Effects of Electrolyzed Reducing Water on Pesticides Reduction and Postharvest Qualities in Cherry Tomato

Wanwarang Pattanapo*, Kanda Wanchai and Usawadee ChanasutPublished Date : August 8, 2023

DOI : https://doi.org/10.12982/NLSC.2023.056

Journal Issues : Number 4, October-December 2023

Abstract This study investigated the effect of electrolyzed reducing water (ERW) on the reduction of profenofos (PF) and carbendazim (CBZ) residue of cherry tomato (Solanum lycopersicum var. cerasiforme). Organic tomato were soaked with pesticides solution (PF and CBZ) at 5 mg L-1, then air dried at room temperature. Thereafter, the treated fruits were washed with ERW at different concentrations (50, 100, 250, and 500 mg L-1) for various times (10, 20, and 30 min). The result found that the removal percentages of standard profenofos and carbendazim were significantly induced with ERW 500 mg L-1 for 20 min. Wherewith, the profenofos released the substance to pyrocatechol and 4-Methylphenol (p-Cresol), and carbendazim was degraded to a N-Acetyl-2,6-diethylaniline. The removal percentage of profenofos and carbendazim residues in tomato was found to be possible to effectively reduce residues 71.54% and 80.49%, respectively. On the other hand, distilled water (DW) could achieve removal of only 21.67%. The quality of the tomato stored at 25ºC for 8 days showed that not significant changes in weight loss, firmness, total soluble solids (TSS), titratable acidity (TA), lycopene content, and visual appearance for both pesticides.

Keywords: Electrolyzed reducing water, Profenofos, Carbendazim, Cherry tomato

Funding: The authors are grateful for the research funding provided by the Chiang Mai University, Chiang Mai, Thailand.

Citation: Pattanapo, W., Wanchai, K., and Chanasut, U. 2023. Effects of electrolyzed reducing water on pesticides reduction and postharvest qualities in cherry tomato. Natural and Life Sciences Communications. 22(4): e2023056.

INTRODUCTION

Consumers are becoming increasingly concerned about food safety and health, with many actively seeking out information and products that align with their values. In a survey conducted by the International Food Information Council (IFIC) in 2021, 69% of respondents reported that food safety was their top concern when purchasing food, followed closely by nutrition and health (International Food Information Council, 2021). Fresh vegetables are highly beneficial for human health, they are major source of vitamins and nutrients. Cherry tomato (Solanum lycopersicum L. var. cerasiforme) is one of the popular tomato varieties in Thailand which is locally consumed and exported. They are known for their nutritional properties, including high levels of vitamins, minerals, and antioxidants, especially vitamins A, C, E, rich in carotenoids, like lycopene, phenolic compounds, folate flavonoids, and potassium (Mangels et al., 1993; Beecher, 1998; Leonardi et al., 2000; Sahlin et al., 2004). Nevertheless, in 2020, Thai Pesticide Alert Network reported that they found 100% residues in tomato samples there (Thai Pesticide Alert Network, 2022). The report showed the pesticide residue mostly found in tomato fruit were carbendazim and fungicide. In according to a study published in the journal Food Additives and Contaminants: Part B in 2020, carbendazim and profenofos residues were detected in tomato sampled from markets in Thailand. The study analyzed 210 tomato samples collected from eight different provinces in Thailand and found that 10% of the samples contained carbendazim residues above the maximum residue limit (MRL) set by the Thai FDA, while 4.8% of the samples contained profenofos residues above the MRL. Similarly, Govinda et al., (2019) that found the pesticide residues in tomato in range 13.1-3465 µg kg-1. The use of certain pesticides and fungicides can lead to a reduction in the nutritional quality of tomato. For example, carbendazim has been shown to reduce the levels of antioxidants, phenolics, and flavonoids in tomato fruits. Profenofos has also been found to decrease the nutritional quality of tomato by reducing their antioxidant capacity and ascorbic acid content. (Abou-Donia et al., 2021; Ali et al., 2019). Furthermore, consumption of tomato containing these residues can have adverse effects on human health, such as neurological and developmental disorders, reproductive problems, and increased risk of cancer (Kim et al., 2017).

There are different approaches to clean the agricultural products by varieties of chemical removal. There were proposed as tap water, washing with salt, washing in potassium permanganate, ozone (O3), ultraviolet (UV) irradiation, ultrasound (US) and plasma, (Sun et al., 2021; Klinhom et al., 2008; Hongsibsong, and Sapbamrer, 2018; Zheng et al., 2019; Ranjitha et al., 2019) Currently, the advanced oxidation processes (AOPs) have been proposed for removing pesticide residues from fruits and vegetables such as electrolyzed water (EW). It is a green technique for food sterilization and disinfection in Japan in 2002 (Al-Haq et al., 2002; Huang et al., 2008). The EW produced by NaCl solution in an electrolytic chamber with anode and cathode. Electrolyzed reducing water (ERW) is generated from the cathode side. It may also be able to reduce the residues through alkaline hydrolysis. Moreover, it was found that electrolyzed water is an effective treatment to degrade the insecticide residues on agricultural products. For example, Liu et al., (2021) also found that washing fresh-cut cabbages, broccoli and color peppers by Alkaline electrolyzed water (AlEW) and acidic electrolyzed water (AEW) could reduce pyrethroid organophosphates, and fungicides. Pattanapo et al., (2020) found that various ACC in AlEW by 30 mins could removal the carbendazim residues in cherry tomato. In addition, Yang et al. (2020) evaluated the degradation effect of AIEW on 10 pesticides from the kumquats. The study demonstrated that pH 12 of AlEW was removing 10 kinds of pesticide residues. At present, the mechanism of degradation of pesticide residues in fruits and vegetable by Electrolyzed water is unclear. Therefore, the purpose of current study was to efficacy of ERW for removing the profenofos and carbendazim from cherry tomato fruit, include to identify the degradation products of pesticides after treated ERW and their effect on quality of postharvest during storage at 25ºC.

MATERIALS AND METHODS

Chemical preparation

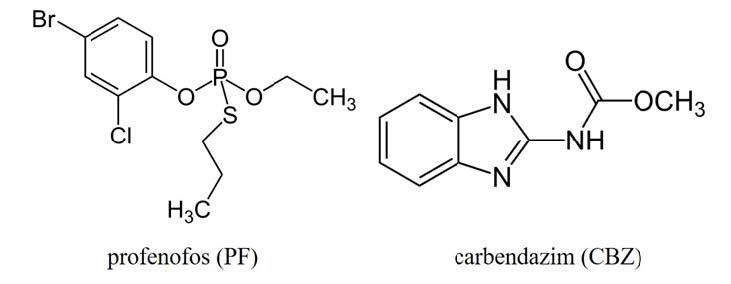

Standard profenofos (PF) and standard carbendazim (CBZ) were purchased from Ehrenstorfer™ with 99.0% purity. The structure of PF and CBZ is shown in Figure 1. Stock solution (1000 mg L-1) for the residue analysis was prepared in acetone. The solution was diluted with distilled water (DW) to the appropriate working concentration (5 mg L-1).

Figure 1. Structure of profenofos and carbendazim.

Electrolyzed reducing water preparation

The electrolyzed reducing water (ERW) was generated by electrolyzing 5% NaCl solution by mixing 500 g NaCl in 10 L of distilled water (DW) in an electrolytic chamber with an anode and cathode. The electrodes were then subjected to a direct current of 8 A and 8 V using a DC power source for 1 hour. The ERW was in the cathode side. The pH and Oxidation Reduction Potential (ORP) were measured using a pH/ion meter. The properties of the ERW were determined immediately after preparation.

Effects of electrolyzed reducing water on the removal of standard profenofos and carbendazim at several concentrations and various times

The pH and Oxidation Reduction Potential (ORP) of ERW at 50, 100, 250 and 500 mg L-1 were measured using a pH/ion meter. The properties of the ERW were determined immediately after preparation. The pH and ORP values of ERW measure for select optimum concentration for washing pesticides. Tyler et al., (2022) report that the pH of ERW may range from slightly alkaline to pH 11.5, the ORP may range from −300 mV to over −800 mV. And the optimum conditions for PF and CBZ reduction using ERW were determined at various times. Concentrations of PF and CBZ standard solution on 10 mL were prepared in the flask and added to 20 mL of ERW at 50, 100, 250, and 500 mg L-1 for different exposure times (10, 20, and 30 min). Samples were taken out periodically and compared with the control, which was distilled water (DW). The degradation percentage of the PF samples was examined by gas chromatography-mass spectrometer (GC/MS) (Agilent 7000C Triple Quad), and CBZ was determined by liquid chromatograph (LC/MS) (Agilent 1290 Infinity II). The solutions were analyzed in five replicates. Data were calculated to find the degradation percentage of each pesticide (PF and CBZ) using the following equation:

Pesticide degradation (%) = [(C0-Ct)/C0] x 100

where C0 is the pesticide concentration at the initial time, and Ct is the pesticide concentration at the treatment time

Extraction and analyzation of profenofos and carbendazim residues in cherry tomato

ERW 500 mg L-1 for 20 min can be selected as the optimum condition for the removal of PF and CBZ residue. The PF and CBZ residues in cherry tomato were extracted with the QuEChERS extraction kit (Agilent Quick, USA.) and homogenized according to Anastassiades et al., (2003). Tomato samples (5 g) were cut into small pieces and extracted with 15 mL acetronitrile in a 50 mL teflon centrifuge tube. The Q-sep QuEChERS extraction salt was added, and immediately shaken on a vortex mixer for 2 min, then centrifuged at 4,000 rpm for 5 min. Additionally, a clean-up step was conducted in the optimization procedure. After the centrifugation step, the supernatant (about 5 mL) was transferred into a QuEChERS Dispersive SPE 15 mL. After shaking for 2 min and centrifugation at 8,000 rpm for 12 min, 1 mL of the supernatant was taken, and filtered through a 0.45 μm nylon filter. The samples were evaluated via GC/MS analysis (Agilent Technologies model 7000C Triple Quad). The GC/MS was carried out using a fused silica column 2 of DP-5MS, UI, 5% Phenyl Methyl Siloxane, dimensions of 15 m x 0.25 mm and 25 µm film thickness. The temperature regime was as follows: initial temperature at 60°C, increasing 12°C min-1 to the final temperature of 280°C. A purified helium carrier gas was used at a flow rate of 3.6 mL min-1. The detector temperature was 250°C. Sample solution (1 µL) was injected in splitless mode and quantification of PF was performed using standard PF; each analysis was done with 5 replicates. The CBZ samples were evaluated via LC/MS analysis, using an Agilent 1290 Infinity II with a Poroshell 120 EC-C18 analytical column of 2.1 mm x 100 mm, and 2.7 μm particle size. The detector was as follows: ion source dual AJS ESI positive; gas temp 150°C; drying gas 10 L min-1; nebulizer 45 psig fragmentor 125V. A mobile phase gradient (A is water with 5 mM NH4 formate and 0.1% formic acid: B is with 5 mM NH4 formate and 0.1% formic acid MeOH) 0 - 1 min (A: 95%; B: 5%), 1 - 10 min (A: 5%; B: 95%), 10-15 min (A: 95%; B: 5%) was used at a flow rate of 0.4 mL min-1. The temperature column was 25ºC. Sample solution (1.0 µL) was injected in 3 µL and the quantification of CBZ was performed using CBZ standard.

Effects of electrolyzed reducing water on the degradation product, the removal percentage, and postharvest quality changes in cherry tomato

Organic tomato at maturity (40-45 days after flowering) from Chiang Mai Province, Thailand. Fruit was transported to the Postharvest Technology Research Center, Faculty of Agriculture, Chiang Mai University. Fruit were carefully selected for uniformity of shape, color and size, and insect bites. Blemished or diseased fruit will be discarded. The uniform fruits were selected and kept at room temperature (25°C) for further experiments. Five grams of organic tomato samples were treated with 5 mg L-1 of pesticide (PF or CBZ) and then air dried at room temperature. Thereafter, the treated fruits were washed in ERW 500 mg L-1 for 20 min. After that, they were divided into 2 groups to determine degradation product and percentage removal of pesticide residues in the first group, and examination of fruit quality in the second group while in storage for 8 days at 25°C.

The degradation product and the removal percentage in cherry tomato

PF and CBZ residues of tomato in first group were extracted with the Agilent Quick, Easy, Cheap, Effective, Rugged and Safe (QuEChERS) extraction kit. Then the samples were analyzed for PF residues by GC/MS to determine the removal percentage of PF. The degradation products were determined by liquid chromatography tandem mass spectrometry ((LC-MS/MS) Agilent 1260 Infinity II with QTOF Model 6545). The electrospray ionization (ESI) source was operated in positive ionization mode and its parameters were as follows: temperature: 150ºC, gas flow: 10 L min-1, nebulizer gas: 45 psig, capillary voltage: 3500 V. Nitrogen was served as the nebulizer and collision gas. Multiple reaction monitoring (MRM) was used, with a delta time of 1.0 min for each analyte.

Postharvest quality changes in cherry tomato

Tomato in second group that stored at 25°C were taken on day 0, 2, 4, 6, and 8 to determine the fruit quality. The percentage of weight loss, firmness, total soluble solids (TSS), titratable acidity (TA), lycopene content, and visual appearance of wilting were measured.

Weight loss

Weight loss percentage was determined by weighing the whole fruits before and after storage at 25°C for 8 days. The results were calculated using the following equation:

Weight loss (%) = Fruit weight before storage – Fruit weight after storage ×100

Fruit weight before storage

Firmness

Texture Analyzer (TA-XT 21/50) with the pressing probe diameter of 100 mm P100 (100 mm compression platen) was set to 15 mm from the samples. The velocity of the probe was set at 1.0 mm sec-1. The force was set at 8 N. The fruit samples were analyzed with 5 replications/treatment.

Total soluble solids (TSS, %Brix)

The tomato juice was measured for TSS with a digital refractometer (Model PR-101 Atago, Tokyo, Japan) at room temperature (AOAC, 2005 method No. 940.31). The TSS had 5 replications per treatment. The values were expressed as a percentage of total soluble solids.

Titratable acidity (TA)

The TA was determined by diluting 5 mL of tomato juice to 50 mL with distilled water and titrating with 0.1 M NaOH to an end point of 8.2 using a pH meter (Model Titroline Easy, Schott, Germany). Each treatment was measured in 5 replications. TA was expressed as percentage of citric acid per 50 mL fruit juice, using the following equation:

TA (%) = normality of NaOH (0.1 N) × vol. NaOH × equi.wt. of citric acid (0.070) × 100

Volume of sample

Lycopene content

The 0.5 g of tomato flesh was extracted with 50 mL of mixed solution consisting of Hexane : ethanol : acetone with a ratio of 2 : 1 : 1, and the extraction was performed for 15 min under light-free conditions. Then, 7.5 mL of distilled water was added for 10 min. The extract was then analyzed for its lycopene content using a spectrophotometer. The remaining extract was taken for measurement of the lycopene content using a spectrophotometer at 503 nm, using a blank hexane solution, then calculation of the value was performed using the following equation:

Lycopene (mg kg FW-1) = A503 × 171.7 × W

where W is the weight of the extracted tomato (g)

Visual appearance of wilting

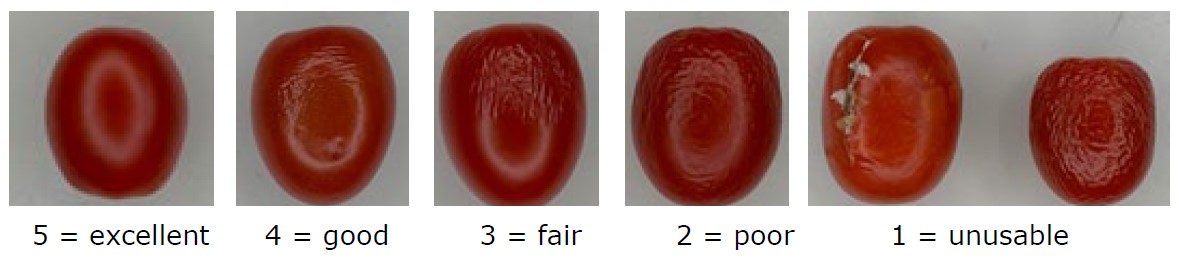

Tomato fruits were rated for visual appearance of wilting, using a scale of 1 to 5 in which 5 = excellent, 4 = good, 3 = fair, 2 = poor and 1 = unusable. Fruit appearance was rated “unacceptable” when the score was below 3.

Figure 2. Visual appearance of wilting score in cherry tomato.

Statistics description.

Statistical software (SPSS version 17.0) was used to perform statistical analyses. The data were analyzed using one-way analysis of variance (ANOVA). Means were considered significantly different at P < 0.05.

RESULTS

Effects of electrolyzed reducing water on the removal of standard profenofos and carbendazim at several concentrations and various times

The use of pH and oxidation-reduction potential (ORP) values in ERW are optimum value at ERW 500 mg L-1, pH 11.51 and ORP 415 mV (Table 1) follow by Tyler et al., (2022). The maximum reduction of standard PF residues was 6.66%, after treatment with ERW 500 mg L-1 for 30 min compared with the control, but there was no significant difference (P <0.05) compared to those treated with ERW 500 mg L-1 for 20 min. Similar results were found in standard CBZ. The maximum reduction of standard CBZ residues was 99.89%, after treatment with ERW 500 mg L-1 for 30 min, but there was no significant difference (P <0.05) in treatment with ERW 500 mg L-1 (Table 2).

Table 1. The pH and ORP values of electrolyzed reducing water.

|

Treatments |

pH |

ORP (mV) |

|

Control (DW) |

7.00 |

587 |

|

ERW 50 mg L-1 |

10.96 |

435 |

|

ERW 100 mg L-1 |

11.26 |

428 |

|

ERW 250 mg L-1 |

11.46 |

422 |

|

ERW 500 mg L-1 |

11.51 |

415 |

Table 2. Removal percentage of standard PF and CBZ after washing with several concentrations of ERW at different exposure times.

|

Treatments |

PF reduction (%) |

CBZ reduction (%) |

||||

|

10 min |

20 min |

30 min |

10 min |

20 min |

30 min |

|

|

Control (DW) |

0.22 bc ± 3.88 |

0.25 cdef ± 1.83 |

0.55 bcd ± 1.81 |

0.00 f ± 0.00 |

0.80 e ± 1.04 |

1.06 e ± 0.52 |

|

ERW 50 mg L-1 |

3.44 cdef ± 2.70 |

4.00 b ± 1.99 |

5.96 e ± 0.00 |

83.71 de ± 0.74 |

86.54 d ± 0.80 |

85.58 cd ± 0.33 |

|

ERW 100 mg L-1 |

1.12 cdef ± 2.06 |

3.15 c ± 2.81 |

5.13 de ± 1.94 |

82.70 e ± 0.60 |

90.22 c ± 0.71 |

91.58 b ± 0.99 |

|

ERW 250 mg L-1 |

3.71 cdef ± 1.70 |

5.72 c ± 1.61 |

6.53 e ± 0.43 |

89.39 c ± 2.36 |

96.32 b ± 0.88 |

99.85 a ± 0.34 |

|

ERW 500 mg L-1 |

5.19 a ± 0.99 |

5.97 a ± 1.25 |

6.66 a ± 0.65 |

97.93 ab ± 0.62 |

99.65 a ± 0.00 |

99.89 a ± 0.00 |

Note: The data followed by the same letter within the column are not significantly different by DMRT (P ≤0.05).

Effects of electrolyzed reducing water on the degradation product, the removal percentage, and postharvest quality changes in cherry tomato

The degradation product and the removal percentage in cherry tomato

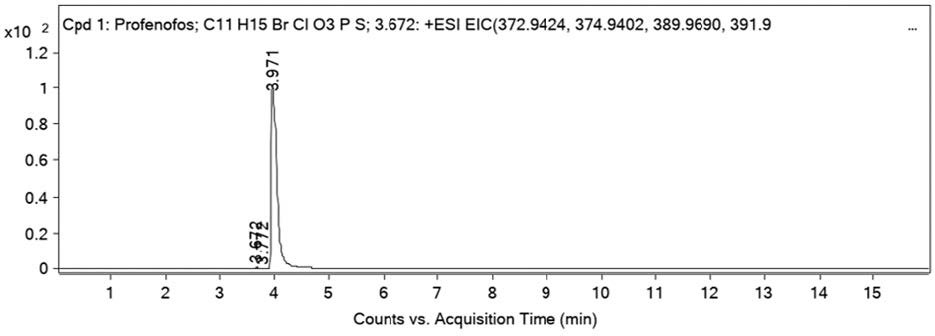

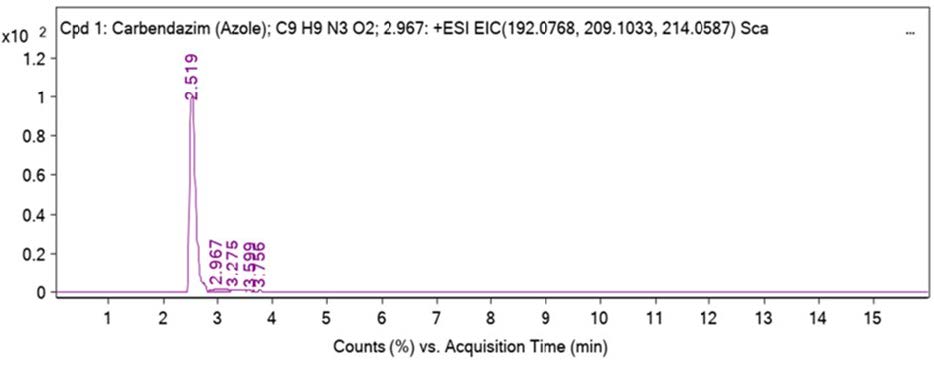

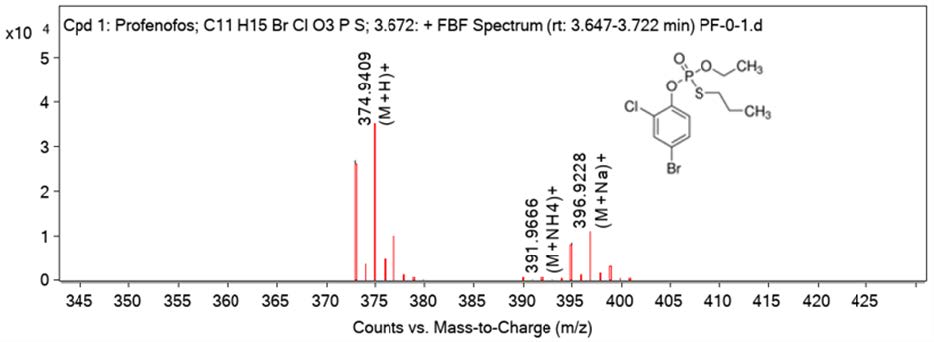

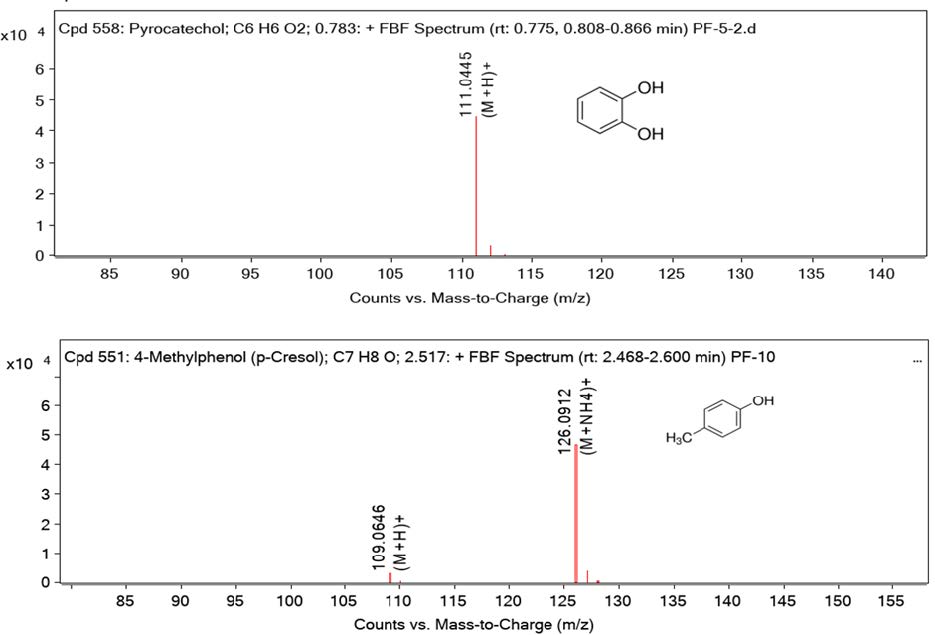

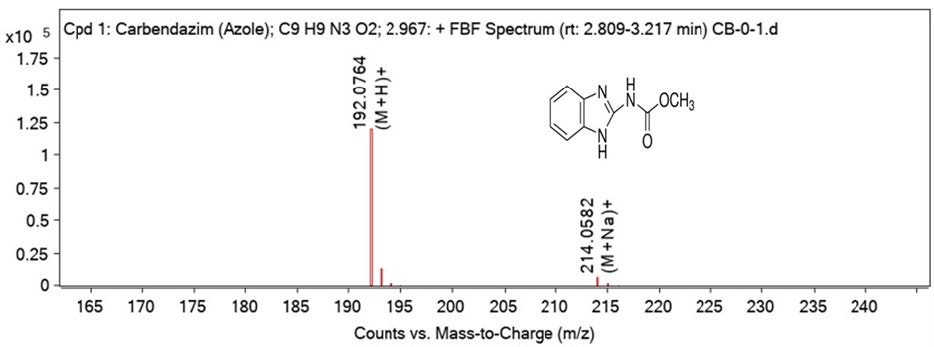

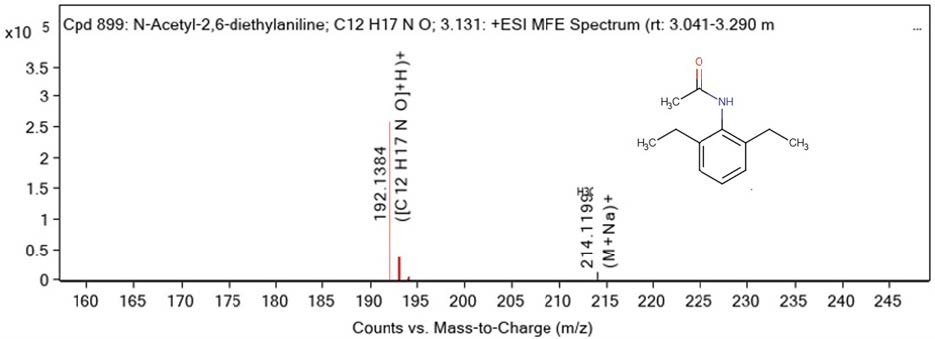

The standard PF and CBZ solutions after washing with ERW 500 mg L-1 for 20 min were analyzed with LC-MS/MS. The results showed the chromatograms of standard PF and CBZ before treatment with ERW 500 mg L-1 in Figure 3 and Figure 4. The analyzed mass spectra of the PF before and after washing with ERW 500 mg L-1 are shown in Figure 5 and Figure 6. Whereas the mass spectra of the CBZ before and after washing with ERW 500 mg L-1 are shown in Figure 7 and Figure 8. They were confirmed by the pesticide Mass Spectral Library.

Figure 3. Chromatogram of profenofos before washing with ERW 500 mg L-1

Figure 4. Chromatogram of carbendazim before washing with ERW 500 mg L-1

Figure 5. Mass spectrum peaks of profenofos before washing with ERW 500 mg L-1

Figure 6. Mass spectrum peaks of profenofos after washing with ERW 500 mg L-1 for 20 min

Figure 7. Mass spectrum peaks of carbendazim before washing with ERW 500 mg L-1

Figure 8. Mass spectrum peaks of carbendazim after washing with ERW 500 mg L-1 for 20 min

The PF decomposition by ERW may possibly be explained from the fragment ions accompanied by released anions. It could be a possible pathway from this experiment (Figure 9A). The degradation products of PF (C11H15BrClO3PS = 373.63 g mol-1) after washing ERW might be pyrocatechol (C6H6O2 = 111.04 g mol-1) and 4-Methylphenol (p-Cresol) (C7H8O = 126.09 g mol-1). Furthermore, the possible CBZ degradation can be seen in Figure 9B. The first product from CBZ (C9H9N3O2 = 191.19 g mol-1) transformation might be N-Acetyl-2,6-diethylaniline (C12H17NO) = 191.26 g mol-1.

Figure 9. Possible profenofos (A) and carbendazim (B) degradation pathway after washing with ERW 500 mg L-1 for 20 min.

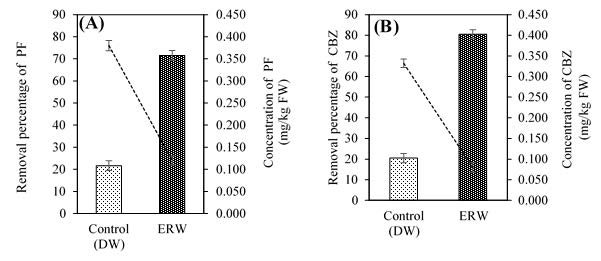

Tomato were washed by ERW 500 mg L-1 for 20 min to remove the residual PF. It was found that the PF residues on flesh tomato showed a removal percentage of PF residues of 71.54% which was significantly (P<0.05) different when compared with the control (21.67%). The PF residues were eliminated from 1 mg kg FW-1 to 0.1200 mg kg FW-1 with washing by ERW 500 mg L-1 compared with the control that disposed of residues to 0.3800 mg kg FW-1 (Figure 10A). Moreover, the maximum degradation of CBZ residues on the tomato was 80.49%. Treatment with ERW 500 mg L-1 eliminated CBZ residues from 1 mg kg FW-1 to 0.0796 mg kg FW-1 when compared to those of the control which was sanitized in distilled water (Figure 10B). All residues were below MRL levels by washing the tomato with ERW 500 mg L-1 for 20 min. The amounts of both chemical residues in tomato were not over the maximum residue limits (MRLs) determined by National Bureau of Agricultural Commodity and Food Standards, (2022).

Figure 10. The removal percentage of profenofos (A) and carbendazim (B) residues and concentrations in cherry tomato after washing with ERW 500 mg L-1 for 20 min

Postharvest quality changes in cherry tomato

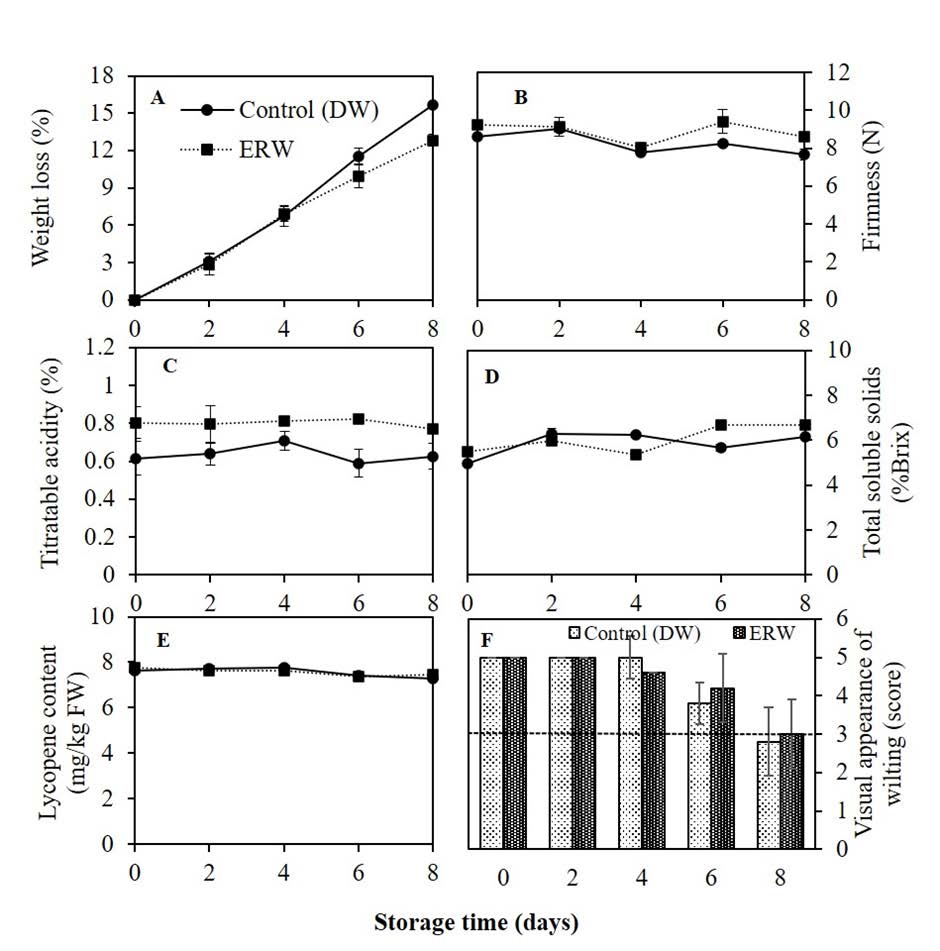

The postharvest quality changes in the cherry tomato after using the ERW 500 mg L-1 for 20 min were compared with a controlled method. All treatments were kept at 25ºC for 8 days. The results showed that the washed PF with ERW in tomato fruit had a percentage of weight loss lower than the control on day 8. The results were 15.62 ± 0.05% and 12.83 ± 0.45% in ERW washed fruits and the control, respectively (Figure 11A). It was also found that the firmness of tomato that were treated with PF showed a trend of decreasing during storage. There were no difference in the firmness of tomato among those washed with ERW and the control. The results were 9.22 ± 0.03 to 8.63 ± 0.23 N and 8.63 ± 0.13 to 7.65 ± 0.28 N in ERW washed fruits and the control, respectively (Figure 11B). The percentages of titratable acidity in all treatments were not significantly different. The results were 0.80 ± 0.08 to 0.07 ± 0.01% and 0.61 ± 0.09 to 0.62 ± 0.07% in ERW washed fruits and the control, respectively (Figure 11C). The total soluble solids of tomato barely changed during storage. The levels of percentage of total soluble solids in ERW washed fruits and the control were in the range of 5.50 ± 0.07 to 6.70 ± 0.07%Brix and 4.96 ± 0.09 to 6.14 ± 0.09%Brix, respectively (Figure 11D). Likewise, the lycopene contents in all treatments were not significantly different. The results were 7.74 ± 0.01 to 7.44 ± 0.01 mg kg FW-1 and 7.63 ± 0.02 to 7.26 ± 0.03 mg kg FW-1 in ERW washed fruits and the control, respectively (Figure 11E). At the same time, the acceptance scores of visual appearances of wilting in cherry tomato after ERW treatment and the control still had the visual appearance acceptance scores over the minimum acceptance score (3.0) after storage for 1 to 6 days. They were lower than the minimum acceptance score at 8 days of storage in both treatments (Figure 11F).

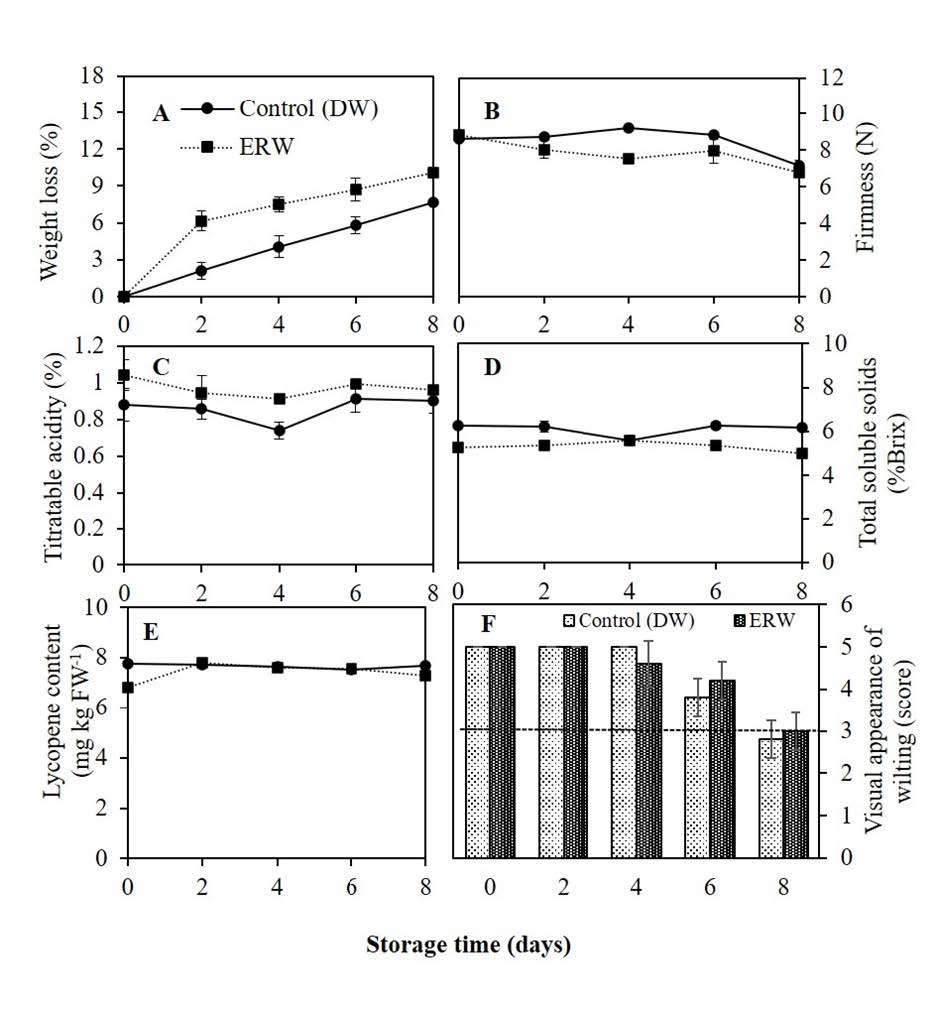

The results of fruit quality changes during storage at 25ºC in tomato washed in CBZ with ERW were similar to the PF. The weight loss of all treatments dramatically increased during storage. The results were 10.10% and 7.69% after washing with ERW and DW (control) on day 8, respectively (Figure 12A). It was also found that the firmness showed a trend of decreasing during storage. There were no difference in the firmness of tomato among treated ERW samples and the control (Figure 12B). The percentage of titratable acidity and the total soluble solids of tomato barely changed during storage (Figure 12C and 12D). Identically, the lycopene content after the ERW washing treatment fluctuated slightly, compared to the control (Figure 12E). Concurrently, in both treatments, the acceptance scores of visual appearances of wilting were lower than the limit of the scores (3.0) at 8 days of storage (Figure 12F).

Figure 11. Percentage of weight loss (A), firmness (B), total soluble solids (C), titratable acidity (D), lycopene content (E) and visual appearances of wilting (F) after washing the cherry tomato PF treated by ERW 500 mg L-1 for 20 min and storing at 25°C for 8 days.

Figure 12. Percentage of weight loss (A), firmness (B), total soluble solids (C), titratable acidity (D), lycopene content (E) and visual appearances of wilting (F) washing the cherry tomato CBZ treated by ERW 500 mg L-1 for 20 min and storing at 25°C for 8 days.

DISCUSSION

ERW remove different types of pesticide. CBZ was more effectively eliminated from cherry tomato than PF. Similarly, Yuan et al., (2021) studied the effect of electrolyzed water treatment to remove various pesticides in fresh-cut cabbage, broccoli, and color peppers. It was found that 100 mg L-1 AIEW for 20 min could more effectively remove almost all the pesticide residues in color peppers. In addition, Liu et al., (2021) investigated the effect of ERW for the removal the pesticides from fresh-cut cabbages, broccoli, and color peppers. The results showed that the ERW delivered good removal on fungicides in all samples. Several factors lead to the degradation of pesticide residue, such as the physical and chemical properties of the washing solution, the pesticide physicochemical characteristics, and the vegetable matrix surface texture. In this research, tomato have a wax layer on the skin that affects the efficiency of pesticide removal. The pesticide adhesion between the matrix surface and molecules represents adsorption behavior by the adsorbate and adsorbent (Bastien et al., 2017).

PF are organophosphorus pesticides, and have been widely reported in photolysis, thermal, hydrolysis and biodegradation effects. However, there has been no pertinent report on the oxidative degradation products of PF using ERW. Many reports showed the major by-product of PF was 4-bromo-2-chlorophenol (Xiangying et al., 2019; Ismail and Nasr, 2020; Li et al., 2023; Shalini and Chatterjee, 2021). They contain P = S and C = O double bonds, and AEW or EOW and AlEW or ERW can break those double bonds (Bhilwadikar et al., 2019). The disintegration of the ERW may be due to the reaction of the hydroxyl group with the electrophilic center of the studied molecules, whereas with the CBZ, the common function is the carbonyl. This group contains carbon in the alpha position with electron inequity, making the molecules more reactive towards nucleophiles. This reaction leads the way to formation of an organic salt, which is more soluble in the aqueous medium (Silvina et al., 2019). The ERW is more capable of degrading pesticides containing other free double bonds including C=O, C=N and N=C (Qi et al., 2018). Therefore, it is possible that the C=O was ruptured from CBZ.

Electrolyzed water (EW) could enhance the postharvest quality of fruit and vegetables, such as delaying senescence (Aday, 2016) Furthermore, it is used to reduce pesticide residues in fruits and vegetables (Qi et al., 2018). The overall postharvest quality of the PF and CBZ treated tomato fruit after cleaning with ERW in this research did not show significant differences during storage at 25ºC for 8 days. Likewise, Lin et al., (2006) found that EOW can reduce the dimethoate residue by up to 99.90%, which is better than the reduced ER water. The dimethoate residue was only 44.6%, but there was no difference. In any case, in the methamidophos group, both types of water could reduce the residue to 99.00%. Similarly, Islam et al., (2018) conducted an experiment washing cherry tomato with water that applied the EOW and compared with the tap water, showing no significant difference in retention quality such as loss of fresh weight, firmness, and lycopene content. Where the percentage of fresh weight loss is increased, this is due to the respiration and dehydration of the tomato fruit (Islam et al., 2016). The loss of firmness tends to increase as a result of enzyme activity. The decay of pectin, such as polygalacturonase and pectin methylesterase (Barbagallo et al., 2012), changes the color and lycopene content resulting from the process of respiration and ethylene production that affects the maturation process of fruit (Tzortzakis and Chrysargyris, 2017). This may be the result of electrolyte juice reducing the number of germs on the tomato fruit. For example, in cherry tomato, it was found that the use of electrolyte water can reduce the number of bacteria and reduce the incidence of rot in peaches. Water electrolytes are used as an extremely effective antimicrobial agent in many food industries and agricultural products. This efficiency is due to the inhibition of the growth of all microorganisms (microbiota) at the surface of the product. This is another reason for the longer shelf life of produce (Calvo et al., 2019).

However, the conclusions drawn with respect to the removal mechanism of various pesticides are still unclear. Consequently, further research may be needed to examine particular mechanisms for the degradation of pesticides, maybe applying the combination of EW with other processes and technologies to address the challenges of reduced efficacy of individual treatments and to improve the quality control effects during the storage of fruits and vegetables.

CONCLUSION

Electrolyzed reducing water (ERW) at 500 mg L-1 for 20 min was the most effective in reducing residual PF and CBZ in cherry tomato and the chemical residual amounts were below MRLs requirements.

ACKNOWLEDGMENTS

The authors thank the graduate school Chiang Mai University to provide the opportunity to get research fund. Also thanks to Postharvest Technology Research Center, Faculty of Agriculture, Chiang Mai University and Postharvest Technology Innovation Center, Ministry of Higher Education, Science, Research and Innovation for providing facilities for laboratory operation.

AUTHOR CONTRIBUTIONS

Wanwarang Pattanapo and Kanda Wangchai applied electrolyzed water in the condition of eliminated profenofos and carbendazim residue in cherry tomato. In addition, the authors designed and performed experiment works statistical analysis, visualization and writing manuscript. All authors have read and approved the final manuscript.

CONFLICT OF INTEREST

The authors declare that they hold no competing interests.

REFERENCES

Abou-Donia, M.A., Tohamy, A.A., and Ali, F.E. 2021. Effects of carbendazim fungicide on the nutritional quality of tomato (Solanum lycopersicum) fruits. Journal of Plant Protection Research. 61(1): 85-92.

Aday, M.S. 2016. Application of electrolyzed water for improving postharvest quality of mushroom. LWT-Food Science and Technology. 68: 44-51.

Al-Haq, M.I., Seo, Y., Oshita, S., and Kawagoe Y. 2002. Disinfection effects of electrolyzed oxidizing water on suppressing fruit rot of pear caused by Botryosphaeria berengeriana. Food Research International. 35(7): 657-664.

Ali, M.A., El-Harty, E.H., and Hassan, N. M. 2019. Effect of profenofos on the biochemical and nutritional composition of tomato plants. Journal of Environmental Science and Health, Part B. 54(4): 260-268.

Anastassiades, M., Steven, J.L., Darinka, S., and Frank, J.S. 2003. Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for determination of pesticide residue in produce. Journal of AOAC International. 86(2): 412-431.

Barbagallo, R.N., Chisari, M., and Caputa, G. 2012. Effects of calcium citrate and ascorbate as inhibitors of browning and softening in minimally processed ‘Birgah’ eggplants. Postharvest Biology and Technology. 73: 107-114.

Bastien, B., Sophie, H., Magali, B., Nathalie, T., and Fabienne, B. 2017. Theoretical study of the atrazine pesticide interaction with pyrophyllite and Ca2+ - Montmorillonite clay surfaces. Journal of Computational Chemistry. 38(3): 133-143.

Beecher, G.R. 1998. Nutrient content of tomato and tomato products. Biology and Medicine. 218(2): 98-100.

Bhilwadikar, T., Pounraj, S., Manivannan, S., Rastogi, N.K., and Negi, P.S. 2019. Decontamination of microorganisms and pesticides from fresh fruits and vegetables: A comprehensive review from common household processes to modern techniques. Comprehensive Reviews in Food Science and Food Safety. 18: 1003-1038.

Calvo, H., Redondo, D., Remon, S., Venturini, M.E., and Arias, E. 2019. Efficacy of electrolyzed water, chlorine dioxide and photocatalysis for disinfection and removal of pesticide residues from stone fruit. Postharvest Biology and Technology. 148: 22-31.

Govinda, B., Paul, Z., Kishor, A., Hans, G.J.M., Xiaomei, Y., and Violette, G. 2019. Pesticide residues in Nepalese vegetables and potential health risks. Environmental Research. 170: 511-521.

Hongsibsong, S., and Sapbamrer, R. 2018. Removal of organophosphorus pesticide residues in leaf and non-leaf vegetables by using ozone water. Chiang Mai Journal of Science. 45(4): 1759-1769.

Huang, Y.R., Hung, Y.C., Hsu, S.Y., Huang, Y.W., and Hwang, D.F. 2008. Application of electrolyzed water in the food industry. Food Control. 19(4): 329-345.

International Food Information Council. 2021. Food & Health Survey. [accessed 2023 April 10]. https://foodinsight.org/2021-food-health-survey/

Islam, M.Z., Mele, M.A., Baek, J.P., and Kang, H.M. 2016. Cherry tomato qualities affected by foliar spraying with boron and calcium. Horticulture, Environment and Biotechnology. 57(1): 46-52.

Islam, M.Z., Mele, M.A., Hussein, K.A., and Kang, H.M. 2018. Acidic electrolyzed water, hydrogen peroxide, ozone water and sodium lypochlorite influence quality, shelf life and antimicrobial efficacy of cherry tomato. Research Journal of Biotechnology. 13(4): 51-55.

Ismail, I.I., and Nasr, S.K. 2020. Thermal and photolysis degradation of three profenofos formulations Egyptian. Journal of Agricultural Research. 98(2): 348-358.

Kim. K., Kabir, E., and Jahan, S.A. 2017. Exposure to pesticides and the associated human health effects. Science of The Total Environment. 575: 525-535.

Klinhom, P., Halee, A., and Methawiwat, S. 2008. Reduction of methomyl and carbaryl residue in Chinese-kale by wash treatments. Kasetsart University Annual Conference, Bangkok, Thailand, January 29, - February 1, 2008; 437-446.

Leonardi, C., Ambrosino, P., Esposito, F., and Fogliano, V. 2000. Antioxidant activity and carotenoid and tomatine contents in different typologies of fresh consumption tomato. Journal of Agricultural and Food Chemistry. 48(10): 4723-4727.

Li, H., Chen, X., Zhang, X., Tang, Y., Yao, Y., Lin, T., and Zha, S. 2023. Zn-ZrMOF containing Lewis acid-base catalytic sites for hydrolysis and visual detection of profenofos. Sensors and Actuators B: Chemical. 375: 32902.

Lin, C.H., Tsai, P.J., Wu, C., Yeh, J.Y., and Saali, F.K. 2006. Evaluation of electrolysed water as an agent for reducing methamidophos and dimethoate concentrations in vegetables. Journal of Food Science and Technology. 41(9): 1099-1104.

Liu, Y., Wang, J., Zhu, X., Liu, Y., Cheng, M., Xing, W., Wan, Y., Li. N., Yang, L. and Song, P. 2021. Effects of electrolyzed water treatment on pesticide removal and texture quality in freshcut cabbage, broccoli, and color pepper. Food Chemistry. 353: 129408.

Mangels, A.R., Holden, J.M., Beecher, G.R., Forman, M.R., and Lanza, E. 1993. Carotenoid content of fruit and vegetables: An evaluation of analytic data. Journal of the American Dietetic Association. 93: 284-296.

National Bureau of Agricultural Commodity and Food Standards. 2022. Pesticide residues: Maximum residue limits, Thai agricultural standard TAS 9 0 0 2 -2 0 1 6, ministry of agriculture and cooperatives, published in the Royal Gazette Vol. 133 special section 288D [accessed 2022 Nov 22]. Available: http://www.acfs.go.th/standard/download/ MAXIMUM-RESIDUE-LIMITS.pdf.

Pattanapo, W., Whangchai, K., Uthaibutra, J., Pankasemsuk, T., and Chanasut, U. 2020. Effect of electrolyzed reducing water with various concentration on carbendazim removal in cherry tomato. International Journal of Geomate. 18: 54 - 59.

Qi, H., Huang, Q., and Hung, Y.C. 2018. Effectiveness of electrolyzed oxidizing water treatment in removing pesticide residues and its effect on produce quality. Food Chemistry. 239: 561-568.

Ranjitha, G.T.K., Gupta, V., and Mahendran, R. 2019. Effect of plasma activated water (PAW) on chlorpyrifos reduction in tomato. International Journal of Chemical Studies. 7 (3): 5000 - 5006.

Sahlin, E., Savage, G.P., and Lister, C.E. 2004. Investigation of the antioxidant properties of tomato after processing. Journal of Food Composition and Analysis. 17(5): 635-647.

Shalini, V., and Chatterjee, S. 2021. Biodegradation of profenofos, an acetylcholine esterase inhibitor by a psychrotolerant strain Rahnella sp. PFF2 and degradation pathway analysis. Biodegradation. 158: 105169.

Silvina, E.F., Daniel, E.B., Cristian, R., José, F.A., and Pablo, R.D. 2019. Conformation-independent quantitative structure-property relationships study on water solubility of pesticides. Ecotoxicology and Environmental Safety. 171(30): 47-53.

Sun, J., Jiang, X., Chen, Y., Lin, M., Tang, J., Lin, Q., Fang, L., Li, M., Hung, Y.C., and Lin, H. 2021. Recent trends and applications of electrolyzed oxidizing water in fresh food stuff preservation and safety control. Food Chemistry. 369: 130873.

Thai Pesticide Alert Network. 2022. Surveillance of pesticide residues in fruits and vegetables on 2020 [accessed 2022 Nov 22]. Available: https://www.thaipan.org/wp-content/uploads/2020/12/ thaipan_press_4-12-2563-last.pdf.

Tyler, W.L., Randy, S., and Kinji, O. 2022. Electrolyzed–reduced water: Review II: Safety concerns and effectiveness as a source of hydrogen water. International Journal of Molecular Sciences.23(23): 14508.

Tzortzakis, N., and Chrysargyris, A. 2017. Postharvest ozone application for the preservation of fruits and vegetable. Food Review International. 33(3): 270-315.

Xiangying, L., You, Z., Zhongqin, Z., Lang, P., Lifeng, H., Kailin, L., Xuguo, Z., and Lianyang, B. 2019. Photocatalytic degradation of profenofos and triazophos residues in the Chinese cabbage, Brassica chinensis, using Ce-doped TiO2. Catalysts. 9(3): 294.

Yang, J., Song, L., Pan, C.P., Han, Y.T., and Kang, L. 2020. Removal of ten pesticide residues on/in kumquat by washing with alkaline electrolysed water. International Journal of Environmental Analytical Chemistry. 102(15): 3638 - 3651.

Yuan, L., Jian, W., Xuran, Z., Yang, L., Ming, C., Weihai, X., Yuping, W., Na, L., Liting, Y., and Pengfei, S. 2021. Effects of electrolyzed water treatment on pesticide removal and texture quality in fresh-cut cabbage, broccoli, and color pepper. Food Chemistry. 353: 129408.

Zheng, Y., Wu, S., Dang, J., Wang, S., Liu, Z., Fang, J., Han, P., and Zhang, J. 2019. Reduction of phoxim pesticide residues from grapes by atmospheric pressure non-thermal air plasma activated water. Journal of Hazardous Materials. 377: 98–105.

OPEN access freely available online

Natural and Life Sciences Communications

Chiang Mai University, Thailand. https://cmuj.cmu.ac.th

Wanwarang Pattanapo1, 3, *, Kanda Wanchai1, 2, 3 and Usawadee Chanasut1, 2, 3

1 Postharvest Technology Research Center, Faculty of Agriculture, Chiang Mai University, Chiang Mai 50200, Thailand.

2 Department of Biology, Faculty of Science, Chiang Mai University, Chiang Mai 50200, Thailand.

3 Postharvest Technology Innovation Center, Ministry of Higher Education, Science, Research and Innovation, Bangkok 10400, Thailand.

Corresponding author: Wanwarang Pattanapo E-mail: wanwarang.pat@gmail.com

Total Article Views

Editor: Wasu Pathom-aree,

Chiang Mai University, Thailand

Article history:

Received: April 28, 2023;

Revised: June 30, 2023;

Accepted: July 10, 2023;

Online First: August 8, 2023