Prediction of Maize Yield and Assessment of the Material Circularity of Maize Residues Used in the Dairy Cattle Feed Production

Nongnuch Poolsawad, Weerapattra Phimphakarn, Prakaytham Suksatit, and Thanwadee Chinda*Published Date : December 19, 2023

DOI : https://doi.org/10.12982/NLSC.2024.006

Journal Issues : Number 1, January-March 2024

Abstract The dairy cattle industry is expanding rapidly to accommodate the growing demand for human consumption. This results in high cattle feed production. This study aims to forecast the amount of maize residue and calculate the circularity level of using maize residue as a feedstock for total mixed ration feed production in dairy cattle feed production. The multiple linear regression analysis is performed to predict maize yields in Thailand so that maize residues can be calculated and used in feed production. The material circularity indicator is also used with biological cycles to assess the circularity level of dairy cattle feed production under the circular economy concept. The results show that the maize yield is expected to increase, resulting in more maize residues. The use of maize residues in daily cattle feed production gives the MCI value of 0.6038, representing a high degree of circularity and explaining the sustainable management of wastes in the cattle feed industry. Moreover, using maize residues as a part of feed ingredients instead of the Napier grass saves the cost by 14.2%. The study results provide a guideline for farmers and related authorities to plan for managing maize residue in daily cattle feed production to lower operation costs and minimize environmental problems.

Keywords: Biological cycle, Circular economy, Dairy cattle feed production, Maize residues, Material circularity indicator, Multiple linear regression

Funding: The authors are grateful for the research funding provided by Sirindhorn International Institute of Technology (SIIT), Thammasat University, National Science and Technology Development Agency (NSTDA), and TAIST TOKYO-TECH Scholarship.

Citation: Poolsawad, N., Phimphakarn, W., Suksatit, P., and Chinda, T. 2024. Prediction of maize yield and assessment of the material circularity of maize residues used in the dairy cattle feed production. Natural and Life Sciences Communications. 23(1): e2024006.

INTRODUCTION

The dairy cattle industry is expanding rapidly to serve human consumption demand and the growing population. In 2015-2019, the demand for dairy cattle consumption in Thailand increased by an average of 6.62% per year, raw milk production increased by 2.97% per year, and the demand for milk consumption increased by 2.99% per year (Pattamanont et al., 2022). There were 710,445 million dairy cattle in 2020; this increased from 2019 by 6.62% (Department of Livestock Development, 2019; Department of Livestock Development, 2020a). As a result, the demand for feed consumption for total dairy cattle was increased to 1.04 million tons in 2020 to serve the nutrient requirement of dairy cattle in Thailand (Thai Feed Mill, 2021).

Maize is one of the most important cereal crops grown for dairy diets worldwide (Silva et al., 2015). Office of Agricultural Economics (2020) revealed that the maize harvested area in Thailand was 1,100,907 ha in 2020, with an estimated total maize yield of 4.8 million tons per year or 698 kg per rai and an annual growth of 10.2 %. Maize harvesting brings many residues, mainly leaves, stalks, husks, cobs, roots, and dust (Punyalue et al., 2018; Department of Alternative Energy Development and Efficiency, 2016). Rusinamhodzi et al. (2015) mentioned that maize residues may be used for animal feed and soil fertility. Tian et al. (2016) assessed the impacts of various proportions of maize residues on soil retention and forage on soil total organic carbon, total nitrogen, carbon/nitrogen ratio, grain yield, economic benefits, and nutritional contents of removed residues. The results show that the crop yield is improved when the residue retention increases. Mupangwa et al. (2019) examined the crop yield when different amounts of maize residue were used as soil cover in Southern Africa and concluded that using maize residue increases grain yield by 20% across the sites operated. Mazurkiewicz et al. (2019) analyzed the possibility of using methane fermentation maize straw harvested in different weather conditions in Central-Eastern Europe. They concluded that maize straw could be a good substrate for the biogas plant. Klopfenstein et al. (2013) stated that maize residue can be used as a roughage source in finishing diets, mixed with wet byproducts, and fed as an energy source to cattle or beef cows. Silva et al. (2015), however, mentioned that the residues are mostly burned or plowed into the soil, even though they can be used as energy and fiber sources for dairy cattle to promote high intake and milk production. If the maize residues are fully utilized in the cattle industry, they will benefit the industry and the environment (Kahyani et al., 2019).

The circular economy (CE) concept has recently been considered in waste management. It is a regenerative economic system in the value chain to optimize waste management (Blomsma and Brennan, 2017; SCG, 2023). CE is based on the make-use-return practice in the closed-loop system with appropriate processes. At the same time, the linear economy focuses on using resources to produce the product, and that waste is discarded and not recycled (Hetbroenebrein, 2023). The business model must shift from the linear economy to the CE to modify the emerging resource shortage crisis, use fewer raw materials, and contribute to sustainable growth (Jahier, 2018; Ellen MacArthur Foundation, 2023a).

Therefore, this study aims to predict maize yields in Thailand and examine the level of circularity in dairy cattle feed production from the use of maize residues. Multiple linear regressions (MLR) and material circularity indicators (MCI) are the main approaches to achieving the research aims. The study results are expected to give insights into sustainable maize residue management. Several objectives are listed to achieve the research aims.

• To extract key factors affecting the maize yield from the Thai and abroad literature.

• To conduct the MLR analysis to predict the maize yield in Thailand.

• To calculate the MCI from using maize residues in the daily cattle feed production to achieve circularity and sustainable development.

MATERIALS AND METHODS

Multiple linear regression (MLR) model

MLR is an extension of simple linear regression used to predict the value of a variable based on the value of two or more other variables. The variable required to indicate is called the dependent variable, and the variables used to predict the value of the dependent variable are called the independent variables or the predictors (Laerd Statistics, 2018). Several forecasting studies have been conducted utilizing the MLR method. For example, Sathya and Gnanasekaran (2023) utilized the MLR-LSTM model to predict the paddy yield in the Tamil Nadu Delta, India. Piekutowska et al. (2021) applied the MLR and artificial neural network models to predict the yield of very early potato cultivars before harvesting in Poland. Jantankaew and Soonthornphisaj (2023) used regression algorithms to predict maize prices sold by Thai farmers.

In this study, maize yield prediction involves forecasting maize yield based on historical data, such as historic maize yield and soil, rainfall, and weather parameters, see Equation 1, where yi is the dependent variable, which is the maize yield, xi is an independent variable, which is the factor that affects the farmer's maize production, β0 is the y-intercept (constant term), βn is slope coefficients for each independent variable, ε is a random disturbance, and i is several observations (Laerd Statistics, 2018; Shastry et al., 2017).

yi= β0+β1xi1+⋯+βnxin+ε (1)

Key factors affecting maize yield in this study are extracted from the maize- and agricultural-related literature from Thailand and other countries. For example, Tofa et al. (2022) mentioned that nitrogen (N) and phosphorus (P) fertilizers affect maize productivity in Nigeria. Li et al. (2023) optimized the N, P, and potassium (K) fertilization regimes to improve maize productivity in China under double ridge-furrow planting with full film mulching. Baffour-Ata et al. (2023) explored the effects of rainfall and temperature variability on maize yield in Ghana. They concluded that the increase in annual rainfall and temperature patterns significantly affect maize yield positively. Supasri et al. (2021) stated that maize seed and N, P, and K fertilizers are crucial factors in maize cultivation in Thailand.

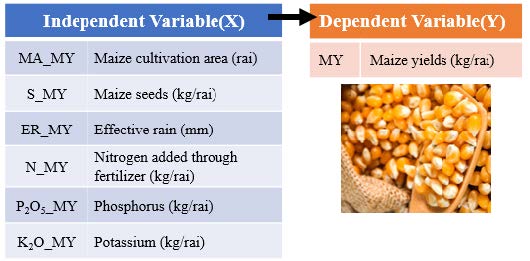

Based on the above literature, the maize yield in this study is affected by six key factors: maize cultivation area, maize seed, effective rain, and N, P, and K fertilizers, see Figure 1 (Niedbała, 2018). Data used in the MLR analysis to predict the maize yield in Thailand are retrieved from the Office of Agricultural Economics (2020) and Meteorological Information Research and Developments (2023), see Table 1.

Figure 1. Factors affecting maize yield in this study.

Table 1. Data used in the MLR analysis (Office of Agricultural Economics, 2020; Meteorological Information Research and Developments, 2023).

|

Year |

MY |

MA_MY |

S_MY |

ER_MY |

N_MY |

P2O5_MY |

K2O_MY |

|

2010 |

646 |

139,680 |

2.99 |

64.66 |

8.11 |

5.58 |

5.95 |

|

2011 |

657 |

136,399 |

3.79 |

82.68 |

9.61 |

7.35 |

5.77 |

|

2012 |

692 |

173,328 |

3.57 |

58.30 |

8.18 |

6.86 |

5.53 |

|

2013 |

676 |

192,378 |

3.02 |

71.02 |

8.91 |

6.92 |

6.23 |

|

2014 |

676 |

189,443 |

3.00 |

77.38 |

9.17 |

7.81 |

6.15 |

|

2015 |

652 |

149,240 |

3.62 |

51.94 |

7.48 |

4.66 |

5.67 |

|

2016 |

689 |

176,700 |

3.39 |

71.02 |

7.62 |

4.43 |

5.91 |

|

2017 |

737 |

174,584 |

3.52 |

94.34 |

8.37 |

5.72 |

6.16 |

|

2018 |

745 |

183,128 |

3.45 |

58.30 |

9.36 |

6.43 |

6.86 |

|

2019 |

674 |

226,475 |

3.12 |

64.66 |

8.46 |

5.82 |

6.21 |

|

2020 |

678 |

227,550 |

3.00 |

82.68 |

8.51 |

5.85 |

6.25 |

According to Laerd Statistics (2018), the steps of MLR analysis are as follows.

- Perform the backward elimination to specify how independent variables (i.e., six key factors affecting the maize yield in Thailand) are entered into the analysis. The variables with the smallest partial correlation with the dependent variable are removed. The procedure ends when no variables in the equation satisfy the removal criteria.

- Input the data into the model and calculate the adjusted R2, the adjusted coefficient of determination. A value closer to 1 indicates good model results.

- Calculate the coefficients of the independent variables and test the multicollinearity between them using the variation inflation factors (VIF). The value lower than the threshold of 10 indicates no multicollinearity problems (Mohammed, 2021).

- Summarize the MLR equation used in the maize yield prediction.

Circular economy (CE)

CE is designed under the concept of recycling waste, focusing on effectively using resources to minimize waste management problems. It considers the 3Rs: reduce, reuse, and recycle (Hetbroenebrein, 2023; De Oliveira Neto et al., 2023). This concept works in the long term and focuses on value preservation. The CE model has two different cycles: biological and technical cycles. Organic materials and products are returned to the bioeconomy in the biological cycle through regenerating natural systems. In the technical cycle, on the other hand, products, components, and materials are kept in the market at the highest possible quality and for as long as possible through repair and maintenance, reuse, refurbishment, remanufacture, and ultimately recycling (Ellen MacArthur Foundation, 2023a; Chorolque et al., 2022).

The concept of circularity for biological cycles

Biological cycles enable the recycling of bio-based material back into the manufacturing processes and new applications (University of Helsinki, 2023). Composting provides an inexpensive alternative for the disposal of animal-based wastes and other biological residuals in the agricultural sector (Ayilara et al., 2020). It is a natural, biological process by which organic material is decomposed. It is also the fast aerobic degradation of biodegradable organic wastes. Generally, it takes 4-6 weeks for the degradation. This compost material is odorless, soft, not stiff, dark brown, and has a fine texture and a moisture content of 40-50% (Rayne and Aula, 2020).

Consequently, cow manure is considered in this study with biological cycles to maintain soil fertility for growing certain crops. Biogas generated in the process is also considered in this study for energy production (Organics Group, 2022). Biogas is produced during the anaerobic digestion of organic materials, which contains methane (CH4) by 50‐70%, carbon dioxide (CO2) by 30‐40%, and the remaining gases, such as ammonia (NH3), hydrogen sulfide (H2S), and water vapor (H2O) (Department of Alternative Energy Development and Efficiency, 2016). The types and contaminants in biogas depend on the sources of raw materials used in the production. The biogas produced from livestock waste accumulation is affected by different factors, such as animal feeding systems, animal proportional weights, and total solid wastes (Shapovalov et al., 2020).

Material circularity indicator (MCI)

MCI is used to identify the degree of circularity of materials from their products and mitigate material supply (Ellen MacArthur Foundation, 2023a). It was developed by the Ellen MacArthur Foundation and constructed by first computing virgin feedstock, see Equation 2, where V is the mass of virgin material, M is the mass of the product, FR is the fraction of mass of recycled feedstock, FU is the fraction from reused sources, and FS is the fraction of mass of a product’s biological feedstock from sustained production.

V=M1-FR-FU-FS (2)

Unrecoverable waste through a product's material going into landfill (W0) is subsequently calculated, as shown in Equation 3, where CR is the fraction of the mass of the product being collected for recycling, CU is a fraction of the mass of a product that is going into reuse material, CC is a fraction of mass of a product being collected going into a composting process, and CE is a fraction of mass of a product being collected for energy recovery. The CE in Equation 3 is calculated using Equation 4, where EE is the energy recovery efficiency into biological materials and BC is carbon content (default value of 45%) (Ellen MacArthur Foundation, 2023a). EE is achieved through Equation 5, where ER is energy recovered (in MJ or BTU), HHV is a higher heating value (in MJ or BTU), and MB is the mass of biological material.

W0=M1-CR-CU-CC-CE (3)

CE=EE×BC (4)

EE=ER/HHV×MB (5)

Mass of unrecoverable waste from the recycling of a product is then achieved, as shown in Equation 6, where EC is the efficiency of the product collected for recycling, and CR is a fraction of the mass collected for a recycling process. The mass of unrecoverable waste generated when producing recycled feedstock for a product is given in Equation 7, where EF is the efficiency of the recycling process used to produce recycled feedstock. The overall amount of unrecoverable waste (W) is then achieved by considering W0 (in Equation 3), WC (in Equation 6), and WF (in Equation 7), as shown in Equation 8. The linear flow index (LFI) is calculated, as shown in Equation 9. It measures the proportion of material flowing in a linear from virgin materials and as unrecoverable wastes.

The utility (X) is then calculated using Equation 10, where L is the actual average lifetime of a product, L_av is the average lifetime of an industry-average product of the same type, U is the actual average number of functional units achieved during the use phase of a product, and U_av is an average number of functional units achieved during the use phase of an industry's average product of the same type. The MCI is finally calculated, see Equations 11-13, by considering the LFI of the product and a factor

RESULTS

Maize yield prediction and maize residues

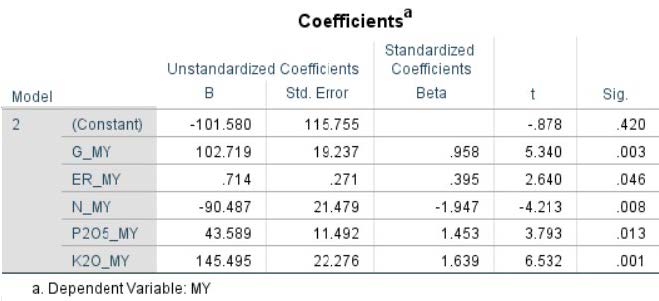

Six key factors affecting the maize yield in Thailand are analyzed with the MLR method. The backward elimination results reveal that the maize cultivation area (MAMY) has the smallest partial correlation with the maize yield (MY); thus it is removed from the analysis, resulting in five key factors affecting the maize yield, including maize seeds (G_MY), effective rain (ER_MY), N fertilizer (N_MY), P fertilizer (P2O5_MY), and K fertilizer (K2O_MY). The adjusted R2 is calculated as 0.825, closer to 1, revealing good model results. Figure 2 shows the coefficients, where the K2O_MY has the most effect on the maize yield, followed by the G_MY, N_MY, P2O5_MY, and ER_MY, respectively. The calculated VIF values confirm the non-multicollinearity of the five factors as they fall within the threshold value of 10 (Mohammed, 2021).

Figure 2. Coefficients of factors affecting maize yield.

The coefficient values in Figure 2 are input into Equation 1 to achieve the equation used in the maize prediction in Equation 15.

MY=-101.58+145.495×K2OMY+102.719×GMY-90.487×NMY+43.589×P2O5MY+0.714×ERMY (15)

Maize yield in 2022 is then predicted based on Equation 15. According to Srisaikham and Lounglawan (2021), it is recommended that 3.5 kg of maize seed be used per rai (i.e., GMY = 3.5). The nutrients of N, P, and K fertilizers (NMY, P2O5MY, and K2OMY) should be 7.5, 3.27, and 6.23 kg/rai, respectively (National Bureau of Agricultural Commodity and Food Standards, 2010). The effective rainfall value (ERMY) is set at 110.24 mm (Meteorological Information Research and Development, 2023).

Inputting the above data into Equation 15, the maize yield prediction in 2022 is 706.54 kg/rai or 4,415.88 kg/ha. Based on this maize yield, the cattle feed industry can analyze the agricultural waste from maize residues used as feedstock in cattle feed production. The proportion of agricultural wastes from maize residues, including maize stalks, leaves, roots, husk, and maize cobs, are 0.44, 0.31, 0.45, 0.16, and 0.21 kg maize residues per kg of maize yield, respectively (National Bureau of Agricultural Commodity and Food Standards, 2010; Meteorological Information Research and Development, 2023). Consequently, maize residues of stalks, leaves, roots, husk, and cobs based on the maximum maize yield in 2022 are calculated as 307.49, 218.85, 206.55, 113.05, and 150.24 kg/rai of maize residues, respectively. According to the Office of Agricultural Economics (2021), approximately 79.27 % of the agricultural waste of maize residues is used for dairy cattle feed, which helps preserve the environment.

Results of maize residues used in dairy feed production

In this study, eight Holstein Friesians male dairy cows of about 2–3 months old (near weaning) weighing 100 kg each are used in the experimental period of 126 days. Male dairy cows weighing 100 - 200 kilograms can grow up to 1 kg per day. They require approximately 16% dietary protein and at least 68% digestible nutrients. General dairy cattle feed should have roughages with a concentration ratio (R:C ratio) of 60:40 (Srisaikham and Lounglawan, 2020; National Research Council, 2001). The dairy cattle feed ingredients (total mix ratio, TMR) are shown in Table 2. The total TMR feed is produced at 100 kg per cycle. Approximately 60% of TMR feed is from maize residues, with the remaining 40% from other feed ingredients (National Research Council, 2001). In 2021, dairy cows had a TMR feed demand of 1.07 million tons. With 5.433 million tons of maize residues mixed with other feed ingredients, it can produce about 9.055 million tons of TMR feed, which is sufficient for the consumption of dairy cattle.

Table 2. TMR of the daily cattle feed ingredients.

|

Source of raw material |

Feed ingredient |

Quantity (kg/cycle) |

|

Energy source |

Casava chip |

2.5 |

|

Cavalcade straw |

13.0 |

|

|

Maize residue silage |

60.0* |

|

|

Plant protein source |

Soybean meal |

24.0 |

|

Mineral supplement |

Dicalcium phosphate |

0.5 |

|

Total |

|

100 |

Note: *With the R:C ratio of 60:40, 60 kg of TMR feed is from maize residues, with the remaining 40 kg are from other feed ingredients, including the casava chip, cavalcade straw, soybean meal, and dicalcium phosphate (Srisaikham and Lounglawan, 2020; National Research Council, 2001).

Implementation of circularity in dairy cattle production

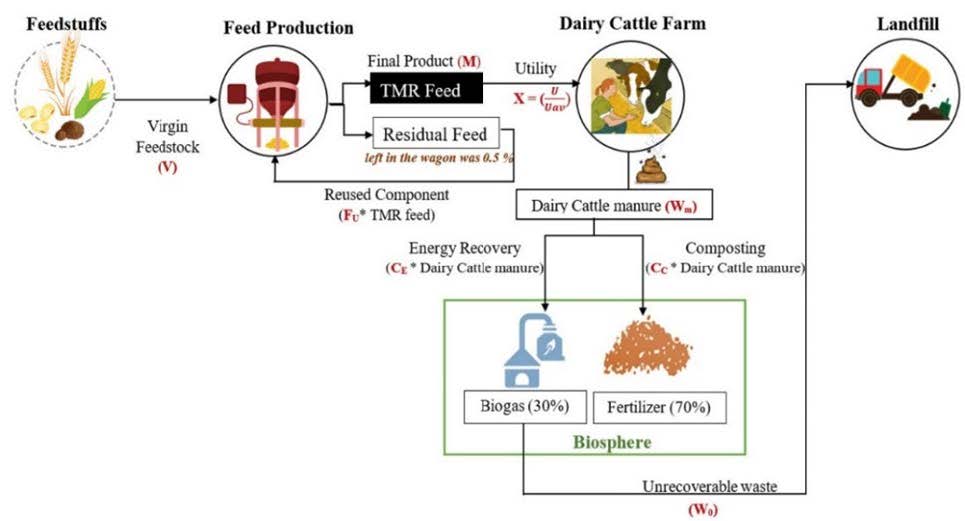

This study considers the circularity in the dairy cattle industry in terms of biological cycles. The system boundary of feed production and the utilization of dairy cattle manure in terms of biological cycles are shown in Figure 3. TMR feed is produced by crushing maize residues, including cobs, husks, leaves, and stalks, and mixing them with another feedstuff. With this, the residual feed left in the wagon is less than 0.5 % of the total TMR feed (Homhual and Photong, 2011). This residual feed can substitute soybean meal, the feedstuff in the TMR feed production process, by comparing the same protein content. After dairy cattle consume TMR feed on the farm, the dairy cattle manure is generated. The mass of the waste generated from the use phase of the final product (Wm) is defined as the mass of the total dairy cattle manures. The amount of nutrients used for growth is approximately 75% of nitrogen, 80% of phosphorus, and 90% of potassium (Baanlaesuan, 2022). About 70 % of dairy cattle manure is collected for composting of organic fertilizers. Plants can take up nutrients via their root systems through nitrates and ammonia. This can come from nitrogen fertilizers and the decomposition of manures and organic matter (Srisaikham and Lounglawan, 2021). It is suitable for plants during root expansion (Glazier, 2015). The remaining 30 % of dairy cattle manure is used for energy recovery in biogas for electricity generation (Wijaya, 2018). It can be used as renewable energy or directly for heating and gas released into the biosphere. Unrecoverable waste (W0) through a product’s material, on the other hand, goes to landfills, where materials are no longer recoverable.

The MCI calculation follows step-by-step calculation, as shown in Equations 2-14. In this study, the final product (M) is the mass of 99.50 kg of TMR feed (the efficiency of feed production of 99.5%), and loss at the feed production manufacturing stage, in the form of dust in the wagon, is 0.5% of TMR feed (Homhual and Photong, 2011). The fraction from reused sources (FU), which comes from the summation of a fraction of the feedstock, derives from reusing raw materials containing soybean meal of 23.58% and residual feed of 0.005% in 99.5 kg of dairy cattle feed. To explain, 0.5 kg of dust content can be reused as a substitute for 0.08 kilograms of soybean meals by comparing the same protein content. So, Fu is equal to 0.24. This study has no fractions of recycled feedstock and the product's biological feedstock from sustained production, meaning that FR and FS are 0. The virgin feedstock (V) can then be calculated as V=M(1 - FR - Fu - FS)= 99.5 x (1 – 0 - 0.24 - 0) = 75.54 kg.

Figure 3. Flow diagram of modified MCI with dairy cattle production and the utilization of cattle manures in terms of biological cycles.

After cattle consume the feed, Wm is achieved as the mass of the total cattle manures after the consumption. A 7.28 kg/day dry matter intake for one dairy cattle can defecate 4.55 kg of manure daily. Therefore, a dry matter intake of 10.78 kg/day for eight dairy cattle can defecate 62.12 kg of manure daily. So, Wm equals 62.12 kilograms. Wastes management from cattle manures is usually composted as fertilizers, using an aerobic biological process to break down organic materials (Baanlaesuan, 2022). Farmers compost used these fertilizers for their field crops to improve soil conditions. Cattle manure can also produce renewable energy and generate electricity for cattle farms.

The utilization of dairy cattle manures in this study is, therefore, summarized into two types:

- Compost to organic fertilizer: the fraction of cattle manures collected for composting equals 70% of total cattle manures (CC) equals 0.70

- Produce biogas through anaerobic digestion: 30% of total solid wastes (% TS) of cattle manures are used as biogas and can produce 0.8 m3/kg TS of biogas. Thus, the mass of cattle manures collected for energy recovery in biogas for electricity generation (MB) is calculated by multiplying the total mass of cattle manures with the total solid waste (% TS) content of the cattle manures for biogas. So MB is 18.64 kg.

In this study, cattle manures have a higher heating value (HHV) of 15.48 kJ/kg (Jaiboon, 2015). The carbon content of dairy cattle manures (BC) is 20% (Pornmeeyoo, 2015). The efficiency of the energy recovery process in biogas for biological materials from cattle manures (EE) is 80% (Srichart, 2016). The energy recovered (ER) and fraction of mass of a product being collected for energy recovery (CE) are then:

ER=EE×HHV×MB=0.80×15.48 kJ/kg×18.64 kg=230.79 kJ

CE=EE×BC=0.80×0.20=0.16

The fractions of mass of cattle manures being collected for recycling and reusing (CR and CU) in this study are 0. The calculating unrecoverable waste (W0) through the product is then achieved:

W0=Wm1-CR-CU-CC-CE=62.12×1-0-0-0.70-0.16=8.7 kg

The efficiency of the recycling process used to produce recycled feedstock for a product (EF) and the efficiency of the recycling process used for the portion of a product collected for recycling (EC) equal 1, as this study focuses on a closed loop, in which the recycled raw materials are from the final product. Consequently, no unrecoverable waste is generated from recycling parts of a product (WC) and from producing recycled feedstock for a product (WF), i.e., WC and WF = 0. LFI is then calculated as 0.4233.

W=W_0+((W_F+W_C)/2) = 8.7 kg

LFI=(V+W)/(2M+((W_F-W_C )/2)=(75.54+8.7)/((2×99.5)+0)=0.4233

In this study, Uav is 16% of the protein content of TMR feed in the cattle feed industry (Bureau of Animal Feed Development, 2017). The protein content of dairy cattle feed is derived by substituting materials that cannot be equivalent to the protein content of dairy cattle feed. Thus, it is lower than Uav. (i.e., U = 15.39%). The F(X) is then calculated as 0.9359, leading to the MCIP* of 0.6038.

X=(U/Uav) = 15.39/16 = 0.9616

FX=0.9/X=0.9/0.9616=0.9359

MCIP*=1-LFI×FX=1-0.4233×0.9359= 0.6038

A summary of the parameters used in the MCI calculation is in Table 3. The MCI value for biological cycles is 0.6038. This MCI value approaches 1, representing a high degree of circularity in the system. It is considered more circular than linear circularity (i.e., LFI = 0.4233) in dairy cattle feed production. This confirms that renewable nutrients and biological materials mainly re-enter the biosphere to decompose into valuable feedstock for the new cycle. The calculated MCI value is consistent with various studies. For example, Kolk (2020) achieved an MCI of beef steak using the maize residue as a part of the feed diets of 0.546. He suggested that the beef sector may be more circular by improving the water supply, replacing the supplements with circular products, and reducing greenhouse gas emissions from the manure. Rocchi et al. (2021) applied the modified MCI to the biological cycles of the agricultural system and achieved an MCI of 0.4812.

Table 3. Summary of parameters and MCI values.

|

Parameter |

Initial |

Value |

Unit |

|

Virgin feedstock |

V |

75.54 |

kg |

|

The mass of the TMR feed |

M |

99.50 |

kg |

|

The fraction from reused sources |

FU |

24 |

% |

|

The fraction of cattle manures collected for composting |

CC |

70 |

% |

|

The fraction of cattle manures collected for energy recovery |

CE |

16 |

% |

|

The efficiency of the energy recovery |

EE |

80 |

% |

|

The carbon content of dairy cattle manures |

BC |

20 |

% |

|

The higher heating value of cattle manure |

HHV |

15.48 |

kJ/kg |

|

The mass of cattle manure collected into biogas |

MB |

18.64 |

kg |

|

The energy recovered |

ER |

230.79 |

KJ |

|

The efficiency of the product collected for recycling |

Ec |

100 |

% |

|

The efficiency of the recycling process used to produce recycled feedstock |

EF |

100 |

% |

|

The mass of the total dairy cattle manure |

Wm |

62.12 |

kg |

|

The unrecoverable waste going to landfill |

W0 |

8.70 |

kg |

|

The protein content of the TMR feed |

U |

15.39 |

% |

|

The protein content of TMR feed in the cattle feed industry |

Uav |

16.00 |

% |

|

The utility of a product |

X |

0.9616 |

- |

|

The utility factor |

F(X) |

0.9359 |

- |

|

The Linear Flow Index |

LFI |

0.4233 |

- |

|

The material Circular Indicator |

MCI |

0.6038 |

- |

DISCUSSION

There is a growing demand for cattle feed production in Thailand to meet the needs of dairy farmers and the dairy industry. This study considers the utilization of maize residues, including leaves, stalks, husks, and cobs, as roughages for cattle feed production. The study results reveal that maize residues can produce a TMR feed of 9.055 million tons, which is enough to meet the needs of the dairy cattle industry. Utilizing maize residues in roughage reduces the cost compared to Napier grass, which is commonly used by approximately 14.24 %. It is noted that the proportion of concentrate and mineral supplements in the TMR feed formula in Table 4 is recalibrated to control the protein content of the feed formula, which is sufficient to achieve the needs of dairy cattle.

Table 4. Comparison between TMR feed ingredients and price.

|

Feed ingredient |

Price (Baht/kilogram) |

|

|

|

Formula 1 (Napier grass) |

Formula 2 (maize residues) |

|

Napier grass |

0.47 |

- |

|

Maize residue silage |

- |

1.20 |

|

Casava chip |

1.65 |

0.15 |

|

Cavalcade straw |

0.64 |

0.45 |

|

Soybean meal |

5.00 |

4.84 |

|

Dicalcium phosphate |

0.11 |

0.11 |

|

Total price |

7.87 |

6.75 |

Note: References include Adebowale (1994), Technology Chaoban (2021), and Kato (2022).

Table 4 shows two formulas used as TMR feed ingredients in roughage: one with maize residues and another with Napier grass, which is currently used in feed production. The results show that the TMR feed from maize residues is cheaper than that from Napier grass by 14.2%. The dairy cattle manure from the dairy cattle industry contains the nutrients that plants need, including nitrogen (N), phosphorus (P), and potassium (K), thus increasing the organic matter in the soil (Chinvaroj and Pichawong, 2023). They are also used in biogas to generate electricity. Biogas production from cattle manure exemplifies sustainable biomass and circular economy systems (National Research Council, 2016; Department of Livestock Development, 2020b). Biogas production is mainly recommended for the agricultural industry to treat the waste generated from various production processes, such as large animal farms and agricultural processing plants. It is an alternative energy in both household and large industrial applications. Fagerström et al. (2018) agreed that it has more circularity when the total manure is applied in composting. Biomass, unsuited for direct human consumption, can be recycled as animal feed. Farm animals recycle biomass and nutrients into the food system (Shaibur et al., 2021). This demonstrates the biophysical concept of the role of farm animals in a circular food system, leading to a high circularity.

CONCLUSION

With the growth of the dairy cattle industry, accurate maize yield prediction is needed so that maize residues can be predicted to be used as feedstock in cattle feed production. This study uses the MLR method to predict maize yield based on five key factors: maize seed, effective rain, nitrogen fertilizer, phosphorus fertilizer, and potassium fertilizer. The results indicate that 5.43 million tons of maize residues can produce a TMR feed of 9.055 million tons, which is enough for the needs of the dairy cattle industry. Maize residues as roughage in dairy cattle feed production (TMR feed) could be used to replace Napier grass to reduce the production cost by approximately 14.2%. The dairy cattle industry is then encouraged to utilize maize residues to reduce the total production cost.

The circularity of dairy cattle feed production is measured using the adjusted MCI to be used with the biological cycles. The dairy cattle manure from the cattle industry is used in energy recovery in biogas for electricity generation and is turned into compost as organic fertilizers for the agricultural sector. The calculation results for biological cycles of the waste management method from dairy cattle feed production are 0.6038 for MCI and 0.4233 for LFI, showing a high degree of circularity in the system. The biological materials re-enter the biosphere to decompose into valuable feedstock for the new cycle. It provides an alternative for farmers to produce low-cost feed from maize residues within the farmland to raise their cattle.

There are some limitations and suggestions of this study. This study partially considers manure for circularity in a closed-loop system. Future studies may be conducted by considering the waste utilization of dairy cattle manures as organic fertilizers by presenting various aspects, such as soil structure and nutrients of dairy cattle manures, to complete the field of composting for circularity. It is also suggested that the soil analysis is conducted to determine the optimal balance of nutrients in the cattle manure for plant nutrient requirements.

ACKNOWLEDGEMENTS

This second author received the TAIST TOKYO-TECH Scholarship from the Sirindhorn International Institute of Technology (SIIT), Thammasat University, and the National Science and Technology Development Agency (NSTDA). Data are retrieved from the National Metal and Materials Technology Center (MTEC).

AUTHOR CONTRIBUTIONS

Nongnuch Poolsawad analyzed the data and drafted the manuscript. Weerapattra Pimphakarn performed the literature review, collected and analyzed the data, and drafted the manuscript. Prakaytham Suksatit collected and analyzed the data. Thanwadee Chinda analyzed the data and drafted the manuscript.

CONFLICT OF INTEREST

The authors declare that they hold no competing interests.

REFERENCES

Adebowale, E.A. 1994. Maize residues as ruminant feed resources in Nigeria. Revue Mondiale de Zootechnie. 73: 24-30.

Akerman, E. 2016. Development of circular economy core indicators for natural resources: Analysis of existing sustainability indicators as a baseline for developing circular economy indicators. Master Dissertation, Royal Institute of Technology, Stockholm, Sweden.

Ayilara, M.S., Olanrewaju, O.S., Babalola, O.O., and Adeyemi, O. 2020. Waste management through composting: Challenges and potentials. Sustainability. 12(11): 4456.

Baanlaesuan. 2022. Producing quality compost (in Thai). Retrieved on June 16, 2021 from https://www.baanlaesuan.com/229342/garden-farm/farming-101/manure.

Baffour-Ata, F., Tabi, J.S., Sangber-Dery, A., Etu-Mantey, E.E., and Asamoah, D.K. 2023. Effect of rainfall and temperature variability on maize yield I the Asante Akim North District, Ghana. Current Research in Environmental Sustainability. 5: 100222.

Bureau of Animal Feed Development. 2017. Feed technology development report (in Thai). Retrieved on June 23, 2021 from https://nutrition.dld.go.th/nutrition/images/pdf/techno59-60.pdf.

Blomsma, F., and Brennan, G. 2017. The emergence of circular economy: A new framing around prolonging resource productivity. Journal of Industrial Ecology. 21(3): 603-614.

Chinvaroj, S., and Pichawong, V. 2023. The use of cavalcade straw in total mixed ration on growth performance, cost and compensation of growing crossbreed boar goats. Chai Nat Nutrition Research and Development Center, Registered No. 59(2)-0214-029, Chai Nat, Thailand. https://nutrition.dld.go.th/nutrition/images/pdf/research59-02.pdf.

Chorolque, A., Pellejero, G., Sosa, M.C., Palacios, J., Aschkar, G., and Garcia-Delgado, C. 2022. Biological control of soil-borne phytopathogenic fungi through onion waste composting: Implications for circular economy perspective. International Journal of Environmental Science and Technology. 19: 6411-6420.

De Oliveira Neto, G.C., Silva, A.C., and Filho, M.G. 2023. How can industry 4.0 technologies and circular economy help companies and researchers collaborate and accelerate the transition to strong sustainability? A bibliometric review and a systematic literature review. International Journal of Environmental Science and Technology. 20: 3483-3520.

Department of Alternative Energy Development and Efficiency. 2016. Compressed biomethane gas; CBG (in Thai). Retrieved on June 19, 2021 from http://e-lib.dede.go.th/mm-data/BibA11521.pdf.

Department of Livestock Development. 2019. Animal farmers and dairy farmers information 2019 (in Thai). Retrieved on August 20, 2021 from http://ict.dld.go.th/webnew/images/stories/stat_web/yearly/2562/country/3---milk.pdf.

Department of Livestock Development. 2020a. Animal farmers and dairy farmers information 2020 (in Thai). Retrieved on June 23, 2021 from http://ict.dld.go.th/webnew/images/stories/report/regislives/2020/country/3-milk.pdf.

Department of Livestock Development. 2020b. Selling prices of forage crops and animal supplies (in Thai). Retrieved on August 10, 2021 from https://nutrition.dld.go.th/nutrition/images/pdf/price63.pdf.

Ellen MacArthur Foundation. 2023a. Material circularity indicators. Retrieved on August 10, 2021 from https://ellenmacarthurfoundation.org/material-circularity-indicator.

Ellen MacArthur Foundation. 2023b. What is the circular economy? Retrieved on August 15, 2021 from https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview.

Fagerström, A., Al Seadi, T., Rasi, S., and Briseid, T. 2018. The role of anaerobic digestion and biogas in the circular economy. Murphy, J.D. (Ed.) IEA Bioenergy Task 37, 8, UK.

Glazier, N. 2015. Nitrogen cycling in pastures. Retrieved on June 25, 2021 from https://smallfarms.cornell.edu/2015/10/nitrogen-cycling/.

Hetbroenebrein. 2023. How is a circular economy different from a linear economy? Retrieved on August 12, 2021 from https://kenniskaarten.hetgroenebrein.nl/en/knowledge-map-circular-economy/how-is-a-circular-economy-different-from-a-linear-economy.

Homhual, S., and Photong, W. 2011. Design and development of the total mixed ration (TMR) machine for small dairy farms. Kamphaengsaen Academic Journal. 9: 13-26.

Jahier, L. 2018. Opinion of the European Economic and Social Committee on the communication from the commission to the European Parliament, the Council, the European Economic and Social Committee, the Committee of the Regions on a monitoring framework for the circular economy. Document 52018AE0464, Luxembourg, City, Luxembourg. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52018AE0464&from=EN

Jaiboon, P. 2015. Biogas producing from dung with barnyard grass. The 8th Thailand Renewable Energy for Community Conference, 4-6 November 2015, Pathumthani, Thailand, 66-68.

Jantankaew, P., and Soonthornphisaj, N. 2023. Data analytics for maize price prediction using regression algorithms. KKU Research Journal. 23(2): 92-106.

Kahyani, A., Ghorbani, G.R., Alikhani, M., Ghasemi, E., Sadeghi-Sefidmazgi, A., Beauchemin, K.A., and Nasrollahi, S.M. 2019. Performance of dairy cows fed diets with similar proportions of undigested neutral detergent fiber with wheat straw substituted for alfalfa hay, corn silage, or both. Journal of Dairy Science. 102(12): 10903-10915.

Kato, J. 2022. Grow Pakchong 1 super Napier for improved livestock production and income generation. Retrieved on September 1, 2021 from https://www.harvestmoney.co.ug/grow-pakchong-1-super-napier-for-improved-livestock-production-and-income-generation/.

Klopfenstein, T.J., Erickson, G.E., and Berger, L.L. 2013. Maize is a critically important source of food, feed, energy and forage in the USA. Field Crops Research. 153: 5-11.

Kolk, B. 2020. The future of circular agriculture in the Netherlands. Master Dissertaton. Wageningen University, the Netherlands.

Laerd Statistics. 2018. Multiple regression analysis using SPSS statistics. Retrieved on September 1, 2021 from https://statistics.laerd.com/spss-tutorials/multiple-regression-using-spss-statistics.php.

Li, W., Gu, X., Du, Y., Zheng, X., Lu, S., Cheng, Z., Cai, W., and Chang, T. 2023. Optimizing nitrogen, phosphorus, and potassium fertilization regimes to improve maize productivity under double ridge-furrow planting with full film mulching. Agricultural Water Management. 287: 108439.

Mazurkiewicz, J., Marczuk, A., Pochwatka, P., and Kujawa, S. 2019. Maize straw as a valuable energetic material for biogas plant feeding. Materials. 12: 3848.

Meteorological Information Research and Development. 2023. Effective rainfall in Chang Mai (in Thai). Retrieved on June 15, 2021 from http://www.rnd.tmd.go.th/.

Mohammed, M. 2021. Empirical analysis of the factors that affecting maize production of farmers among smallholders: the case of Eastern Oromia, Ethiopia. Turkish Journal of Agriculture-Food Science and Technology. 9(1): 137-145.

Mupangwa, W., Thierfelder, C., Cheesman, S., Nyagumbo, I., Muoni, T., Mhlanga, B., Mwila, M., Sida, T.S., and Ngwira, A. 2019. Effects of maize residue and mineral nitrogen applications on maize yield in conservation-agriculture-based cropping systems of Southern Africa. Renewable Agriculture and Food Systems.35(3):322-335.

National Bureau of Agricultural Commodity and Food Standards. 2010. Good agricultural practice for maize. Thai Agricultural Standard TAS4402-2010. Ministry of Agriculture and Cooperatives, Bangkok, Thailand.

National Research Council. 2001. Nutrient requirements of dairy cattle. 7th revised ed. National Academy Press, Washington DC, USA.

National Research Council. 2016. Assessment of the biogas potential from agricultural waste in northern Thailand (in Thai). Executive Summary, National Research Council of Thailand (NRCT), Thailand. https://erdi.cmu.ac.th/download/publications/summary_report.pdf.

Niedbała, G. 2018. Application of multiple linear regression for multi-criteria yield prediction of winter wheat. Journal of Research and Applications in Agricultural Engineering. 63: 125-131.

Office of Agricultural Economics. 2020. Agricultural statistics of Thailand 2020. Ministry of Agriculture and Cooperatives. https://www.oae.go.th/assets/portals/1/files/jounal/2564/yearbook2563.pdf.

Organics Group. 2022. Environmental protection biogas and environmental protection. Retrieved on September 2, 2021 from https://organicsbiogas.com/biogas/.

Pattamanont, J., Nutdechanan, J., Vangtal, A., Maneetup, C., and Ajariyakhajorn, K. 2022. Towards sustainability of the daily industry in Thailand. FFTC Agricultural Policy Platform, Food and Fertilizer Technology Center for the Asian and Pacific Region, Taipei, Taiwan.

Pathanaissaranukool, W., Polprasert, S., and Neamhom, T. 2023. Carbon smart agriculture: low carbon emissions and higher economic benefits of maize production in Thailand. International Journal of Environmental Science and Technology. 20: 6003-6014.

Piekutowska, M., Niedbała, G., Piskier, T., Lenartowicz, T., Pilarski, K., Wojciechowski, T., Pilarska, A.A., and Czechowska-Kosacka, A. 2021. The application of multiple linear regression and artificial neural network models for yield prediction of very early potato cultivars before harvest. Agronomy. 11: 885.

Phimphakarn, W., Suksatit, P., Poolsawad, N., and Chinda, T. 2021. An application of biological circularity in broiler feed production. The 8th Burapha University International Conference, 3 September 2021, Chonburi, Thailand, 2-12.

Pornmeeyoo, S. 2015. Effect of cow manure, compost and chemical fertilizers on water convolvulus (Ipomoea Aquatica) production. The 2nd STOU Graduate Research Conference, 4-5 September 2015, Nonthaburi, Thailand. 1-12.

Punyalue, A., Jongjaidee, J., Jamjod, S., and Rerkasem, B. 2018. Legume intercropping to reduce erosion, increase soil fertility and grain yield, and stop burning in highland maize production in Northern Thailand. Chiang Mai University Journal of Natural Sciences. 17(4): 265-274.

Rayne, N., and Aula, L. 2020. Livestock manure and the impacts on soil health: a review. Sustainability. 4(4): 64.

Rocchi, L., Paolotti, L., Cortina, C., Fagioli, F., and Boggia, A. 2021. Measuring circularity: An application of modified material circularity indicator to agricultural systems. Agricultural Food Economics. 9(1): 9.

Rusinamhodzi, L., Wijk, M. T., Corbeels, M., and Rufino, M.C. 2015. Maize crop residue uses and trade-offs on smallholder crop-livestock farms in Zimbabwe: economic implications of intensification. Agriculture, Ecosystems and Environment. 214: 31-45.

Sathya, P. and Gnanasekaran, P. 2023. Paddy yield prediction in Tamil Nadu Delta region using MLR-LSTM model. Applied Artificial Intelligence. 37(1): e2175113.

SCG. 2023. Why circular economy important now? Retrieved on June 20, 2021 from https://www.scg.com/sustainability/circular-economy/en/scg-circular-way/.

Shaibur, M., Husain, R.H., and Arpon, S.H. 2021. Utilization of cow dung residues of biogas plant for sustainable development of a rural community. Current Research in Environmental Sustainability. 3: 100026.

Shapovalov, Y., Zhadan, S., Bochmann, G., Salyuk, A., and Nykyforov, V. 2020. Dry anaerobic digestion of chicken manure: A review. Applied Science. 10(21): 7825.

Shastry, A., Sanjay, H.A., and Bhanusree, E. 2017. Prediction of crop yield using regression techniques. International Journal of Soft Computing. 12: 96-102.

Silva, M.S., Jobim, C.C., Poppi, E.C., Tres, T.T., and Osmari, M.P. 2015. Production technology and quality of corn silage for feeding dairy cattle in Southern Brazil. Revista Brasileira de Zootecnia. 44(9): 303-313.

Srichart, A. 2016. Study of biogas production from layer chicken manure by modified covered lagoon reactor. Farm Engineering and Automation Technology Journal. 2: 107-166.

Srisaikham, S., and Lounglawan, P. 2020. Utilization of sunnhemp meal in beef cattle diet supplemented with urea-treated rice straw. Chiang Mai University Journal of Natural Sciences. 19(4): 879-899.

Srisaikham, S., and Lounglawan, P. 2021. Nutrient yield of brown hemp and its utilization as protein source in concentrate on Brahman×Thai-Native cattle performances. Chiang Mai University Journal of Natural Sciences. 20(1): e2021006.

Supasri, T., Itsubo, N., Gheewala, S.H., and Sampattagul, S. 2021. Life cycle assessment of maize cultivation and biomass utilization in northern Thailand. Scientific Reports. 11: 24393.

Technology Chaoban. 2021. Fresh corn with pods a high-value food crop in cattle farms (in Thai). Retrieved on August 15, 2021 from https://www.technologychaoban.com/bullet-news-today/article_164352.

Thai Feed Mill. 2021. Feed consumption. Retrieved on August 15, 2021 from https://www.thaifeedmill.com/wp-content/uploads/2020/12/Feed-consumtion-2000-2021.pdf.

Tian, S.Z., Liu, Z., Wang, B.W., Wang, Y., Li, Z.J., Lal, R., and Ning, T.Y. 2016. Balancing the use of maize residues for soil amendment and forage. Plant, Soil, and Environment. 62(11): 490-496.

Tofa, A.I., Kamara, A.Y., Babaji, B.A., Aliyu, K.T., Ademulegun, T.D., and Bebeley, J.F. 2022. Maize yield as affected by the interaction of fertilizer nitrogen and phosphorus in the Guinea savanna of Nigeria. Heliyon. 8(12): e11587.

University of Helsinki. 2023. Biological and technical cycles. Retrieved on June 10, 2021 from https://blogs.helsinki.fi/inventionsforcirculareconomy/circular-economy/biological-and-technical-cycles/.

Wijaya, A.S. 2018. Biogas production from co-digestion of livestock manure with lignocellulosic biomass. Master Thesis, Prince of Songkla University, Songkla, Thailand.

OPEN access freely available online

Natural and Life Sciences Communications

Chiang Mai University, Thailand. https://cmuj.cmu.ac.th

Nongnuch Poolsawad1, Weerapattra Phimphakarn2, Prakaytham Suksatit1, and Thanwadee Chinda2, *

1 Technology and Informatics Institute for Sustainability, National Metal and Materials Technology Center, National Science and Technology Development Agency, Pathum Thani, 12120, Thailand.

2 School of Management Technology, Sirindhorn International Institute of Technology, Thammasat University, Pathum Thani, 12120, Thailand.

Corresponding author: Thanwadee Chinda, E-mail: thanwadee@siit.tu.ac.th

Total Article Views

Editor: Tonapha Pusadee,

Chiang Mai University, Thailand

Article history:

Received: June 12, 2023;

Revised: November 24, 2023;

Accepted: December 12, 2023;

Online First: December 19, 2023