiato, M.C., dos Santos, D.M., Haddad, M.F., Pesqueira, A.A., and Bannwart, L.C. 2014. Influence of different disinfecting solutions on the color change of artificial irises used in ocular prostheses. Color Research and Application. 39(1): 56-62.

Moreno, A., Goiato, M.C., Oliveira, K.F., Iyda, M.G., Haddad, M.F., de Carvalho Dekon, S.F., and dos Santos, D.M. 2015. Color stability of the artificial iris button in an ocular prosthesis before and after acrylic resin polymerization. Contact Lens and Anterior Eye. 38(6): 414-418.

Mundim, F.M., Antunes, P.L., Sousa, A.B.S., Garcia, L.F.R., and Pires-de-Souza, F.C.P. 2012. Influence of artificial accelerated ageing on the colour stability of paints used for ocular prosthesis iris painting. Gerodontology. 29(2): e312-e317.

Nimeroff I. 1968. Colorimetry. US National Bureau of Standards.

Paravina, R.D., Majki,c G., Del Mar Perez, M., and Kiat-Amnuay, S. 2009. Color difference thresholds of maxillofacial skin replications. Journal of Prosthodontics. 18(7): 618-625.

Paravina, R.D., Pérez, M.M., and Ghinea, R. 2019. Acceptability and perceptibility thresholds in dentistry: A comprehensive review of clinical and research applications. Journal of Esthetic and Restorative Dentistry. 31(2): 103-112.

Pizzimenti, S., Bernazzani, L., Tinè, M.R., Treil, V., Duce, C., and Bonaduce, I. 2021. Oxidation and cross-linking in the curing of air-drying artists’ oil paints. ACS Applied Polymer Materials. 3(4): 1912-1922.

Pricop, M., Balescu, H., Rosu, S., Urechescu, H., and Crainiceanu, Z. 2016. Original alternative technique of iris fabrication for ocular prostheses. Materiale Plastice. 53(1): 79-81.

Raizada, K., and Rani, D. 2007. Ocular prosthesis. Contact Lens and Anterior Eye. 30(3): 152-162.

Reis, R.C., Brito e Dias, R., and Mesquita Carvalho, J.C. 2008. Evaluation of iris color stability in ocular prosthesis. Brazilian Dental Journal. 19(4): 370-374.

Ren, J., Lin, H., Huang, Q., Liang, Q., and Zheng, G. 2015. Color difference threshold determination for acrylic denture base resins. Bio-medical Materials and Engineering. 26 Suppl. 1: S35-S43.

Sedlak, J., Vocilka, O., Slany, M., Chladil, J., Polzer, A., and Varhanik M. 2020. Design and production of eye prosthesis using 3d printing. Mm Science Journal. 2020(March): 3806-3812.

Shara, S.I., Aboul El-Magd, A.A., Moustafa, Y.M., Bakr, A.A., and Aziz, I.A. 2013. Removal of laser printer toner from the paper surface using some chemical methods. Al-Azhar Bulletin of Science. 24(Issue 2-A): 81-96.

Sharma, G., Wu, W., and Dalal, E. 2005. The CIEDE2000 color-difference formula: Implementation notes, supplementary test data, and mathematical observations. Color Research and Application. 30: 21-30.

Verma, N., Kumar, R., and Sharma, V. 2018. Analysis of laser printer and photocopier toners by spectral properties and chemometrics. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy. 196: 40-48.

Walshaw, E., Zoltie, T., Bartlett, P., and Gout, T. 2018. Manufacture of a high definition ocular prosthesis. The British Journal of Oral and Maxillofacial Surgery. 56(9): 893-894.

Wheeler, J.S.R., and Yeates, S.G. 2016. Polymers in inkjet printing. In Fundamentals of Inkjet Printing. Wiley-VCH. p.117-140.

Yordanova, D., Angelova, S., and Dombalov, I. 2014. Utilisation options for waste toner powder. International Scientific Journal Environmental Science. 3: 140-144.

Zoltie, T., Bartlett, P., Archer, T., Walshaw, E., and Gout, T. 2021. Digital photographic technique for the production of an artificial eye. Journal of Visual Communication in Medicine. 44(2): 41-44.

OPEN access freely available online

Natural and Life Sciences Communications

Chiang Mai University, Thailand. https://cmuj.cmu.ac.th

Bongkot Sirinirund and Panarat Kodkeaw*

Department of Prosthodontic, Faculty of Dentistry, Chiang Mai University, Chiang Mai 50200, Thailand.

Corresponding author: Panarat Kodkeaw, E-mail: panarat.k@cmu.ac.th

ORCID: Panarat Kodkeaw: https://orcid.org/0009-0006-3725-1673

Total Article Views

Editor: Anak Iamaroon,

Chiang Mai University, Thailand

Article history:

Received: October 31, 2024;

Revised: January 21, 2025;

Accepted: March 4, 2025;

Online First: March 21, 2025

technique

technique