Fluidized Bed Heat Treatment for Controlling the Lesser Grain Borer (Rhyzopertha dominica) and Sawtoothed Grain Beetle (Oryzaephilus surinamensis) on Paddy cv. Khao Dawk Mali 105

Kunlayaa Boonsa-nga, Damorn Bundhurat, Viboon Changrue, and Yaowaluk Chanbang*Published Date : February 27, 2024

DOI : https://doi.org/10.12982/NLSC.2024.022

Journal Issues : Number 2, April-June 2024

Abstracts The efficacy of fluidized bed (FDB) heating was studied for controlling stored product insects on rough rice using laboratorial heat-fluidized bed equipment, and the milling quality of rice was later examined. Rough rice cv. Khao Dawk Mali 105 (13% wb) infested with insects was treated with FDB. The lesser grain borer (Rhyzopertha dominica, Fabricius) (internal feeders) had a higher tolerance for heat than the sawtoothed grain beetle (Oryzaephilus surinamensis Linnaeus, external feeders). At a hot air velocity of 3.7 m/s at 55°C for 90 s, the mortality of the lesser grain borer treated by FDB significantly differed (P <0.05) between all stages and from the untreated control. The pulpal stage, as an FDB-tolerant stage of the lesser grain borer, was treated with 55–65 °C for 60–150 s. FDB heat treatment at 55°C for 150 s, 60°C for 90 s, and 65°C for 60 s caused 100% mortality. At a hot air velocity of 3.7 m/s at 40°C for 120 s, the mortality of the sawtoothed grain beetle significantly differed (P <0.05) between all stages and the untreated control. The egg stage, as the FDB-tolerant stage, was treated at 40–50 °C for 60–150 s. FDB heat treatment at 45°C for 150 s and 50°C for 60 s caused 100% mortality. Some of the adults that survived FDB exposure were able to reproduce, but there were significantly less progeny than in the untreated control. Heat FDB slightly affected rice quality in terms of physical and chemical properties.

Keywords: Heat, Fluidized bed heat, Paddy, Stored insect pests

Funding: The authors appreciate the research scholarships provided by the Postharvest Technology Innovation Center, Ministry of Higher Education, Science, Research and Innovation.

Citation: Boonsa-nga, K., Bundhurat, D., Changrue, V., and Chanbang, Y. 2024. Fluidized bed heat treatment for controlling the lesser grain borer (Rhyzopertha dominica) and sawtoothed grain beetle (Oryzaephilus surinamensis) on Paddy cv. Khao Dawk Mali 105. Natural and Life Sciences Communications. 23(2): e2024022.

INTRODUCTION

The rice paddy cv. Khao Dawk Mali 105 is a major export from Thailand. There are many kinds of stored product insects that infest rough rice and milled rice during storage. The lesser grain borer (Rhyzopertha dominica, Fabricius) is an internal feeder in which immature stages (larvae and pupae) live inside grain kernels and feed on the endosperm of cereal and cause quality losses, including nutrient loss in the grain (Jood and Kapoor, 1993; Stathas et al., 2023). External feeders, such as the sawtoothed grain beetle (Oryzaephilus surinamensis), are also present when rough rice or other processed rice is harvested. Infestation by these insects and the presence of insect fragments affect grain quality and, eventually, market value. In addition, insect growth in commodities directly increases grain moisture content. These species are recognized as the most destructive stored product insects. The optimal conditions for population growth of major pest species are between 28 and 33°C at 60–75 % relative humidity (RH). At low suboptimum temperatures, the minimum theoretical threshold for population growth is around 18°C, at which time adults can live for many months (Fields, 1992; Beckett et al., 2007). Chemical treatment has been a common way to eliminate stored rice insects. In any case, alternative methods are needed to reduce the causes of non-target organism effects, environmental effects, and insecticide resistance. Physical control by applying a high temperature is an alternative technique that can be classified as a humane and ecologically friendly procedure. Generally, heat above 60°C can affect stored product insects and cause death in some minutes (Fields and Muir, 1996). Conventional heat from hot air takes several hours to kill stored product insects. Due to the long period of time and non-uniformity of conventional hot air treatment, electromagnetic heating (microwave or radio frequency) has been introduced to kill postharvest insects (McLeod et al., 1999; Wangspa et al., 2015). Although they have shown a rapid heating time and uniformity, the high investment and operating costs are not accepted by farmers. Fluidized bed heating is another method that can be performed with a shorter time and better uniformity. This heating method involves air transported vertically upward through a grain bed at an adequate velocity. Individual grain kernels are lifted and mixed by passing air vertically upward through a bed of grain at a proper velocity, allowing the grain to be quickly uniform for 1–2 min. In addition, fluidized bed heating can control and eliminate stored insect pests in the warehouse. Evans and Dermott (1979) and Abd El-Aziz (2011) reported that fluidized bed heating had good mortality for insect infestations in a relatively short period of time, without significantly affecting the grain moisture content or the baking quality of wheat. At air temperatures of 60, 70, and 80°C, exposure times of 12, 6, and 4 min, and grain surface temperatures of 59, 62, and 65°C, the rice weevil (S. oryzae), lesser grain borer (R. dominica), and Angoumois grain moth (S. cerealella) on wheat were completely killed. Pande and Mishra (2013) reported that fluidized bed heat treatment at 80°C for 60 s completely killed Callosobruchus sp. on green gram (Vigna radiata) seeds.

However, the heat profile information on rough rice in terms of the efficacy of the combination of appropriate fluidized bed conditions for killing internal and external feeders and the effects on grain quality differ, especially among insect species, stage of development, acclimation, and relative humidity (Fields, 1992).

A minimal combination of heat and exposure time is more attractive and requires more precise heat use, especially to maximize the cost benefit of energy consumption. Therefore, the objectives of this research were to determine the efficacy and conditions of fluidized bed heating for controlling postharvest insect pests and its effects on grain quality, focusing on the lesser grain borer (R. dominica) and sawtoothed grain beetle (O. surinamensis) on rice paddy cv. Khao Dawk Mali 105.

MATERIALS AND METHODS

Laboratory-scale fluidized bed dryer

The laboratory fluidized bed dryer (Christison Scientific, Gateshead, Tyne and Wear United Kingdom) used in this study is shown in Figure 1. Specific conditions were simulated to expose small samples in the fluidization chamber. In a fluidization chamber (16.5 cm in diameter, 37 cm in length), the air is passed through the distributor with sufficient velocity to suspend, separate, and mix the grain and air at a high temperature, allowing rapid and uniform heat transfer and precise temperature treatment of the grain mass. Air can be heated in the range of 0–200°C before moving across the fluidization chamber. The mesh screen at the outlet is supposed to lock the air inside. A 200 g paddy sample was collected for the experiment and treated with various air temperatures and exposure times.

Figure 1. A laboratory-scale fluidized bed dryer was used in this experiment.

Numbering key: 1. fluidization chamber; 2. Blower speed (0–10 level); 3. On/Off blower bottom switch; 4. Temperature setting (0–200°C); 5. On/Off heater bottom switch; 6. Wire mesh screen closed at the air outlet; 7. On/Off bottom switch; 8. Start bottom switch; 9. Stop bottom switch.

Insect culture

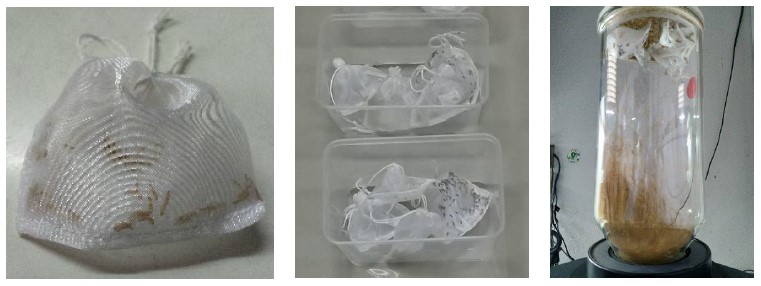

Rough rice, brown rice, and milled rice (Khao Dawk Mali 105, KDML 105) were frozen at −21°C for 72 h to eliminate all insects and then thawed at room temperature. The moisture content of rough rice was adjusted to 18% (w.b.), and the moisture content of brown rice and milled rice was adjusted to 15% (w.b.). To culture the lesser grain borer, 200 g of disinfected rough rice, brown rice, and milled rice were filled in each plastic container together with 100–200 lesser grain borer (R. dominica) adults. Each container was stored under laboratory conditions at 30.9 ± 6.5°C and 70 ± 5% relative humidity (R.H.) for 7 days, allowing the insects to reproduce. After a 7-day storage period, insects at each stage were collected from the rice by sieving through 2.5- and 0.5-mm strainers. Eggs were collected on day 4. Larvae were collected on day 17. Pupae were collected on day 35, and adults were collected on days 40–45 (Sumetha et al., 2009). Larval and pupal stages of the lesser grain borer remained inside the grain kernels. After exposure to the FDB heat treatment, dead and live insects were counted and measured when the surviving insects in each stage developed into the adult stage (4–6 weeks). All stages of the insect were kept separately at 28°C and 75% RH.

The sawtoothed grain beetles (O. surinamensis) were cultured with wheat flour to increase the population after being reared on broken rice before testing. Adult insects were introduced to 200 g of broken rice in plastic containers. The containers were stored in laboratory settings at 30.9 ± 6.5°C and 70 ± 5% RH for 5 days, allowing the insects to reproduce. Insects at each stage were collected from the rice by sieving through a 1.25-mm strainer. Eggs, larvae, pupae, and adults of the sawtoothed grain beetle were collected on days 5, 10, 19, and 25, respectively (Keatmaneerat et al., 2011).

Figure 2. Fine cloth bags containing the insects before being treated with fluidized bed heat treatment.

Effectiveness of fluidized bed heat treatment for completely killing lesser grain borers and sawtoothed grain beetles

The aim of this experiment was to determine the minimum temperature and exposure period that would completely kill the most tolerant stage of the lesser grain borer and sawtoothed grain beetle. Rough rice infested with the most tolerant stages of insects was exposed to FDB heat treatment at a velocity speed of 3.7 m/s. The lesser grain borers were exposed to temperatures of 55–65 °C for 60–150 s, and the sawtoothed grain beetles were exposed to temperatures of 45–50 °C for 60–150 s. For each combination of treatments, there were 4 replications of 100 insects. After the emergence of surviving insects, insect mortality was determined. The F1 progeny were counted after 5–6 weeks.

Effects of fluidized bed heat treatment on grain physical characteristics, milling quality, grain chemical quality, and cooking and eating quality

The grain’s physical properties and milling quality, such as moisture content, percentage of whole grain kernels and head rice, and grain color, were investigated after the paddy rice was treated with a fluidized bed heat treatment. The chemical quality of the grain, as well as cooking and eating quality, such as amylose content and 2-AP, were measured (National Bureau of Agricultural Commodity and Food Standards, 2017; Wongpornchai et al., 2007).

Statistical analyses

Insect mortality was counted, and Abbott’s formula was used to calculate the mortality percentage (Abbott, 1925). The physical and milling properties of the grain, as well as the grain chemical, cooking, and eating quality, were examined. Analysis of variance (ANOVA) was used to examine all data. The least significant difference (LSD) was used to compare the means of the treatment differences. Mean differences were considered significantly different at P <0.05 for all comparisons.

RESULTS

FDB tolerance of lesser grain borer and sawtoothed grain beetle stages

After being exposed to a fluidized bed heating temperature of 55°C for 90 s, the lesser grain borer showed a significant difference between stages. Complete mortality, the highest mortality, was found only in the adult stage, followed by egg (98.50 ± 0.29%), larva (98.50 ± 0.29%), and pupa (5.25 ± 1.25%) stages, but was not different from egg and larval stages. (Table 1). For pupae that survived the FDB heat treatment, 332.56 ± 51.20 insects were discovered as F1 progeny, which was significantly less than the number of progeny in the control (Table 2). Complete mortality was found only in the larva stage when the sawtoothed grain beetle was exposed to a fluidized bed heating temperature of 40°C for 90 s. Mortality rates of were 98.50 ± 0.65, 9.00 ± 1.43, and 1.00 ± 0.41% were found for the pupa, adult, and egg stages, respectively (Table 1). The number of F1 progeny that survived the FDB heat treatment were 107.69 ± 4.11 and 54.73 ± 6.73 insects for eggs and adults, respectively, which were significantly less than the number of progeny found in the control (Table 2).

Table 1. Average mortality of the lesser grain borer (Rhyzopertha dominica) and sawtoothed grain beetle (Oryzaephilus surinamensis) at various developmental stages after exposure to fluidized bed heating at 55°C for 90 s and 40°C for 90 s.

|

Developmental stage |

Mortality (%) ± SE* |

||||

|

R. dominica |

O. surinamensis |

||||

|

Control |

55°C for 90 s |

Control |

40 °C for 90 s |

||

|

Egg |

4.25 ± 1.11 b |

98.50 ± 0.29 a |

3.00 ± 0.71 cd |

1.00 ± 0.41 d |

|

|

Larva |

5.50 ± 1.44 b |

98.50 ± 0.29 a |

3.25 ± 0.85 cd |

100.00 ± 0.00 a |

|

|

Pupa |

5.00 ± 1.78 b |

5.25 ± 1.25 b |

4.50 ± 1.04 c |

98.50 ± 0.65 a |

|

|

Adult |

3.75 ± 1.49 b |

100.00 ± 0.00 a |

4.75 ± 1.38 c |

9.00 ± 1.43 b |

|

* Means followed by a common letter within a column or row are not significantly different from each other at P<0.05 according to the least significant difference (LSD) test.

Table 2. Average progeny of the lesser grain borer (Rhyzopertha dominica) and sawtoothed grain beetle (Oryzaephilus surinamensis) at various developmental stages after exposure to fluidized bed heating at 55°C for 90 s and 40°C for 90 s.

|

Developmental stage |

Number of progeny ± SE* |

Developmental stage |

Number of progeny ± SE* |

||

|

R. dominica |

O. surinamensis |

||||

|

Control |

55 °C for 90 s |

|

Control |

40 °C for 90 s |

|

|

Egg |

547.19 ± 32.26b |

0.00 ± 0.00d |

Egg |

669.52 ± 113.55a |

107.69 ± 4.11b |

|

Larva |

633.91 ± 60.05b |

0.00 ± 0.00d |

Pupa |

747.87 ± 83.43a |

0.00 ± 0.00b |

|

Pupa |

803.19 ± 66.66a |

332.56 ± 51.20c |

Adult |

737.79 ± 97.48a |

54.73 ± 6.73b |

* Means followed by a common letter within a column or row are not significantly different from each other at P <0.05 according to the least significant difference (LSD) test.

Responses of the lesser grain borer and sawtoothed grain beetle stages to FDB heat treatment

Lesser grain borer pupae and sawtoothed grain beetle eggs were chosen as the most FDB heat treatment-tolerant stages to identify the most effective temperature and exposure time combination to kill each insect.

FDB heat treatment of 55°C for 150 s, 60°C for 90-150 s, and 65°C for 60-150 s caused 100% mortality for the lesser grain borer (Table 3). For the sawtoothed grain beetle, FDB heat treatment of 45°C for 150 s and 50°C for 60-150 s caused 100% mortality (Table 4).

Table 3. Average mortality of lesser grain borer pupae (Rhyzopertha dominica) after exposure to fluidized bed heat treatment with different temperature (55, 60, and 65°C) and exposure time (60, 90, 120, and 150 s) combinations.

|

Time (s) |

Mortality(%) ± SE* at various temperature (°C) |

||

|

55 |

60 |

65 |

|

|

Control |

5.75 ± 0.63d |

7.75 ± 1.11d |

8.25 ± 0.85d |

|

60 |

3.50 ± 1.04d |

53.75 ± 5.15c |

100.00 ± 0.00a |

|

90 |

5.25 ± 1.25d |

100.00 ± 0.00a |

100.00 ± 0.00a |

|

120 |

91.25 ± 0.63b |

100.00 ± 0.00a |

100.00 ± 0.00a |

|

150 |

100.00 ± 0.00a |

100.00 ± 0.00a |

100.00 ± 0.00a |

* Means followed by a common letter within a column or row are not significantly different from each other at P<0.05 according to the least significant difference (LSD) test.

Table 4. Average mortality of sawtoothed grain beetle (Oryzaephilus surinamensis) eggs after exposure to fluidized bed heat treatment with different temperature (40, 45, and 50°C) and exposure time (60, 90, 120, and 150 s) combinations.

|

Time (s) |

Mortality(%) ± SE* at various temperature (°C) |

||

|

40 |

45 |

50 |

|

|

Control |

4.50 ± 0.87d |

3.50 ± 0.29d |

5.25 ± 1.31d |

|

60 |

0.00 ± 0.00d |

97.50 ± 0.50ab |

100.00 ± 0.00a |

|

90 |

1.00 ± 0.41d |

90.00 ± 0.41b |

100.00 ± 0.00a |

|

120 |

0.75 ± 0.48d |

96.00 ± 0.71ab |

100.00 ± 0.00a |

|

150 |

58.75 ± 6.57c |

100.00 ± 0.00a |

100.00 ± 0.00a |

* Means followed by a common letter within a column or row are not significantly different from each other at P <0.05 according to the least significant difference (LSD) test.

From those treatments that did not kill 100% of the pupae and eggs, they survived and later developed to the adult stage and were able to reproduce F1 progeny, but there were significantly less than the control (Tables 5 and 6).

Table 5. Average progeny of the lesser grain borer (Rhyzopertha dominica) after exposure to fluidized bed heat treatment under a combination of temperatures (55, 60, and 65°C) and exposure times (60, 90, 120, and 150 s) after 6 weeks of storage.

|

Time (s) |

Number of progeny ± SE* at various temperature (°C) |

||

|

55 |

60 |

65 |

|

|

Control |

708.75 ± 112.07a |

770.25 ± 100.65a |

658.97 ± 117.18a |

|

60 |

365.34 ± 38.24b |

155.06 ± 45.27c |

0.00 ± 0.00d |

|

90 |

359.75 ± 77.06b |

0.00 ± 0.00d |

0.00 ± 0.00d |

|

120 |

0.00 ± 0.00d |

0.00 ± 0.00d |

0.00 ± 0.00d |

|

150 |

0.00 ± 0.00d |

0.00 ± 0.00d |

0.00 ± 0.00d |

* Means followed by a common letter within a column or row are not significantly different from each other at P<0.05 according to the least significant difference (LSD) test.

Table 6. Average progeny of sawtoothed grain beetle (Oryzaephilus surinamensis) after exposure to fluidized bed heat treatment under a combination of temperatures (40, 45, and 50°C) and exposure times (60, 90, 120, and 150 s) after 5 weeks of storage.

|

Time (s) |

Number of progeny ± SE* at various temperature (°C) |

Mean of progeny ± SE |

|||||

|

40 |

45 |

50 |

|

||||

|

Control |

549.76 ± 136.54a |

708.00 ± 90.56a |

622.19 ± 120.32a1/ |

626.65 ± 45.73X2/ |

|||

|

60 |

127.00 ± 7.27b |

0.02 ± 0.02b |

0.00 ± 0.00b |

42.34 ± 42.33Y |

|||

|

90 |

109.42 ± 4.92b |

4.05 ± 0.39b |

0.00 ± 0.00b |

37.82 ± 35.82Y |

|||

|

120 |

74.51 ± 8.48b |

0.02 ± 0.01b |

0.00 ± 0.00b |

24.84 ± 24.83Y |

|||

|

150 |

9.58 ± 2.10b |

0.00 ± 0.00b |

0.00 ± 0.00b |

3.19 ± 3.19Y |

|||

|

Mean of progeny ± SE |

174.05 ± 96.05A |

142.42 ± 141.40A |

124.44 ± 124.44A3/ |

|

|||

Note: 1/ Means within the same column and row followed by the same letter are not significantly different from each other at P <0.05 according to the least significant difference (LSD) test.

2/ Means within the same column followed by the same letter are not significantly different from each other at P <0.05 according to the least significant difference (LSD) test.

3/ Means within the same row followed by the same letter are not significantly different from each other at P <0.05 according to the least significant difference (LSD) test.

Effects of fluidized bed heat treatment on grain physical characteristics, milling quality, grain chemical quality, and cooking and eating quality

When exposed to high temperatures (45°C and above) following the same grain temperature, the physical properties and milling quality of milled rice were changed, showing increased yellow (higher b*) and brightness (L*) values and a decreased whiteness index. The percentages of moisture content, whole kernels, and head rice were no different from the control. Chemical quality and cooking and eating quality, such as amylose content and 2-AP content, were all within acceptable standards compared to the control (Table 7).

Table 7. Moisture content, grain temperature, color (L*, b*), whiteness index, whole kernels and head rice, and amylose content of rice paddy cv. Khao Dawk Mali 105 when exposed to fluidized bed heat treatment at various temperatures and exposure times to completely kill lesser grain borer pupae and sawtoothed grain beetle eggs.

|

Treatment |

Moisture content (%) |

grain temperature (°C) |

Color |

Whiteness index |

Whole kernels and Head rice (%) |

Amylose Content (%) |

2-AP (ppm) |

|

|

L* |

B* |

|||||||

|

45°C 150 S |

11.93 ns |

41.00d |

68.98a |

10.82b |

67.11a |

42.30 ns |

14.51cd |

1.00ab |

|

50°C 60 S |

11.87 ns |

47.00c |

69.92a |

10.23bc |

68.20a |

42.65 ns |

14.90bc |

0.98ab |

|

55°C 150 S |

11.70 ns |

53.67b |

65.63c |

13.43a |

62.85c |

42.02 ns |

14.78bcd |

0.95b |

|

60°C 90 S |

11.73 ns |

54.67ab |

65.26c |

12.98a |

62.69c |

42.62 ns |

14.45d |

0.93b |

|

65°C 60 S |

11.83 ns |

56.67a |

67.14b |

13.52a |

64.20b |

41.51 ns |

15.02ab |

0.87b |

|

Control |

12.07 ns |

29.67e |

68.83a |

9.64c |

67.35a |

44.07 ns |

15.39a |

1.74a |

|

CV (%) |

1.27 |

1.80 |

1.15 |

4.28 |

1.08 |

2.12 |

1.52 |

25.91 |

* Means followed by a common letter within a column are not significantly different from each other at P <0.05 according to the least significant difference (LSD) test.

DISCUSSION

Lesser grain borer pupae were the most tolerant to FBD heat treatment at 55°C for 90 s, and their mortality was significantly different from that of the egg, larval, and adult stages. The mortality of pupae was only 5.25% compared to the other stages, with mortality rates of 98.5 to 100%. A similar result has been observed in S. zeamais. Boonsa-nga et al. (2021) reported that maize weevil pupae were the most tolerant to FDB heat treatment since those insects were protected by the grain. Thus, internal feeders have grain protection. The sawtoothed grain beetle, which is an external feeder, showed higher susceptibility to FDB heat treatment than internal feeders and was completely killed after treatment at 40°C for 90 s. Divagar et al. (2019) showed that S. oryzae, which stayed inside the kernel, had more tolerance to hot air heat treatment than adults outside the kernel after hot air treatment of wheat at 105°C for 60 s. For adults of T. castaneum, Criptolestes ferrugineus, and S. oryzae outside kernels with 12.5 and 14.5% moisture content, the conditions resulted in 100% death at 60 s, while the S. oryzae adults and immature stages inside the kernels showed a 100% mortality rate at 90 s.

No progeny of lesser grain borer adults or sawtoothed grain beetle larvae were produced because those insects died at 55°C for 90 s and 40°C for 90 s, respectively. The survival of both species depends on reproduction. However, the lower survival rates of insects exposed to FDB heat treatment were due to their inability to reproduce. The lesser grain borer at the egg and larval stages had 98% mortality and could not produce progeny, and the pupal stage, with 98% mortality, also showed no progeny production.

The combination of temperature and exposure time in the FBD heat treatment indicated that the lesser grain borer pupae had been completely killed at 55°C for 150 s, 60°C for 90-150 s, and 65°C for 60 s, while the sawtoothed grain beetle had been killed at 45°C for 150 s and 50°C for 60-150 s . The results showed that the sawtoothed grain beetle, as an external feeder, showed less tolerance to heat than the lesser grain borer, an internal feeder. The results of this experiment supported the findings of Uraichuen et al. (2010), who found that maize weevil’s adult stages were more sensitive to heat from hot air ovens than other stages. Furthermore, according to Evans and Dermott (1979) and Abd El-Aziz (2011), treatment at air temperatures of fluidized heat of 60, 70, and 80°C and exposure times of 12, 6, and 4 min completely killed the immature stage of rice weevil (S. oryzae), lesser grain borer (R. dominica), and Angoumois grain moth (S. cerealella) in wheat. The fluidized bed-drying technique can be used as an alternative to insecticides that control insects infesting grain and other commodities (Fleurat-Lessard and Fuzeau, 2014; Venkatesh et al., 2016). The results of the experiment confirm that fluidized bed heating can eliminate internal feeders that feed on the inside of grain (lesser grain borer) and external feeders that feed outside of grain (sawtoothed grain beetle) at all stages. FDB heat treatment, which kills almost all insects or reduces survival, can stop insects from reproducing, resulting in lower progeny production. Heat directly affects insect growth and reproduction since the high temperature causes adverse effects on survival rate and protein denaturation, eventually causing death. Moreover, heat affects survival, causing low fecundity in insects, since the surviving insects in this experiment could not reproduce (Beckett et al., 2007). Normally, high temperatures may have other effects on survival in terms of biochemical changes in the insect body and can affect the next generation, for example, a shorter life span.

FDB heat treatment can directly affect the mechanical ability to lift the grain and insect body and cause insect stress (Mathur and Gishler, 1955; Soponronnarit, 1999). The respiration system of insects (Neven, 2003) damages the sperm cells of insects, ovarian tissue, and spermatozoa, which results in lower fecundity, as shown in yellow mealworm (Tenebrio molitor) treated with 39 MHz of radio frequency heat treatment (Rai et al., 1974; 1977).

Although the fluidized bed heat treatment is more effective at a higher moisture content (Cheenkachorn, 2007), it could be alternately applied for pest control, mainly in rough rice at a combination of temperature (42–65 °C) and exposure time (5–10 min). However, according to Mahatheeranont et al. (2004), an adequate postharvest treatment for KDML 105 should be utilized because a low temperature and short storage duration are better for aroma quality. Furthermore, drying at hot air at temperatures below 70°C resulted in acceptable head rice yield quality. Furthermore, Saad et al. (2021) observed that while the air-drying treatment applied directly to milled rice completely killed insects at 50–70 °C for 300 s, it affected physiochemical quality.

The fluidized bed-drying technique can be used as an alternative to insecticides that control insects infesting grain and other commodities (Fleurat-Lessard and Fuzeau, 2014; Venkatesh et al., 2016). Furthermore, high-temperature short-time treatment is an effective and efficient method for controlling internal feeder stages and is required to meet commercial criteria for insect contaminating products throughout the marketing chain of organically grown cereals and processed cereal foods, as well as to reduce the presence of residue in cereal foods (Fleurat-Lessard and Fuzeau, 2014). Considering the efficacy of eliminating all stored insect pests, FBD treatment killed insects in the paddy, demonstrating that the fluidized bed heat transfer technique can transmit heat evenly to rice kernels. The heat dissipation condition includes adequate airflow and hot air temperature to maintain uniform rice grain movement and a high heat transfer rate.

Heat-fluidized beds slightly affect rice quality in terms of physical and chemical properties. The moisture content dramatically changes over a short exposure period. Normally, a heat-fluidized bed is equipped in mill rice to quickly reduce the grain moisture content (Soponronnarit et al., 1996; Soponronnarit, 1999). New harvest of rough rice can be reduced 5–10 % from 28–30 % of rough rice to 20–22 % using FBD heat treatment and then further dried with sunlight or other measures. In this experiment, the moisture content of rough rice decreased from 13 to 12% in 90 s. Rice quality may be affected by heat. Generally, hot air or conventional heat reduces the moisture content and then promotes the percentage of head rice. However, an appropriate moisture content is required to maintain milled rice quality and high head rice production. Rough rice with a 14–16 % moisture content showed a high percentage of head rice (Tirawanichakul et al., 2004).

Under conditions of FDB heat treatment, which is able to kill storage insects, there is a slight change in milled rice quality, such as rice color, showing a slight decrease in whiteness index and 2-AP brightness (L*) and a slight increase in yellowness (b) and amylose content. The head rice was not significantly different from the other heat treatments. Other sources of heat treatment, such as radio frequency and quick heat treatment, show similar results. Wangspa et al. (2018) showed an increase in yellowness when Khao Dawk Mali 105 was treated with heat from a radio frequency of 65°C for 120 s. However, the chemical quality of rice treated with a heat-fluidized bed has shown an acceptable standard for Thai Hom Mali rice (National Bureau of Agricultural Commodity and Food Standards, 2017).

CONCLUSION

The efficacy of a heat-fluidized bed was studied on a laboratory heat-fluidized bed (Christison Scientific, Gateshead, Tyne and Wear United Kingdom) on Khao Dawk Mali 105 rough rice at 40–65 °C for 60–240 s to control stored product insects. The lesser grain borer at the pupal stage was the most tolerant to FBD heat treatment compared to the other stages, i.e., egg, larval, and adult stages, while the sawtoothed grain beetle at the egg stage showed the most tolerance to FBD heat treatment.

The optimum conditions comprised of temperature and exposure time were carried out to treat tolerant stored product insects. The pupal stage of the lesser grain borer showed 100% mortality under various conditions: 55°C for 150 s, 60°C for 90 s, and 65°C for 60 s. The egg stage of the sawtoothed grain beetle showed 100% mortality at 45°C for 150 s and 50°C for 60 s. These conditions did not affect physical rice quality or milling rice quality, depending on the beginning moisture content of the rough rice. All characteristics of grain physical characteristics, milling quality, grain chemical properties, and grain cooking and eating quality were under the Thai Hom Mali Rice standard.

ACKNOWLEDGEMENTS

The authors thank the Postharvest Technology Research Center, Faculty of Agriculture, Chiang Mai University, for providing the instruments. This research was funded by the Postharvest Technology Innovation Center, Ministry of Higher Education, Science, Research and Innovation, Thailand.

AUTHOR CONTRIBUTIONS

Kunlayaa Boonsa-nga assisted in conducting the experiments, designed and conducted the experiments, performed the statistical analysis, and wrote the manuscript. Yaowaluk Chanbang performed the statistical analysis and wrote the manuscript. All authors read and approved the final manuscript.

CONFLICT OF INTEREST

The authors declare that they hold no competing interests.

REFERENCES

Abbott, W.S. 1925. A method of computing the effectiveness of insecticide. Journal of Economic Entomology. 18: 265-267.

Abd El-Aziz, S.E. 2011. Control strategies of stored product pests. Journal of Entomology. 8(2): 101-122.

Beckett, S.J., Fields, P.G., and Subramanyam, Bh. 2007. Disinfestation of stored products and associated structures using heat. p.182-237. In T. Juming, M. Elizabeth, W. Shaojin, and L. Susan [eds] Heat Treatment for Postharvest Pest Control: Theory and Practice. Cromwell Press, Trowbridge, United Kingdom.

Boonsa-nga, K., Bundhurat, D., Changrue, V., and Chanbang, Y. 2021. Effects of laboratory scale fluidized bed heat treatment on maize weevil, (Sitophilus zeamais), red flour beetle (Tribolium castaneum) and milling quality of rice cv. Khao Dawk Mali 105. Agricultural Science Journal. 52:2 (Suppl.): 12-15.

Cheenkachorn, K. 2007. Drying of rice paddy using a microwave-vacuum dryer. p. 1-7. In: Proceeding of European Congress of Chemical Engineering (ECCE-6), 16-20 Sept 2007. Copenhagen, Denmark.

Divagar, D., Jian., F., and Cenkowski, S. 2019. Control of three species of stored product insects in wheat treated with steam and hot air. Journal of Economic Entomology. 112(4): 1964-1974.

Evans, D.E., and Dermott, T. 1979. The potential of fluidized-bed techniques in insect control. p. 222-229. In: Caswell, G.H., Boshoff, W.H., Daramola, A.M., Dina, S.O., Adesuyi, S.A., Singh, S.R., Ivbijaro, M.F., Adeyemi, S.A.O., and Taylor, T.A. (eds) Proceedings of the Second International Working Conference on Stored-Product Entomology, 10-16 Sept 1978. Ibadan, Nigeria.

Fields, P.G. 1992. The control of stored-product insects and mites with extreme temperatures. Journal of Stored Product Research. 28: 89-118.

Fields, P.G., and Muir, W.E. 1996. Physical control. p.195-221. In B. Subramanyam, and D.W. Hagstrum (eds) Integrated Management of Insects in Stored Products. Marcel Dekker, Inc., New York.

Fleurat-Lessard, F., and Fuzeau, B., 2014. High-temperature-short-time (HTST) disinfestation of wheat grain infested by Sitophilus spp. pre-emergent stages with a laboratory scale fluidized-bed. Integrated Protection of Stored Products IOBC-WPRS Bulletin. 98: 213-222.

Jood, S., and Kapoor, A.C. 1993. Protein and uric acid contents of cereal grains as affected by insect infestation. Food Chemistry. 46: 143–146.

Keatmaneerat, S., Chanbang, Y., and Kulsarin, J. 2011. Biology of sawtoothed grain beetle (Oryzaephilus surinamensis L.) and its control efficacy using ozone in milled rice. Journal of Agriculture. 27(2): 145-153.

Mahatheeranont, S., Dumrih, K., Jongkaewwattana, S., and Siri, B. 2004. Effects of drying methods and storage time on the aroma and milling quality of rice (Oryza sativa L.) cv. Khao Dawk Mali 105. Food Chemistry. 87(3): 407-414.

Mathur, K., and Gishler, P. 1955. A study of the application of the sprouted bed technique to wheat drying. Journal of Applied Chemistry. 5(11): 624-636.

McLeod, R., Isvilanonda, S., and Wattanutchariya, S. 1999. Realised and Potential Project Outcomes. p.11-14. In Improved drying of high moisture grains. ACIAR impact assessment series 14. Australian Center for International Agricultural Research, Canberra, Australia.

National Bureau of Agricultural Commodity and Food Standards. 2017. Thai Agricultural Standards TAS 4000-2017 Thai Hom Mali Rice. The National Bureau of Agricultural Commodity and Food Standards, Ministry of Agriculture and Cooperatives. 39 pp. [accessed 2020 Jan 20]. Available: https://www.acfs.go.th/standard/download/Thai-Hom-Mali_Rice-60.pdf.

Neven, L.G. 2003. Physiological effects of physical postharvest treatments on insects (review). HortTechnology. 13(2): 272-275.

Pande, R., and Mishra, H.N. 2013. Effect of fluidized bed heat treatment on insect mortality, proximate composition and antinutritional content of stored green gram (Vigna radiata) seeds. Journal of Food Chemistry and Nutrition. 01(02): 94-99.

Rai, P.S., Ball, H.J., Nelson, S.O., and Stetson, L.E. 1974. Cytopathological effects of radiofrequency electric fields on reproductive tissue of adult Tenebrio molitor following treatment (Coleoptera: Tenebrionidae). Annals of the Entomological Society of America. 67(4): 687-690.

Rai, P.S., Ball, H.J., Nelson, S.O., and Stetson, L.E. 1977. Spermatozoan activity and insemination in Tenebrio molitor following radiofrequency electrical treatment (Coleoptera: Tenebrionidae). Annals of the Entomological Society of America. 70(2): 282-284.

Saad, M.M., Said, W., and Hosni, H.D. 2021. Evaluation on air-dried of fluidized bed dryer for rice pre-treatment to control stored insect pests. Journal of Entomology and Zoology Studies. 9(3): 32-36.

Soponronnarit, S. 1999. Fluidised-bed paddy drying. Science Asia. 25(1999): 51-56.

Soponronnarit, S., Prachayawarakorn, S., and Wangji, M. 1996. Commercial fluidized bed paddy dryer. p.638-644. In: Proceedings of the 10th International Drying Symposium, Vol. A. 30 July-2 Aug 1996. Krakow, Poland.

Stathas, I.G., Sakellaridis, A.C., Papadelli, M., Kapolos, J., Papadimitriou, K., and Stathas, G.J. 2023. The effects of insect infestation on stored agricultural products and the quality of food. Foods. 12, 2046.

Sumetha, K., Chanbang, Y, Hengsawad, V., and Krittigamas, N. 2009. Effect of radio frequency on Rhyzopertha dominica (Fabricius) (Coleoptera: Bostrichidae) and quality of rice cv. Khao Dawk Mali 105. p. 97-104. In: 6th Conference of Agricultural Graduate Research. 12-13 Mar 2009. Chiang Mai University, Thailand.

Tirawanichakul, S., Prachayawarakorn, S., Varanyanond, W., Tungtrakul, P., and Soponronnarit, S. 2004. Effect of fluidized bed drying temperature on various quality attributes of paddy. Drying Technology. 22(7): 1731-1754.

Uraichuen, J., Pedchote, A., and Visarathanonth, P. 2010. High temperature treatments to control maize weevil, Sitophilus zeamais Motschulsky (Coleoptera: Curculionidae). p.54-64. In: Proceedings of 48th Kasetsart University Annual Conference, Plants. 3-5 Feb 2010. Bangkok, Thailand.

Venkatesh, S., Kalyan, C.S., Chiranjeevi, A., and Anish, K.S. 2016. Future prospects of drying operations in fluidized bed dryer. Journal of Agricultural Engineering and Food Technology. 3(3): 268-271.

Wangspa, W., Chanbang, Y., and Vearasilp, S. 2015. Radio frequency heat treatment for controlling rice weevil in rough rice cv. Khao Dawk Mali 105. Chiang Mai University Journal of Natural Sciences. 14(2): 189-197.

Wangspa, W., Vearasilp, S., and Chanbang, Y. 2018. Effects of radio frequency heating and storage time on physical and chemical properties of rough rice cv. Khao Dawk Mali 105. Chiang Mai University Journal of Natural Sciences. 17(2): 97-109.

Wongpornchai, S., Jongkaewwattana, S., Kitsawatpaiboon, P., and Kanjanawong, S. 2007. Development of methods for quantification of an aroma compound in rice. In: Final report of Khao Dawk Mali 105 rice quality research project. 140 pp. [accessed 2020 Jan 20]. Available: https://search.lib.cmu.ac.th/search/?searchtype=.&searcharg=b1372246.

OPEN access freely available online

Natural and Life Sciences Communications

Chiang Mai University, Thailand. https://cmuj.cmu.ac.th

Kunlayaa Boonsa-nga1 ,4, Damorn Bundhurat 3, 4, Viboon Changrue3, 4, and Yaowaluk Chanbang1, 2, 4, *

1 Postharvest Technology Research Center, Faculty of Agriculture, Chiang Mai University, Chiang Mai 50200, Thailand.

2 Department of Entomology and Plant Pathology, Faculty of Agriculture, Chiang Mai University, Chiang Mai 50200, Thailand.

3 Department of Mechanical Engineering, Faculty of Engineering, Chiang Mai University, Chiang Mai 50200, Thailand.

4 Postharvest Technology Innovation Center, Ministry of Higher Education, Science, Research and Innovation, Bangkok 10400, Thailand.

Corresponding author: Yaowaluk Chanbang, E-mail: yaowaluk.c@cmu.ac.th

Total Article Views

Editor: Tonapha Pusadee,

Chiang Mai University, Thailand

Article history:

Received: February 21, 2023;

Revised: January 14, 2024;

Accepted: February 14, 2024;

Online First: February 27, 2024